Method for achieving circular ring connection by utilizing wrinkling of metal pipes

A metal pipe and ring technology, applied in the field of ring connection, can solve the problems of poor appearance of pores and weld seams, affect the appearance of the ring surface, and affect the service life of the workpiece, so as to achieve flexible application parts, avoid cracking or seriously reduce Thin and easy to handle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments, which are explanations of the present invention rather than limitations.

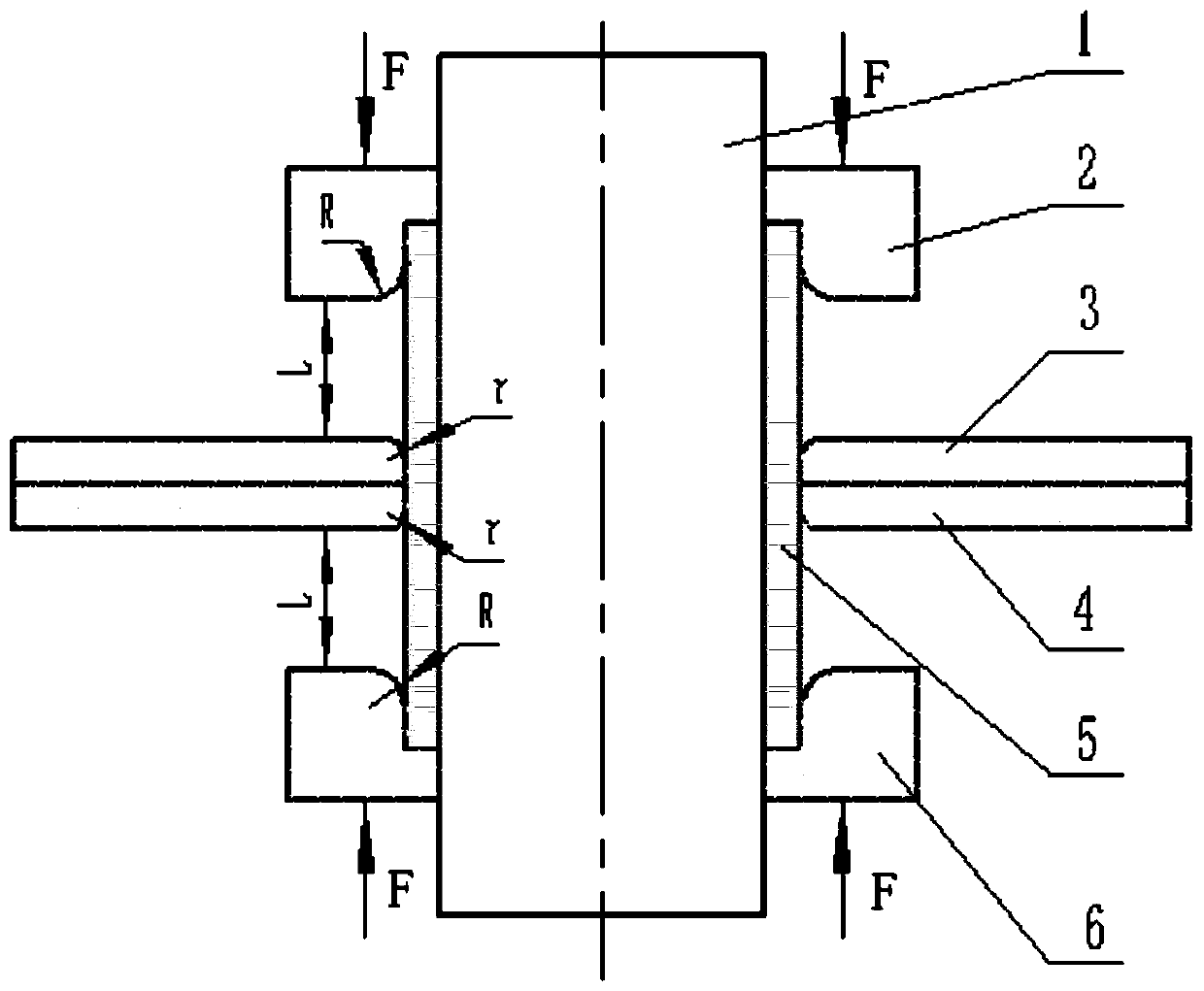

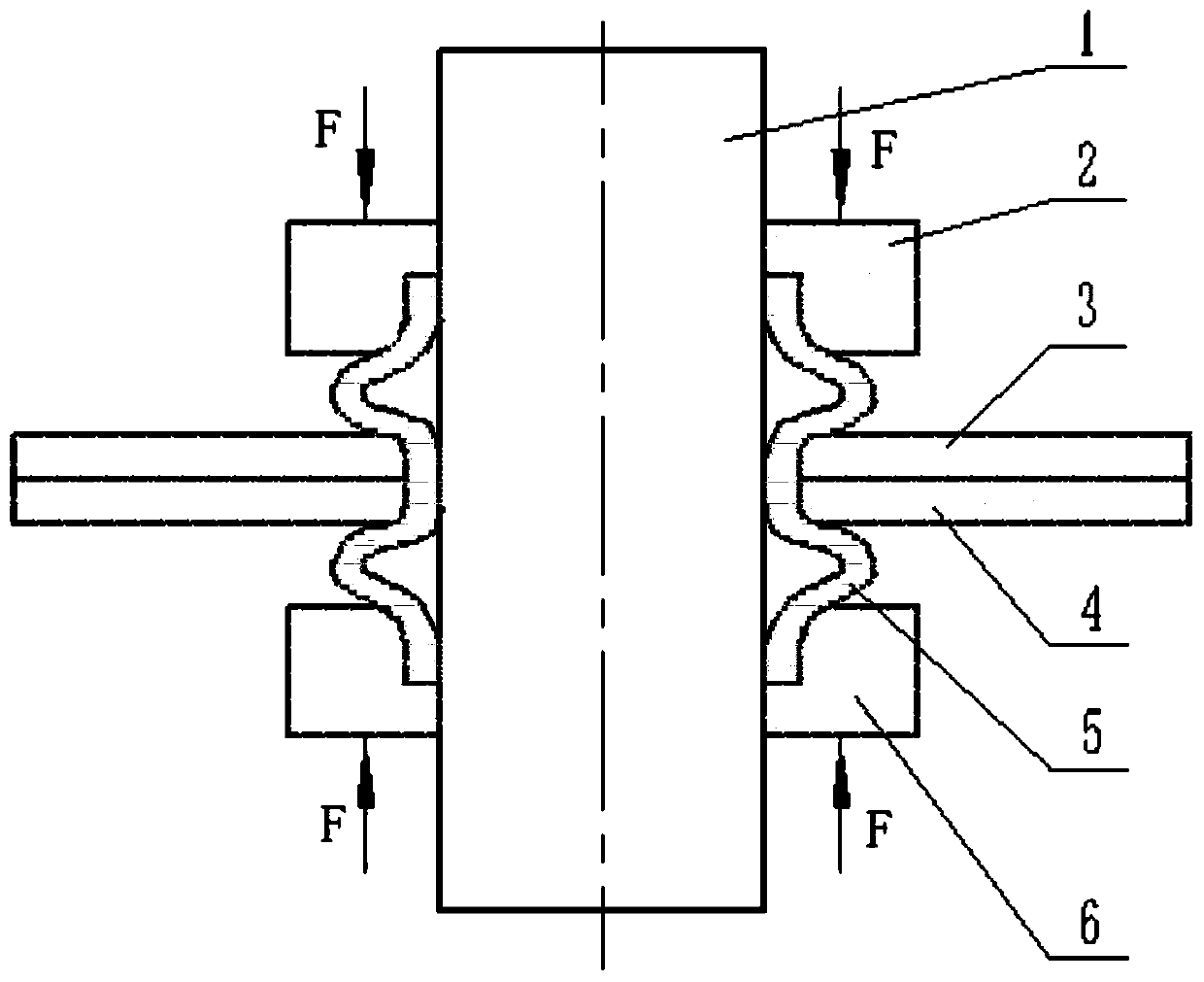

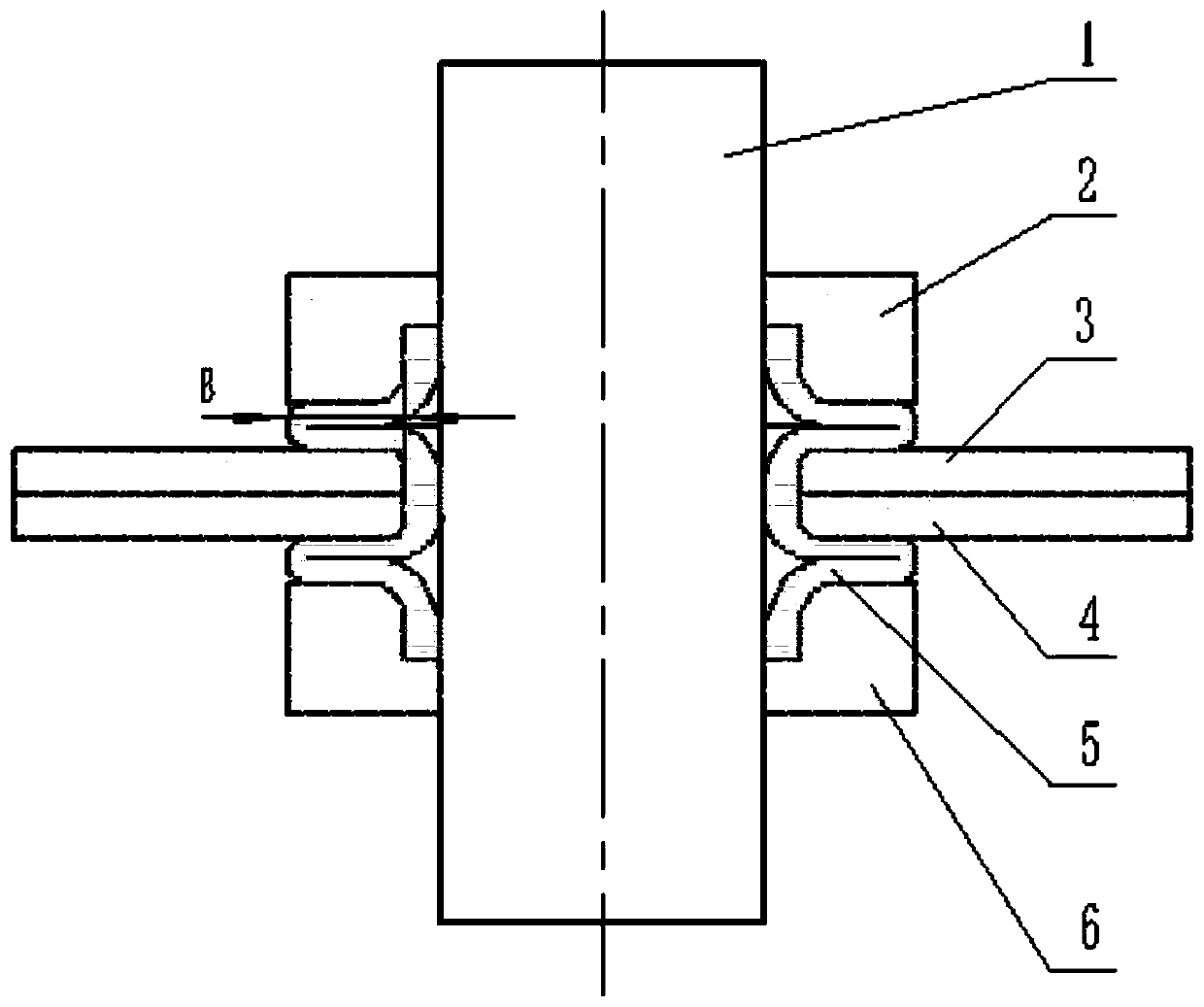

[0030] The method of utilizing metal pipe wrinkling to realize circular connection of the present invention comprises:

[0031] For the upper ring 3 and the lower ring 4 to be connected, the connecting pipe 5 made of metal is placed on the outer wall of the mandrel 1, and the material of the connecting pipe 5 is the same as that of the upper ring 3 and the lower ring 4 with higher tensile strength. The same; put the upper ring 3 and the lower ring 4 on the outer wall of the connecting pipe 5, place the connecting pipe 5 in the center of the holes of the upper ring 3 and the lower ring 4, and keep the upper ring 3 and the lower ring 4 fixed horizontally ; The inner holes of the upper ring 3 and the lower ring 4 can be processed with transition fillets; the radius ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com