A kind of wear-resistant heat-resistant alloy material and preparation method thereof

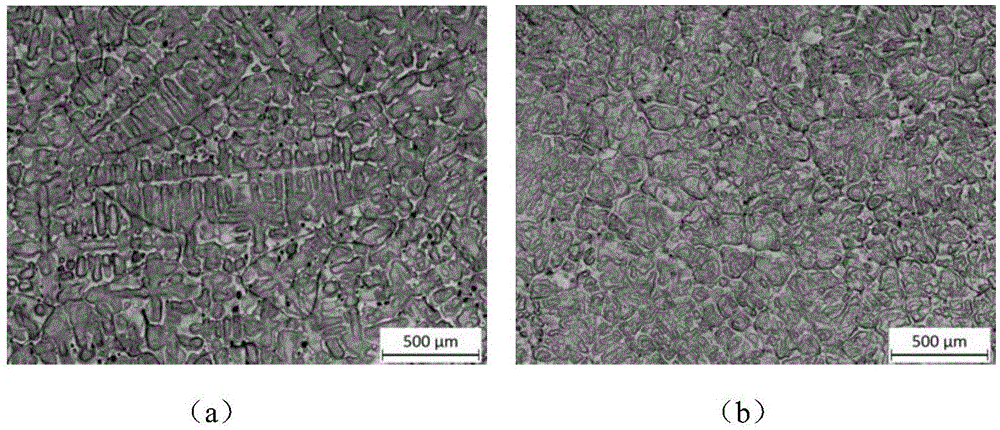

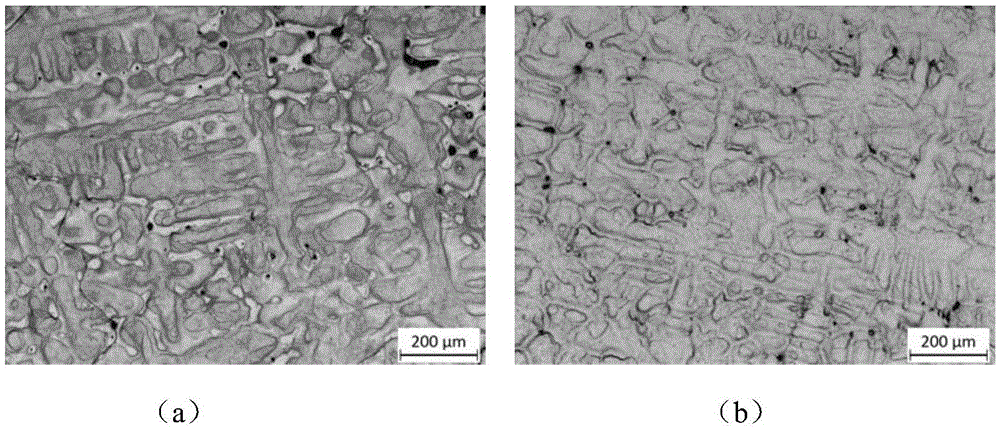

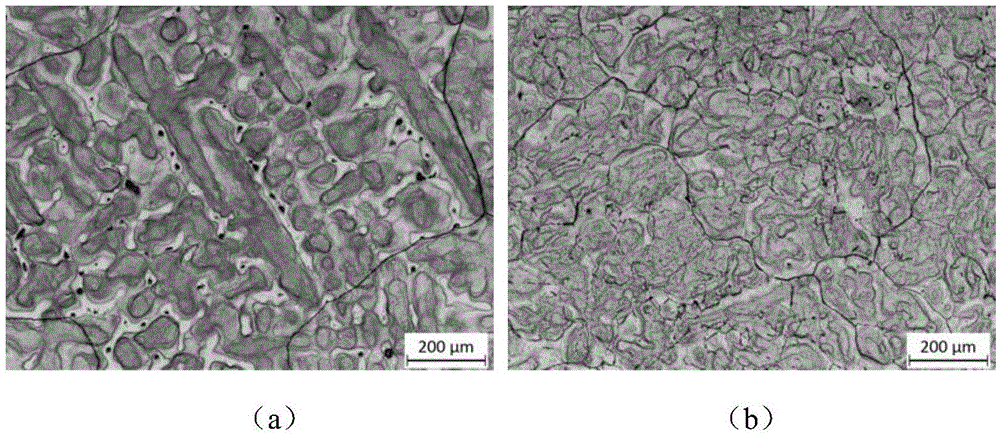

A heat-resistant alloy and casting technology, which is applied to wear-resistant and heat-resistant alloy materials and their preparation, and the field of wear-resistant and heat-resistant alloys, can solve the problems of difficult control of production process, poor thermal shock resistance, difficult material recovery, etc. The effect of reducing the dendrite structure, improving the properties of heat-resistant steel, and improving heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] The preparation method of the wear-resistant and heat-resistant alloy material of the present invention comprises the following steps:

[0036] 1) Put waste stainless steel, low-carbon ferrochrome, nickel plate, ferrosilicon, ferromanganese, and ferrotungsten in an induction furnace for smelting; use ferrosilicon, ferromanganese, and aluminum precipitation deoxidation, and use silicon-calcium diffusion deoxidation for refining. 1600°C-1650°C, place ferroniobium and Y-based rare earths in a ladle baked to 800°C, the particle size of ferroniobium and Y-based rare earths is 1mm-3mm;

[0037]2) Quartz sand is used for the selection of the mold, and water glass is used as the binder, carbon dioxide is used as the curing agent, and the surface of the mold is painted with zircon powder alcohol-based paint;

[0038] 3) Fix the casting mold to the box and lock the box on the vibration device platform, turn on the vibration device, pour the molten metal, the pouring temperature i...

Embodiment 1

[0043] 1. Composition: C: 0.3%, Cr: 24%, Ni: 11.5%, Si: 2.6%, Mn: 2.0%, P and S≤0.03%, W: 0.6%, Nb: 0.1%, Y-based rare earth 0.2 %.

[0044] 2. Put waste stainless steel, low-carbon ferrochrome, nickel plate, ferrosilicon, ferromanganese, and ferrotungsten in an induction furnace for smelting; use ferrosilicon, ferromanganese, and aluminum precipitation deoxidation, and use silicon-calcium diffusion deoxidation for refining. 1620°C, put ferroniobium and Y-based rare earths in a ladle with a particle size of 1-3mm, and bake the ladle to no less than 800°C.

[0045] 3. The casting mold uses quartz sand and water glass as binder, carbon dioxide solidifies, and the surface of the casting mold is painted with zircon powder, and the box is closed and locked.

[0046] 4. Place the locked mold and the sand box on the platform of the vibrating device, turn on the vibrating equipment, pour molten steel, and turn off the vibration after the solidification is complete. Vibration paramete...

Embodiment 2

[0050] 1. Composition: C: 0.25%, Cr: 25%, Ni: 12%, Si: 2.2%, Mn: 1.8%, P and S≤0.03%, W: 0.7%, Nb: 0.12%, Y-based rare earth 0.25 %.

[0051] 2. Put waste stainless steel, low-carbon ferrochrome, nickel plate, ferrosilicon, ferromanganese, and ferrotungsten in an induction furnace for smelting; use ferrosilicon, ferromanganese, and aluminum precipitation deoxidation, and use silicon-calcium diffusion deoxidation for refining. Place ferroniobium and Y-based rare earths in a ladle at 1610°C to a depth of 1-3mm, and bake the ladle to no less than 800°C.

[0052] 3. The casting mold uses quartz sand and water glass as binder, carbon dioxide solidifies, and the surface of the casting mold is painted with zircon powder, and the box is closed and locked.

[0053] 4. Place the locked mold together with the sand box on the platform of the vibrating device, turn on the vibrating equipment, pour molten steel, and turn off the vibration after the solidification is complete. Vibration par...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com