High-density nano W alloy with good self-passivation behavior and preparation method thereof

A nano-alloy technology, applied in the field of high-density nano-W alloy and its preparation, can solve the problems of easy growth, increase the heating rate, and reduce the sintering temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Under the protective Ar atmosphere, 96.36g of W powder with a purity of 99.5%, 12.54g of Cr powder with a purity of 99.5%, 0.66g of Y powder with a purity of 99.5% and 0.44g of Zr powder with a purity of 99.5% together with ball milling media Put them together into a 250ml WC ball mill jar, and then carry out alloying on a full-range planetary ball mill to obtain a ZW4 alloy powder with a homogeneous structure. The ZW4 alloy powder is filled in a graphite mold and densified by FAST technology. The FAST process parameters are: heating rate of 146°C / min, sintering temperature of 1000°C, external load of 50MPa, and no heat preservation.

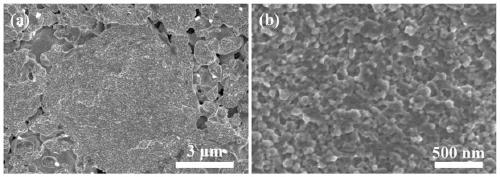

[0027] figure 1 It is the microstructure picture of ZW4 alloy obtained under this process condition. Depend on figure 1 (a) It can be found that the W alloy contains a large number of pores. It shows that at lower sintering temperature, it is difficult for ZW4 alloy powder to be completely densified. Through the Archimedes method, it...

Embodiment 2

[0029] Under the protective Ar atmosphere, 96.36g of W powder with a purity of 99.5%, 12.54g of Cr powder with a purity of 99.5%, 0.66g of Y powder with a purity of 99.5% and 0.44g of Zr powder with a purity of 99.5% together with ball milling media Put them together into a 250ml WC ball mill jar, and then carry out alloying on a full-range planetary ball mill to obtain a ZW4 alloy powder with a homogeneous structure. The ZW4 alloy powder is filled in a graphite mold and densified by FAST technology. The FAST process parameters are as follows: the heating rate is 150°C / min, the sintering temperature is 1300°C, the applied load is 50MPa, and there is no heat preservation.

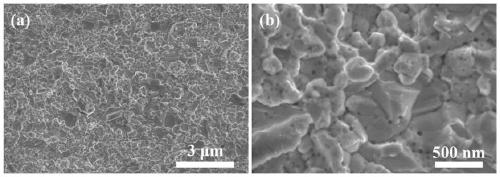

[0030] figure 2 It is the microstructure picture of ZW4 alloy obtained under this process condition. Depend on figure 2 (a) It can be found that the W alloy has a dense structure without obvious pores. It shows that at higher sintering temperature, the ZW4 alloy powder has been completely densified. T...

Embodiment 3

[0032] Under the protective atmosphere of Ar, 96.36g of W powder with a purity of 99.5%, 12.54g of Cr powder with a purity of 99.5%, 0.66g of Y powder with a purity of 99.5% and 0.44g of Zr powder with a purity of 99.5% together with ball milling media Put them together into a 250ml WC ball mill jar, and then carry out alloying on a full-range planetary ball mill to obtain a ZW4 alloy powder with a homogeneous structure. The ZW4 alloy powder is filled in a graphite mold and densified by FAST technology. The FAST process parameters are: heating rate of 146°C / min, sintering temperature of 1150°C, external load of 90MPa, and no heat preservation.

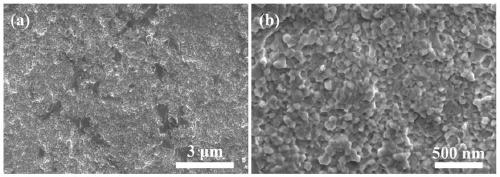

[0033] image 3 It is the microstructure picture of ZW4 alloy obtained under this process condition. Depend on image 3 (a) It can be found that the W alloy has a dense structure without obvious pores. Through the Archimedes method, its relative density was measured to be greater than 98.5%. image 3 (b) for image 3 Partial enla...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com