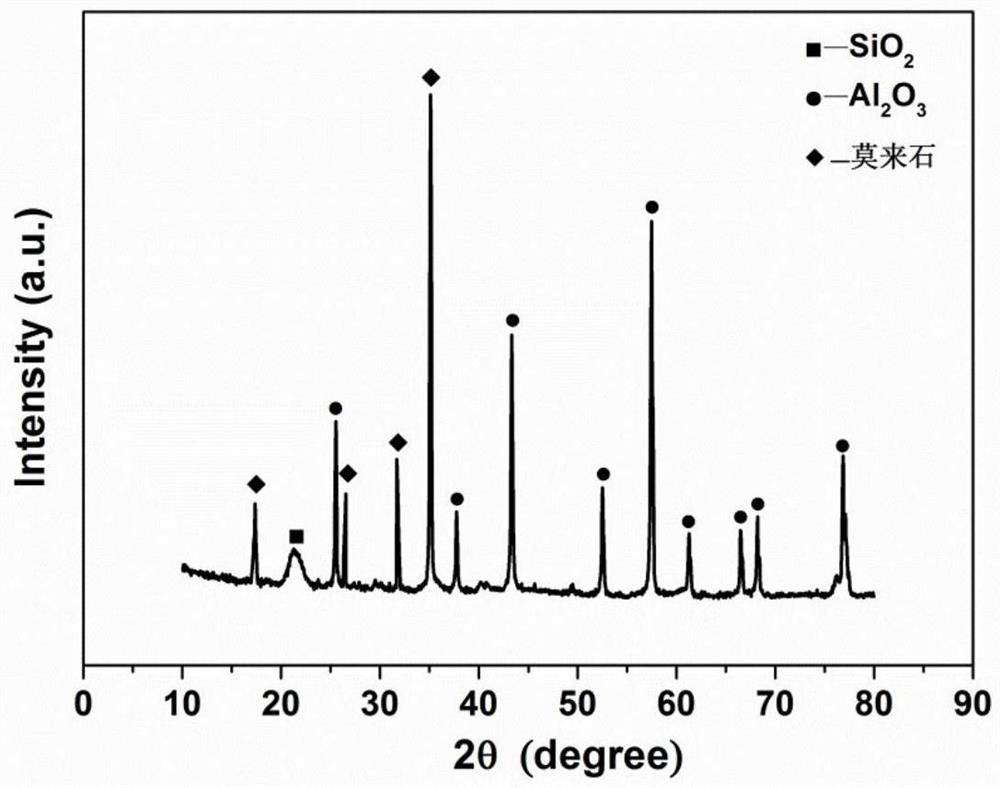

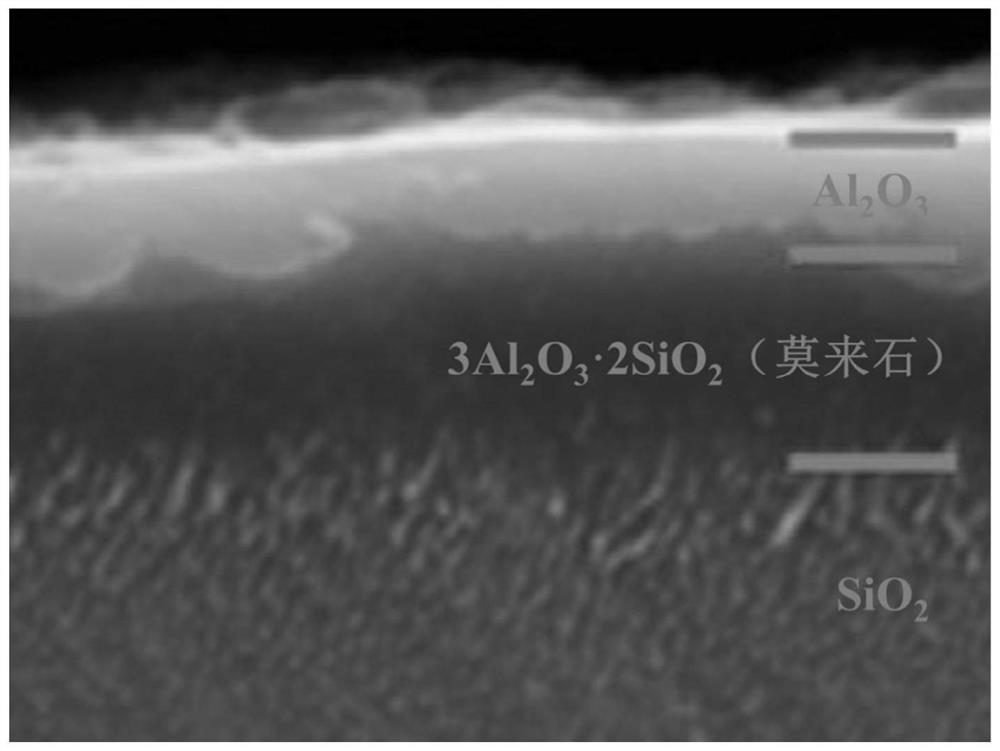

SiO2-mullite-Al2O3 multi-component gradient anti-oxidation coating and preparation method thereof

A multi-component, anti-oxidation technology, applied in coating, metal material coating process, superimposed layer plating, etc., can solve problems such as composition, uneven thickness, poor coating adhesion, easy peeling, etc., to achieve Reduced weight gain, improved antioxidant performance, and low cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

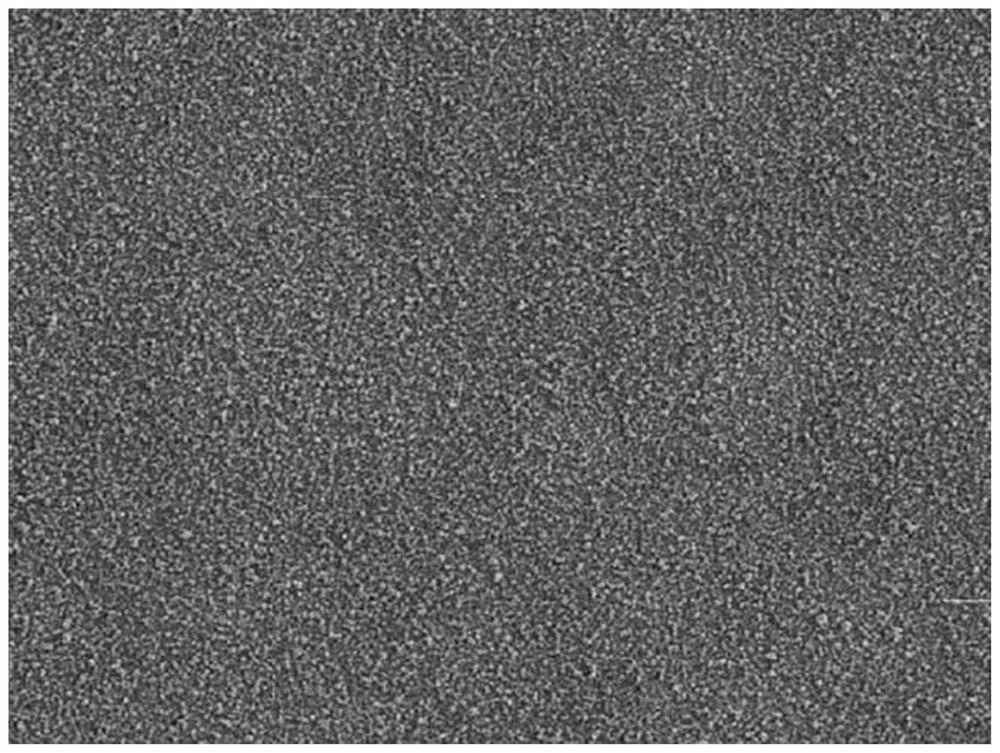

[0034] The present invention relates to a SiO 2 -Mullite-Al 2 o 3 The multi-component gradient anti-oxidation coating and its preparation method are specifically implemented according to the following steps:

[0035] Step 1, the titanium alloy substrate is polished with 500#, 1000#, 1500#, 2000# sandpaper in sequence, and polished with abrasive paste;

[0036] Step 2, ultrasonically cleaning the titanium alloy substrate obtained in step 1 using absolute ethanol and deionized water in sequence, and the cleaning time is 10 to 20 minutes;

[0037] Step 3, drying the titanium alloy substrate obtained in step 2 in a blast drying oven, the drying temperature is 60-90° C., and the drying time is 60-80 minutes;

[0038] Step 4, place the substrate obtained in step 3 on the sample stage of the magnetron sputtering instrument, install the Si target on the target base, and coat the Si single substance layer on the surface of the titanium alloy by DC sputtering. The purity is 99.99%, an...

Embodiment example 1

[0044] Step 1, the titanium alloy substrate is polished with 500#, 1000#, 1500#, 2000# sandpaper in sequence, and polished with abrasive paste;

[0045] Step 2, ultrasonically cleaning the titanium alloy substrate obtained in step 1 using absolute ethanol and deionized water in sequence, and the cleaning time is 10 minutes;

[0046] Step 3, drying the titanium alloy substrate obtained in step 2 in a blast drying oven, the drying temperature is 60°C, and the drying time is 60 minutes;

[0047] Step 4, place the substrate obtained in step 3 on the sample stage of the magnetron sputtering instrument, install the Si target on the target base, and coat the Si single substance layer on the surface of the titanium alloy by DC sputtering. The purity is 99.99%, and the background vacuum is about 3×10 -4 Pa, the deposition temperature is 300°C, and the chamber pressure is 10 -3 Pa, the bias voltage is 200V, the argon flow rate is 15mL / min, and the continuous sputtering time is 60min; ...

Embodiment example 2

[0053] Step 1, the titanium alloy substrate is polished with 500#, 1000#, 1500#, 2000# sandpaper in sequence, and polished with abrasive paste;

[0054] Step 2, ultrasonically cleaning the titanium alloy substrate obtained in step 1 using absolute ethanol and deionized water in sequence, and the cleaning time is 20 minutes;

[0055] Step 3, drying the titanium alloy substrate obtained in step 2 in a blast drying oven, the drying temperature is 90°C, and the drying time is 80 minutes;

[0056] Step 4, place the substrate obtained in step 3 on the sample stage of the magnetron sputtering instrument, install the Si target on the target base, and coat the Si single substance layer on the surface of the titanium alloy by DC sputtering. The purity is 99.99%, and the background vacuum is about 3×10 -4 Pa, the deposition temperature is 500°C, and the chamber pressure is 10 -2 Pa, the bias voltage is 300V, the argon flow rate is 25mL / min, and the continuous sputtering time is 120min;...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com