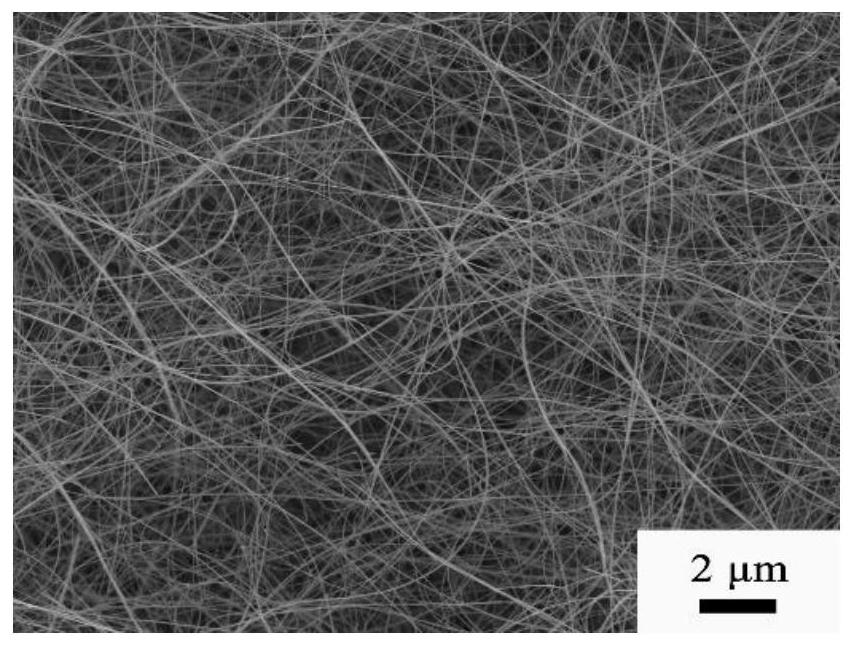

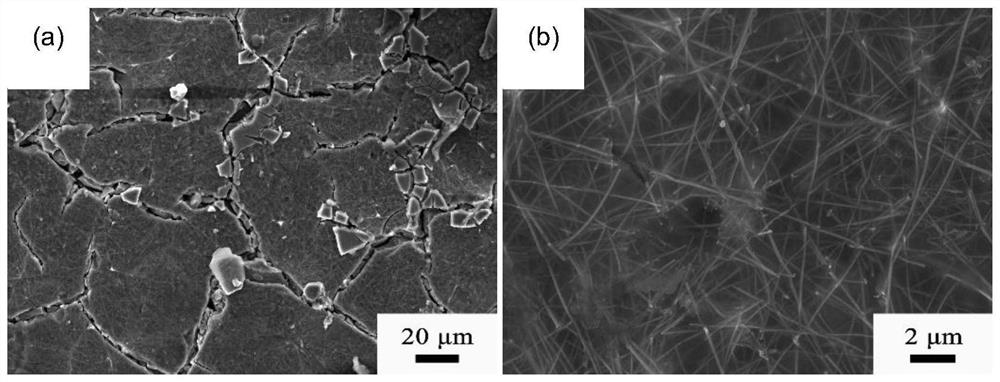

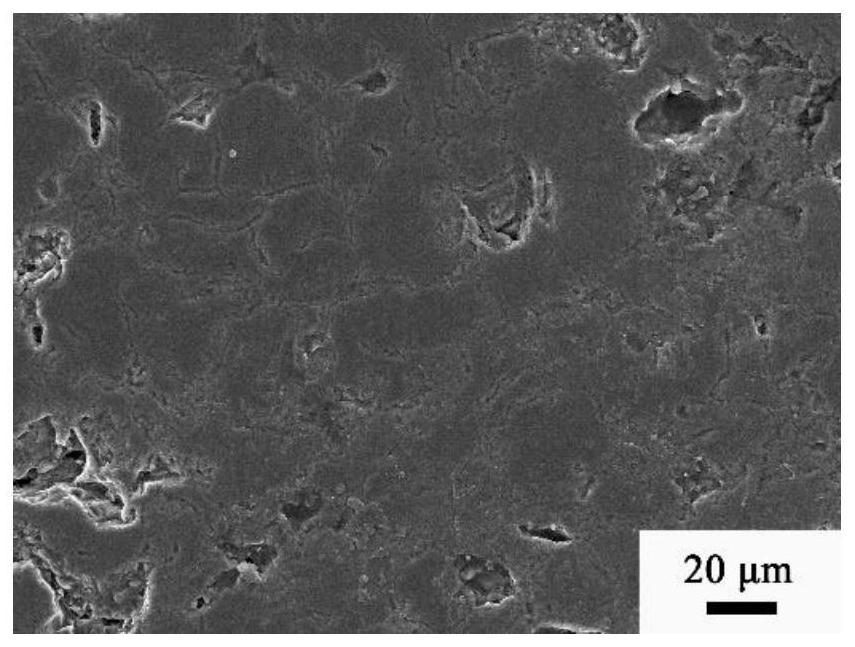

A kind of preparation method of silicon carbide nanowire toughened silicon carbide ceramics in situ

A silicon carbide nanowire and nanowire toughening technology, which is applied in the field of preparation of silicon carbide ceramics, can solve the problems of complex process, high cost, and difficulty in controlling the dispersion of nanowires, and achieve simple and controllable preparation process, low cost, Effect of reducing cracking tendency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] (1) Take 50 g of PCS raw material, place it in an agate mortar and grind it into a powder with a particle size of 200 mesh, then place it in a box furnace, and oxidize it in an air environment at 300 ° C for 3 hours;

[0043] (2) Weigh 0.2g of ferrocene, 19.8g of pre-oxidized PCS powder and 20g of xylene to form a mixed solution, stir it magnetically for 1 hour, dry it, and grind it into a precursor powder with a particle size of 200 mesh for later use;

[0044] (3) Take by weighing 20g of pre-oxidized PCS powder and 80g of xylene respectively to form a mixed solution, stir magnetically for 2h, and mix well for subsequent use;

[0045] (4) Take 0.3g of the precursor powder prepared in step (2) and pour it into a stainless steel cold press mold and spread it evenly, use a pressure of 15MPa for 30s, and press it into a precursor green body at room temperature;

[0046] (5) Wrap the precursor green body obtained in step (4) with graphite paper, embed it in activated carbon p...

Embodiment 2

[0052] (1) Take 50 g of PCS raw material, place it in an agate mortar and grind it into a powder with a particle size of 200 mesh, then place it in a box furnace, and oxidize it in an air environment at 300 ° C for 3 hours;

[0053] (2) Weigh 0.6g of ferrocene, 19.4g of pre-oxidized PCS powder and 20g of xylene to form a mixed solution, stir it with magnetic force for 1 hour, dry it, and grind it into a precursor powder with a particle size of 200 mesh for later use;

[0054] (3) Take by weighing 30g of pre-oxidized PCS powder and 70g of xylene respectively to form a mixed solution, magnetically stir for 2h, and mix uniformly for subsequent use;

[0055] (4) Take 0.5g of the precursor powder prepared in step (2) and pour it into a stainless steel cold press mold and spread it evenly, use a pressure of 15MPa for 30s, and press it into a precursor green body at room temperature;

[0056] (5) The activated carbon powder is loaded into the corundum crucible to half of its depth, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| oxidation rate | aaaaa | aaaaa |

| oxidation rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com