Hf modified PtAl coating and preparation method and application thereof

A coating and modification technology, applied in the direction of coating, metal material coating process, mechanical equipment, etc., can solve the problems of complex process and low high temperature oxidation resistance of coating, and achieve simple process and good high temperature oxidation resistance. , Controllable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

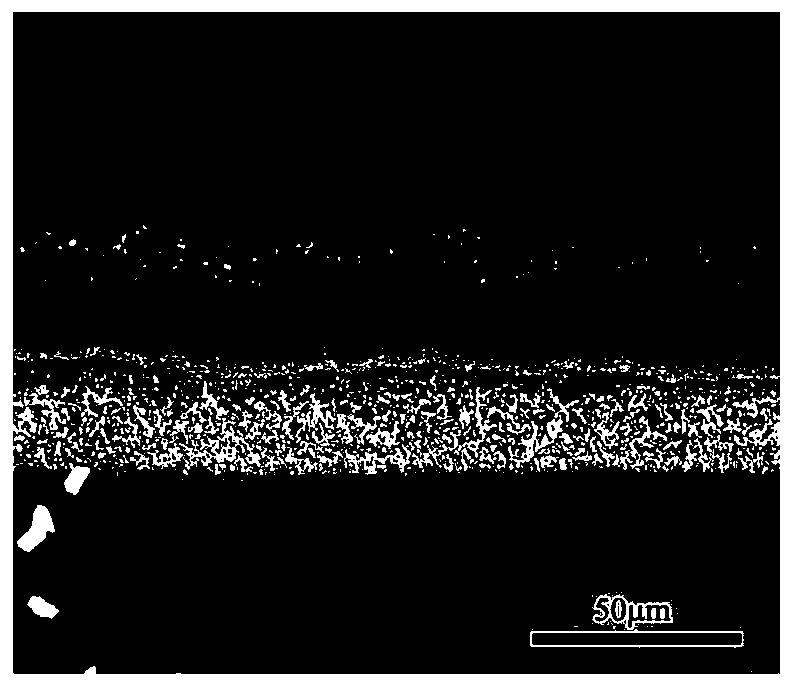

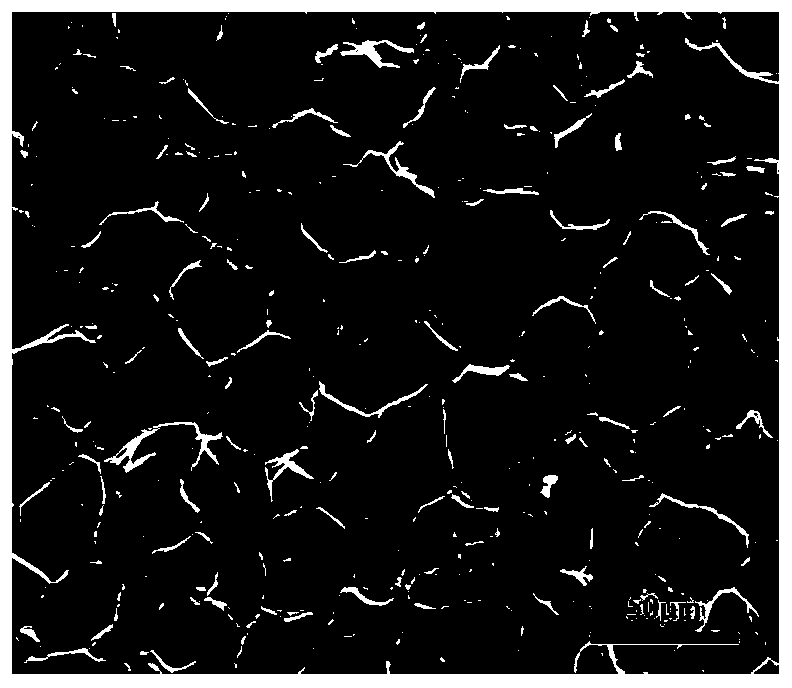

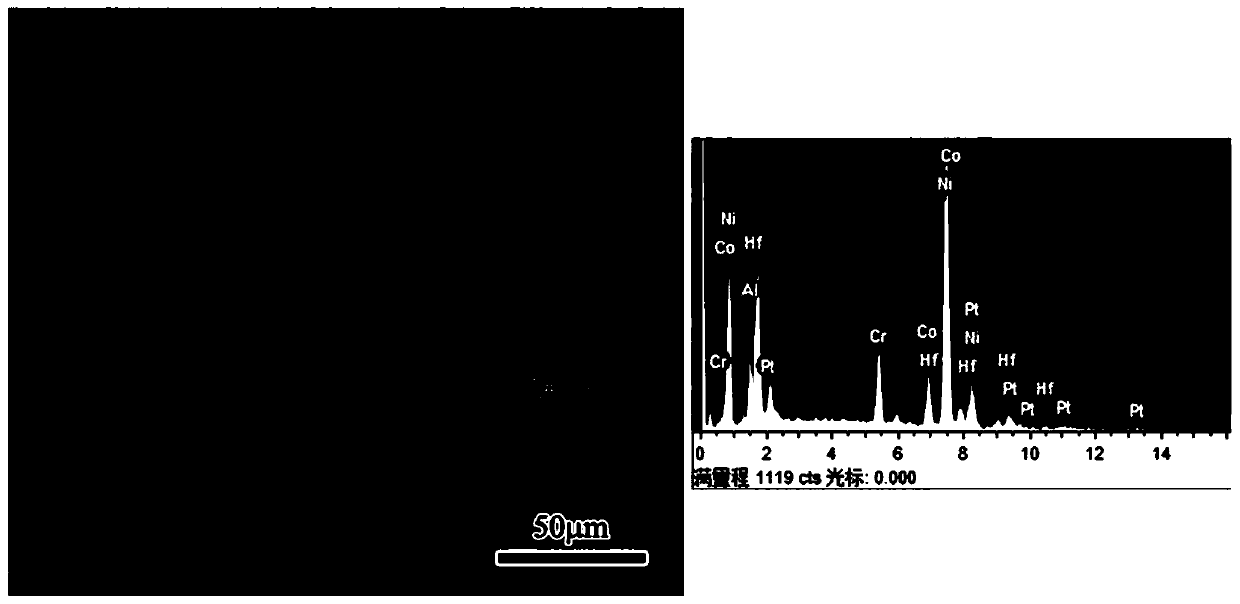

Image

Examples

Embodiment 1

[0049] This embodiment is to prepare Hf-modified PtAl coatings on nickel-based superalloys, and the coating preparation process is as follows:

[0050] First, the superalloy substrate is polished and sandblasted, and the substrate is polished with 150#~800# SiC sandpaper in turn; 100~220 mesh Al 2 o 3 Sandblasting is performed to obtain a fresh surface; the substrate after sandblasting is ultrasonically treated in deionized water for 30 minutes, then in acetone for 30 minutes, and dried for use after ultrasonication.

[0051] Before electroplating Pt, first perform electrochemical degreasing on the substrate after sandblasting, activate and pre-plate Ni, and perform electrochemical degreasing in 10wt.% NaOH aqueous solution, with the substrate as the anode and the pure nickel plate as the cathode, Using 8A / dm 2 Electrochemical degreasing at a current density of 2 min; activation is carried out in a mixed solution of concentrated hydrochloric acid and deionized water accordin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com