Preparation method of high-temperature-resistant high-salt polymer oil-replacement agent

A polymer and oil-displacing agent technology, applied in the field of preparation of high-temperature and high-salt polymer oil-displacing agents, can solve the problems of hydrodynamic volume reduction, precipitation, and viscosity reduction, and achieve improved solubility and good water solubility , Improve the effect of temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

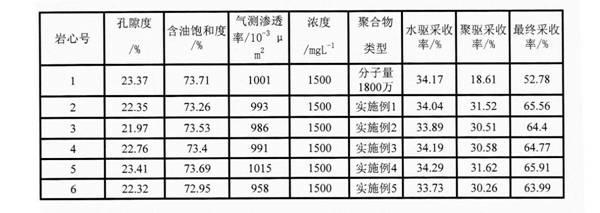

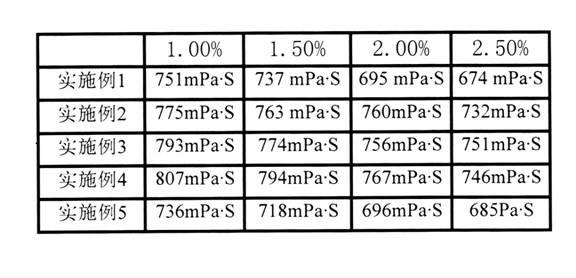

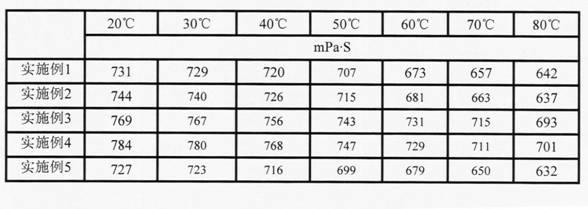

Examples

Embodiment 1

[0011] 10Kg of acrylic acid, 53Kg of propylene sulfonate, 12Kg of N, N-diethyl diallyl ammonium chloride, 4Kg of octadecyl acrylate and 58Kg of acrylamide were dissolved in deionized water. The mass is 16% concentration, then add sodium lauryl sulfate of 2% of the total monomer weight, adjust the pH of the solution: 9-10, and pass N under the condition of temperature 35°C 2 Add the initiator ammonium persulfate after 30 minutes, the amount of ammonium persulfate added is 0.06% of the total weight of the monomer, react for 12 hours at a temperature of 35 ° C, precipitate with acetone, wash, and dry in vacuum to obtain a white powder polymer.

Embodiment 2

[0013] 11Kg of acrylic acid, 65Kg of 2-acrylamido-2-sodium methylpropanesulfonate, 15Kg of N, N-diethyl diallyl ammonium chloride, 3Kg of lauryl acrylate, 2Kg of C 6-10 α-Olefin and 59Kg of acrylamide were dissolved in deionized water, the total mass concentration of the monomer was 17%, and then 2% of the total monomer weight of sodium lauryl sulfate was added to adjust the pH of the solution: 9 to 10, at temperature N at 40°C 2 Add the initiator potassium persulfate after 30 minutes, the amount of potassium persulfate added is 0.06% of the total weight of the monomer, react for 12 hours at a temperature of 40°C, precipitate with acetone, wash, and dry in vacuum to obtain a white powder of polymers.

Embodiment 3

[0015] 15Kg of methacrylic acid, 63Kg of sodium methacrylate hydroxypropyl sulfonate, 20Kg of trimethallyl ammonium chloride, 3Kg of lauryl acrylate, 2Kg of C 12-16 α-Olefin and 51Kg of acrylamide were dissolved in deionized water, the total mass concentration of the monomer was 19%, and then 2.9% of the total monomer weight of sodium dodecyl sulfate was added to adjust the pH of the solution to 9-10, and the temperature was 35 N at ℃ 2 Add the initiator potassium persulfate after 30 minutes, the amount of potassium persulfate added is 0.08% of the total weight of the monomer, react at a temperature of 35°C for 12 hours, precipitate with acetone, wash, and dry in vacuum to obtain a white powdery polymer thing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com