Double-layer Cr/Cr2AlC coating for accident fault-tolerant fuel cladding and preparation method of double-layer Cr/Cr2AlC coating

A fuel cladding and coating technology, which is applied in the direction of metal material coating process, coating, reactor fuel elements, etc., can solve the problems of poor thermochemical compatibility and difficulty in meeting the needs of accident fault-tolerant fuel cladding coatings, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Preparation of Cr coating on Zry-4 zirconium alloy cladding tube substrate:

[0034] 1) Mechanically grind the base of the zirconium alloy cladding tube (use sandpaper to grind in the following order: 500 mesh → 1000 mesh → 1500 mesh → 2000 mesh → 2500 mesh → 3000 mesh), and then polish with diamond abrasive paste with a particle size of 3.5 μm , and ultrasonically cleaned with acetone and alcohol, respectively.

[0035] 2) Before the sputtering starts, the equipment is pre-evacuated to 6×10 -5 Pa, in order to minimize the pollution of residual gas during the sputtering process; then pass in high-purity argon (volume purity 99.999%), and adjust the working pressure to keep at 0.40Pa; then use Ar + The target is cleaned to remove contamination from the target surface.

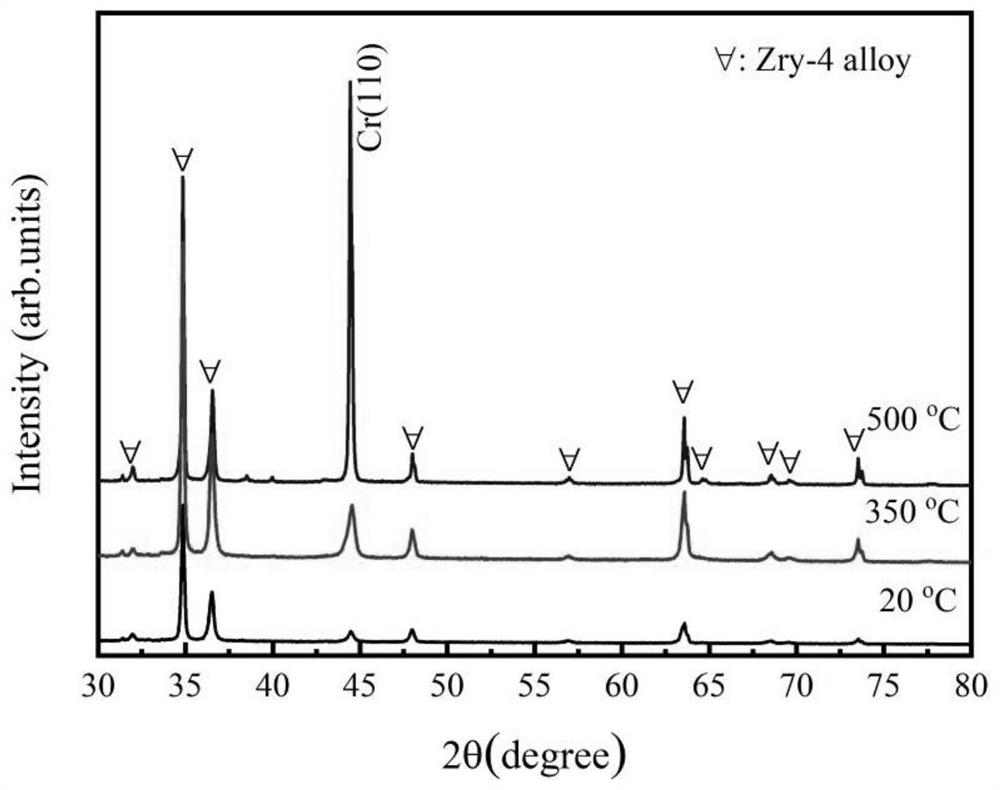

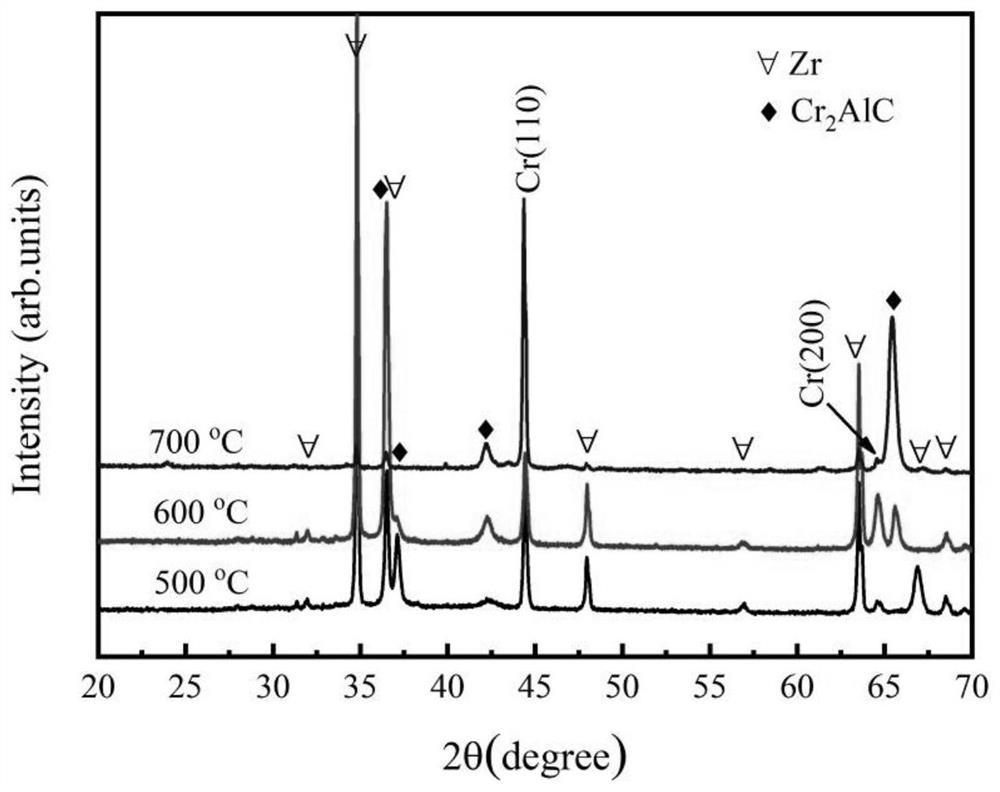

[0036] 3) Using a Cr target (purity of 99.95wt%) as a sputtering target, a Cr coating was deposited on the surface of the zirconium alloy cladding tube. The Cr target power was 80W, the preparation tem...

Embodiment 2

[0038] Preparation of Cr coating on Zry-4 zirconium alloy cladding tube substrate:

[0039] 1) Mechanically grind the base of the zirconium alloy cladding tube (use sandpaper to grind in the following order: 500 mesh → 1000 mesh → 1500 mesh → 2000 mesh → 2500 mesh → 3000 mesh), and then polish with diamond abrasive paste with a particle size of 3.5 μm , and ultrasonically cleaned with acetone and alcohol, respectively.

[0040] 2) Before the sputtering starts, the equipment is pre-evacuated to 6×10 -5 Pa, in order to minimize the pollution of residual gas during the sputtering process; then pass in high-purity argon (volume purity 99.999%), and adjust the working pressure to keep at 0.40Pa; then use Ar + The target is cleaned to remove contamination from the target surface.

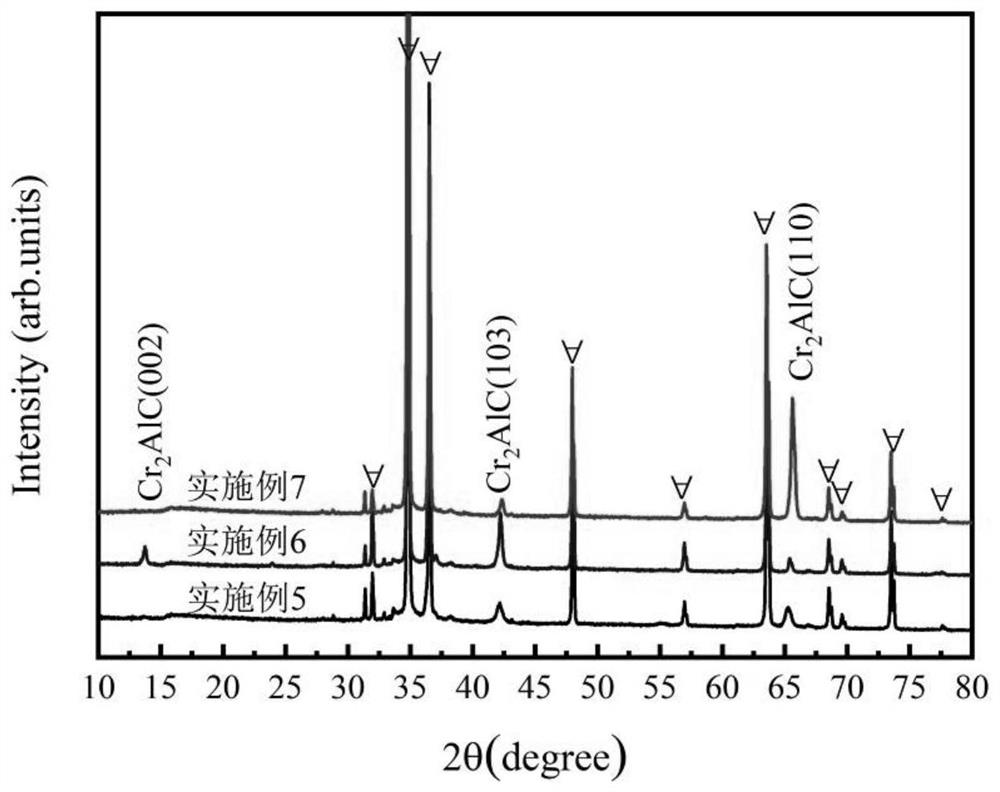

[0041] 3) Using a Cr target (purity of 99.95wt%) as a sputtering target, a Cr coating was deposited on the surface of the zirconium alloy cladding tube. Among them, the Cr target power was 130W, the pr...

Embodiment 3

[0043] Preparation of Cr coating on Zry-4 zirconium alloy cladding tube substrate:

[0044] 1) Mechanically grind the base of the zirconium alloy cladding tube (use sandpaper to grind in the following order: 500 mesh → 1000 mesh → 1500 mesh → 2000 mesh → 2500 mesh → 3000 mesh), and then polish with diamond abrasive paste with a particle size of 3.5 μm , and ultrasonically cleaned with acetone and alcohol, respectively.

[0045] 2) Before the sputtering starts, the equipment is pre-evacuated to 6×10 -5 Pa, in order to minimize the pollution of residual gas during the sputtering process; then pass in high-purity argon (volume purity 99.999%), and adjust the working pressure to keep at 0.40Pa; then use Ar + The target is cleaned to remove contamination from the target surface.

[0046] 3) Using a Cr target (purity of 99.95wt%) as a sputtering target, a Cr coating was deposited on the surface of the zirconium alloy cladding tube. Among them, the Cr target power was 100W, the pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com