Healthy electric water heater

An electric water heater and water heater technology, applied in fluid heaters, lighting and heating equipment, etc., can solve the problems of poor acid and alkali resistance, weight loss in boiling water, exposure of ordinary steel plates, etc., and achieve enhanced oxidation resistance, delayed brittleness increase, and improved safety. performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

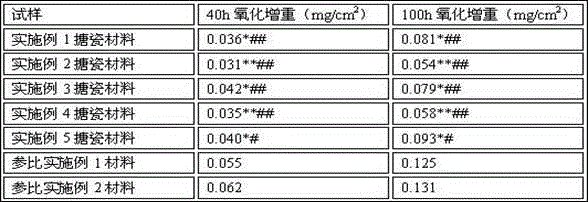

Embodiment 1

[0027] Example 1 A healthy water heater

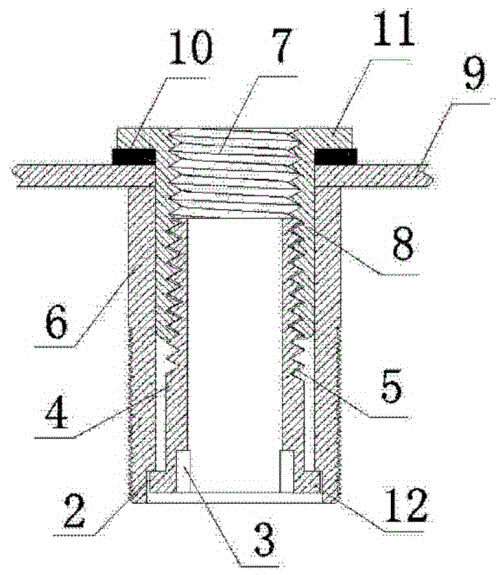

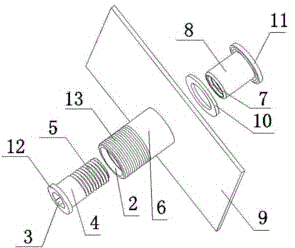

[0028] A healthy electric water heater, comprising a water heater enamel liner (9) and a pipe joint connection device for the water heater enamel liner, used to connect the enamel liner (9) and the pipe joint (6), the connection device includes an inner Lining (8), fixed ring (4), sealing ring (10), the upper end of the inner lining (8) is located at the drain outlet connected to the enamel liner (9), and there is a blank holder (11) larger than the inner diameter of the drain outlet, and the inner lining The inner wall of the inner wall is provided with an internal thread (7), the fixed ring (4) is provided with an external thread (5), the lower end of the lining (8) passes through the drain of the enamel liner (9), the fixed ring (4) and The inner liner (8) is connected by threads, the outer wall of the lower end of the fixed ring (4) is provided with a boss (12), and the lower end of the pipe joint (6) is provided with a sinker (2) ...

Embodiment 2

[0037] Embodiment 2 A healthy water heater

[0038] A healthy electric water heater, the structure of which is the same as that of Embodiment 1 of the present invention, the difference is that the enamel material of the inner layer of the enamel liner (9) is prepared from the following components by weight:

[0039] 40 parts of silicon dioxide, 0.02 parts of copper oxide, 5.5 parts of barium carbonate, 0.008 parts of cobalt oxide, 8 parts of zinc oxide, 2 parts of calcium oxide, 4 parts of sodium oxide, 3 parts of antimony trioxide, 1.5 parts of nickel oxide , 2 parts of titanium dioxide, 6 parts of calcite, 2 parts of kaolin, 5.5 parts of alumina, 40 parts of silica powder, 5.5 parts of soda ash and 1.3 parts of boron oxide.

[0040] The above-mentioned preparation method for the enamel material used for healthy water heaters includes the following steps: weighing the raw materials according to the weight ratio; After melting for 1.5-2.0 hours, pour the melted mixture into...

Embodiment 3

[0042] Example 3 A healthy water heater

[0043] A healthy electric water heater, the structure of which is the same as that of Embodiment 1 of the present invention, the difference is that the enamel material of the inner layer of the enamel liner (9) is prepared from the following components by weight:

[0044] 50 parts of silicon dioxide, 0.03 parts of copper oxide, 8 parts of barium carbonate, 0.01 parts of cobalt oxide, 10 parts of zinc oxide, 3 parts of calcium oxide, 5 parts of sodium oxide, 5 parts of antimony trioxide, 2.5 parts of nickel oxide , 3 parts of titanium dioxide, 8 parts of calcite, 3 parts of kaolin, 8 parts of alumina, 55 parts of silica powder, 8 parts of soda ash and 2.0 parts of boron oxide.

[0045] The above-mentioned preparation method for the enamel material used for healthy water heaters includes the following steps: weighing the raw materials according to the weight ratio; After melting for 1.5-2.0 hours, pour the melted mixture into cold wat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com