Method and device for testing tensile strength

A technology of tensile strength and test method, applied in the direction of applying stable tension/pressure to test the strength of materials, etc., can solve the problems of complex test system, large test sample, difficult to put into the irradiation chamber, etc., to achieve accurate test results, The effect of expanding the scope of application and simple testing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

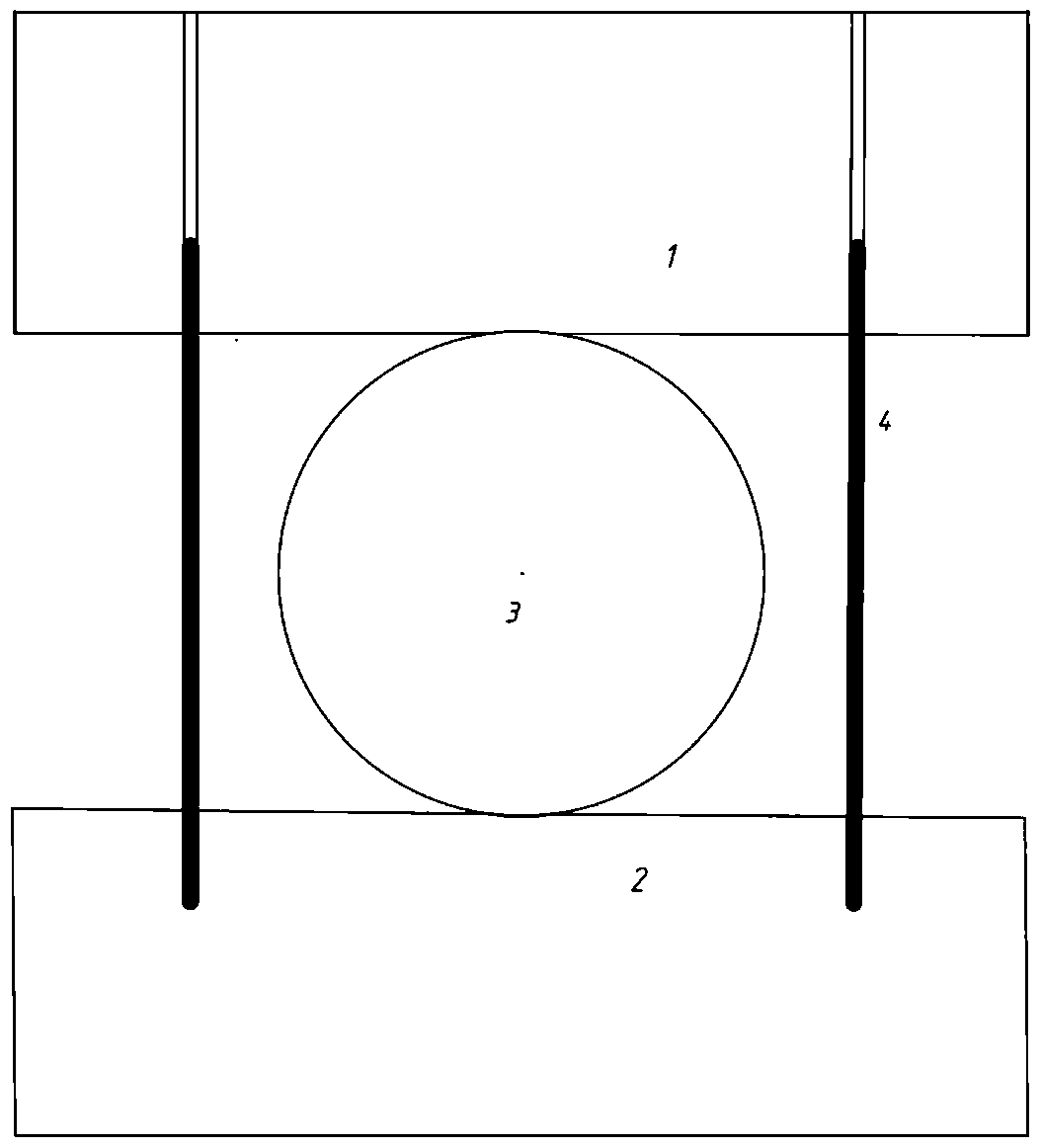

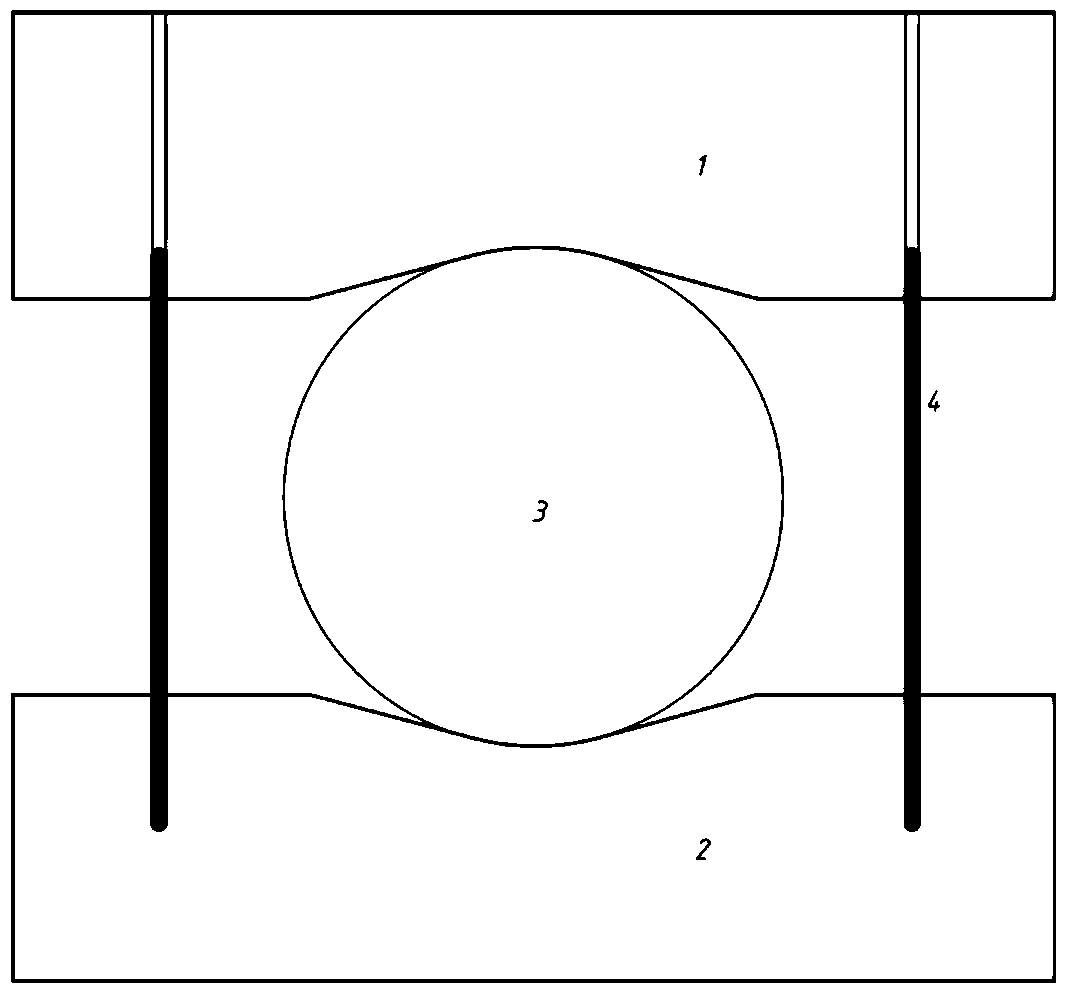

[0023] The technical scheme of the present invention is described in detail below in conjunction with accompanying drawing:

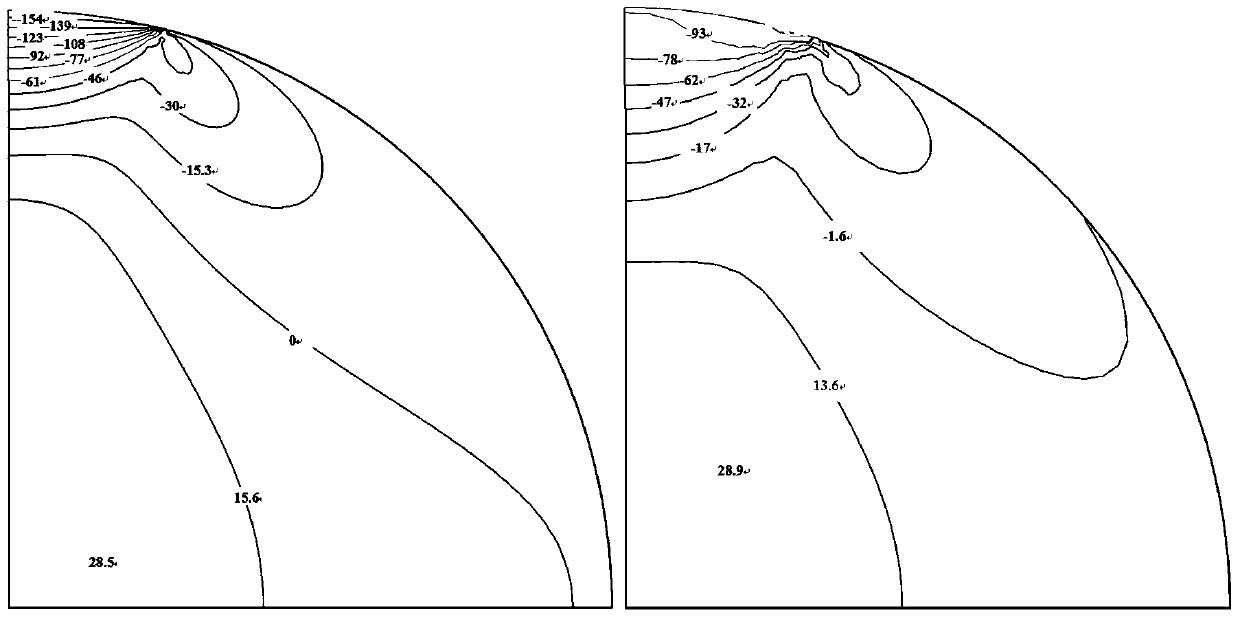

[0024] Aiming at the shortcomings of the existing direct stretching method, the present invention creatively introduces the existing Brazilian disc splitting method used in the measurement of rock tensile strength into diamond, graphite, etc., where the ratio of compressive strength to tensile strength is less than 5 The tensile strength test of the material, and through the improvement of the test fixture, overcome the problem that the sample cannot be split along the diameter direction because the force point of the disc sample fails before the center of the sample.

[0025] In order to facilitate the public's understanding, before the technical solution of the present invention is described in detail, the existing Brazilian disc splitting method is briefly introduced.

[0026] The splitting method originated from the tensile strength test of brittle ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com