Universal milling fixture for diffuser blades

A diffuser and blade technology, applied in the field of general milling fixtures, can solve the problems of high production cost of tooling, high repetitive work intensity, long production and manufacturing cycle, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

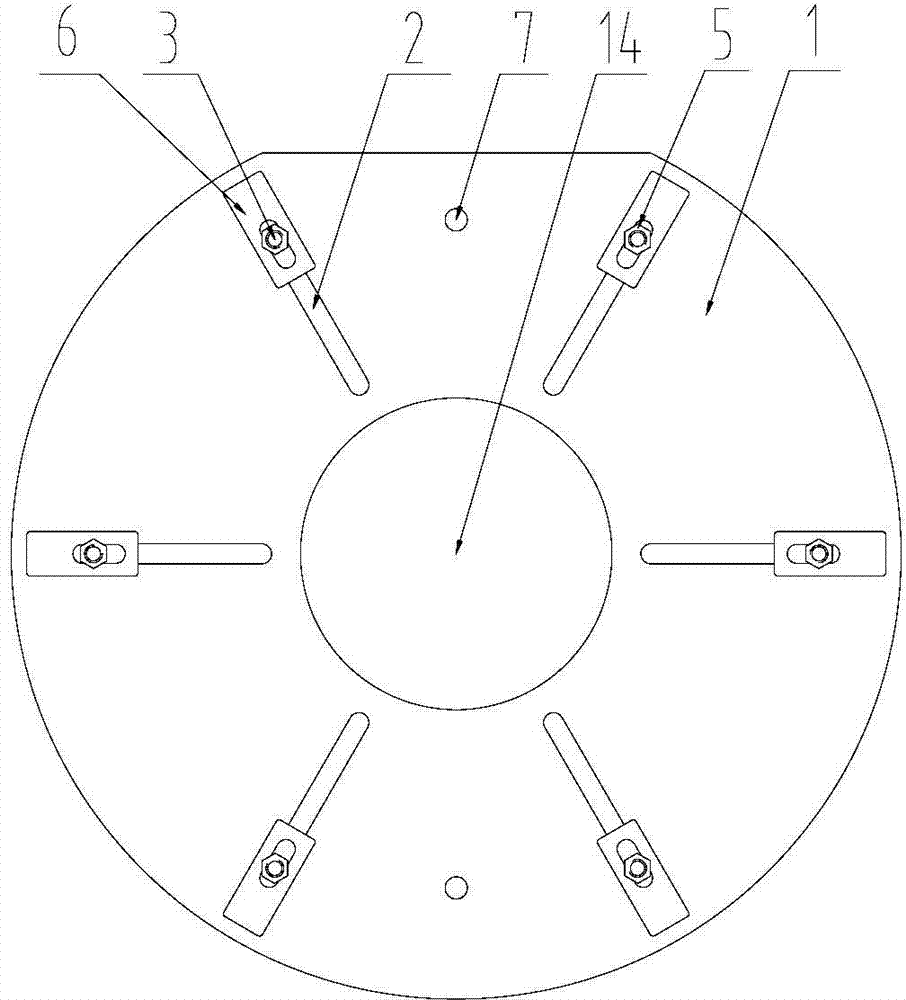

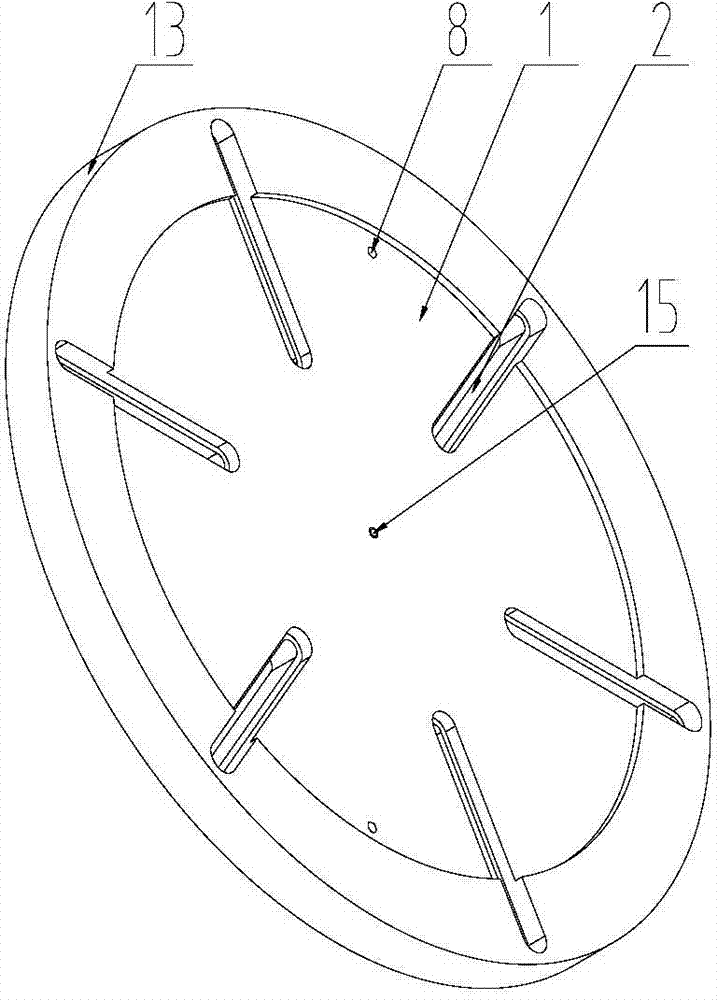

[0034] see Figure 1 to Figure 10 , is a preferred embodiment of a universal milling fixture for diffuser blades, comprising a disc-shaped base 1, the disc-shaped base 1 is provided with a cutting straight edge 13 for positioning the base 1, Six strip-shaped guide holes 2 are evenly arranged on the base 1 along the circumference, and the extension lines of each guide hole 2 pass through the axis of the base 1 . In this embodiment, the cutting straight edge 13 is located between two adjacent guide holes 2, and the end surface area of the base is reduced while ensuring that the outer end of the pressing plate does not exceed the outer contour of the base.

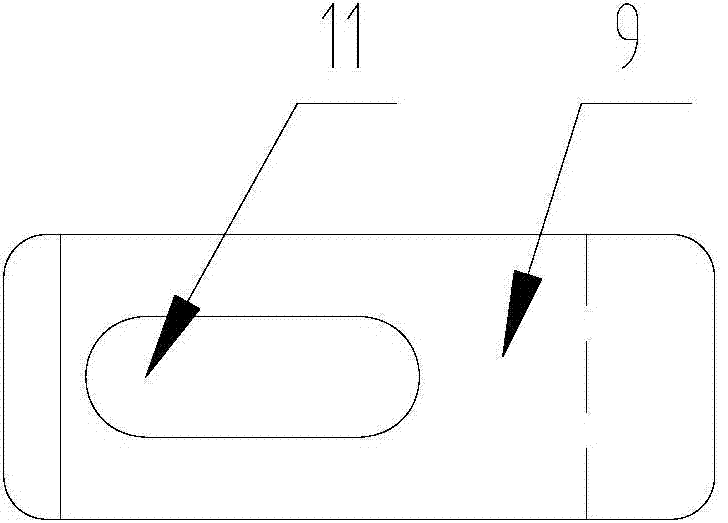

[0035] Each guide hole 2 is respectively provided with a guide rod 3 perpendicular to the upper end surface of the base 1, the lower end of the guide rod 3 is provided with a positioning head 4, and the positioning head 4 of the guide rod 3 cooperates with the lower end surface of the base 1 to form a positioning. In this ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com