Experimental facility for testing electrochemical signals of various materials in high-temperature high-pressure environment

A high-temperature, high-pressure, experimental device technology, applied in the direction of measuring devices, material analysis, and material analysis through electromagnetic means, can solve problems such as low efficiency, difficult electrochemical signal output and measurement, and inability to obtain corrosion process behavior. To achieve the effect of compact structure and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

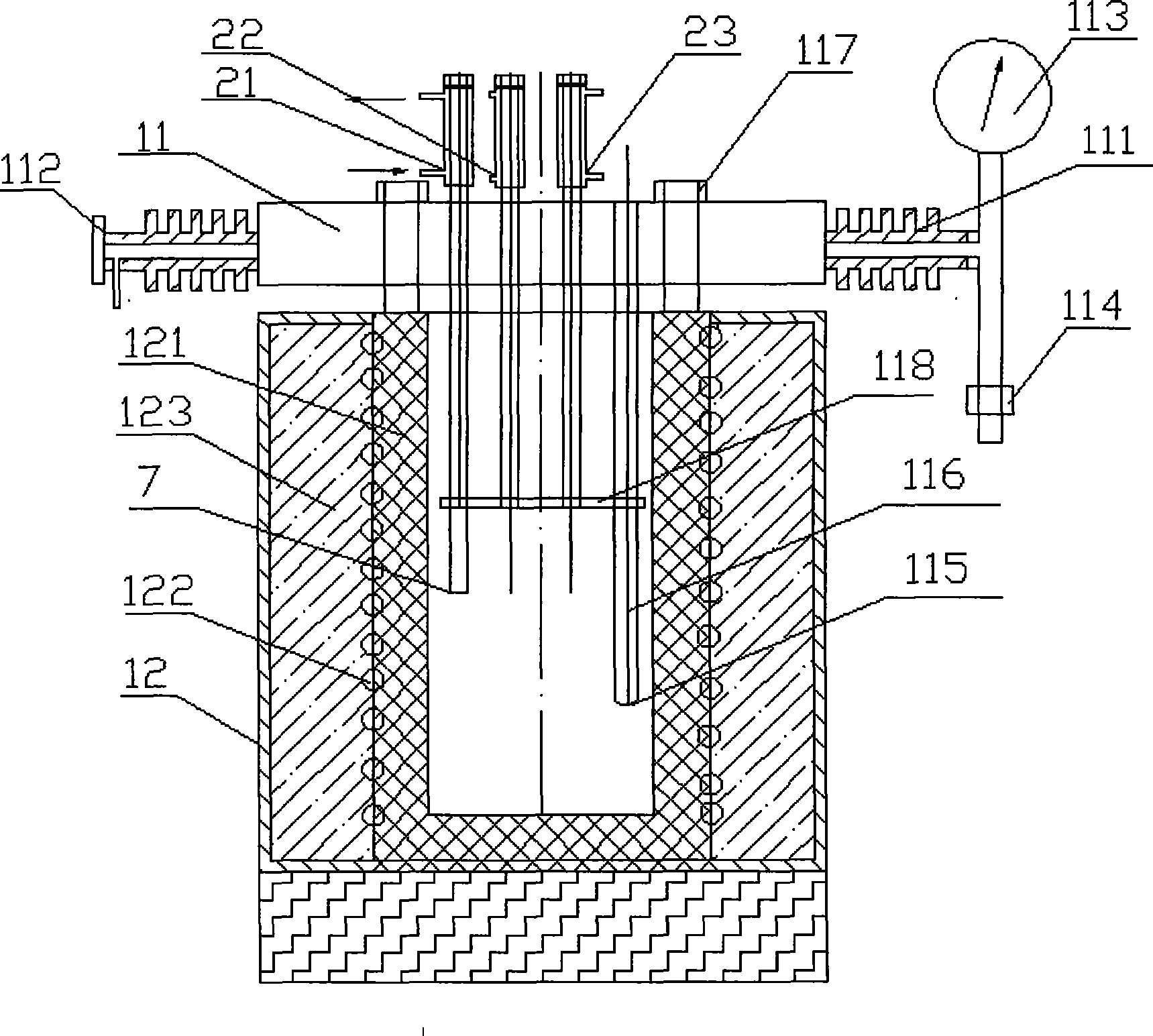

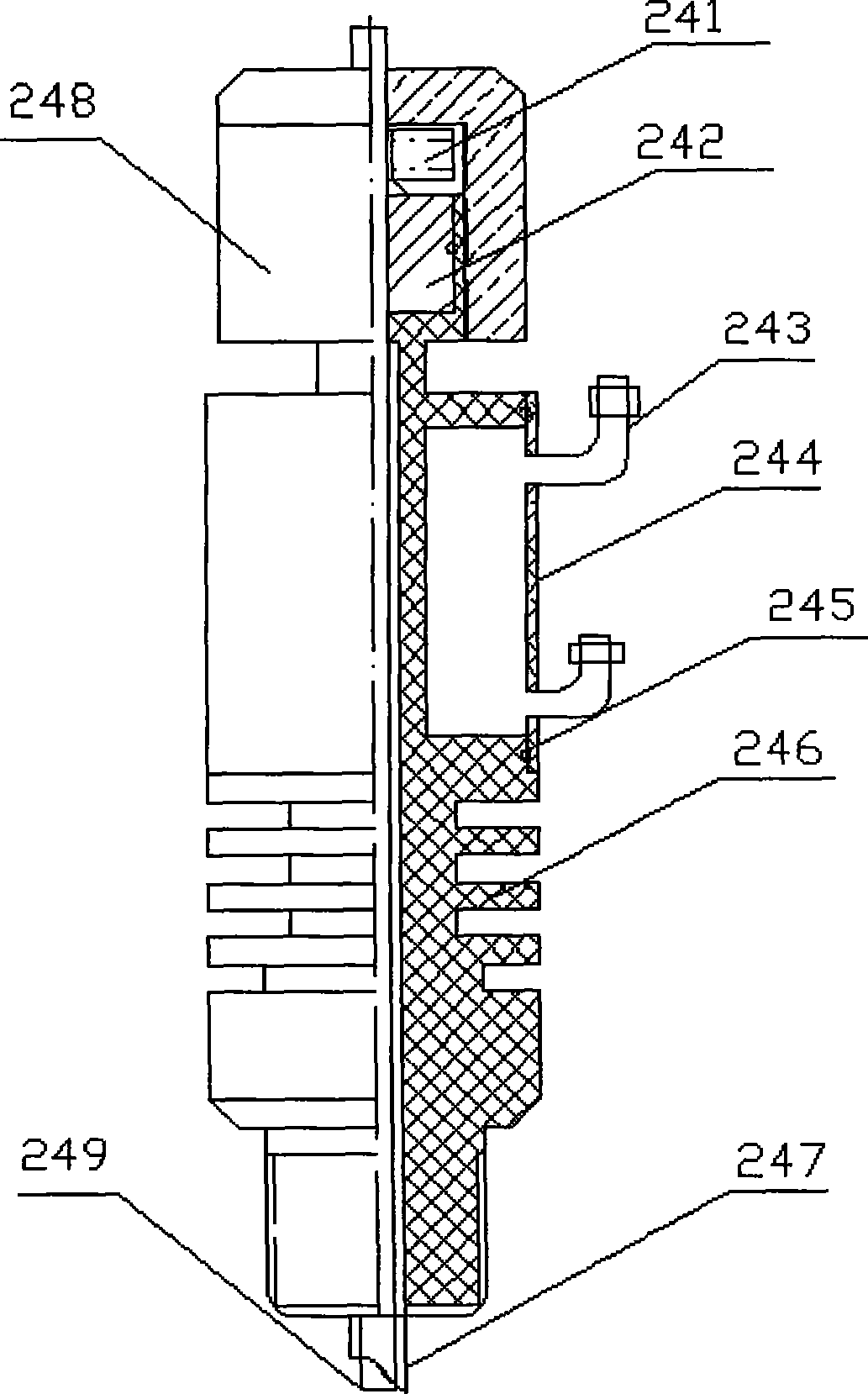

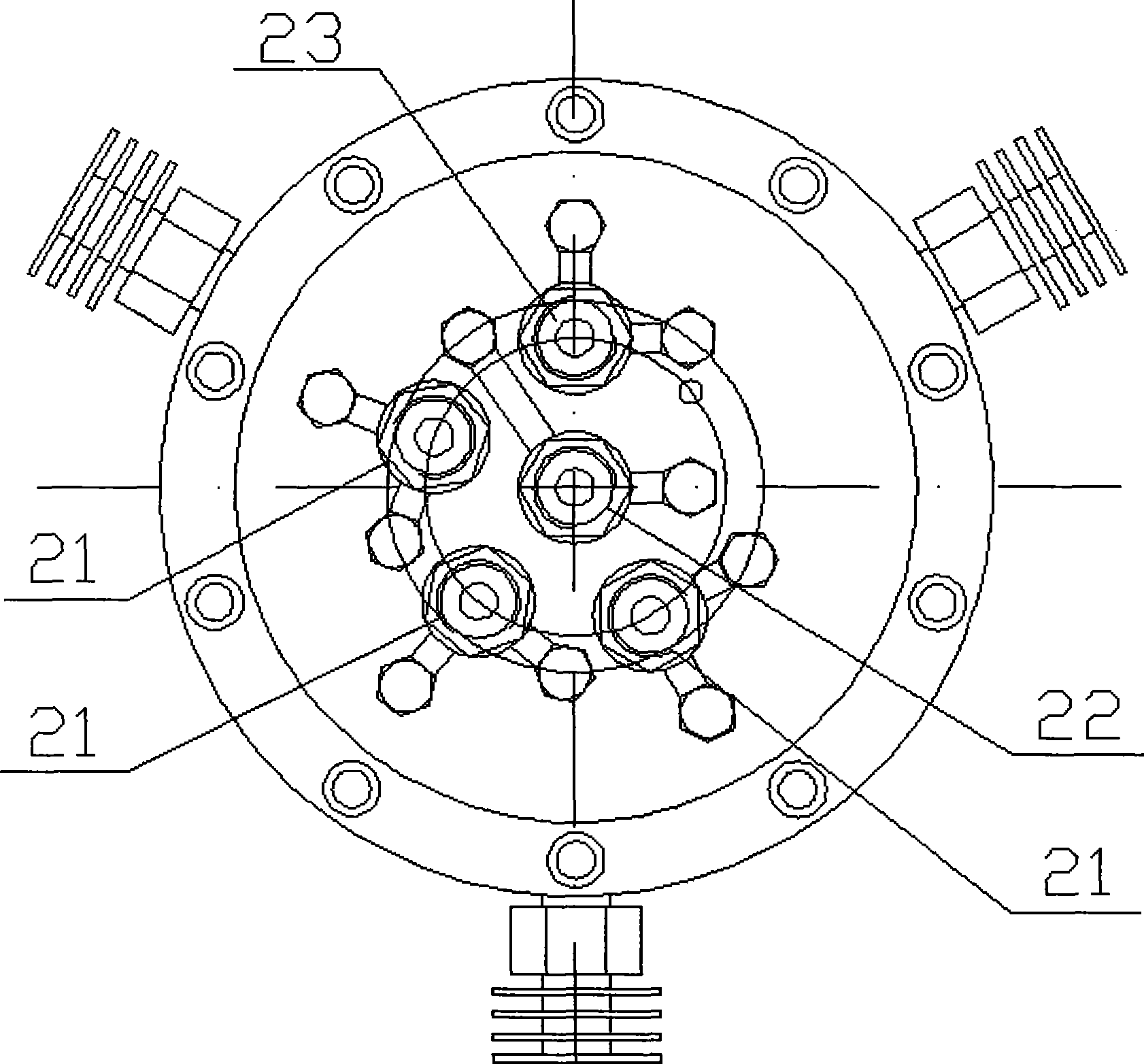

[0014] like figure 1 As shown, the experimental device for testing the electrochemical signals of various materials under the high temperature and high pressure environment of the present invention includes an autoclave, an electrode system, a temperature controller, an external electrochemical tester, and a circulating water cooling system. The autoclave is composed of a kettle cover 11 and a kettle Body 12 forms a pressure vessel, and the outer wall of kettle body 12 is covered with a heating electric furnace wire 122, and its heating power is 5KW, which is used for heating up the autoclave. In order to reduce the heat loss in the heating process, an asbestos thermal insulation layer 123 with a certain thickness is wrapped around the heating furnace wire 122 . Three radiating rods 111 are installed on the lid 11 of the kettle, which are resp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com