Dust removing type circular screening machine for tea

A circular sieve machine and tea technology, which are applied in the directions of removing smoke and dust, sieves, cleaning methods and utensils, etc., can solve problems such as affecting the quality of tea leaves, clogging of sieves, etc., and achieve the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

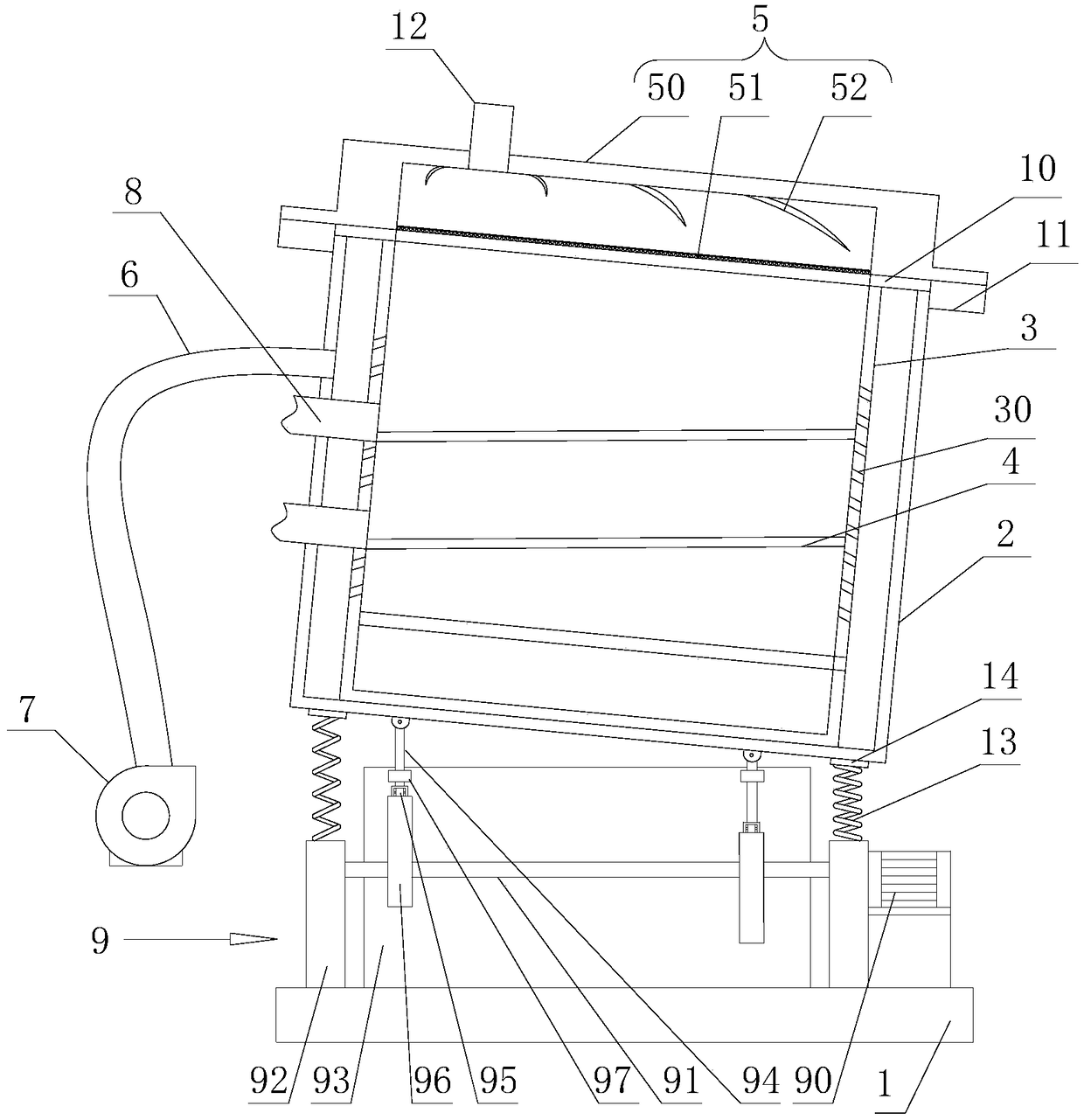

[0024] refer to figure 1 , a round tea sieve machine with dust removal function, comprising a base 1, an outer sieve bed 2, an inner sieve bed 3, a screen 4, a sealing cover 5, a ventilation pipe 6, a blower 7, a tea outlet cylinder 8, and a dust suction pipe 12 and vibration assembly 9;

[0025] The vibration assembly 9 is fixed on the base 1, the vibration assembly 9 is fixedly connected with the outer sieve bed 2, and the vibration assembly 9 drives the outer sieve bed 2 to vibrate up and down;

[0026] The side wall of the inner sieve bed 3 is provided with a plurality of through holes 30, the axes of the through holes 30 are obliquely upward from the outside to the inside, and the plurality of through holes 30 are spirally distributed on the side wall of the inner sieve bed 3, and the inner sieve bed 3. The fixed set is installed in the outer sieve bed 2. There is a reserved distance between the inner sieve bed 3 and the outer sieve bed 2. The tops of the outer sieve bed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com