Air purifier and achieving method thereof

An air purifier and air technology, applied in the field of indoor air purification, can solve problems such as excessive size, damaged temperature sensor, and high temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

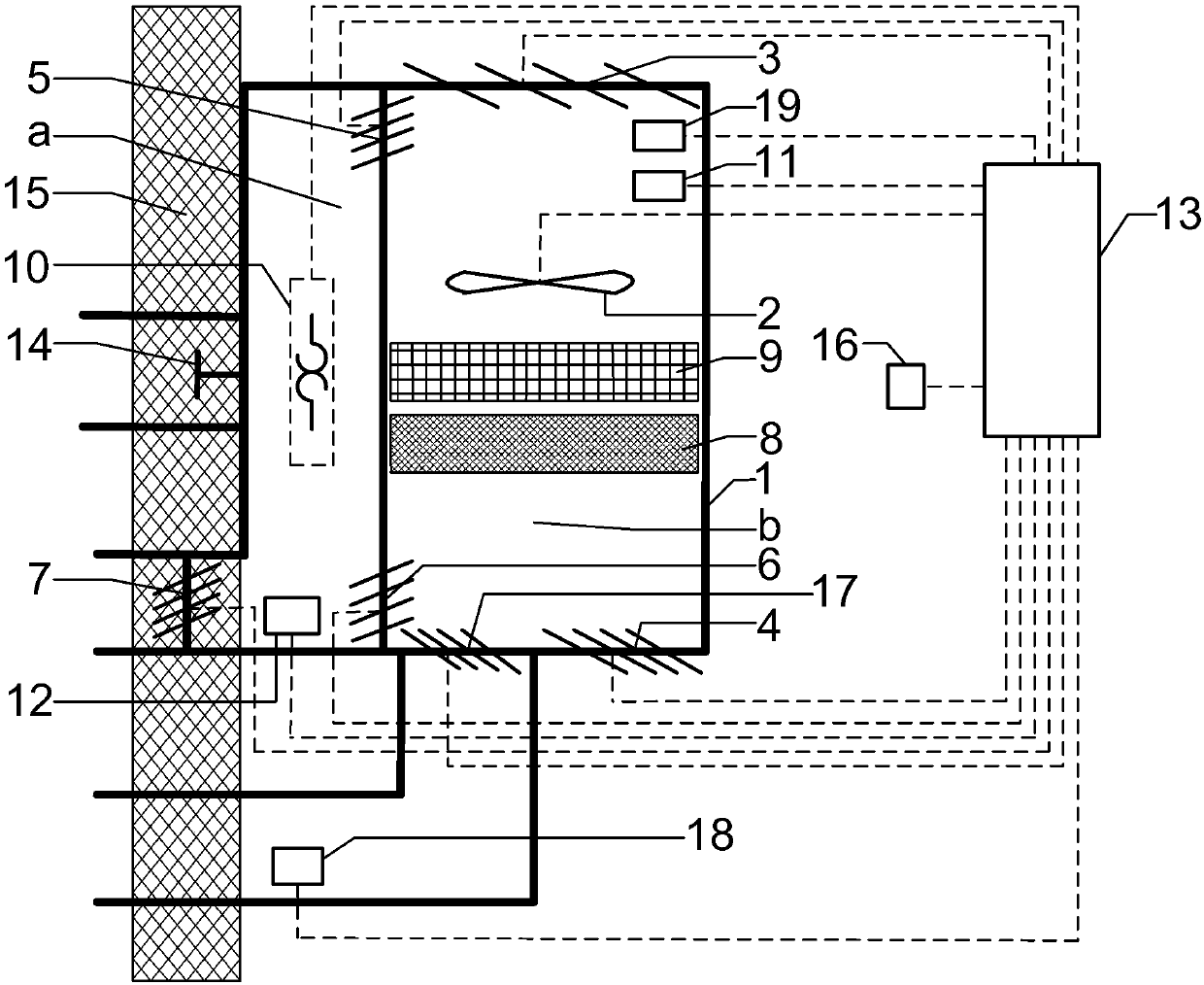

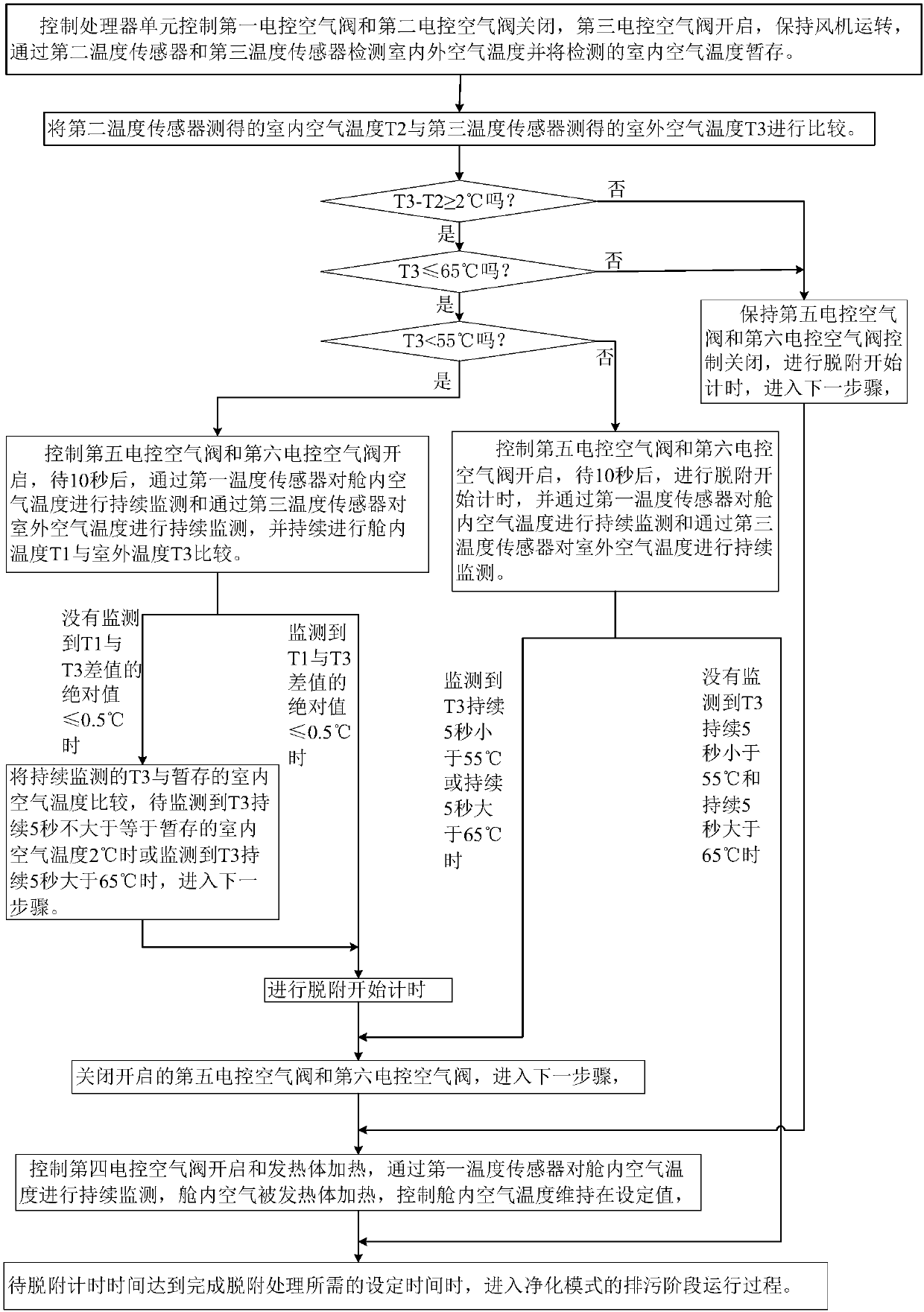

[0055] Such as figure 1 As shown, an air purifier includes: an airtight cabin 1, a fan 2, a first electrically controlled air valve 3, a second electrically controlled air valve 4, a third electrically controlled air valve 5, a fourth electrically controlled air valve 6, The fifth electronically controlled air valve 7, the sixth electronically controlled air valve 17, the coarse filter 8, the high-efficiency renewable VOCs and formaldehyde adsorption material 9, the heating element 10, the VOCs sensor 11, the flow sensor 19, the first temperature sensor 12, The second temperature sensor 16, the third temperature sensor 18, the control processor unit 13, the pressure relief valve 14; the first temperature sensor 12, the second temperature sensor 16, the third temperature sensor 18, the VOCs sensor 11 and the flow sensor 19 They are respectively connected to the input ends of the control processor unit 13; the first electrically controlled air valve 3, the second electrically co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com