Waste incineration device with intermittent wind impact combustion supporting and vibration ash removal functions

An incineration device and ash cleaning technology, which is applied in the direction of combustion method, combustion type, combustion equipment, etc., can solve the problems of inability to turn the incinerated objects, reduced incineration efficiency, and low incineration efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

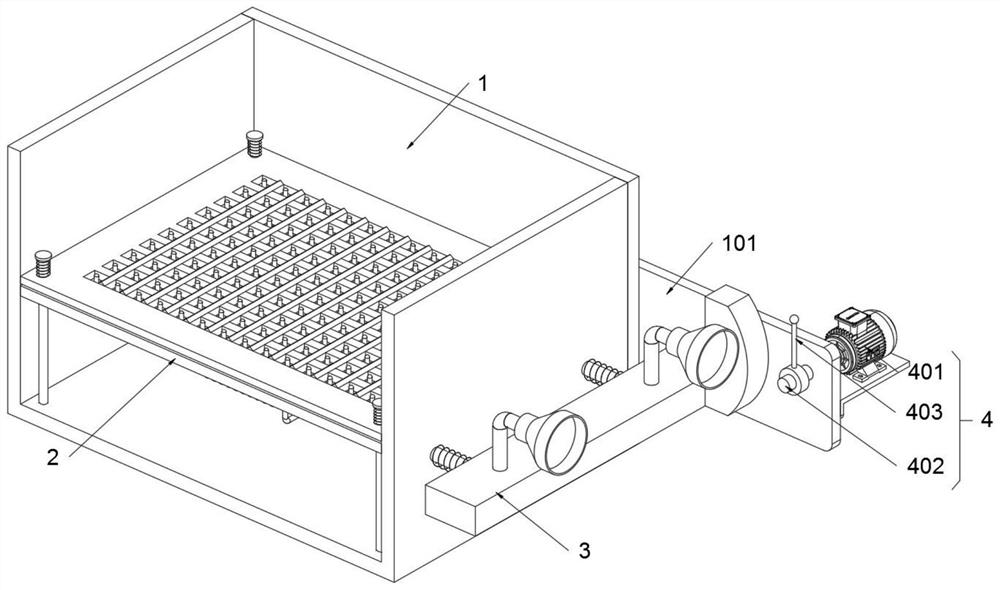

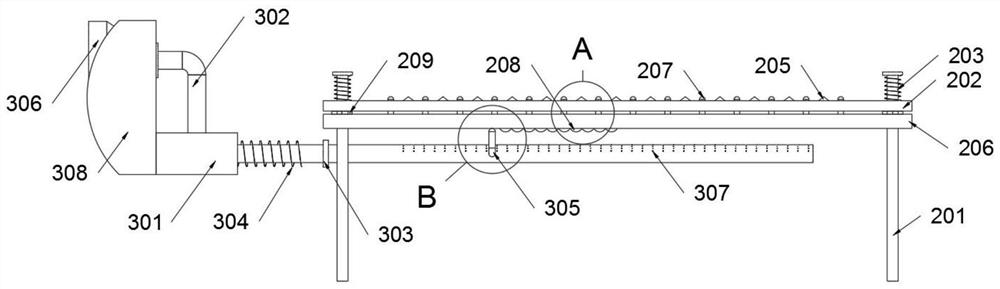

[0033] as attached figure 1 To attach Figure 8 Shown:

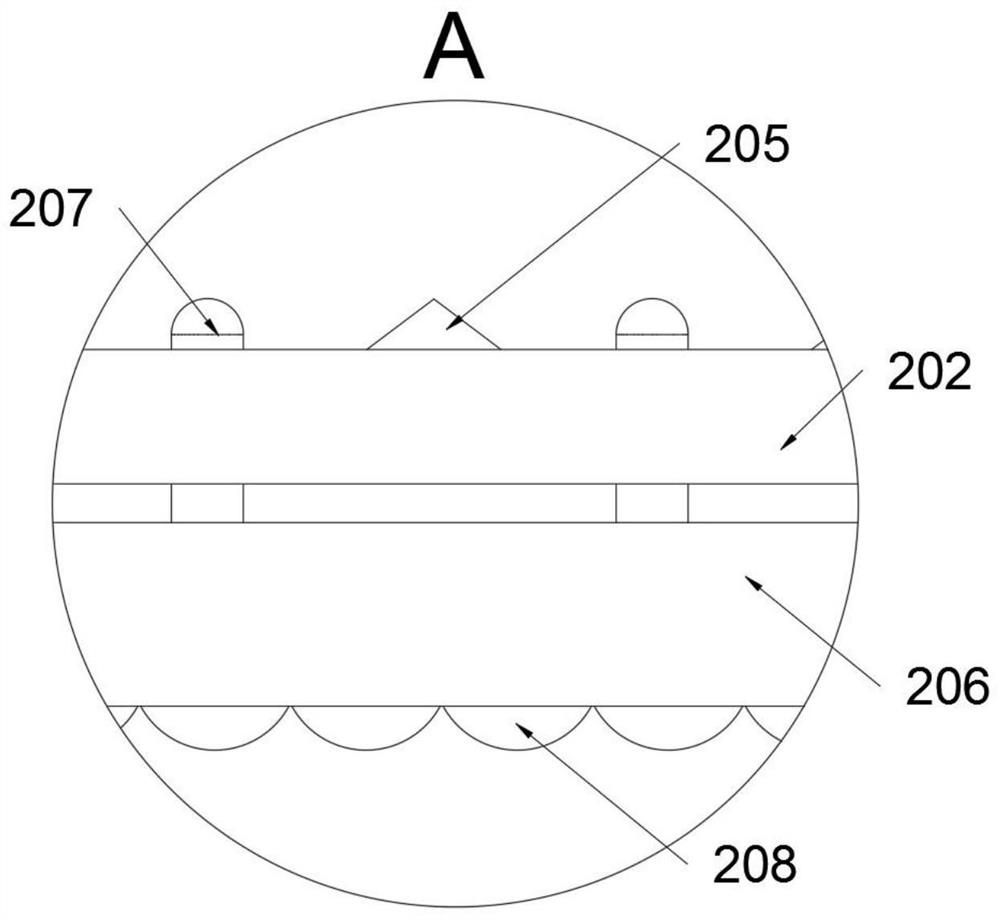

[0034]The invention provides a waste incineration device with the functions of intermittent wind impact combustion and dust removal by vibration, including an incineration box 1; A drive structure 4 is also installed on the box body 1; refer to as figure 2 , the incineration frame structure 2 includes elastic parts B209, four elastic parts B209 are provided in total, and the four elastic parts B209 are respectively sleeved on the four sliding rods 201; the elastic parts B209 are located between the main body 202 of the incineration frame and the auxiliary frame 206 , and the elastic force of the elastic piece B209 is smaller than the elastic force of the elastic piece A203, and the thickness of the elastic piece B209 is smaller than the height of the protrusion B208, so that when the toggle lever A305 and the protrusion B208 are toggled, not only can the incineration be turned over, but also Can realize the vibration...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com