Automatic grain rapid drying device

A technology for fast drying and food, applied in the field of agricultural equipment, can solve the problem of incomplete drying, achieve the effect of increasing temperature, reasonable structure design, and preventing excessive accumulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

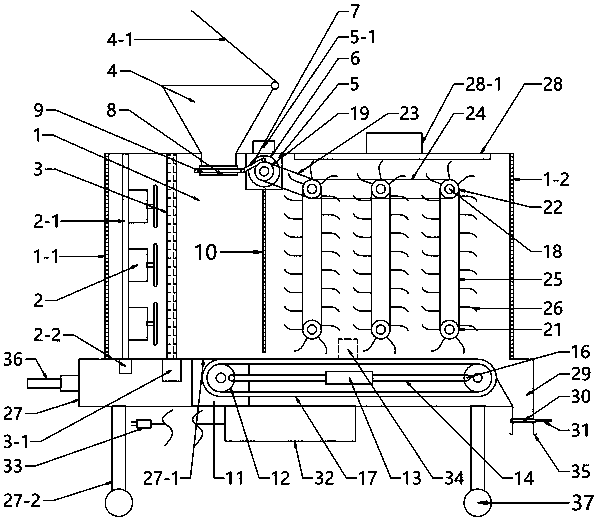

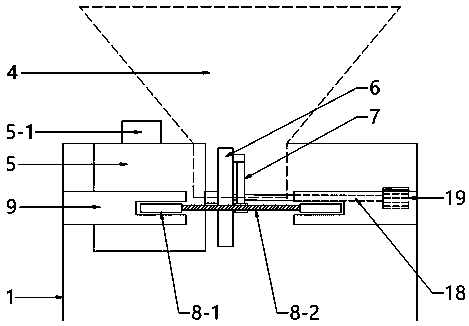

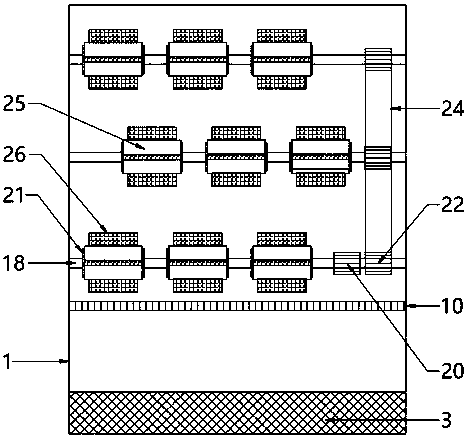

[0019] Attached below Figure 1~8 The present invention is described in detail below.

[0020] Such as Figure 1~8As shown, the present invention includes a base 27, a drying box 1, a conveying device, and a turning device. The base 27 is arranged under the drying box 1 and is hollow inside, and the left side wall of the drying box 1 is an air inlet net 1- 1. The right side wall is the air outlet net 1-2, which can blow out the water vapor in the drying box 1 with the fan 2, and the left side of the drying box 1 is equipped with a fan fixing frame 2-1, which is fixed on the fan fixing frame 2-1. A plurality of blower fans 2 are provided so that the air is evenly blown out. The position below the blower fan 2 on the base 27 is provided with a corresponding fan switch 2-2 for controlling the switch of the blower fan 2. There is a carbon fiber heating net 3, which can heat the airflow generated by the fan 2, and then use the hot air to dry the grain in the drying box 1. The pos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com