Method for realizing anti-shrinkage recarburization sludge drying

A sludge drying and anti-shrinkage technology, which is applied in dewatering/drying/concentrating sludge treatment, energy and wastewater treatment, etc., can solve problems such as unfavorable activated carbon firing, unfavorable heat treatment, low organic carbon content in sludge, etc. Conducive to the effect of subsequent carbon quality, reducing tar production and increasing carbon content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

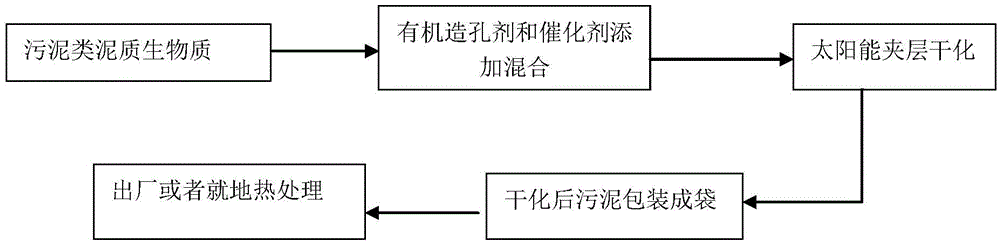

Image

Examples

Embodiment 1

[0046] According to the organic pore-forming agent formula, mix natural fibers such as starch, sawdust, wood chips and straw (1:1:1:1), use the cellulose and other components as pore-forming agents, and then add polyvinyl chloride, polyvinyl chloride, etc. One or several components of styrene, polyvinyl alcohol and resin are used as aggregates, the mass ratio of the pore-forming agent to aggregates is controlled at 50%:50%, and 0.4mol / L KOH is added as a catalyst , the mass ratio of the catalyst to the organic pore-forming agent is 1:1. Mix the prepared organic pore-forming agent and catalyst with the dehydrated sludge dry basis, the dosage of the organic pore-forming agent is 5% of the dehydrated sludge dry basis, and the moisture content of the sludge is 80% %,well mixed. After 15 minutes, the capillary water absorption time of the sludge increased from 3700s of the original sludge to 4357s, pumped in with a high-pressure pump, and evenly distributed in the solar interlayer...

Embodiment 2

[0048] According to the organic pore-forming agent formula, mix natural fibers such as starch, sawdust, wood chips and straw, use the cellulose and other components as pore-forming agents, combine polyvinyl chloride, polystyrene, polyvinyl alcohol and resin in One or several components are used as aggregates, and the mass ratio of the two is controlled at 40%:60%. At the same time, 0.6mol / L KOH with the same mass as the organic pore-forming agent is added as a catalyst and mixed with sludge. The dosage of the pore-forming agent is 15% of the dry basis of the dehydrated sludge, wherein the moisture content of the sludge is 80%, and the mixture is uniform. After 15 minutes, the capillary water absorption time of the sludge increased from 3700s of the original sludge to 4654s, pumped in with a high-pressure pump, evenly distributed in the solar interlayer drying system, and dried under normal sunlight conditions. The temperature in the interlayer during the day is 38 Fluctuating ...

Embodiment 3

[0050] According to the formula of organic pore-forming agent, mix natural fibers such as starch, sawdust, wood chips, and straw arbitrarily, use the cellulose and other components in it, combine polyvinyl chloride, polystyrene, polyvinyl alcohol, and resin, etc. Components, the ratio of which is controlled at 30%:70%, while adding an equal mass of 0.7mol / L KOH, and mixing with the sludge at a mass ratio of 20% of the sludge dry basis, wherein the moisture content of the sludge is 80% , mixed evenly, after 15 minutes, the capillary water absorption time of the sludge increased from 3700s of the original sludge to 4807s, pumped in with a high-pressure pump, uniformly distributed in the solar interlayer drying system, and dried under normal sunlight conditions. The temperature fluctuates between 38-80°C during the day, and the time required for the moisture content to drop from 80% to 20% is 1.5d (the actual effective time is 12h), while the simple solar drying without adding an ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com