Thin loop type radiating apparatus

A technology of heat dissipation device and loop, which is applied to circuits, indirect heat exchangers, lighting and heating equipment, etc., can solve the problems of poor working liquid return and steam damage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

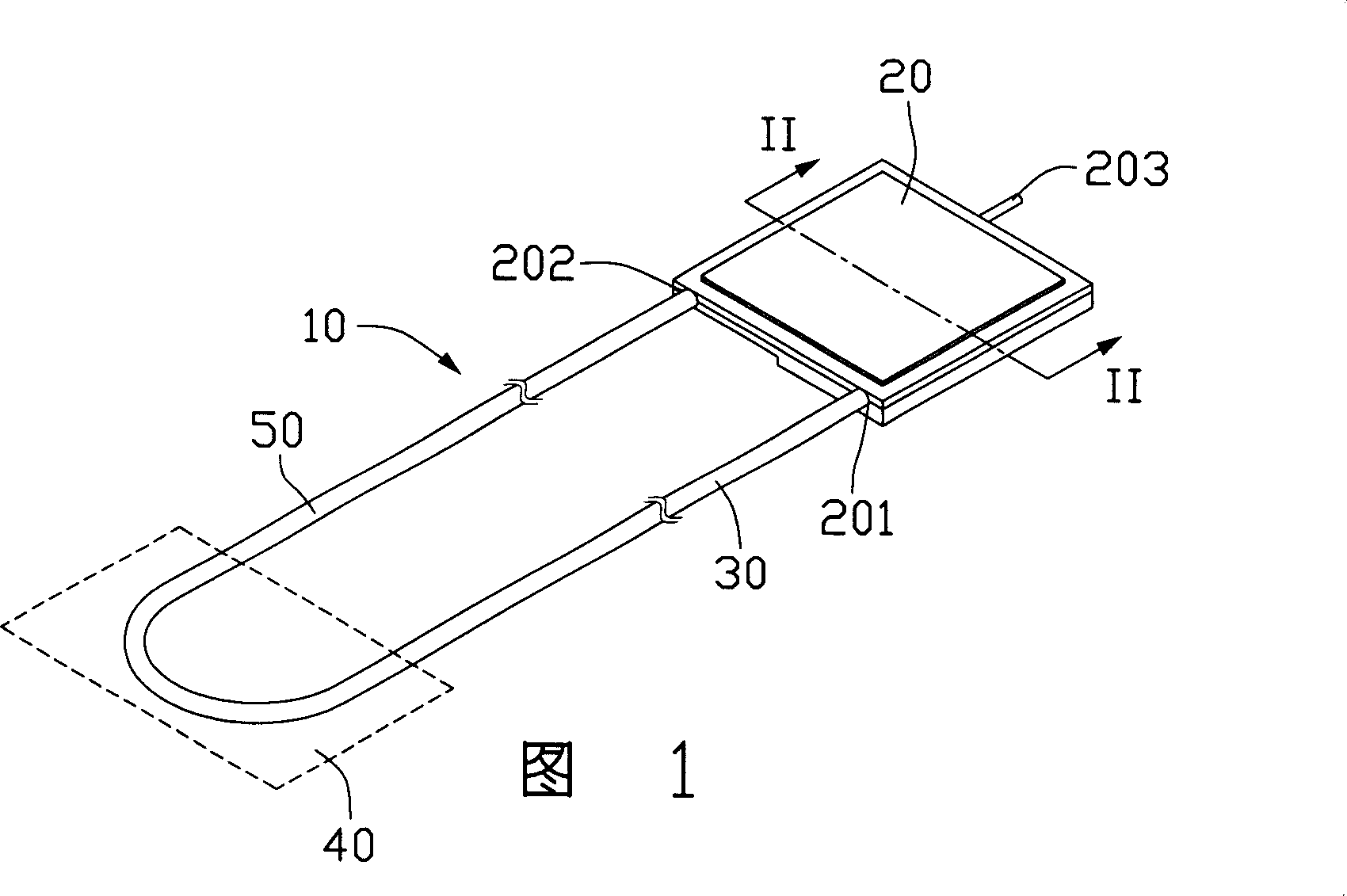

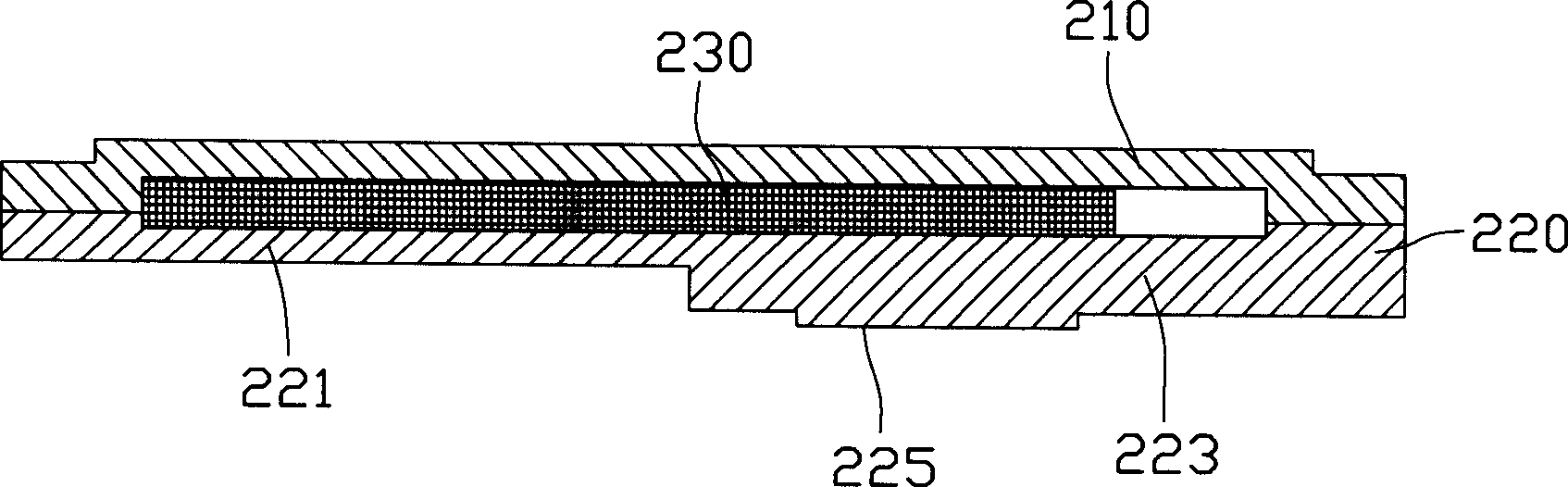

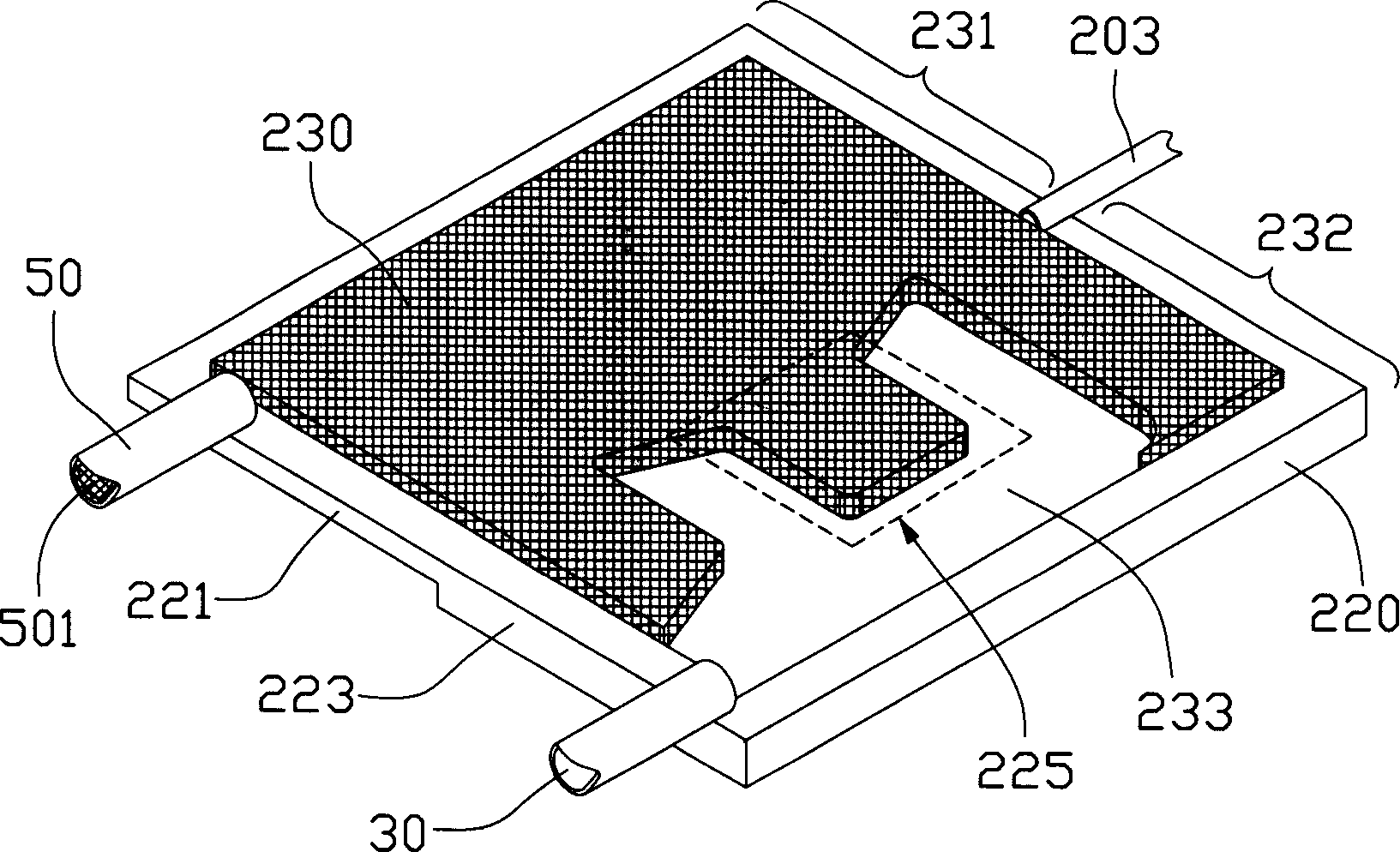

[0020] FIG. 1 is a schematic perspective view of a first embodiment of a thin loop heat dissipation device of the present invention. The heat dissipation device 10 includes an evaporator 20 , a steam conduit 30 , a condenser 40 and a return conduit 50 . One side wall of the evaporator 20 is respectively provided with an outlet 201 and an inlet 202 at opposite positions, and the steam conduit 30 and the return conduit 50 are coilable metal or coilable non-metallic pipes, respectively communicating with the outlet of the evaporator 20 201 is connected to the inlet 202 and to the remote condenser 40, so as to communicate with each other to form a heat conduction tight loop. The condenser 40 can be any existing heat dissipation structure, such as heat dissipation fins, fans, water circulation heat dissipation devices, etc., aiming at releasing heat from the steam transferred here and cooling it into a liquid state. The evaporator 20 is formed in a flat plate shape, combined with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com