Production line for washing and sterilizing chopsticks

A cleaning and disinfection, production line technology, applied in the direction of washing machine/rinsing machine parts, irradiation and other directions of tableware, can solve problems such as the reduction of forest resources, and achieve the effect of reducing the spread of intestinal diseases, increasing employment, and saving trees.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

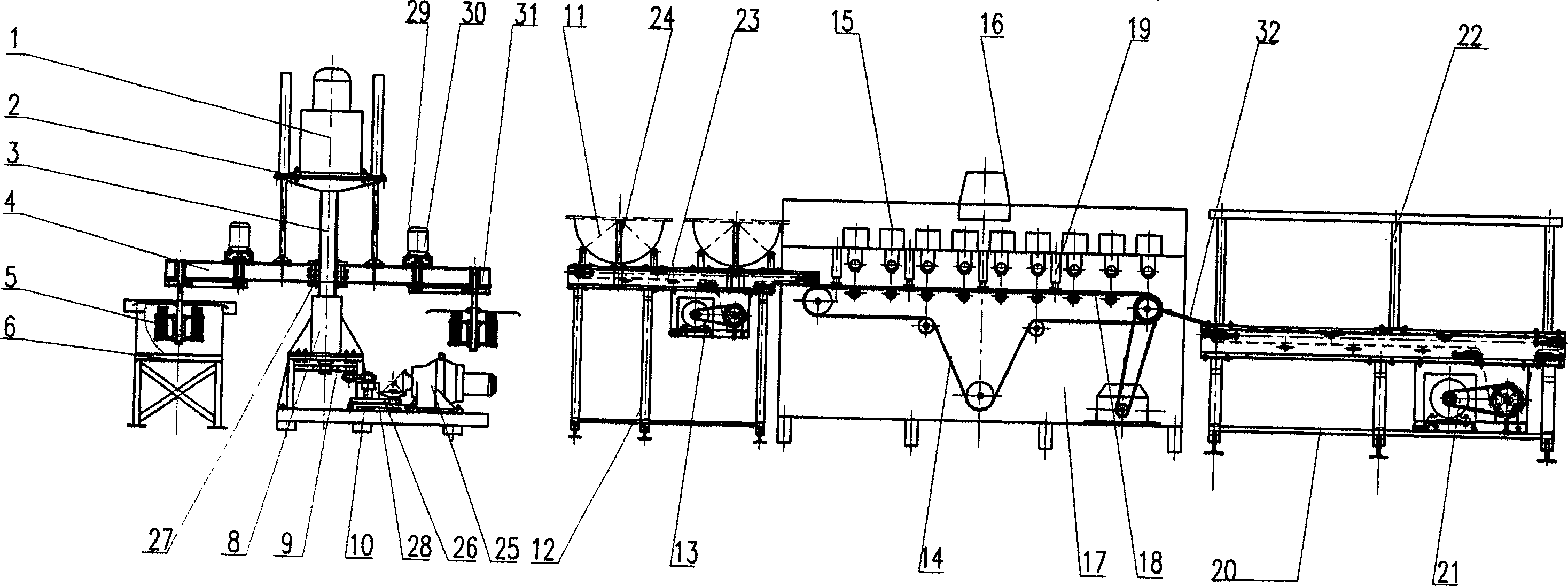

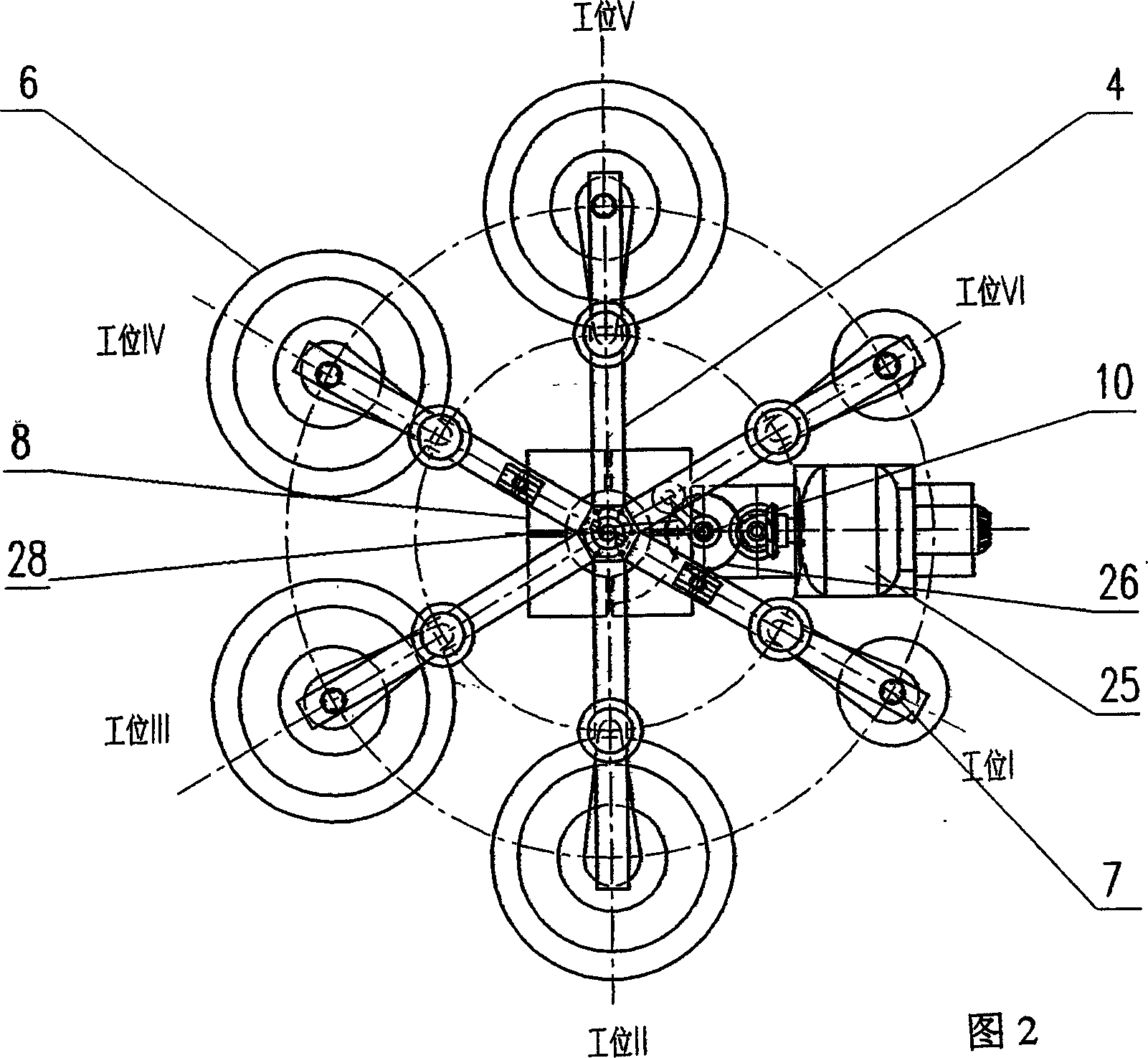

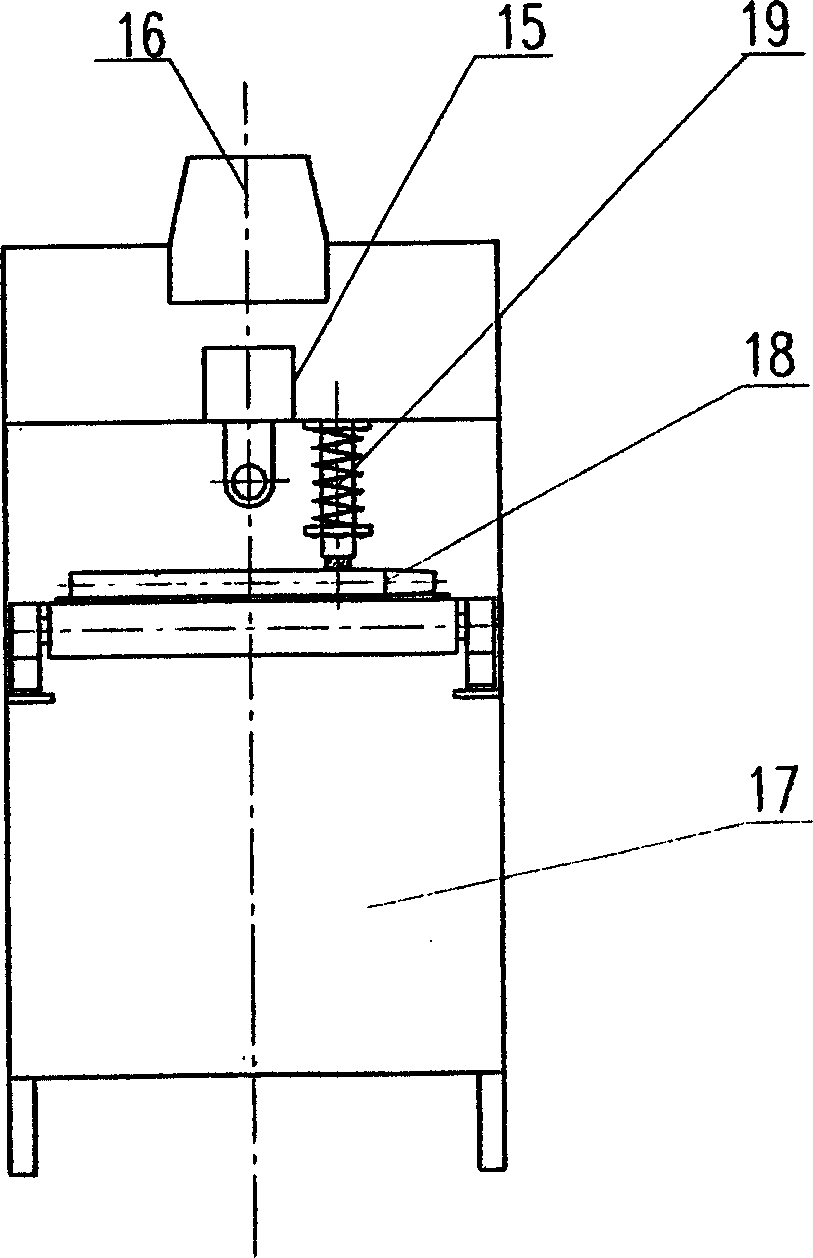

[0019] A chopstick cleaning and disinfection production line includes a washing machine, a disinfection machine, and a central electrical control cabinet. The washing machine 1 is provided with six stations 7, which are respectively the loading tray station, the rough washing station, the fine washing station, the cleaning station, the drying station, and the discharge tray station. Each station is connected to A cantilever mechanism 4, the cantilever mechanism 4 is connected with the rotary main shaft 3 through a sliding sleeve 27; A hydraulic oil cylinder 2 is arranged at the upper end of the rotary main shaft 3 . The lower end of the rotary main shaft 3 is connected with a column base 8 . The recovered chopsticks are soaked and installed on the tray 5. The amount of chopsticks in each tray is 210 pairs. The tray is installed on the cleaning machine 1, and the tray acts on the hydraulic cylinder 2 through the cantilever mechanism 4 and the sliding sleeve 27. The lower edge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com