Wet fermentation protein feed for efficient fattening process of beef cattle

A fermented protein feed, wet state technology, applied in the field of high-efficiency fattening process of beef cattle with wet fermented protein feed, can solve the problems of loss of nutritional value, excessive reduction, air pollution, etc., to achieve content increase, maintenance and regulation of intestinal bacteria The effect of group balance and nutritional value improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

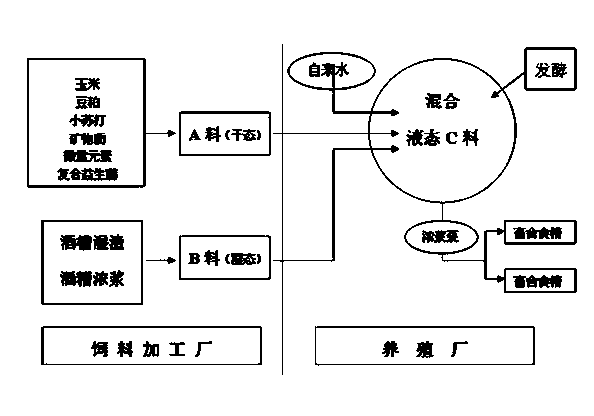

[0036] Embodiment 1: see figure 1 .

[0037] (1) Production of material A (dry state)

[0038] The production of material A (dry state) is carried out in the wet state feed processing plant. 50.5% of corn, 24.0% of soybean meal, 14.5% of baking soda, 7.2% of minerals, 2.8% of trace elements, and 1.0% of compound probiotics were crushed and mixed in proportion and packed into bags.

[0039] (2) Production of material B (wet state)

[0040] The production of material B (wet state) is also carried out in the wet state feed processing plant. Mix the wet dregs of the distiller tank and thick distiller's grains in a ratio of 1:1 and put them into a closed container (sealed plastic bag or sealed barrel). The storage period is more than 6 months, which can fully meet the storage requirements in production. time. If the material B is not used up at one time, the air in the packaging bag needs to be drained, and the airtight storage should be carried out to prevent corruption.

...

Embodiment 2

[0053] Embodiment 2: see figure 1 .

[0054] (1) Production of material A (dry state)

[0055] The production of material A (dry state) is carried out in the wet state feed processing plant. 48.5% of corn, 25.0% of soybean meal, 14.5% of baking soda, 8.2% of minerals, 2.8% of trace elements, and 1.0% of compound probiotics are crushed and mixed in proportion and packed into bags.

[0056] (2) Production of material B (wet state)

[0057] The production of material B (wet state) is also carried out in the wet state feed processing plant. Mix the wet dregs of the wine tank and the concentrated distiller's grains at a ratio of 1:1.2 and put them in a closed container (sealed plastic bag or sealed barrel). The storage period is more than 6 months, which can fully meet the storage requirements in production. time. If the material B is not used up at one time, the air in the packaging bag needs to be drained, and the airtight storage should be carried out to prevent corruption...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com