Cold light firework powder column and screw compression forming process thereof

A technology of cold light fireworks and molding process, applied in explosives processing equipment, pyrotechnics, explosives, etc., can solve the problems of difficult control of burning speed, dangerous discharge operation, and difficult to compact, and achieve the effect of controllable burning speed and stable product quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

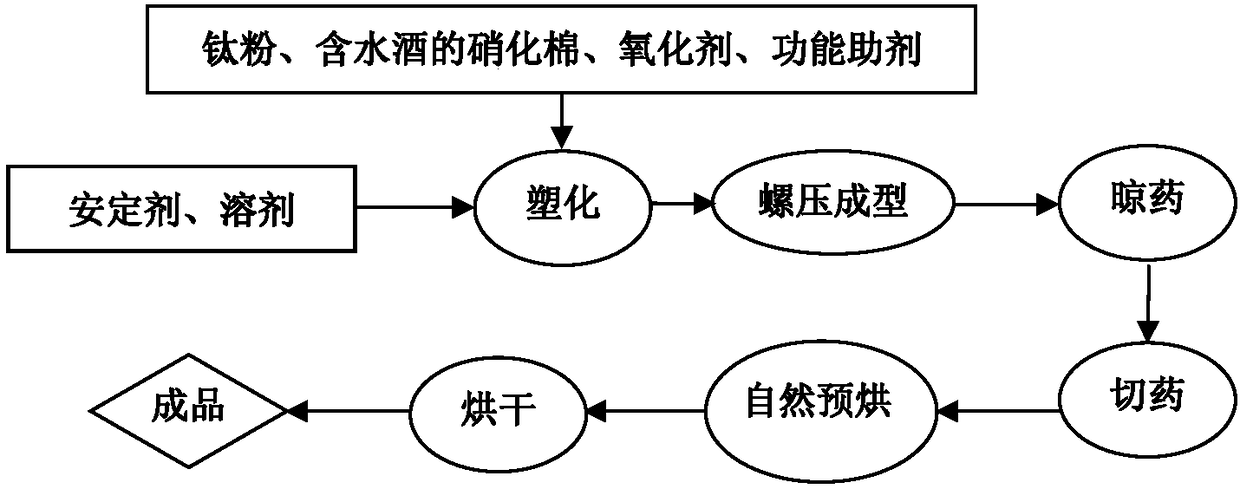

Method used

Image

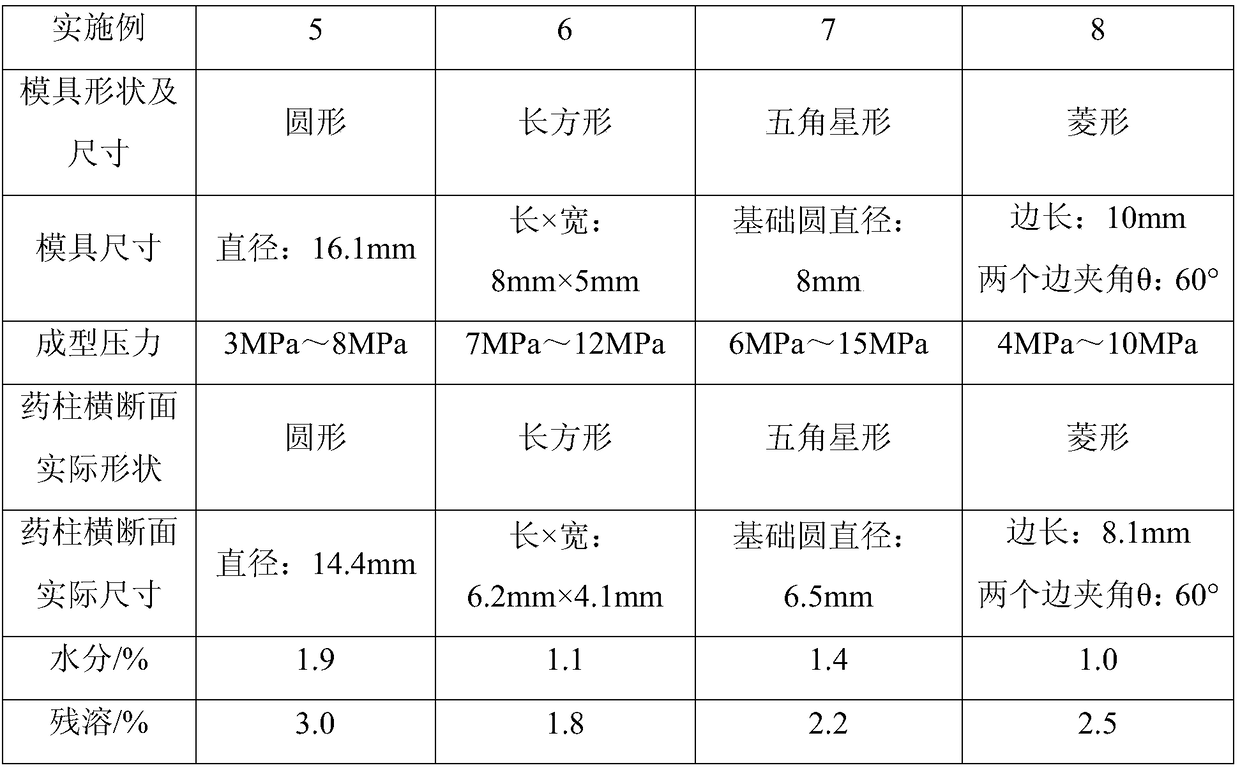

Examples

Embodiment 1

[0057] 60 parts by weight of nitrocellulose of water-containing wine (the water-containing nitrocellulose is placed in a water-displacing machine and made by driving water with alcohol, and the contained moisture and ethanol content of the nitrocellulose of water-containing wine are both 10%), ammonium perchlorate Add 30 parts by weight and 10 parts by weight of titanium hydride powder into the kneader, and mix in reverse for 5 minutes; take the solvent diethyl ether according to the ratio of dissolving cotton to 1.2, take diphenylamine according to the mass ratio of diphenylamine to solvent of 0.05, and add diphenylamine to the solvent to dissolve ; Pour the diphenylamine-dissolved solvent into the kneader, cover the machine cover, drive the front car for 10 minutes, scrape the cylinder, and then drive the front car for 10 minutes, reverse the car for 5 minutes alternately, the total plasticizing time is 50 minutes, and the plasticization is completed. to obtain plastic materi...

Embodiment 2

[0061] 58 parts by weight of nitrocellulose containing wine (purchased in Northern Sichuan Nitrocellulose Co., Ltd., trade mark H1 / 2, the contained moisture and the content of ethanol in the nitrocellulose containing wine are 29%), 30 parts by weight of ammonium perchlorate Parts, 10 parts by weight of yellow light titanium powder, 2 parts by weight of functional additive barium nitrate were added in the kneader, reversed and mixed for 4 minutes; the solvent ethyl acetate was taken according to the solvent-to-cotton ratio of 0.9, and diphenylamine was taken according to the mass ratio of diphenylamine to solvent of 0.08 , add diphenylamine to the solvent to dissolve; pour the solvent dissolved in diphenylamine into the kneader, cover the machine cover, drive the front car for 10 minutes, scrape the cylinder, and then drive the front car for 10 minutes, reverse the car for 5 minutes alternately, the total plasticizing time 60min, the plasticization is over, and the plasticized m...

Embodiment 3

[0065] 65 parts by weight of nitrocellulose of water-containing wine (the water-containing nitrocellulose is placed in a water-displacing machine and made by driving water with alcohol, and the contained moisture and ethanol content of the nitrocellulose of water-containing wine are both 27%), ammonium perchlorate 25 parts by weight and 10 parts by weight of titanium sponge powder were added to the kneader, and mixed in reverse for 3 minutes; according to the solvent-to-cotton ratio of 0.7, take solvent ether and ethanol (mass ratio of ether and ethanol 1:1), and mix according to the mass ratio of diphenylamine and mixed solvent 0.04 Take diphenylamine, add diphenylamine to the solvent to dissolve; pour the solvent dissolved in diphenylamine into the kneader, cover the machine cover, drive the front car for 10 minutes, scrape the cylinder, then drive the front car for 10 minutes, and reverse the car for 5 minutes alternately, The total plasticizing time is 70 minutes, and the p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com