Biomass fuel heating furnace capable of improving heat absorption efficiency and heating equipment for biomass fuel heating furnace

A technology of biomass fuel and heating stove, which is applied to solid heating fuel, lighting and heating equipment, stove/stove with convection heating device, etc., which can solve the problems of increasing use cost, high fuel consumption, and excessive combustion efficiency, etc. problem, to achieve the effect of high heating efficiency, uniform crushing and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

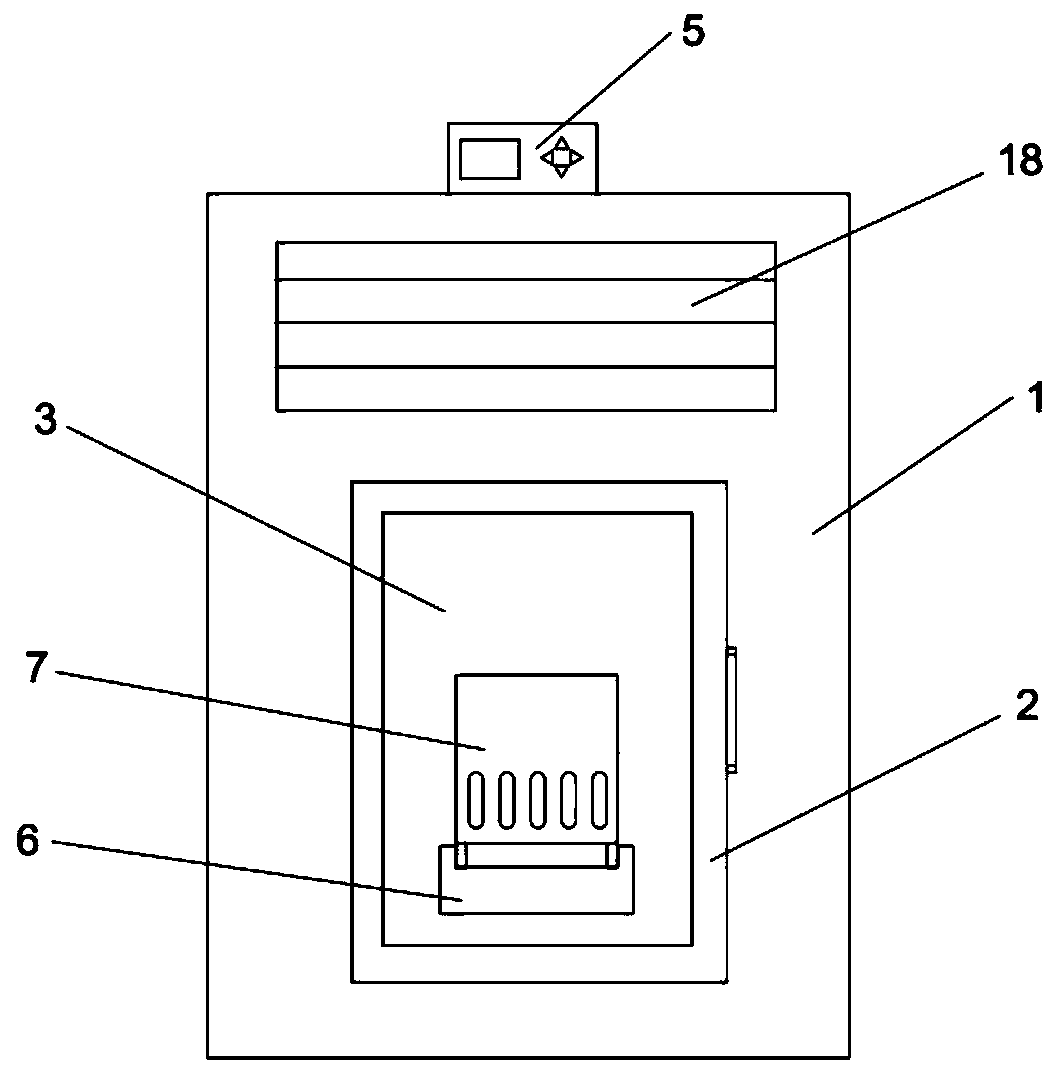

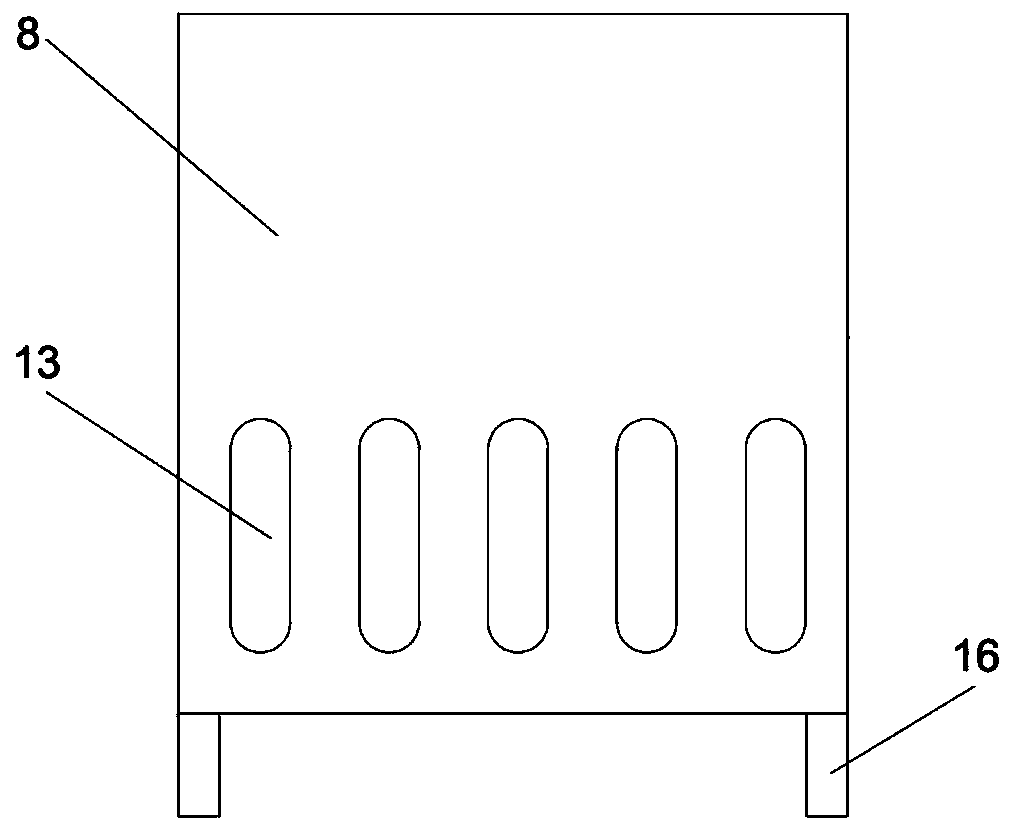

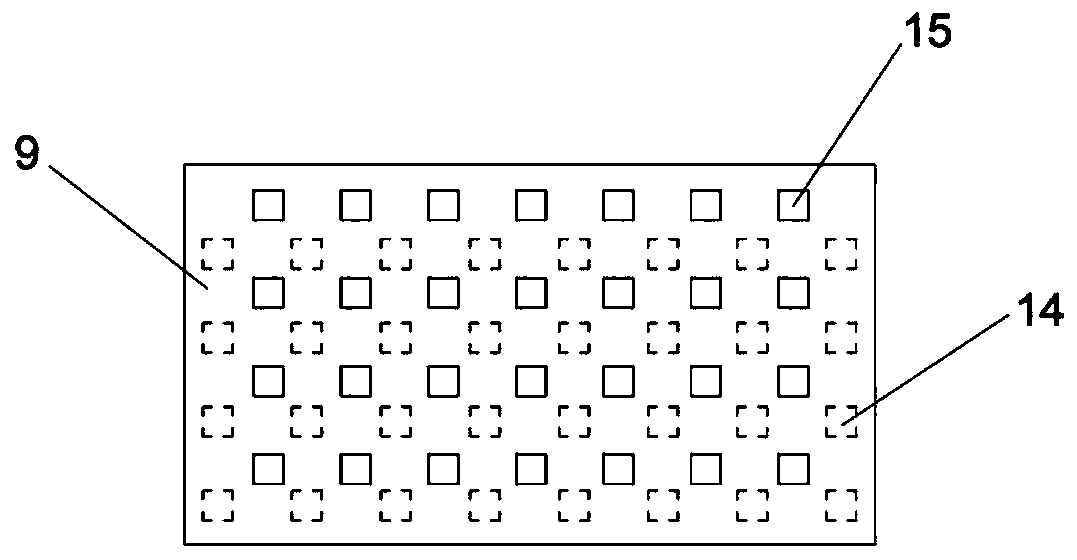

[0035] like Figure 1-3 , as shown in 5-7, a biomass fuel heating furnace with improved heat absorption efficiency, including a furnace body 1, a furnace door 2, a furnace 3, a combustion device, a smoke exhaust device 4, an intelligent control panel 5, an air supply device, a combustion The device includes a furnace core 6 arranged at the bottom of the furnace 3 and a flame hood 7 placed above the furnace core 6. The flame hood 7 is jointly surrounded by a side wall 8, a top plate 9 and a partition 10. The side wall 8, the top plate 9 and the The partition 10 is a steel plate and is fixedly connected by welding. The partition 10 divides the flame arrester 7 into a lower flame arrester 11 and an upper flame arrester 12, and the side wall 8 of the lower flame arrester 11 is provided with several oxygen inlets. 13. The shape of the oxygen inlet 13 is not limited to the elongated shape shown in the figure, and can also be rectangular or irregular. The partition 10 is provided wit...

Embodiment 2

[0038] This example Figure 1-2 , 4, 5, and 7, the same places as in Embodiment 1 will not be repeated, the difference is that the shapes of the lower flame outlet 14 and the upper flame outlet 15 are not limited to the circle shown in the figure, and can be irregular , The shape of the flame hood 7 is a cylinder.

Embodiment 3

[0040] like Figure 1-3, 5-6, and 8-10 show a biomass fuel heating furnace that improves heat absorption efficiency, including a furnace body 1, a furnace door 2, a furnace 3, a combustion device, a smoke exhaust device 4, an intelligent control panel 5, and The wind device, the combustion device includes a furnace core 6 arranged at the bottom of the furnace 3 and a flame hood 7 placed above the furnace core 6, the flame hood 7 is surrounded by a side wall 8, a top plate 9 and a partition 10, and the side wall 8 , the top plate 9 and the partition 10 are steel plates, and are fixedly connected by welding. The partition 10 divides the flame choke 7 into a lower flame choke 11 and an upper flame choke 12, and the side wall 8 of the lower flame choke 11 is provided with Several oxygen inlets 13, the shape of the oxygen inlet 13 is not limited to the elongated shape shown in the figure, and can also be rectangular or irregular. There are several upper flame outlets 15 penetratin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com