A multi-degree-of-freedom submerged arc furnace plugging eye opening machine based on cutting eye opening

A degree of freedom, submerged arc furnace technology, applied in the direction of furnaces, furnace components, lighting and heating equipment, etc., can solve the problems affecting the quality of finished products, affecting the fluidity of smelting melts in submerged arc furnaces, poor safety, etc., and achieve fast and accurate positioning And position and posture adjustment, improve the quality of opening and forming holes, and reduce the effect of fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be described in further detail below in conjunction with accompanying drawing and specific embodiment, and cited example is only used to explain the present invention, is not intended to limit the scope of the present invention:

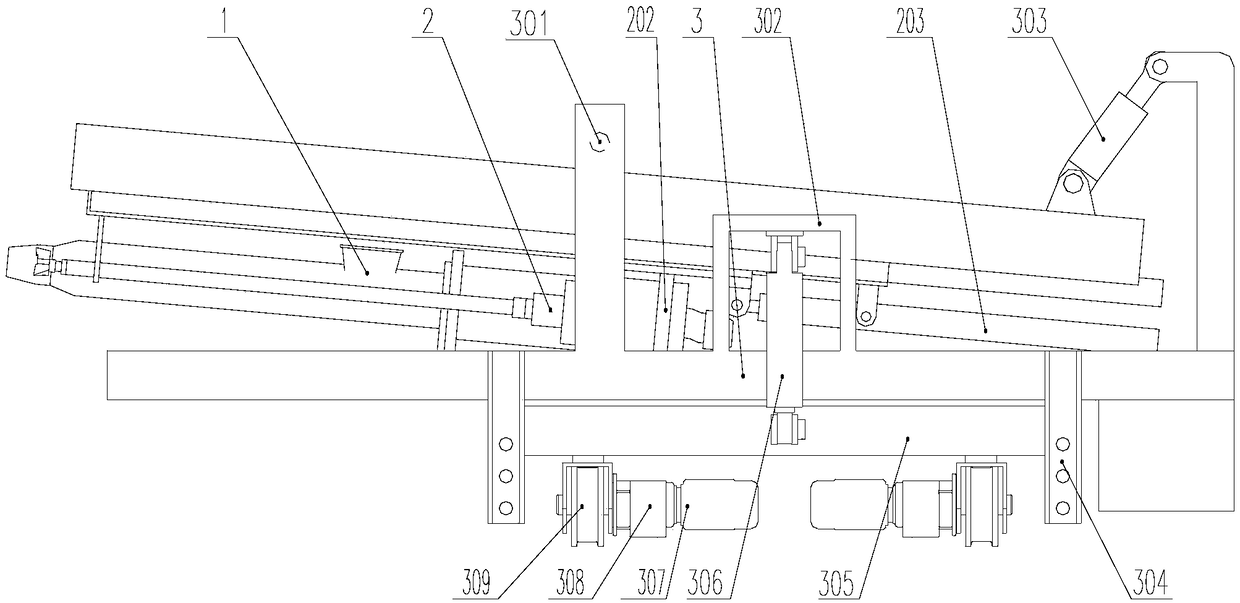

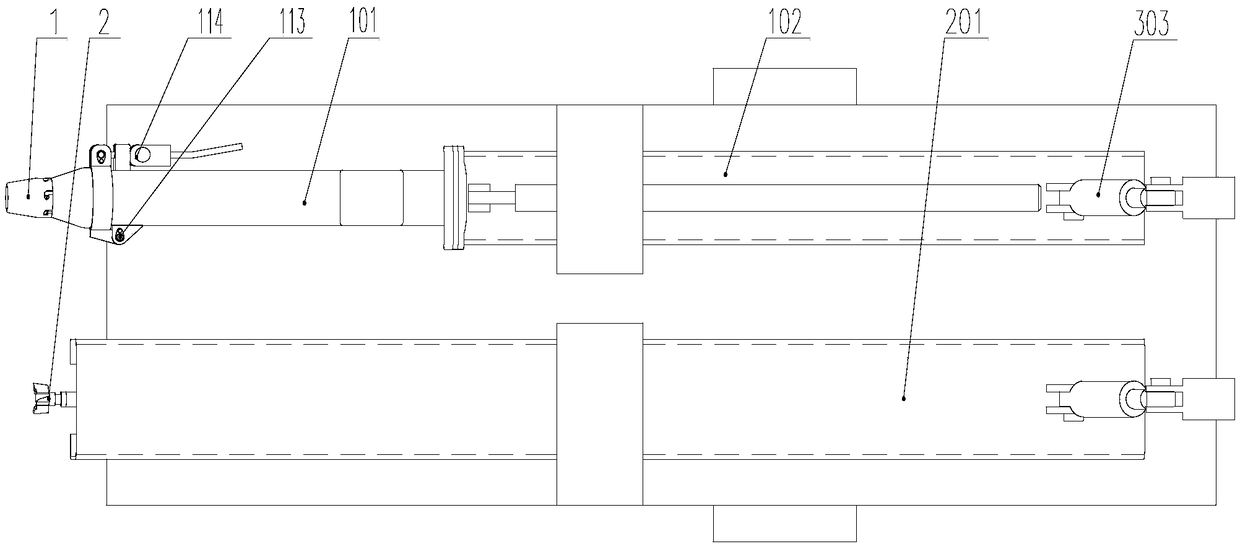

[0037] control figure 1 , figure 2 , the multi-degree-of-freedom submerged arc furnace plugging machine based on cutting-type hole-opening in the illustration includes rotary cutting-type hole-opening machine 2, plugging machine 1, and multi-degree-of-freedom adjustable platform 3.

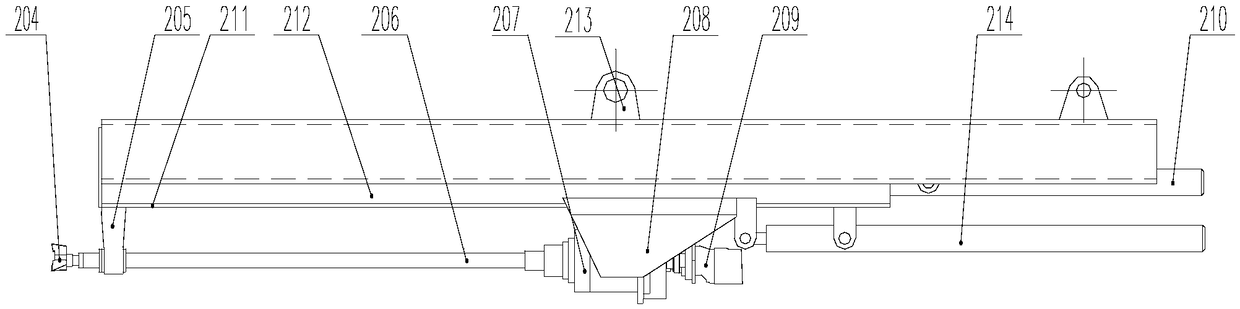

[0038] control figure 1 , figure 2 , image 3 , Figure 4 , the eye opening machine 2 is provided with a rotary cutting device 202, a propulsion device 203, a telescopic arm 201 and a guide seat 205, the rotary cutting device is arranged on the telescopic arm guide rail 211 through a slide seat 208, and the rotary cutting device includes a power gearbox 207, a cutting The motor 209, the power input and output ends of the power tra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com