A kind of high-grip performance and low rolling resistance tire tread compound and its synthesis method

A low rolling resistance, tire tread technology, applied in the direction of rolling resistance optimization, special tires, tire parts, etc., can solve the problems of decreased wear resistance, poor grip performance, low rolling resistance, etc., and achieve the standard of wear resistance. , The effect of strong cornering control ability and low driving rolling resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

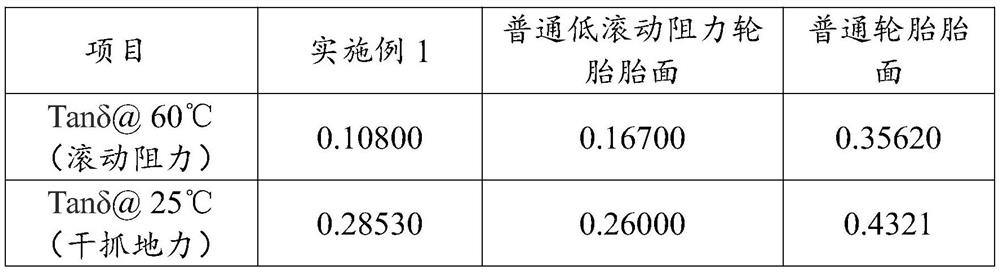

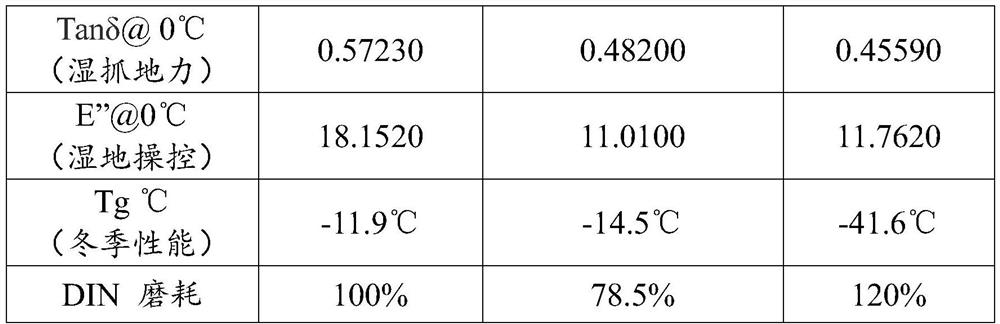

Examples

Embodiment 1

[0023] Raw material components: 95 parts of solution polystyrene-butadiene rubber SSBR6270, 31 parts of natural rubber, 63 parts of high-dispersion white carbon black 9000GR, 7.0 parts of processing oil, 5.5 parts of plasticizer, 4.6 parts of antioxidant (2.0 parts of 6PPD, 1.1 parts of RD , 1.5 parts of B2055), 9.0 parts of coupling agent X-50S, 5.3 parts of active agent (3.0 parts of ZnO, 2.3 parts of SA), 2.0 parts of vulcanizing agent, 3.5 parts of accelerator (2.6 parts of CZ, 0.70 parts of DPG, 0.20 parts of TT ), 0.20 parts of anti-scorch agent.

[0024] Preparation process (this process is carried out in a 270L internal mixer):

[0025] Step 1: Put in solution polystyrene butadiene rubber SSBR, natural rubber, highly dispersed silica, plasticizer, anti-aging agent, coupling agent X-50S, active agent, vulcanizing agent, accelerator, anti-scorch agent, and knead The time is 280-320 seconds, the mixing temperature is 150°C, and the pressure is 0.45-0.60Mpa;

[0026] The...

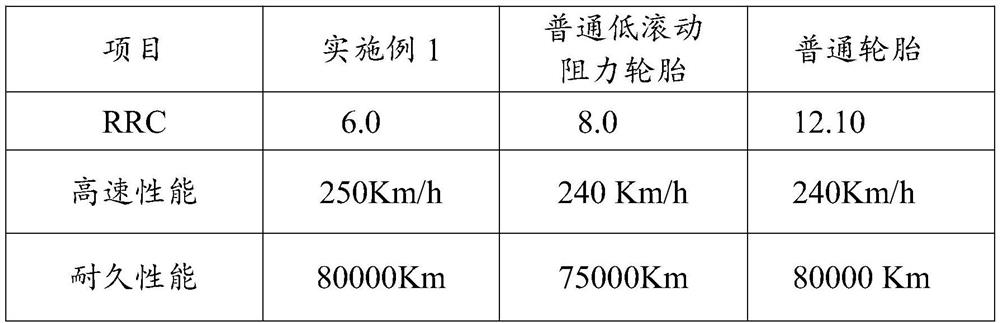

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com