Patents

Literature

34 results about "Low rolling resistance tire" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Low rolling resistance tires are designed to reduce the energy loss as a tire rolls, decreasing the required rolling effort — and in the case of automotive applications, improving vehicle fuel efficiency as approximately 5–15% of the fuel consumed by a typical car may be used to overcome rolling resistance.

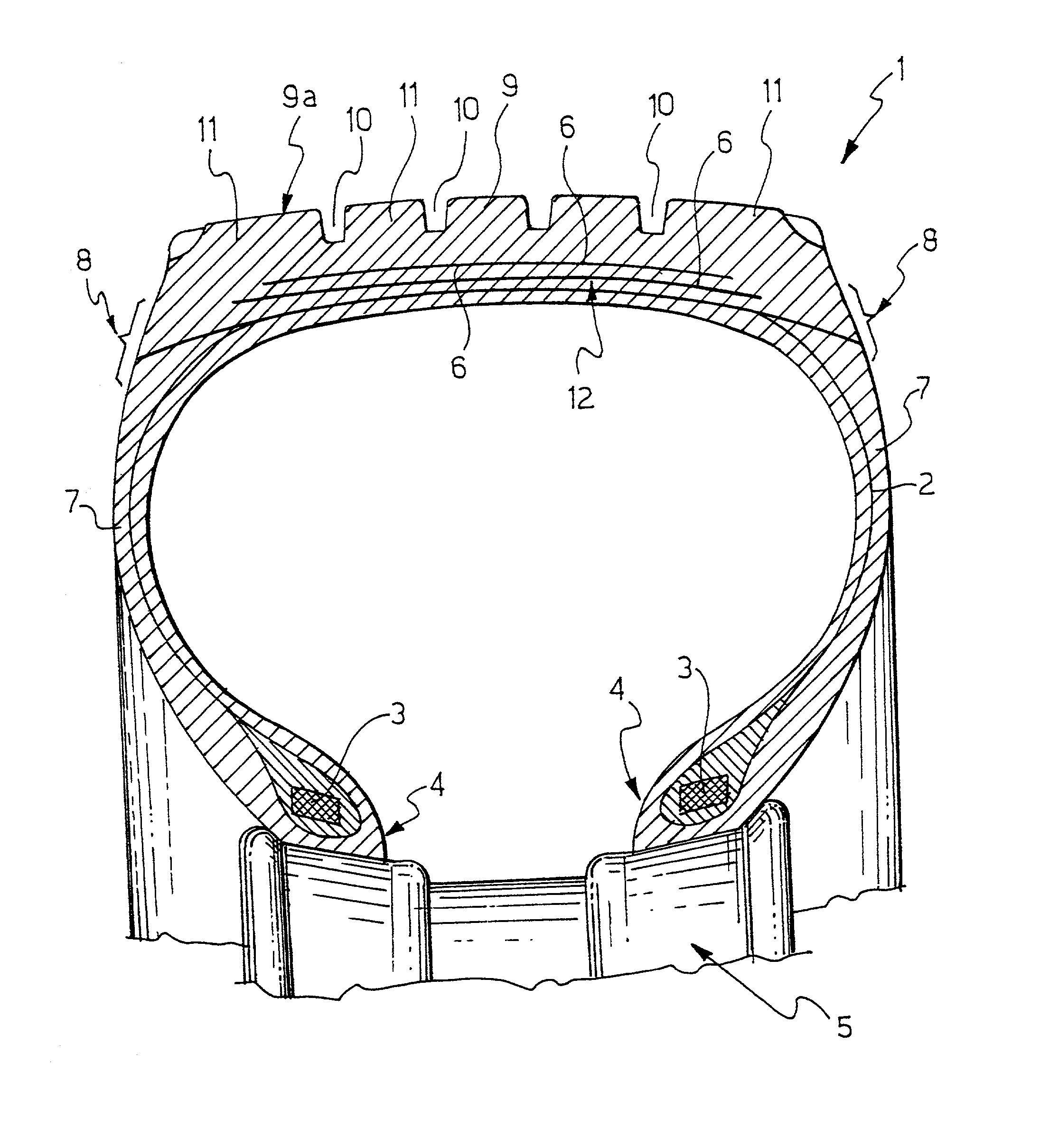

Low rolling resistance tire for vehicles having a composite tread

InactiveUS6516847B1Reduce rolling resistanceEasy to handleLayered productsTyresRolling resistanceLow rolling resistance tire

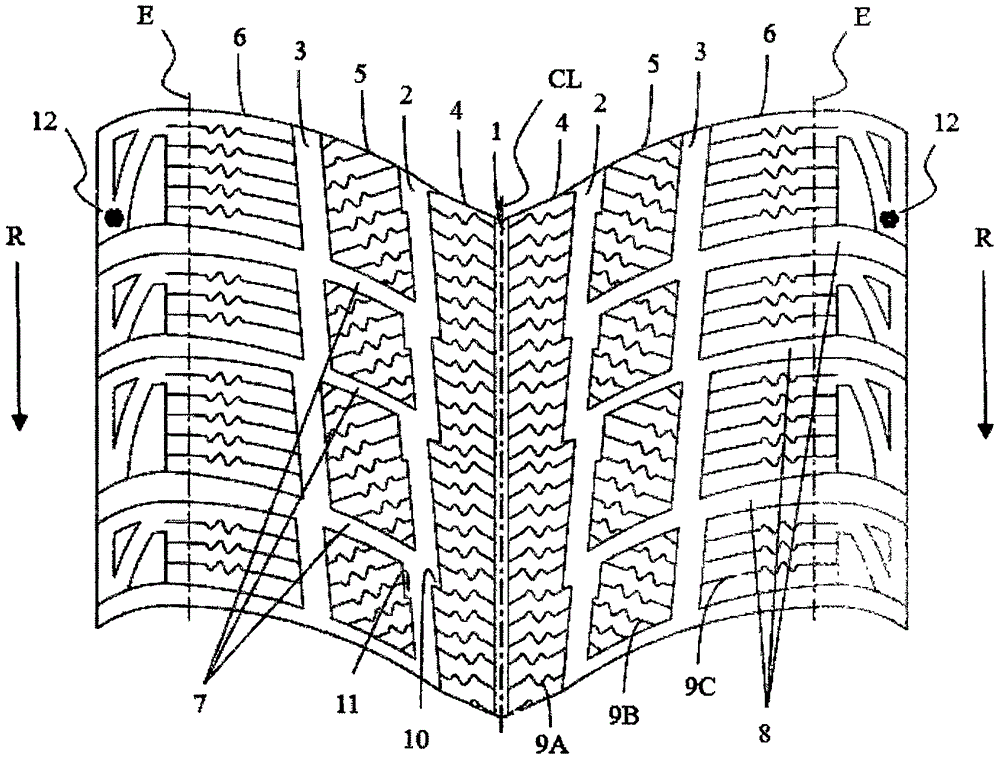

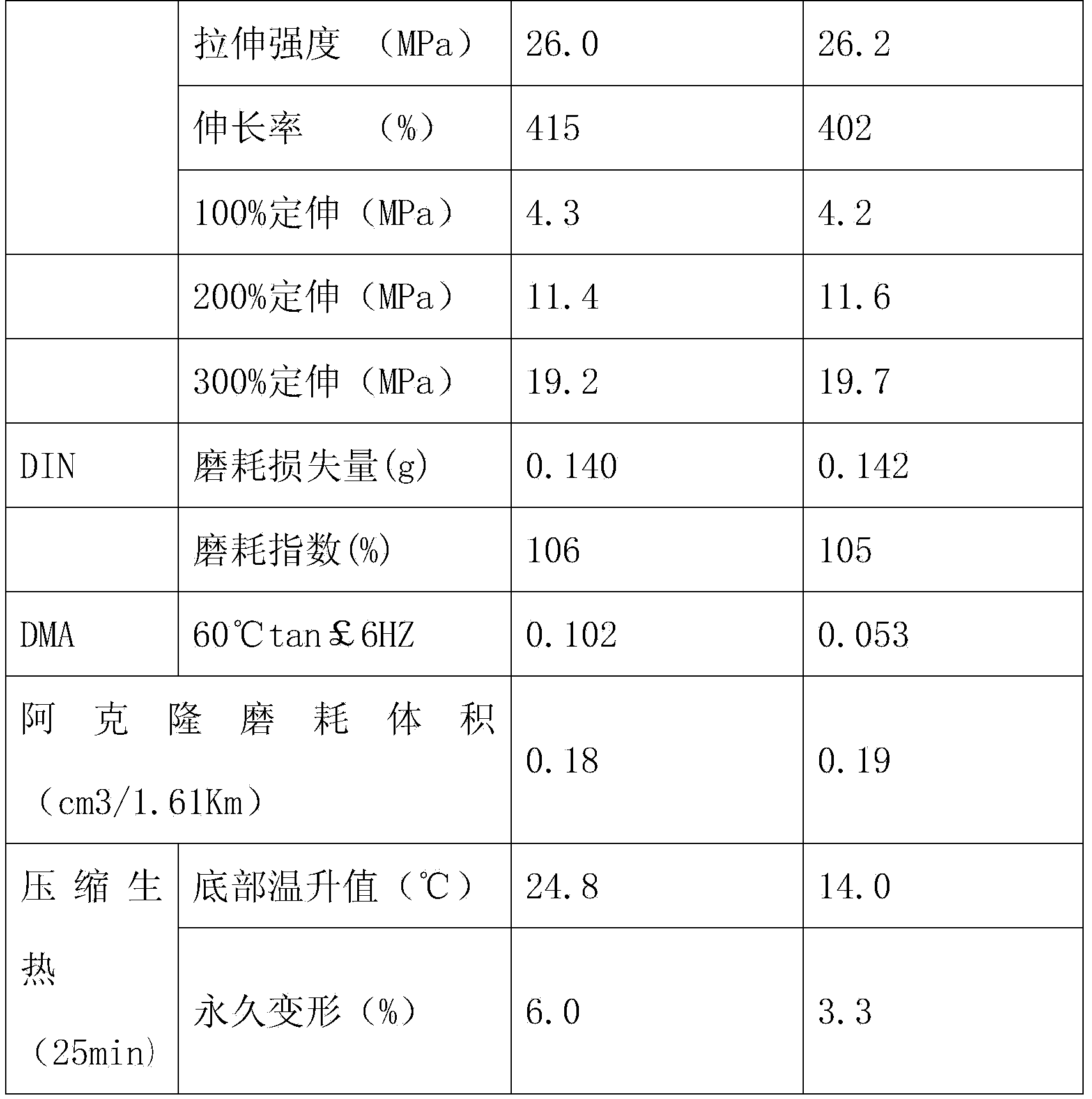

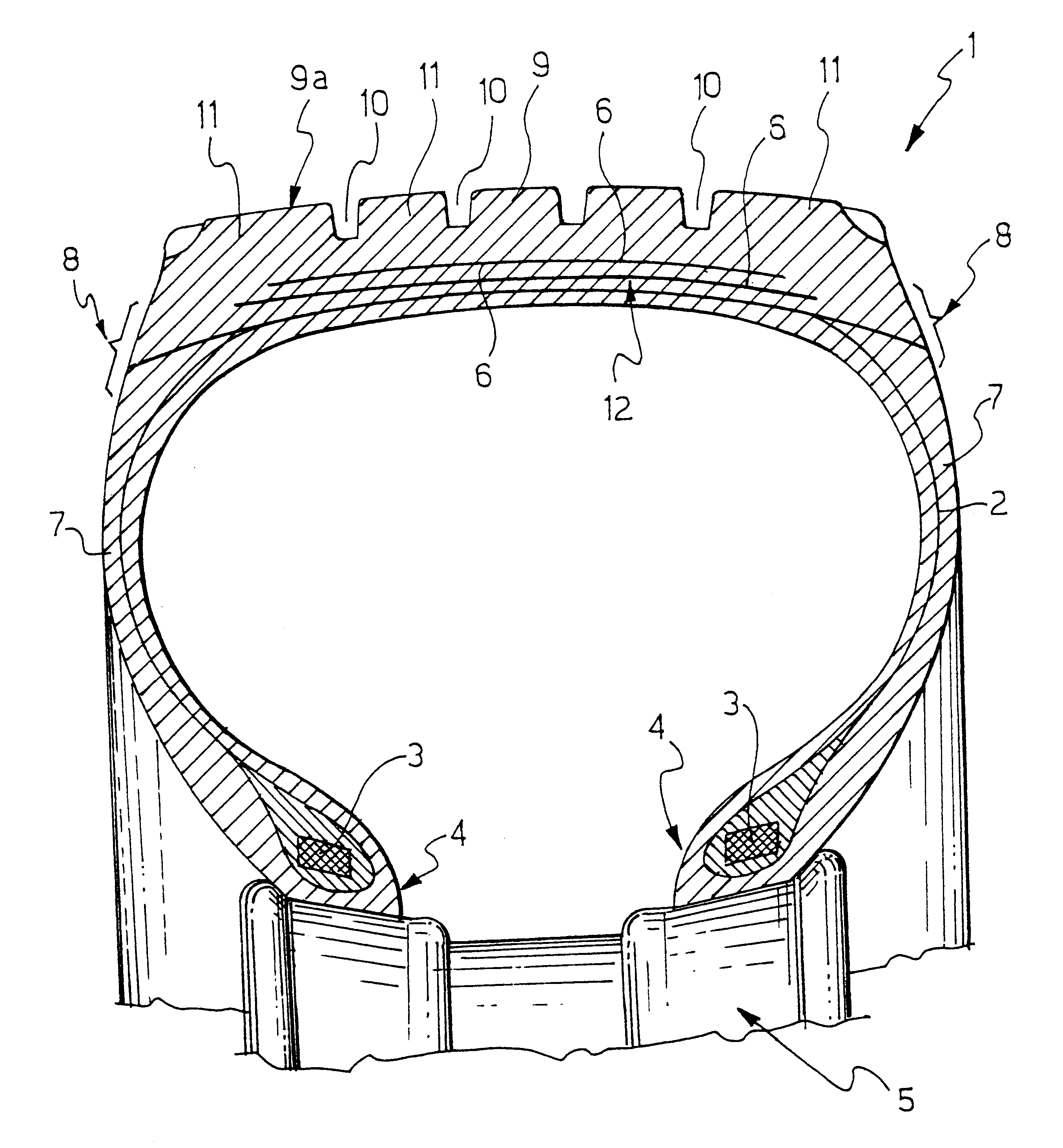

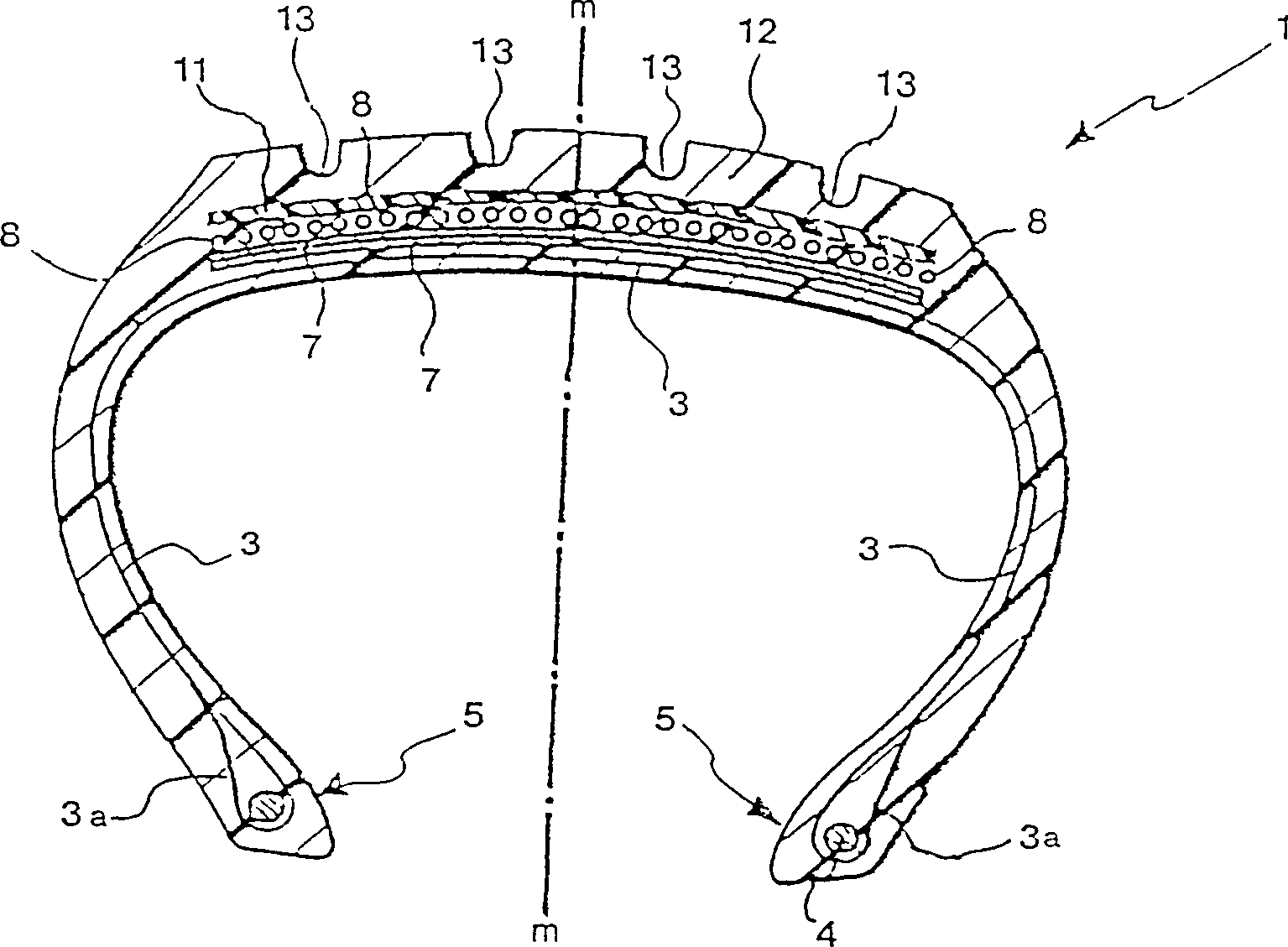

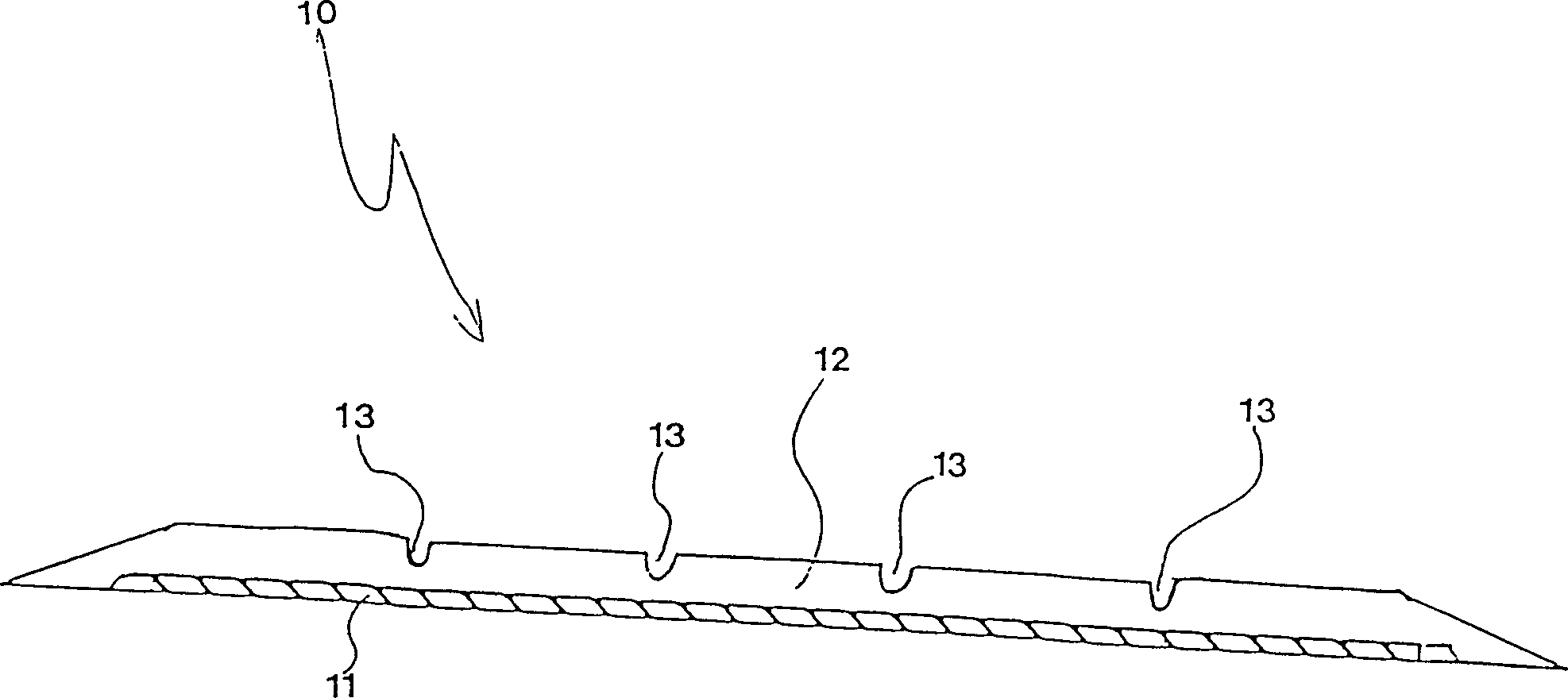

A low rolling resistance tire (1) for vehicles is described which comprises at least one belt layer (7) coaxially extending around at least one carcass ply (3), a composite tread (10) coaxially extending around the belt layer (7) and comprising a radially outer layer (12) and a radially inner layer (11), wherein the ratio between the modulus of elasticity E' at 70° C. of the radially inner layer (11) and the modulus of elasticity E' at 70° C. of the radially outer layer (12) is comprised between 1.1 and 3, and the ratio between the value of tangdelta at 70° C of the radially inner layer (11) and the value of tangdelta at 70° C. of the radially outer layer (12) is lower than 0.8. Advantageously, the tire (1) achieves a better compromise between the characteristics of rolling resistance, handling and comfort with respect to what is obtainable from known tires for the same type of use.

Owner:PIRELLI TYRE SPA

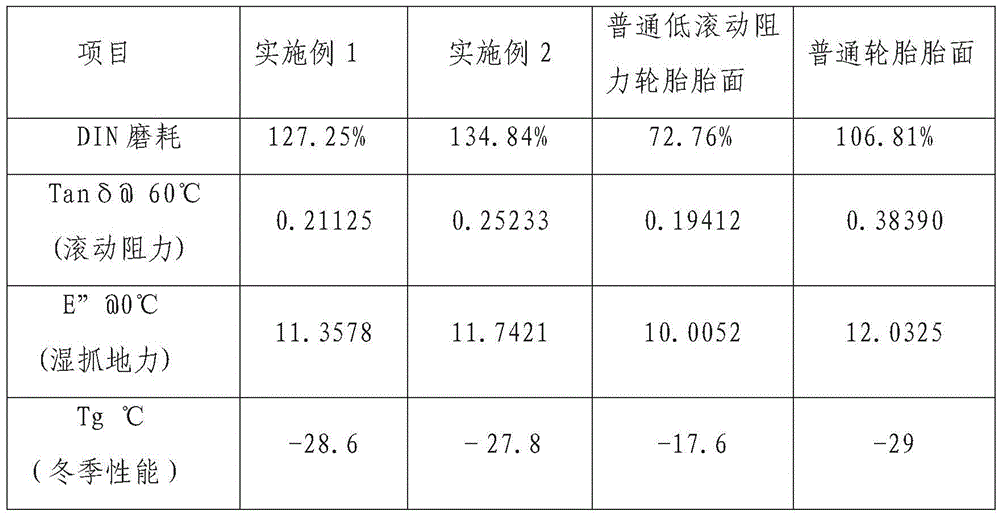

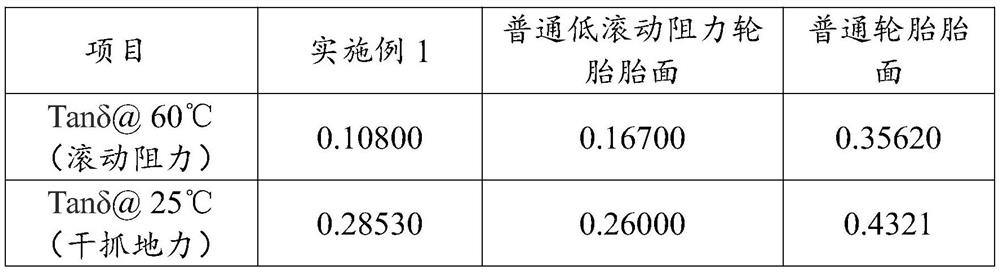

Formula of tread of low-rolling-resistance tire and preparation method thereof

ActiveCN103450508AHigh viscoelasticityReduce rolling resistanceTyresSpecial tyresPolymer scienceMicrocrystalline wax

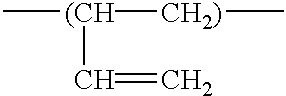

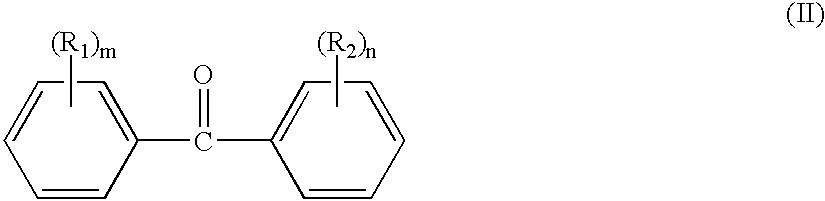

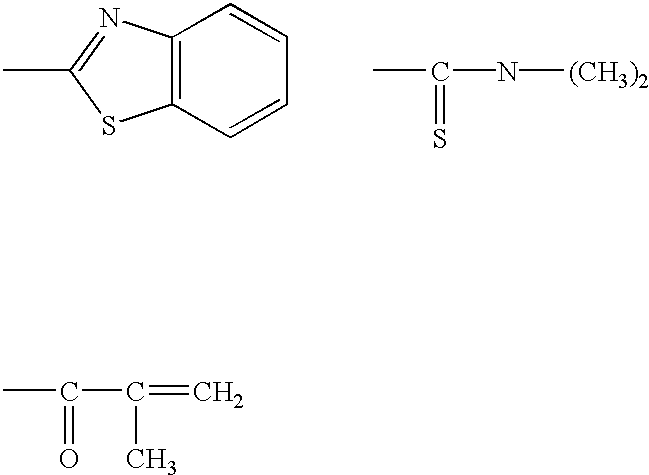

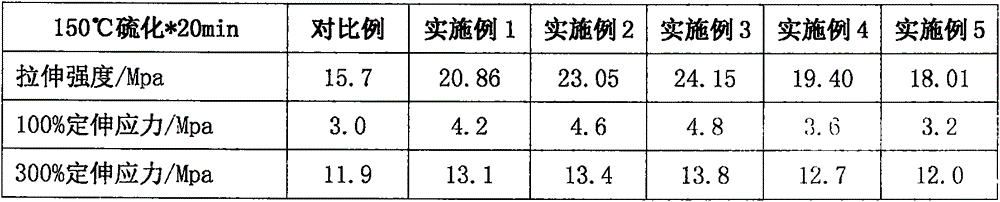

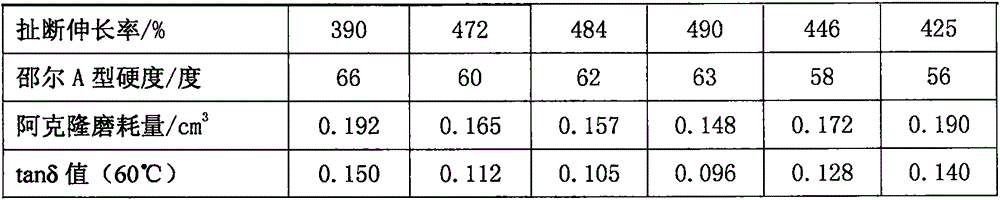

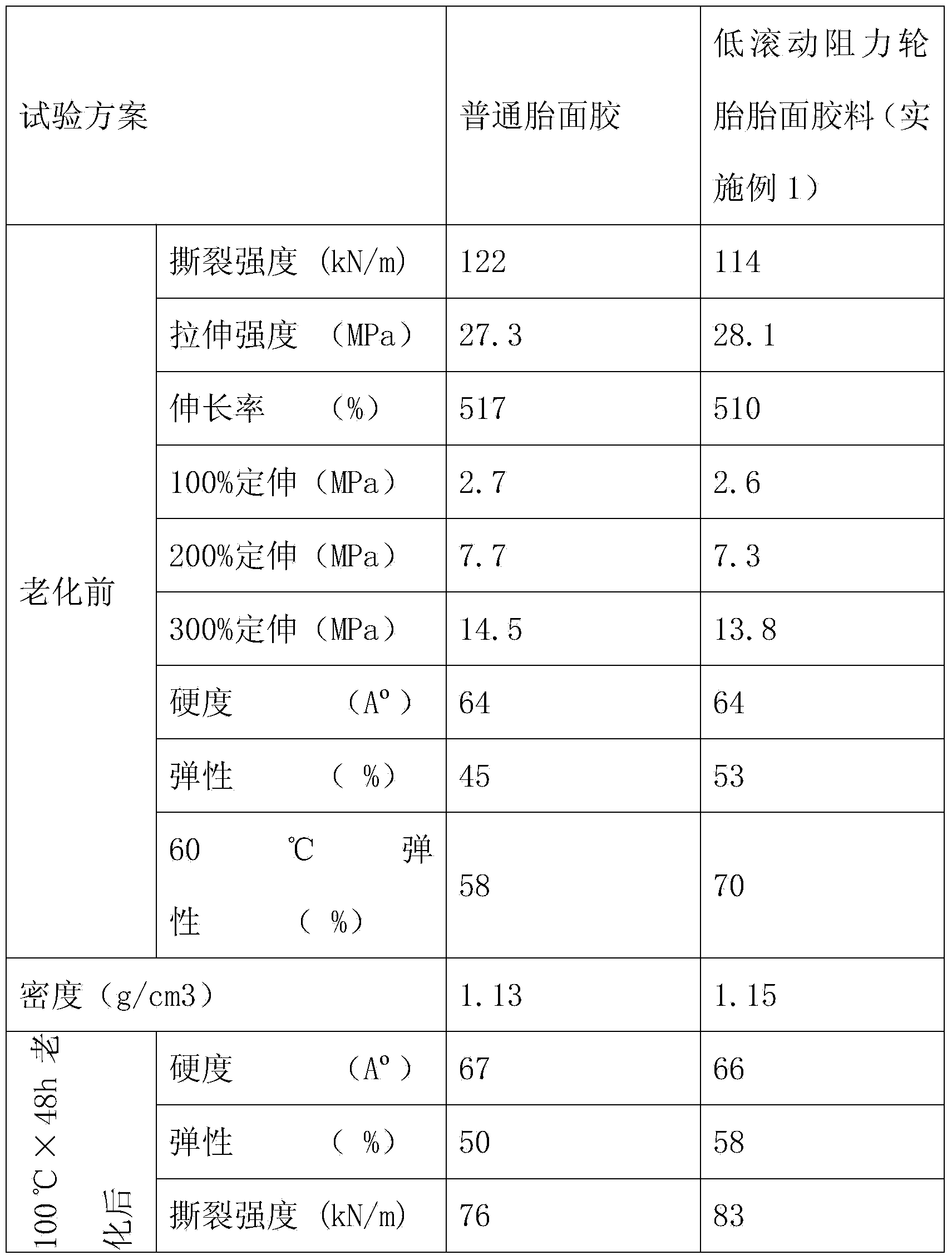

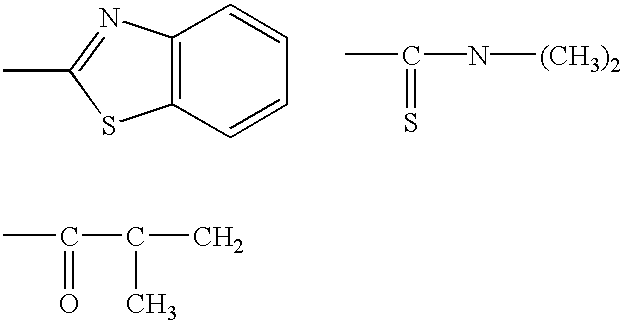

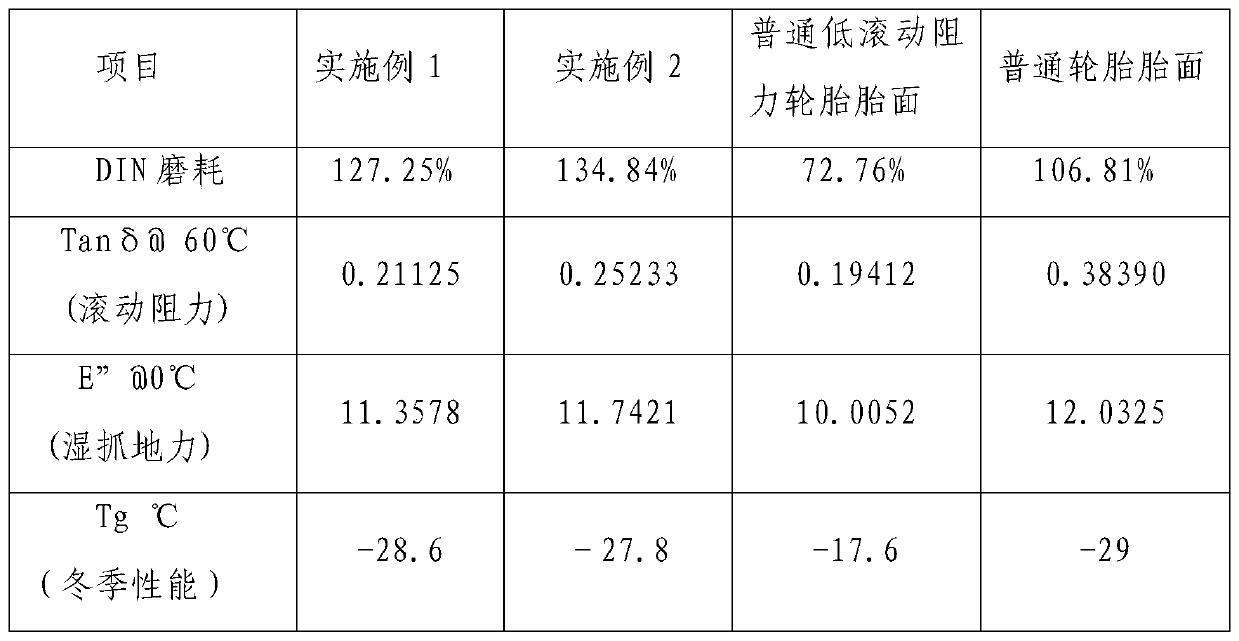

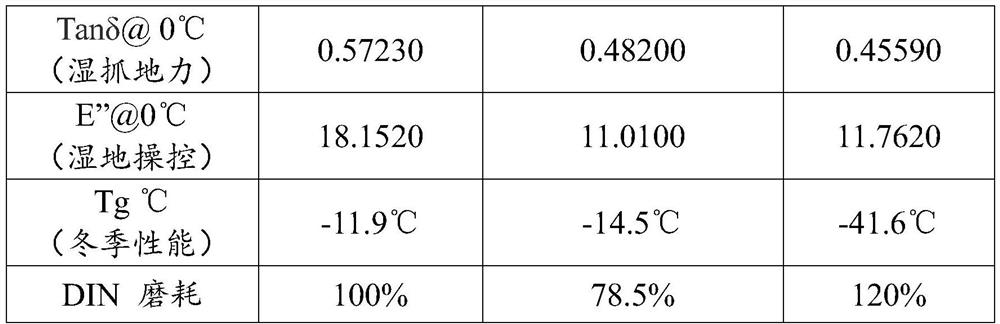

The invention discloses a formula of a tread of a low-rolling-resistance tire and a preparation method thereof. The formula of the tread of the low-rolling-resistance tire comprises the following components: 10-20% of natural rubber, 10-20% of polybutadiene rubber, 20-40% of solution polymerized styrene butadiene rubber, 20-40% of high-dispersion white carbon black, 0.5-1% of a peptizer A-8, 1-2% of a chemical anti-aging agent 6PPD, 1-2% of a physical anti-aging agent microcrystalline wax, 1-3% of an active agent ZNO, 1-3% of an active agent SA, 1-3% of polyethylene glycol PEG, 1-3% of a vulcanizing agent S-325, 1-3% of an accelerant NS, 0.1-0.8% of a special accelerant CTP and 4-8% of a coupling agent SI69. The formula of the tread of the low-rolling-resistance tire has the beneficial effects that the rolling resistance of the tire is low and can reach an A level or a B level, various physical and mechanical properties of the tire are basically consistent to those of a tire having non-low rolling resistance, and the advantages of road holding of the tire on a wetland and a dry land are retained.

Owner:KENDA RUBBER CHINA

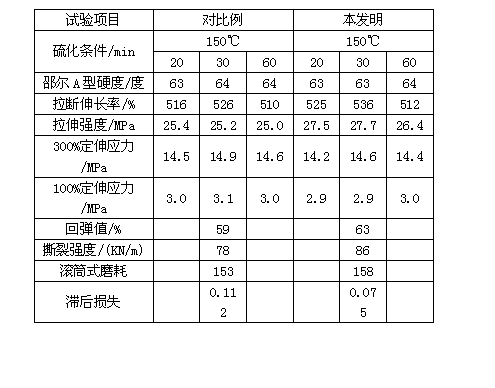

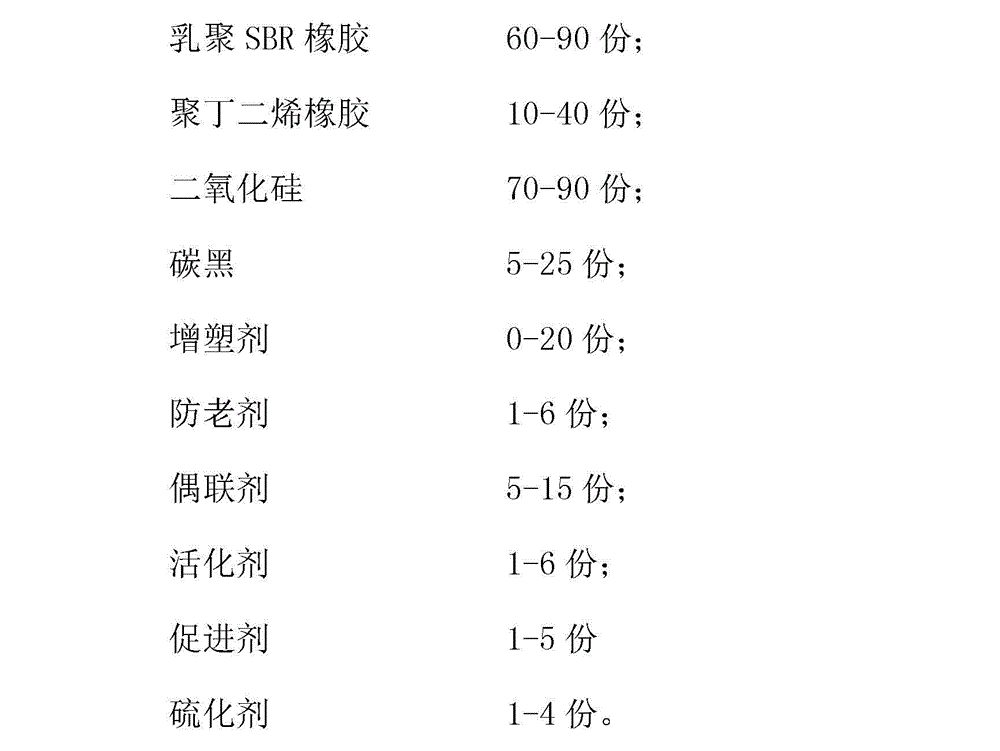

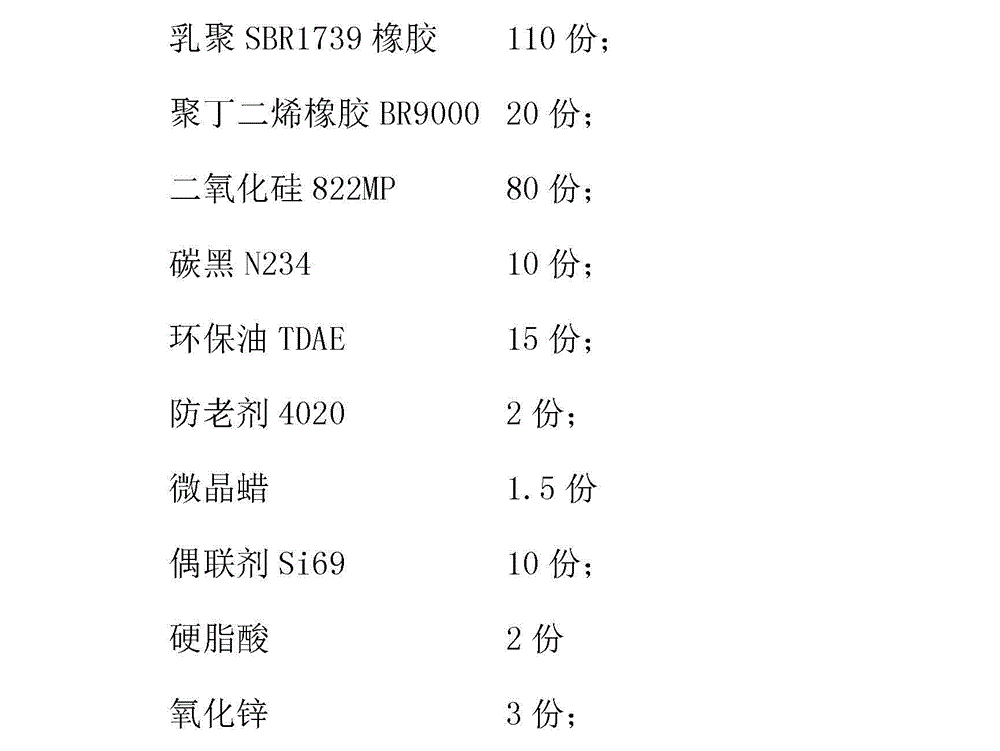

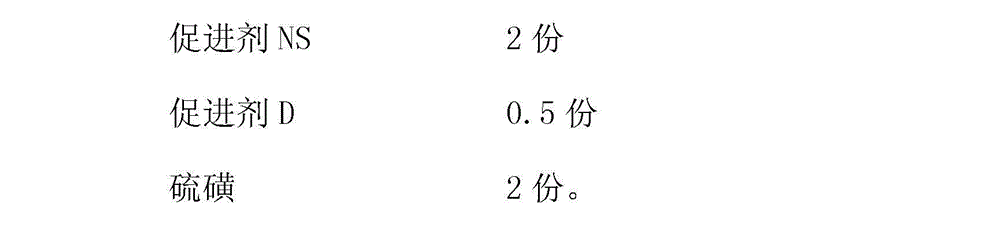

Low-rolling-resistance tire tread rubber composition

ActiveCN103073754AHysteresis loss is smallReduce rolling resistanceSpecial tyresRolling resistance optimizationWaxPolymer science

Owner:TRIANGLE TIRE

Tire tread rubber compound with low rolling resistance and tire made from tire tread rubber compound

ActiveCN106279797AFast and reliable integrationReinforced phase distributionSpecial tyresTyre tread bands/patternsRolling resistanceEngineering

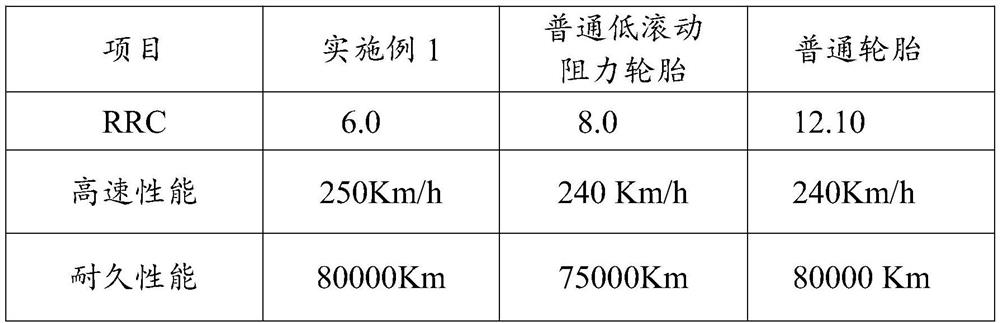

The invention relates to a tire tread rubber compound with low rolling resistance and a tire made from the tire tread rubber compound. The tire tread rubber compound comprises the following raw materials in parts by weight: 50-70 parts of natural rubber STR20, 0-30 parts of solution polymerized styrene-butadiene rubber SSBR4525, 0-20 parts of neodymium butadiene rubber BunaNd22EZ, 0-10 parts of guayule, 20-35 parts of carbon black ECORAX1670, 20-35 parts of white carbon black ULTRASIL 5000GR, 1.5-3.0 parts of a silane coupling agent Si69 and 0.2-0.4 part of a silane coupling agent KH580. A preparation method comprises the following steps: preparing guayule, mixing by adopting an internal mixer and mixing by adopting an open mill, thereby acquiring the tire tread rubber compound with low rolling resistance. Through the tread pattern design for circumferential pattern, transverse pattern, siping pattern, and the like, the tire with low rolling resistance is prepared. According to the tire tread rubber compound with low rolling resistance and the tire made from the tire tread rubber compound provided by the invention, the tread formula is optimized, the mixing technique is improved, the tread pattern is improved and the tread formula, the mixing technique and the tread pattern are organically combined, so that the performances, such as road holding, abrasive resistance and wet sliding resistance of the tread, are guaranteed and the rolling resistance of the tire is reduced.

Owner:郑兴荣

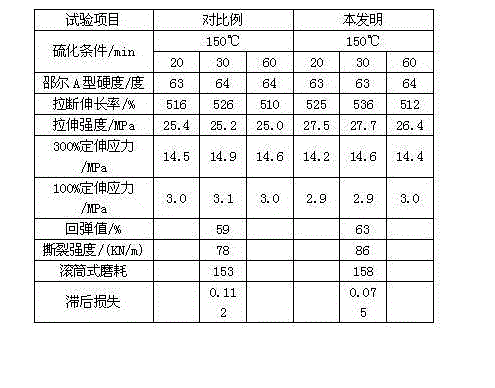

Tire tread mix with low rolling resistance

ActiveCN103408807AImprove rolling resistanceReduce Paine EffectSpecial tyresRolling resistance optimizationRolling resistanceSulfur

The invention relates to tire tread mix with low rolling resistance. The tire tread mix with low rolling resistance has the advantages that carbon black serving as a tread filler of a conventional tire is partially substituted by white carbon black, meanwhile, a right amount of silane coupling agent is added for chemically modifying the white carbon black, so that the Payne effect and loss angle tangent tan delta at a high temperature of the mix can be effectively reduced, further the rolling resistance of a tire is improved, the effects of reduction of oil consumption and exhaust emission and environmental friendliness are achieved, and therefore, by adopting the tire tread mix with low rolling resistance, about 50% of tread lag performance and about 20% of rolling resistance of the tire can be reduced, thus more than 30% of fuel is saved. The tire tread mix with low rolling resistance comprises the following comments in parts by weight according to a formula: 70-90 parts of natural rubber, 10-30 parts of cis-butadiene rubber, 5-30 parts of carbon black, 30-50 parts of white carbon black, 5-10 parts of coupling agent, 3-5 parts of zinc oxide, 1-3 parts of stearic acid, 3-6 parts of antiager, 1-2 parts of sulfur, 1.0-2.0 parts of promoter and 0.1-0.3 part of scortch retarder CTP.

Owner:SAILUN GRP CO LTD

Low-rolling-resistance wet-skid-resistant abrasion-resistant tire tread formula and preparation method thereof

The invention discloses a low-rolling-resistance wet-skid-resistant abrasion-resistant tire tread formula. The low-rolling-resistance wet-skid-resistant abrasion-resistant tire tread formula comprises the following components: 10-20% of natural rubber, 0-20% of polybutadiene rubber, 20-60% of solution polymerized styrene butadiene rubber, 20-40% of high-dispersion white carbon black and 4-8% of a coupling agent SI69. The formula has the beneficial effects that: the hardness of a product is reduced, the wet-skid resistant performance is improved, so that a tire does not easily skid, and thus safety of the tire is improved; the abrasion resistant performance of the tire is excellent, and thus the service life of the tire is greatly increased; the rolling resistance of the tire is low and can reach an A level or a B level, various physical and mechanical properties of the tire are basically consistent to those of a tire having no low rolling resistance, and the advantages of the tire in road holding on a wet land and on a dry land are retained.

Owner:KENDA RUBBER CHINA

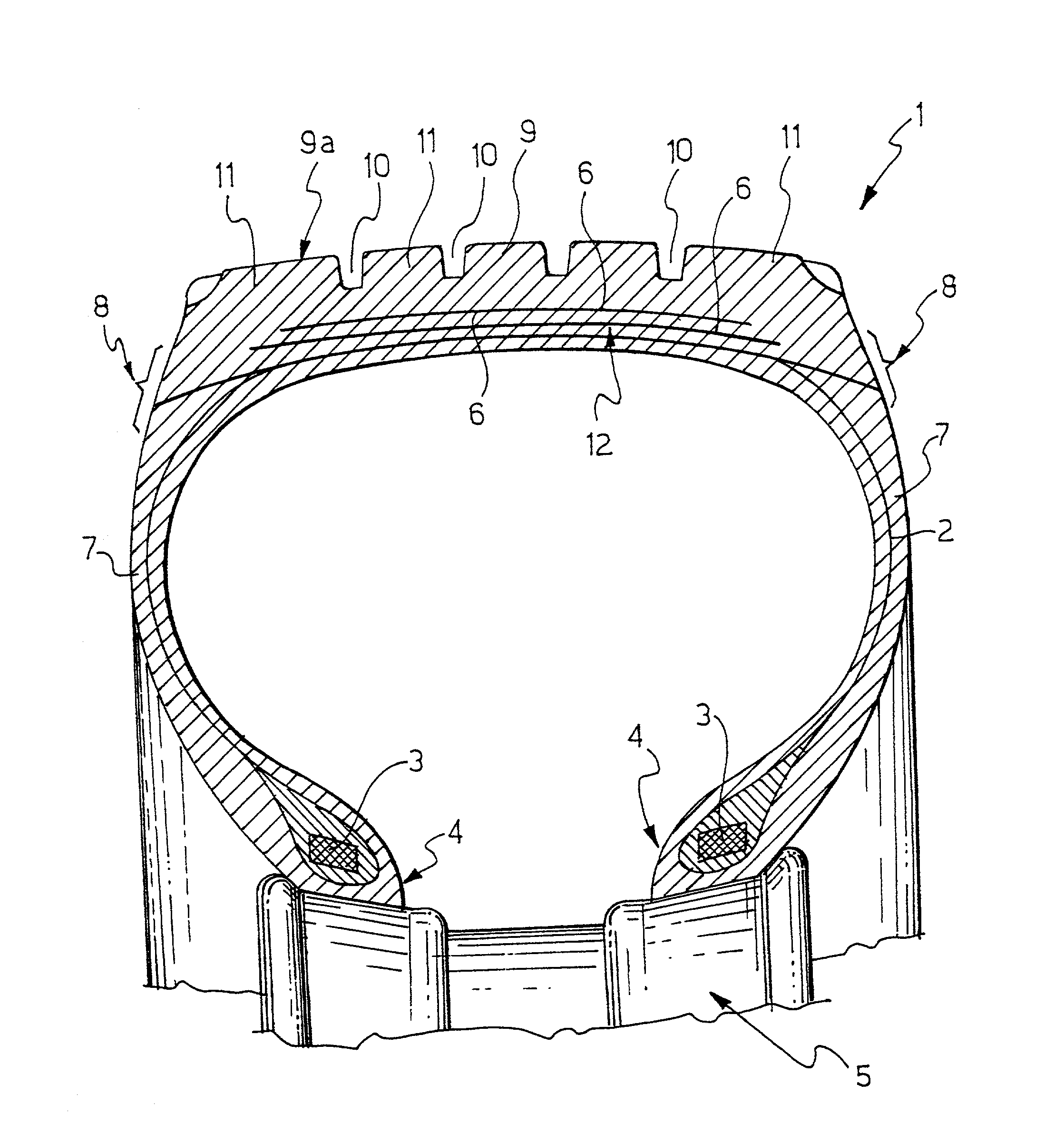

Low rolling resistance tire for vehicles

InactiveUS6624233B2Large specific surface areaOther chemical processesSpecial tyresRolling resistanceProject area

A low rolling resistance tire for vehicles includes a carcass structure, a belt structure coaxially extending around the carcass structure, and a tread coaxially extending around the belt structure and being externally provided with a rolling surface designed to contact the ground. The tread includes a vulcanized polymer base having at least a first silica-based reinforcing filler. The first silica-based reinforcing filler has an average projected area of aggregates, measured before incorporation into the polymer base, lower the 20,000 nm<2>, a dispersion index in the polymer base not lower than 97%, and an average projected area of the aggregates, measured after incorporation into the polymer base, between 8,500 nm<2 >and 18,000 nm<2>.

Owner:PIRELLI TYRE SPA

Low rolling resistance tire for vehicles

InactiveUS20020143096A1Reduce mixing actionLarge specific surface areaOther chemical processesSpecial tyresRolling resistanceProject area

A low rolling resistance tire (1) for vehicles is described which comprises a belt structure (12) coaxially extending around a carcass structure (2) and a tread (9), coaxially extending around the belt structure (12) and being externally provided with a rolling surface (9a) designed to get in touch with the ground, the tread (9) comprising a vulcanized polymer base including at least a first silica-based reinforcing filler, the tire being characterized in that the first silica-based reinforcing filler has: an average projected area of the aggregates as measured before incorporation into the polymer base lower than 20,000 nm2; a dispersion index in the vulcanized polymer base of the tread (9) not lower than 97%; and a projected area of the aggregates after incorporation into the polymer base comprised between 8500 and 18000 nm2. Advantageously, said tire has mechanical properties improved or at least comparable with respect to those of the known tires for the same type of use.

Owner:PIRELLI TYRE SPA

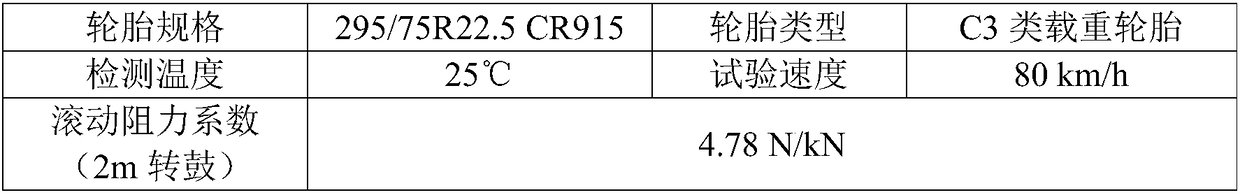

Tread rubber for whole steel load bearing low-rolling-resistant tire

InactiveCN108864499AGood physical and mechanical propertiesReduce rolling resistanceSpecial tyresRolling resistance optimizationRolling resistanceMicrocrystalline wax

The invention discloses tread rubber for a whole steel load bearing low-rolling-resistant tire. The tread rubber is characterized by being prepared from the following raw materials in parts by weight:61 to 79 parts of natural rubber, 21 to 39 parts of neodymium series butadiene rubber, 20 to 35 parts of carbon black, 18 to 32 parts of high dispersion white carbon black, 1.5 to 3.2 parts of silanecoupling agents, 2 to 5 parts of zinc oxides, 1 to 3 parts of stearic acids, 0.5 to 3 parts of anti-aging agents 6PPD, 0.5 to 3 parts of anti-aging agents RD, 0.5 to 3 parts of microcrystalline wax,1 to 1.8 parts of oil filling sulfur, 1 to 2.5 parts of accelerators NS, 0.1 to 1.5 parts of accelerators DTDM and 0.1 to 0.5 part of anti-coking agents CTP. The tread rubber composition provided by the invention has the advantages that on the premise of meeting high load requirements, the tread rubber has good physical and mechanical performance and low rolling resistance.

Owner:ZHONGCE RUBBER GRP CO LTD

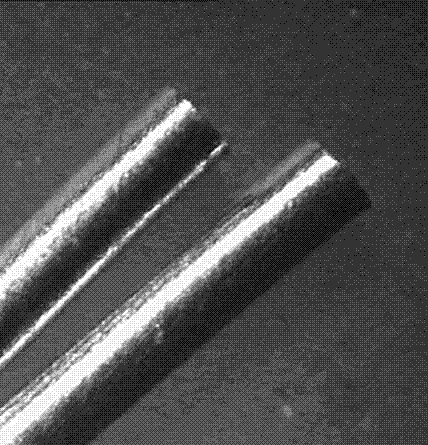

Method for producing torsion-exfoliation-resistant extra-high-strength steel wires with excellent fatigue resistance

The invention discloses a method for producing torsion-exfoliation-resistant extra-high-strength steel wires with excellent fatigue resistance. The method comprises the following steps: (1) dry-drawing until the steel wires are 1.8-2.2mm long; (2) performing sorbitizing heat treatment; (3) performing pinchbeck alloy electroplating; and (4) wet-drawing until the steel wires are 0.20-0.40 mm long. Ultra-high-strength steel wires produced according to the method has high strength, good toughness, torsion-exfoliation resistance and excellent fatigue resistance, the 100d of the steel wire has the torsion number being not less than 30 / 360 degrees, and the fracture after torsion test is an even fracture, that is to say, torsion without exfoliation can be realized. Based on the method for producing torsion-exfoliation-resistant extra-high-strength steel wires with excellent fatigue resistance, the torsion exfoliation of the steel wires is effectively controlled, the requirements of the steel wires on strength and toughness are met, and the requirements for manufacturing ultra-high-strength steel cords for low rolling resistance tyres are well met.

Owner:JIANGSU XINGDA STEEL TYPE CORD

Tire with low rolling resistance

ActiveCN103374154AImprove wear resistanceExtend the life cycleSpecial tyresRolling resistance optimizationElastomerRolling resistance

The invention provides a tire with low rolling resistance. The abrasion resistance of the tire is improved. The rolling resistance coefficient of the tire is smaller than 10.5kg / t. The tire comprises a tire tread which has a split-type structure and consists of a tire crown, a tire shoulder and a tire side, wherein the tire shoulder consists of the following rubber compositions in percentage by weight: 0-30 percent of cis alkadiene elastomer, 15-50 percent of copolymerization olefin polymer, 8-30 percent of carbon black, 10-40 percent of white carbon black and 3.5-35 percent of rubber additive. The tire shoulder of the tire with the low rolling resistance provided by the invention consists of the rubber compositions comprising 8-30 percent of carbon black; by the carbon black, the abrasion resistance of the tire shoulder is improved, the whole use cycle of the tire is prolonged, and the service life of the tire is prolonged. The tire provided by the invention also has low rolling resistance, good wetland road holding capacity and high abrasion resistance.

Owner:CHENG SHIN RUBBER CHINA

Tread compound with high wet slip resistance and low rolling resistance for tire and synthetic method of tread compound

PendingCN110372936AImprove wet skid resistanceIncrease resistanceSpecial tyresRolling resistance optimizationRolling resistanceEngineering

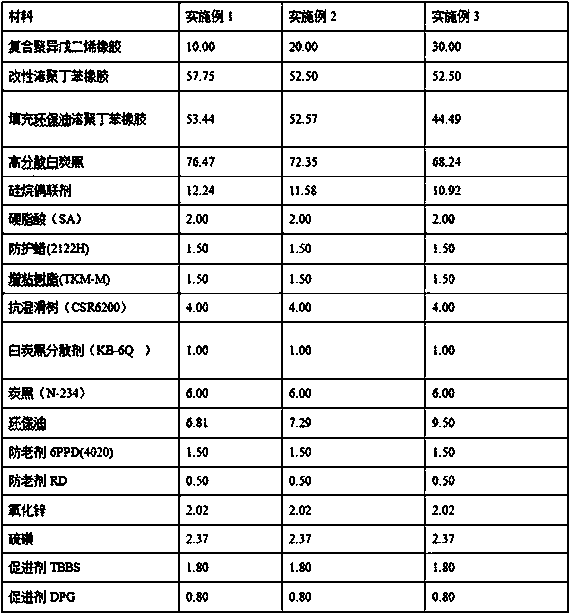

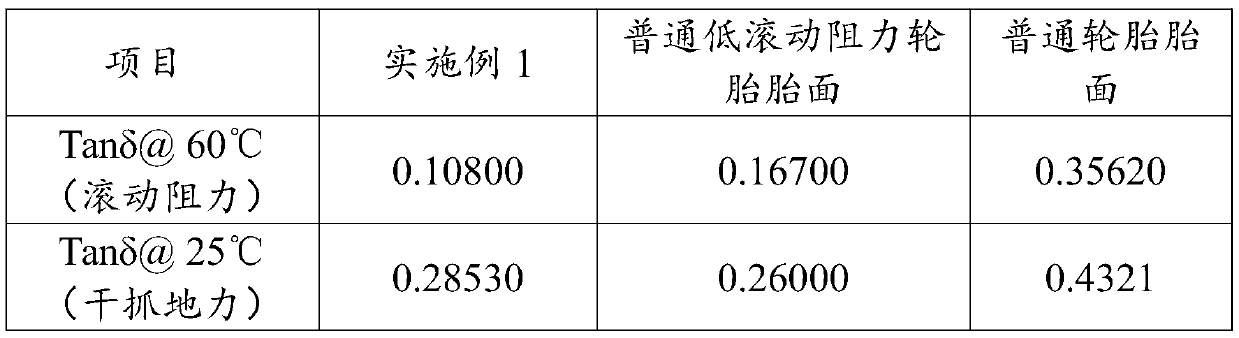

The invention provides a tread compound with high wet slip resistance and low rolling resistance for a tire and a synthetic method of the tread compound. The tread compound for the tire comprises thefollowing components, in parts by weight: 100 parts by weight of a rubber component, 50-90.0 parts of high-dispersion white carbon black, 5.0-15.0 parts of carbon black, 7.0-15.0 parts of environmentally-friendly oil, and 10.0-30.0 parts of a rubber additive, wherein the rubber component comprises the following materials: 0.0-40.0 parts of composite polyisoprene rubber, 35.0-55.0 parts of environmentally-friendly oil filled solution polymerized styrene-butadiene rubber and 40.0-60.0 parts of modified solution polymerized styrene-butadiene rubber. According to the tread compound provided by theinvention, the polymerized styrene-butadiene rubber ensures good processability while providing certain wet slip resistance to the rubber compound; and the composite polyisoprene rubber is added, sothat elasticity of the rubber compound is improved, heat generation is reduced, and rolling resistance of the tire is reduced.

Owner:SHOUGUANG FIREMAX TYRE CO LTD

Tool for detecting aging of tire rubber piece with low rolling resistance

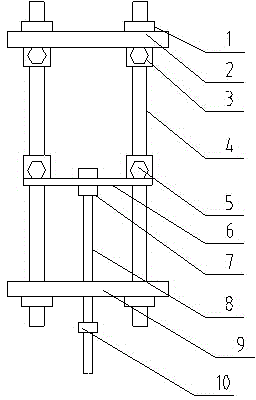

InactiveCN104359774AEasy to fixAdjust stretch lengthInvestigating material ductilityRolling resistanceReciprocating motion

The invention relates to a tool for detecting aging of a tire rubber piece with low rolling resistance. The tool comprises a bracket, elastic mechanisms and a stretching mechanism, wherein the bracket jointly consists of permanent seats which are transversely arranged and guide rods which are longitudinally arranged, wherein two permanent seats are arranged and a plurality of guide rods are sequentially distributed between the two permanent seats along the long axis directions of the permanent seats; through holes through which the guide rods pass are formed in the two permanent seats; the guide rods are movably connected with the elastic mechanism A which can be driven by the stretching mechanism to reciprocate along the long axis directions of the permanent seats, and the elastic mechanism B is fixedly connected to one of the permanent seats. The tool provided by the invention has the advantages that by virtue of the device, the rubber piece is compressed by using a bolt and meanwhile, the fixing mode of the bolt and a nut is stronger than a clamping force of a clip, so that the rubber piece can be better fixed; meanwhile, the stretching length of the rubber piece is directly adjusted by virtue of the stretching mechanism during stretching, so that the tool is very convenient.

Owner:DOUBLE COIN GRP JIANGSU TIRE

Low rolling resistance tire rubber composition and application thereof

ActiveCN108752675AImprove rolling resistanceEasy to processSpecial tyresRolling resistance optimizationRolling resistancePolystyrene

The invention provides a low rolling resistance tire rubber composition and application thereof. The composition is prepared from the following ingredients in percentage by weight: 10 to 35 percent ofsolution polystyrene-butadiene rubber, X percent of emulsified polystyrene-butadiene rubber (X is greater than 0 but smaller than or equal to 25), Y percent of cis-rich polybutadiene (Y is greater than 0 but smaller than or equal to 15), 2 to 25 percent of reinforcing carbon black, 10 to 40 percent of silicon dioxide filling materials, 6 to 15 percent of silane coupling agents, Z percent of hydrocarbon resin (Z is greater than 0 but smaller than or equal to 5), 2 to 18 percent of enhancing system containing amorphous silica spherical particles, fatty acid zinc salt and processing oil. All ingredients jointly act in a certain proportion, so that the tire rubber composition can improve the tire rolling resistance and the workability; good performance compromise is realized on rolling resistance, road holding force and abrasion performance; the problem that the workability is difficult when the use quantity of reinforcing fillers is high can be solved; the low rolling resistance tire rubber composition is particularly suitable for being applied to high-performance tire tread rubber.

Owner:CHENG SHIN RUBBER CHINA

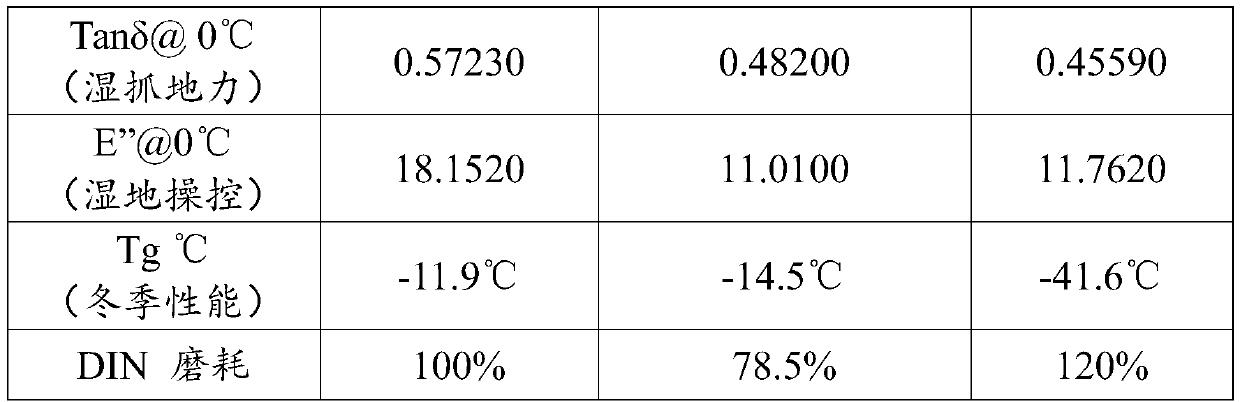

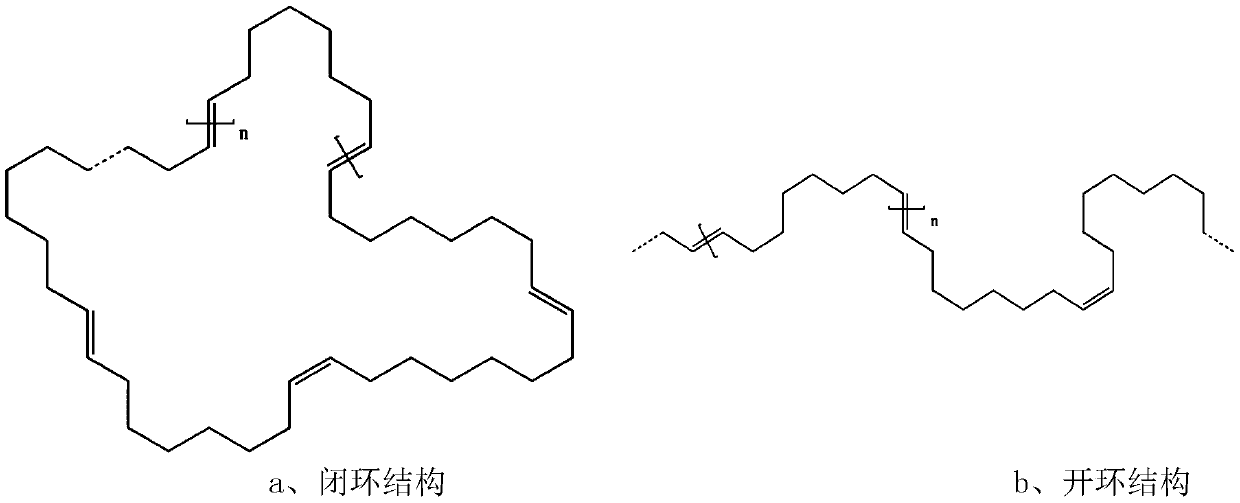

Tire tread rubber material with high road-holding performance and low rolling resistance and synthesis method thereof

ActiveCN109796647AImprove wet gripImproved wet handling performanceSpecial tyresRolling resistance optimizationRubber materialRolling resistance

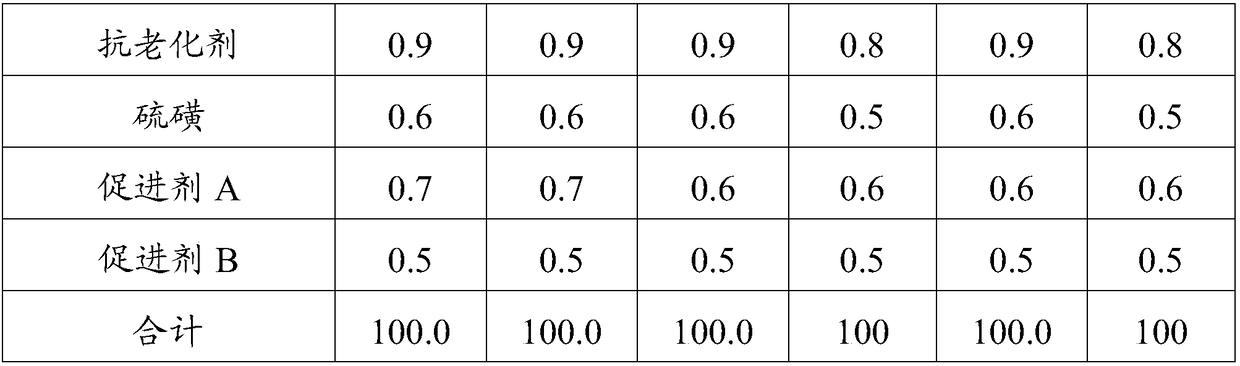

The invention discloses a tire tread rubber material with high road-holding performance and low rolling resistance. The rubber material comprises, by weight percentage, 40-44% of solution-polymerizedstyrene-butadiene rubber SSBR6270, 12-15% of natural rubber SIR20, 26-30% of high-dispersing white carbon black, 2.0-3.0% of an antioxidant, 3-5% of a coupling agent X-50S, 1-3% of an activating agent, 2-4% of a plasticizer, 0.6-0.9% of a vulcanizing agent, 1.2-1.6% of an accelerator and 0.07-0.1% of an anti-scorching agent, the bound styrene content of the solution-polymerized styrene-butadiene rubber SSBR6270 is 23.5-26.5%, the oil content is 25.8-28.8%, the specific surface ratio of the high-dispersing white carbon black is 200-230 m<2> / g, and the total content of all components is 100%. According to the tire tread rubber material, the dried land road-holding force performance is high, the cornering manipulative capability is high, the driving rolling resistance is low, better wet landroad-holding force, wet land manipulative capability and icy and snowy land road-holding force are achieved, the wet land driving safety coefficient can be improved, and the wearing resistance meets the standards.

Owner:KENDA RUBBER CHINA

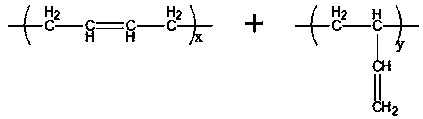

Rubber composition and rubber mixing method and low-tire-rolling-resistance tire using rubber composition

InactiveCN110372931AReduce usageHigh tensile strengthRolling resistance optimizationRubber materialRolling resistance

The invention belongs to the field of rubber tire manufacturing and relates to a rubber composition for a tire and capable of significantly reducing the rolling resistance of the tire without reducingthe wear resistance of the tire, and the rubber composition is particularly suitable for tread manufacture of a low rolling resistance tire. The rubber composition is prepared from the components inparts by weight: 50-90 parts of at least one rubber component selected from natural rubber, polyisoprene rubber, polybutadiene rubber and styrene-butadiene copolymer rubber, 5-30 parts of high cis polybutadiene composite rubber, 5-20 parts of trans polyoctene rubber, 30-70 parts of silica and 5-15 parts of carbon black. When the rubber composition is adopted for manufacturing the tire, the tire rolling resistance is significantly reduced while the wear resistance of the tire is not reduced, and the rubber composition is particularly suitable for tread manufacture of the low rolling resistancetire. The physical and mechanical properties of rubber materials and the high speed and durability of the tire can meet the requirements of normal use.

Owner:ZHONGCE RUBBER GRP CO LTD

Low rolling resistance tire rubber material with ultrahigh wear resistance and synthetic method thereof

ActiveCN105623014AMaintain propertiesImprove wear resistanceRolling resistance optimizationRubber materialRolling resistance

The invention provides a low rolling resistance tire rubber material with an ultrahigh wear resistance, which contains low temperature emulsion polymerized oil charge styrene butadiene rubber SBR1723, low temperature emulsion polymerized oil charge styrene butadiene rubber SBR1739, butadiene rubber BR9000, high structure medium and ultra wear resistant furnace black, high dispersion white carbon black, coumarone resin COUMARONE RESINCY-CR1 tackifying resin; GOYENCHEM-GR80 tackifying resin, antiager, vulcanizing agent, coupling agent X-50S, activating agent and accelerant. The low rolling resistance tire rubber material with the ultrahigh wear resistance is superior to a common tire in rolling resistance, wet road holding capacity, ice road holding capacity and wear resistance. The tire has better wet road holding capacity, a wet land driving safety coefficient is improved, ultrahigh wear resistance is realized, high speed performances are excellent and comprehensive use performances of a tire are improved.

Owner:KENDA RUBBER CHINA

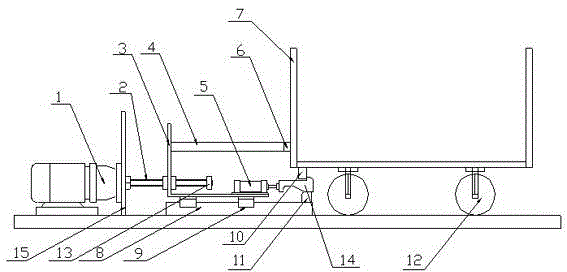

Guide trolley of low-rolling-resistance tire cord tearing machine

The invention relates to a guide trolley of a low-rolling-resistance tire cord tearing machine. The guide trolley comprises a deviation rectifying mechanism, a locking mechanism and a guide trolley main body, wherein the lower end of the guide trolley main body is provided with four pulleys by using which the guide trolley main body moves, wherein the pulleys are distributed on the lower end of the guide trolley main body in a rectangular shape; one side of the guide trolley main body is locked by the locking mechanism, and the guide trolley main body can be driven by the deviation rectifying mechanism to move horizontally in a reciprocating mode. The guide trolley has the advantages that an original fixed guide trolley is changed into a movable guide trolley; when nylon cloth is loaded, the locking mechanism is unlocked firstly, and then the guide trolley is pushed out directly; a fixed suspending arm installed in a production plant is used for loading the nylon cloth on the guide trolley, and then workers push the guide trolley into the locking mechanism for locking so as to complete the nylon cloth loading; in the whole process, the guide trolley is convenient to move, is low in labor intensity, and meanwhile can be used for reducing the safety hazards, and improving the working efficiency.

Owner:DOUBLE COIN GRP JIANGSU TIRE

A kind of low rolling resistance tire tread compound

ActiveCN103408807BImprove rolling resistanceReduce Paine EffectSpecial tyresRolling resistance optimizationRolling resistanceEngineering

Owner:SAILUN GRP CO LTD

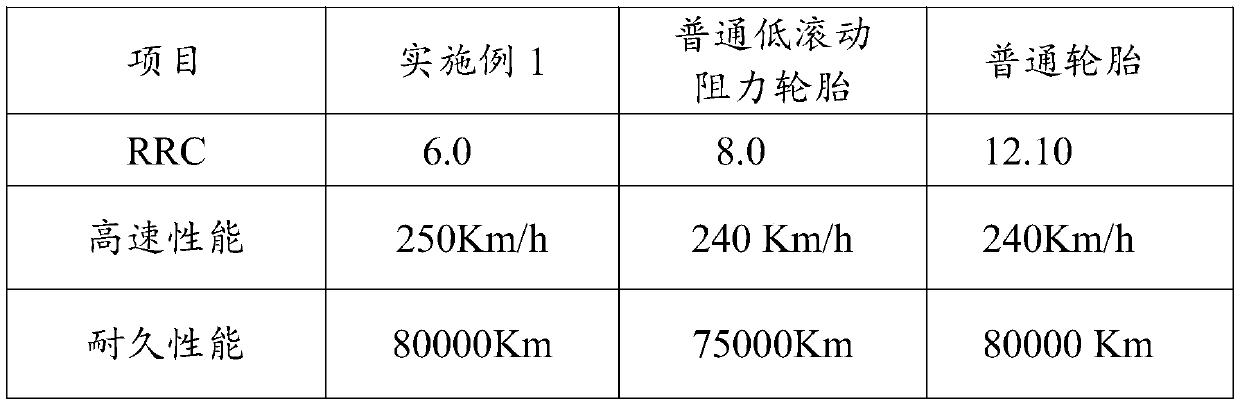

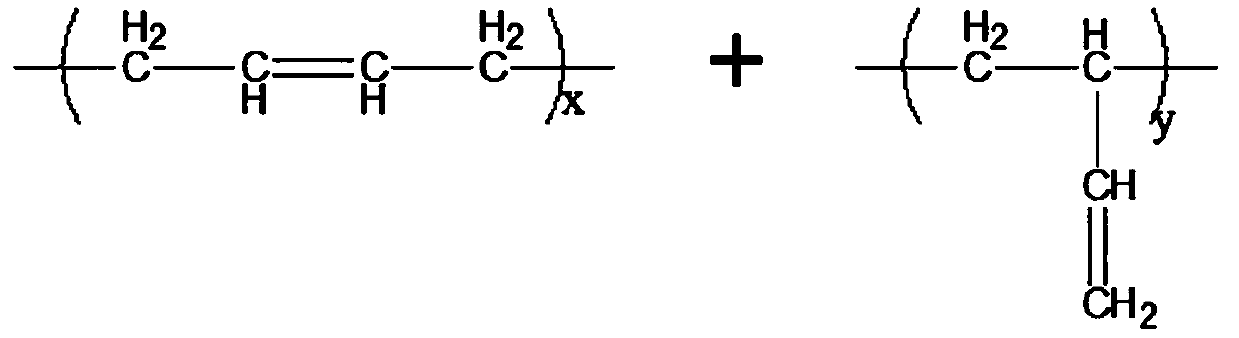

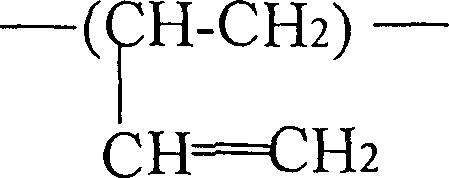

Polyether end group functionalized polymer prepared by negative ion polymerization technology and preparation method and application thereof

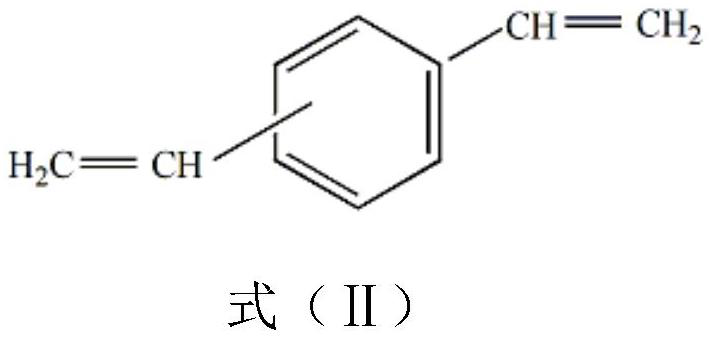

ActiveCN112048043AMild preparation conditionsHigh end-capping efficiencyRolling resistance optimizationEpoxyPolymer science

The invention discloses a polyether end group functionalized polymer prepared by a negative ion polymerization technology and a preparation method and application thereof, and belongs to the field ofpreparation of end group functionalized polymers. The method comprises the following steps: firstly, initiating monovinylarene and / or conjugated diene to carry out negative ion polymerization reactionin a hydrocarbon solvent by taking organic lithium as an initiator and a polar organic compound as a regulator to generate an active polymer, secondly, coupling by adopting divinylbenzene to obtain acoupled active polymer, and thirdly, adding an alkyl metal catalyst to obtain the modified active polymer, carrying out an end-capping reaction on the coupled active polymer and an epoxy compound, and carrying out ring-opening polymerization to prepare the polyether end group functionalized polymer. Compared with epoxy chloropropane end capping, the preparation conditions are mild, and the end capping efficiency is high and can reach 90% or above. After coupling, end capping is carried out, and the processability and the mechanical property are improved. The prepared polyether end group functionalized polymer can be applied to the fields of low rolling resistance tires, sound absorption, shock absorption, noise reduction, resin modification and the like.

Owner:DALIAN MARITIME UNIVERSITY

Formula of tread of low-rolling-resistance tire and preparation method thereof

ActiveCN103450508BHigh viscoelasticityReduce rolling resistanceSpecial tyresTyresBenzenePolymer science

The invention discloses a tire tread formula with low rolling resistance and a preparation method thereof. The tire tread formula with low rolling resistance comprises the following components: 10-20% of natural rubber, 10-20% of butadiene rubber, soluble butadiene Benzene rubber 20-40%, highly dispersed white carbon black 20-40%, peptizer A-80.5-1%, chemical antioxidant 6PPD1-2%, physical antioxidant microcrystalline wax 1-2%, active agent ZNO1- 3%, active agent SA1-3%, polyethylene glycol PEG1-3%, vulcanizing agent S-3251-3%, accelerator NS1-3%, special accelerator CTP0.1-0.8% and coupling agent SI694- 8%. The beneficial effect of adopting the technical solution is that the tire has low rolling resistance, which can reach A grade or B grade, and its physical and mechanical properties are basically the same as those of non-low rolling resistance tires, and the advantages of tires in terms of wet and dry grip are retained.

Owner:KENDA RUBBER CHINA

low rolling resistance tire

ActiveCN103374154BImprove wear resistanceExtend the life cycleSpecial tyresRolling resistance optimizationElastomerRolling resistance

The invention provides a tire with low rolling resistance. The abrasion resistance of the tire is improved. The rolling resistance coefficient of the tire is smaller than 10.5kg / t. The tire comprises a tire tread which has a split-type structure and consists of a tire crown, a tire shoulder and a tire side, wherein the tire shoulder consists of the following rubber compositions in percentage by weight: 0-30 percent of cis alkadiene elastomer, 15-50 percent of copolymerization olefin polymer, 8-30 percent of carbon black, 10-40 percent of white carbon black and 3.5-35 percent of rubber additive. The tire shoulder of the tire with the low rolling resistance provided by the invention consists of the rubber compositions comprising 8-30 percent of carbon black; by the carbon black, the abrasion resistance of the tire shoulder is improved, the whole use cycle of the tire is prolonged, and the service life of the tire is prolonged. The tire provided by the invention also has low rolling resistance, good wetland road holding capacity and high abrasion resistance.

Owner:CHENG SHIN RUBBER CHINA

A kind of ultra-high wear resistance low rolling resistance tire compound and its synthesis method

ActiveCN105623014BImprove wear resistanceGood wet gripRolling resistance optimizationRubber materialRolling resistance

The invention provides a low rolling resistance tire rubber material with an ultrahigh wear resistance, which contains low temperature emulsion polymerized oil charge styrene butadiene rubber SBR1723, low temperature emulsion polymerized oil charge styrene butadiene rubber SBR1739, butadiene rubber BR9000, high structure medium and ultra wear resistant furnace black, high dispersion white carbon black, coumarone resin COUMARONE RESINCY-CR1 tackifying resin; GOYENCHEM-GR80 tackifying resin, antiager, vulcanizing agent, coupling agent X-50S, activating agent and accelerant. The low rolling resistance tire rubber material with the ultrahigh wear resistance is superior to a common tire in rolling resistance, wet road holding capacity, ice road holding capacity and wear resistance. The tire has better wet road holding capacity, a wet land driving safety coefficient is improved, ultrahigh wear resistance is realized, high speed performances are excellent and comprehensive use performances of a tire are improved.

Owner:KENDA RUBBER CHINA

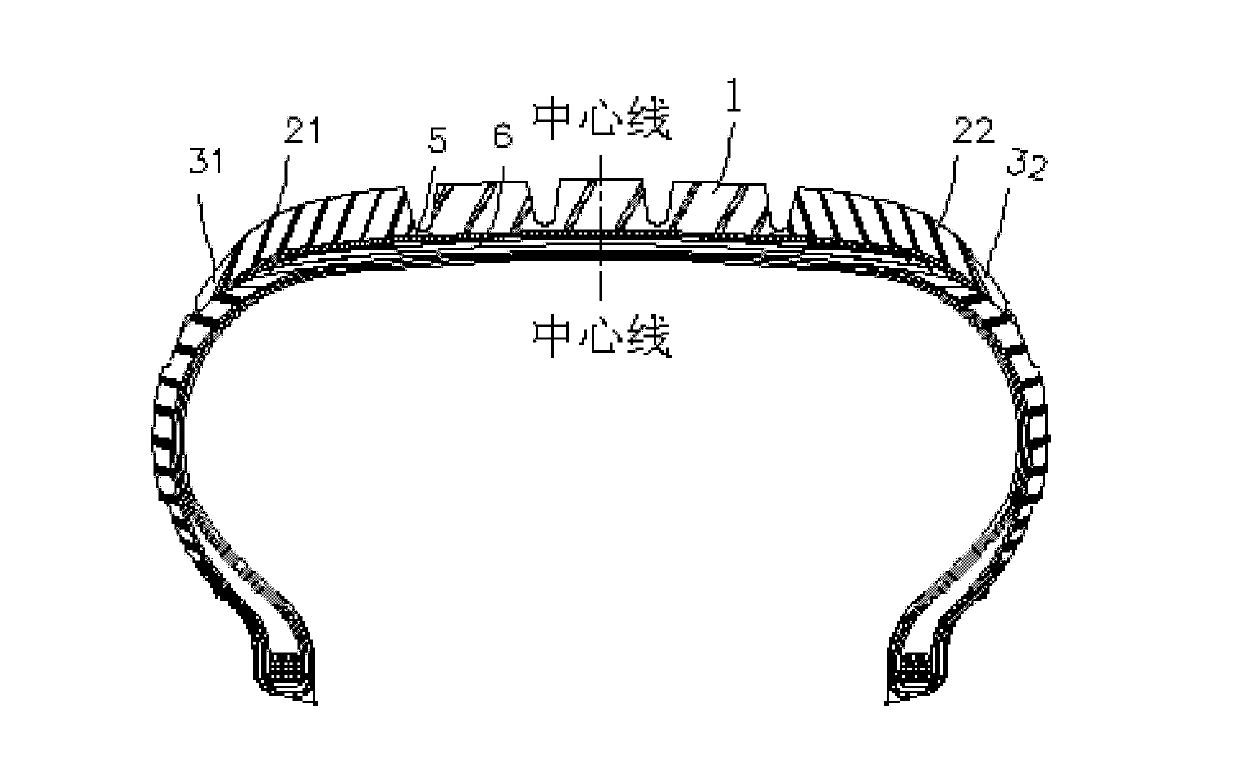

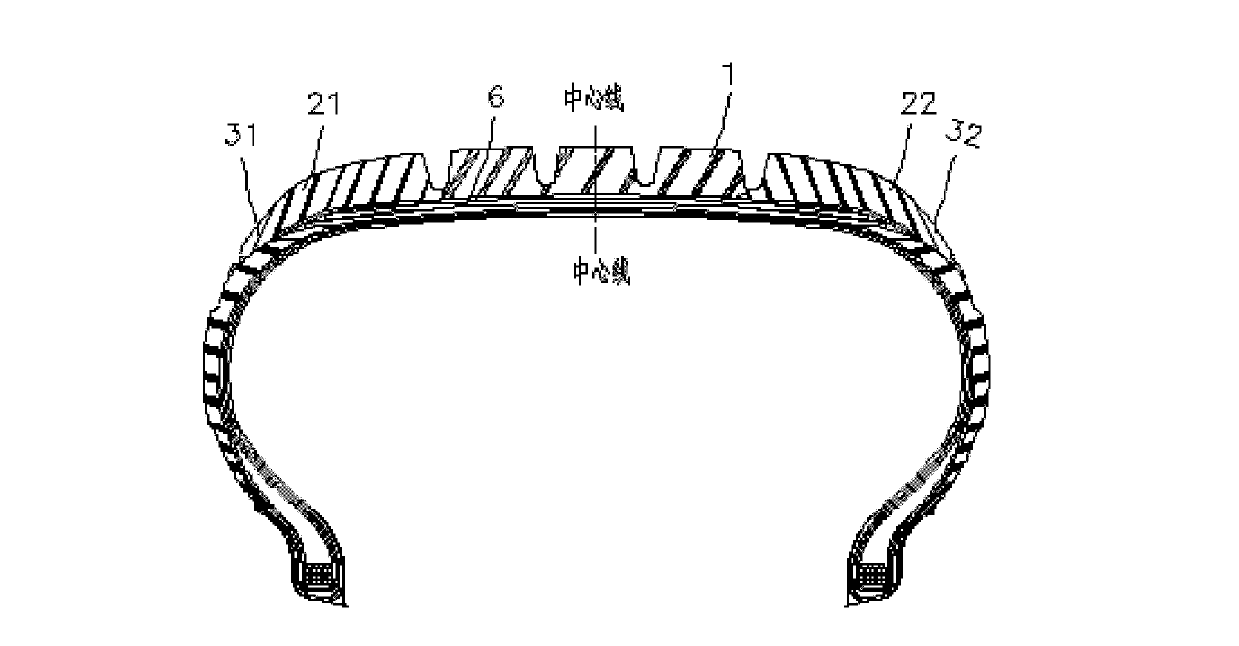

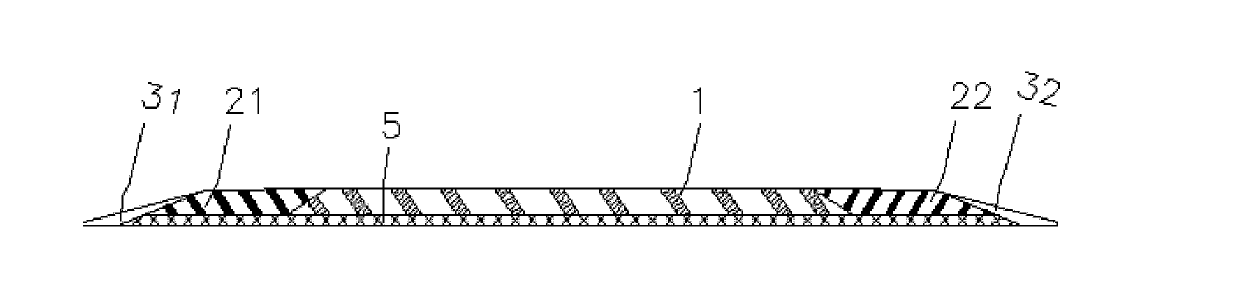

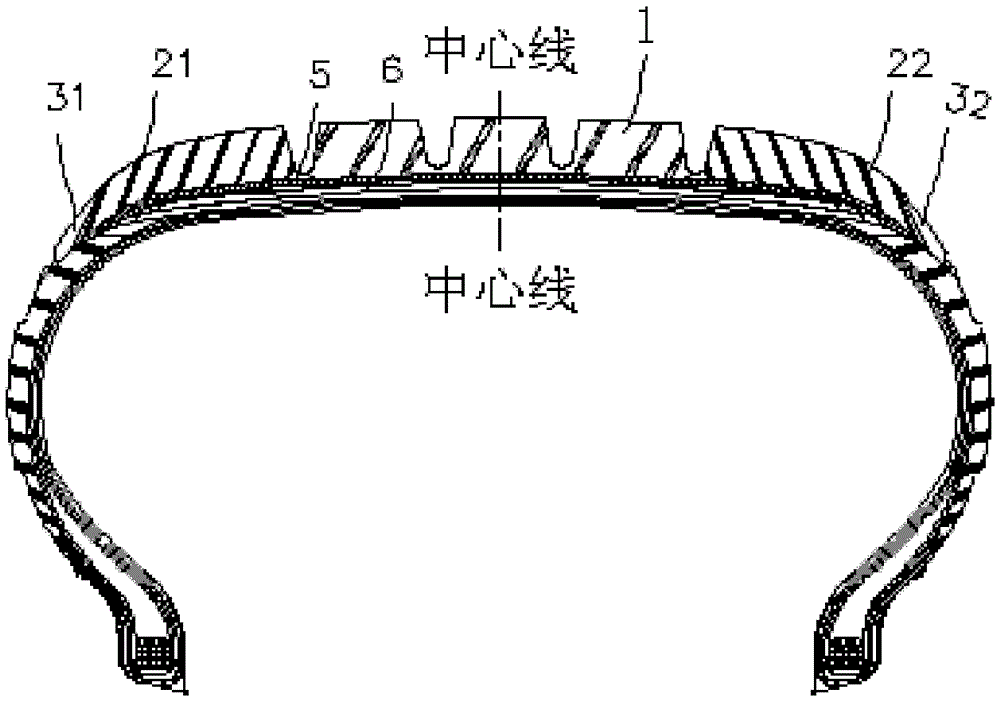

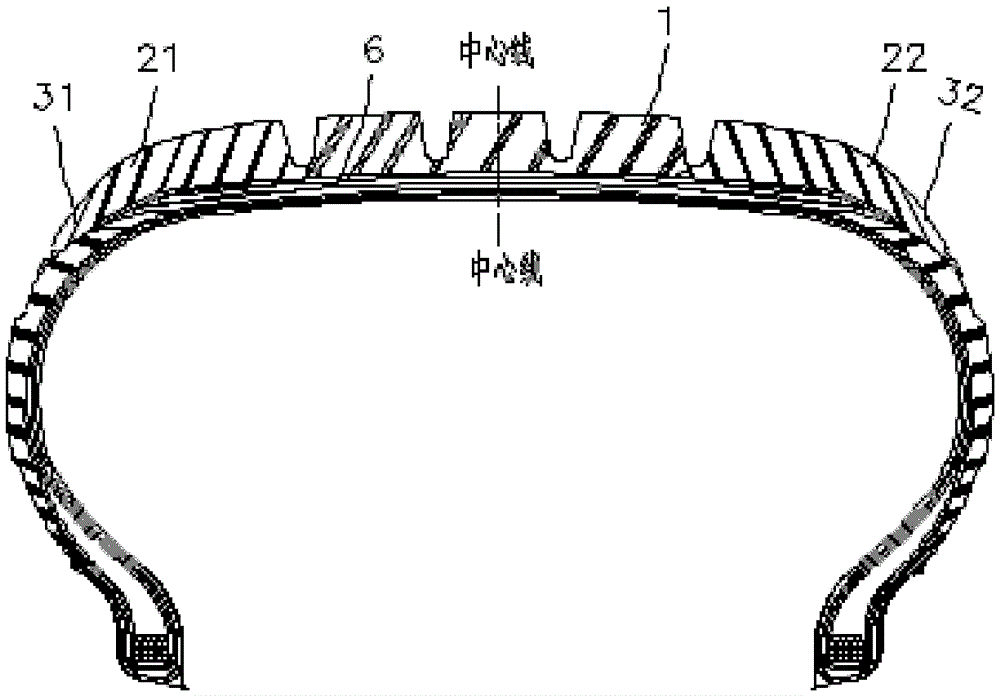

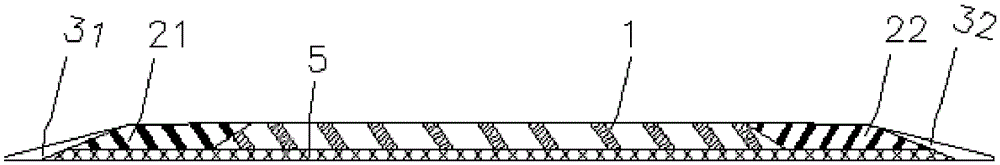

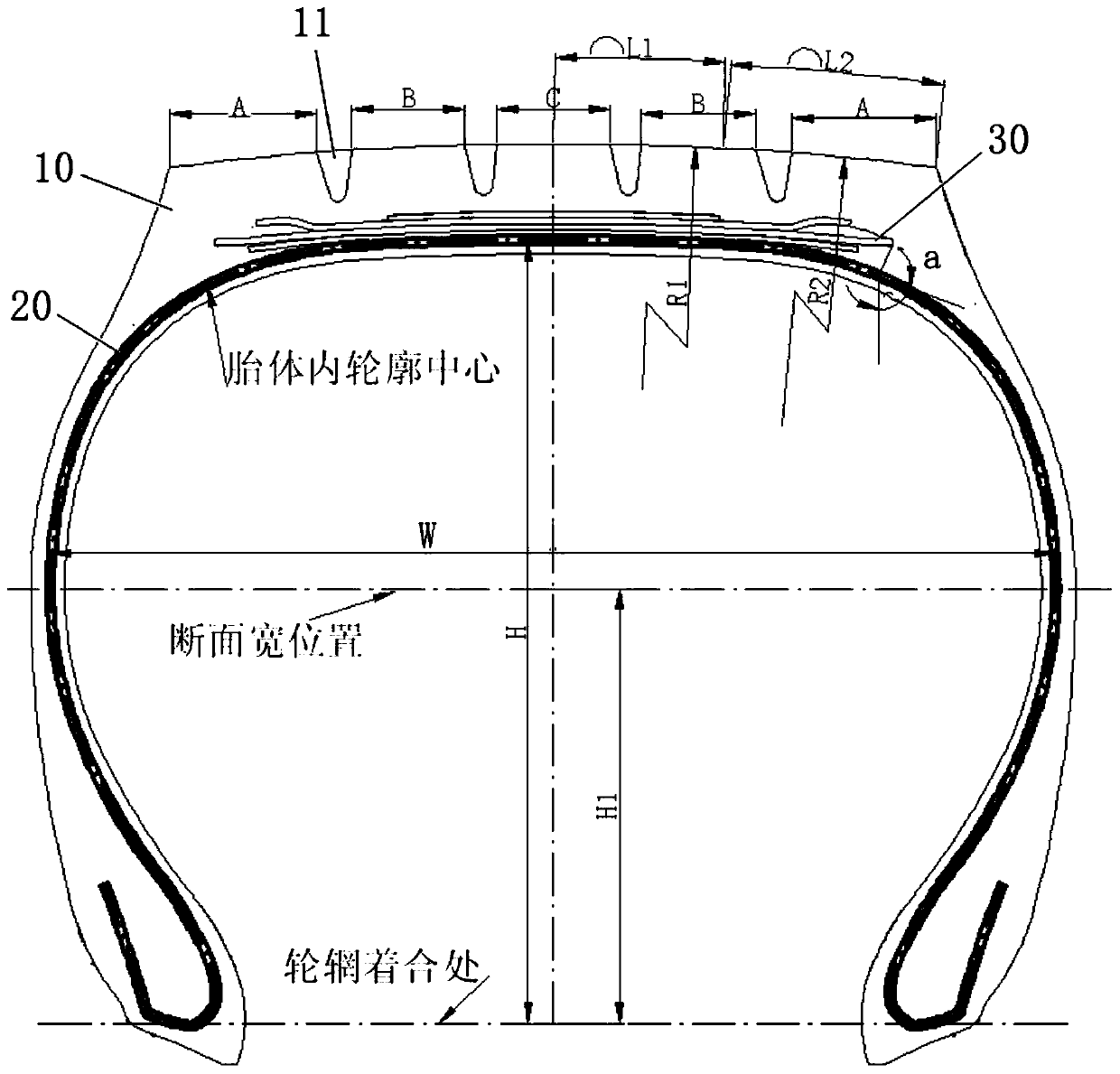

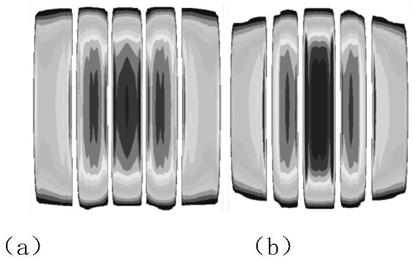

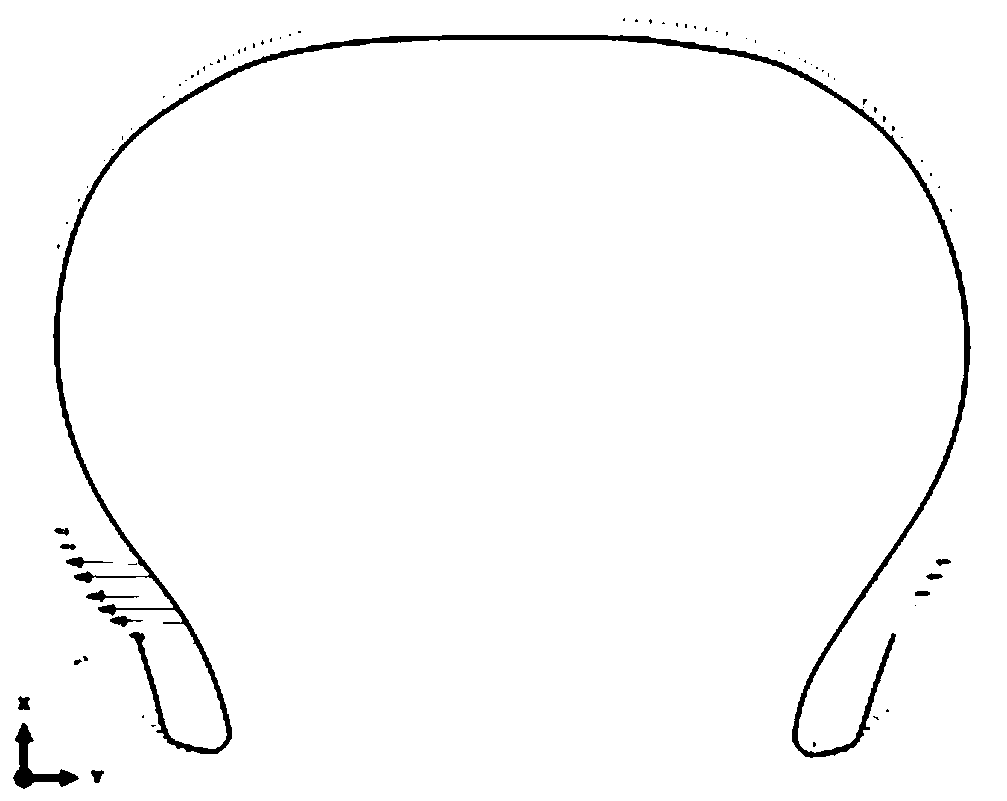

All steel low rolling resistance tire

ActiveCN108437704BImprove wear performanceImprove contour shapeTyre tread bands/patternsRolling resistance optimizationGround contactRolling resistance

The invention provides an all-steel low rolling resistance tire, which comprises a tread, a carcass, a belt layer, and an outer contour of the tread and an inner contour of the carcass. The tread is provided with four circumferential main grooves along the tire circumferential direction. The groove divides the tire from the outside to the inside in turn into inner shoulder block, inner central block, middle block, outer central block and outer shoulder block, the distance W between the tire carcass at the width of the tire section, and the height H of the inner contour of the carcass , the height of the horizontal axis H 1 , The angle a between the tangent line between the second belt layer and the vertical line of the carcass and the center line of the tread has 0.75≤H / W≤0.80, 0.50≤H 1 / H≤0.60, 55°≤a≤70°. In the case of improving the wear performance, the invention improves the tread pattern, the outer contour of the tread and the inner contour of the carcass to improve the rigidity of the tread, improve the ground contact condition, realize uniform tire wear and reduce rolling resistance.

Owner:GITI RADIAL TIRE (ANHUI) CO LTD

A kind of high-grip performance and low rolling resistance tire tread compound and its synthesis method

ActiveCN109796647BLow ride rolling resistanceLow heat generationSpecial tyresRolling resistance optimizationPolymer scienceRolling resistance

The invention discloses a tire tread rubber material with high grip performance and low rolling resistance. The tire tread rubber material with high grip performance and low rolling resistance comprises: SSBR6270 40-44% by weight percentage , natural rubber SIR20 12-15%, highly dispersed silica 26-30%, antioxidant 2.0-3.0%, coupling agent X-50S 3-5%, active agent 1-3%, plasticizer 2-4 %, 0.6-0.9% vulcanizing agent, 1.2-1.6% accelerator and 0.07-0.1% anti-scorch agent, the combined styrene content of the solution-polymerized styrene-butadiene rubber SSBR6270 is 23.5-26.5%, and the oil content is 25.8-28.8%, The specific surface area of the highly dispersed white carbon black is 200-230m 2 / g, the sum of the contents of each component is 100%. Through the above-mentioned method, the technology provided by the present invention has strong grip performance on dry ground, strong cornering control ability, and small driving rolling resistance. Wetland driving safety factor, durability up to standard.

Owner:KENDA RUBBER CHINA

Low rolling resistance tyre for vehicles

InactiveCN1239333CTaking rolling resistance into accountConsider processabilityTyresSpecial tyresGround contactRolling resistance

A low rolling resistance tire (1) for vehicles is described which comprises at least one belt layer (7) coaxially extending around at least one carcass ply (3), a composite tread (10) coaxially extending around the belt layer (7) and comprising a radially outer layer (12) an a radially inner layer (11), wherein the ratio between the modulus of elasticity E' at 70 DEG C of the radially inner layer (11) and the modulus of elasticity E' at 70 DEG C of the radially outer layer (12) is comprised between 1.1 and 3, and the ratio between the value of tang delta at 70 DEG C of the radially inner layer (11) and the value of tang delta at 70 DEG C of the radially outer layer (12) is lower than 0.8. Advantageously, the tire (1) achieves a better compromise between the characteristics of rolling resistance, handling and comfort with respect to what is obtainable from known tires for the same type of use.

Owner:PIRELLI TYRE SPA

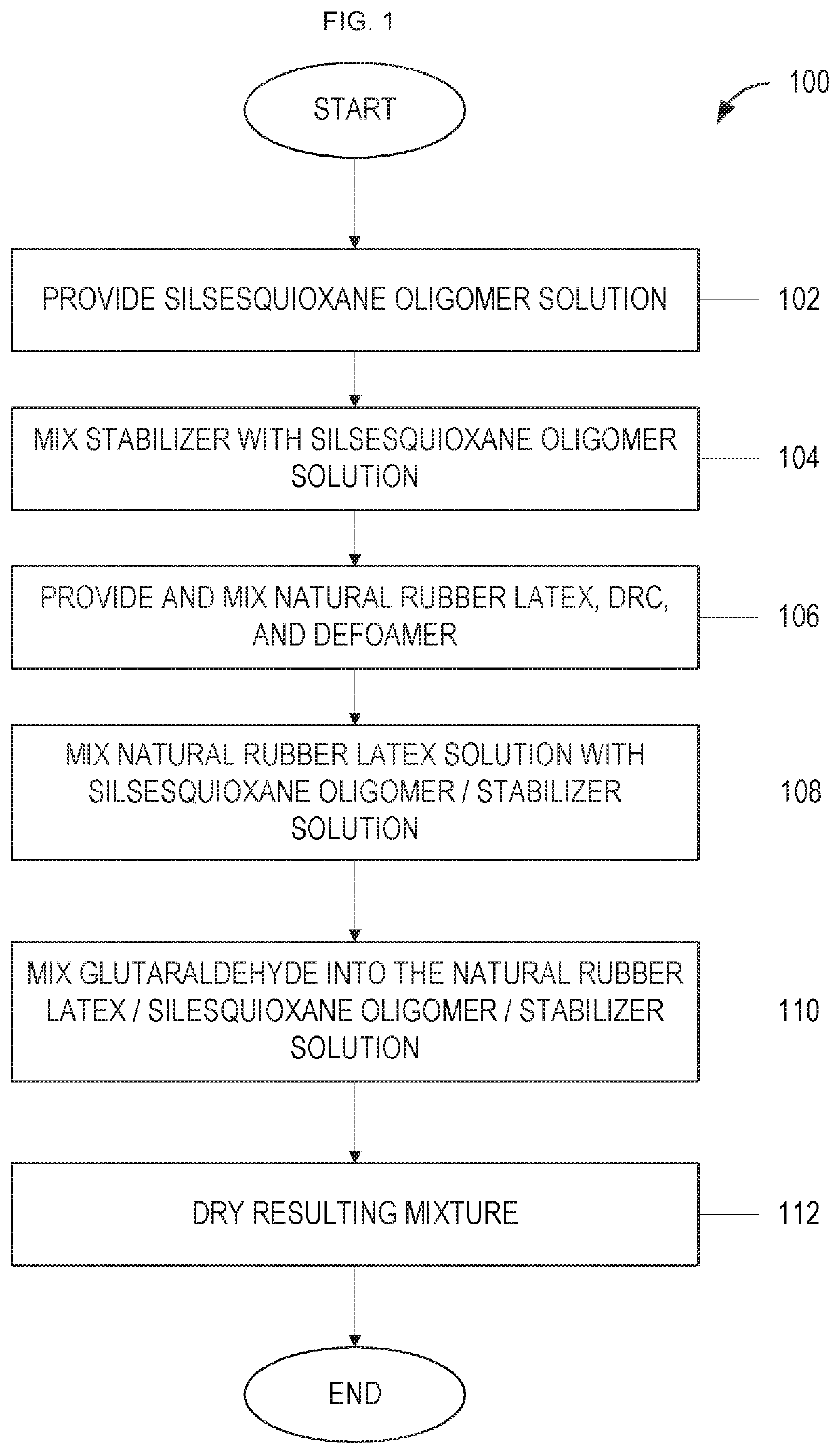

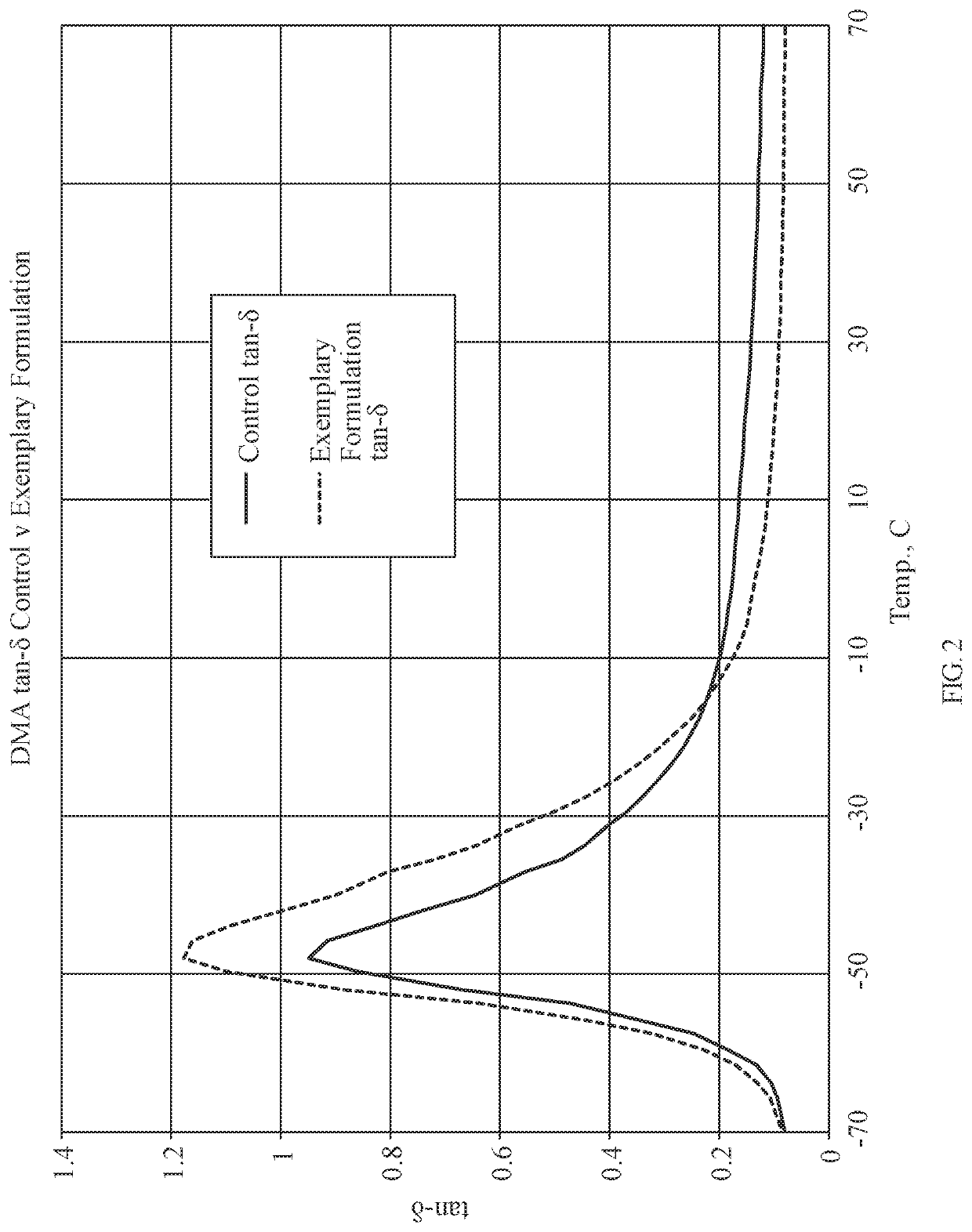

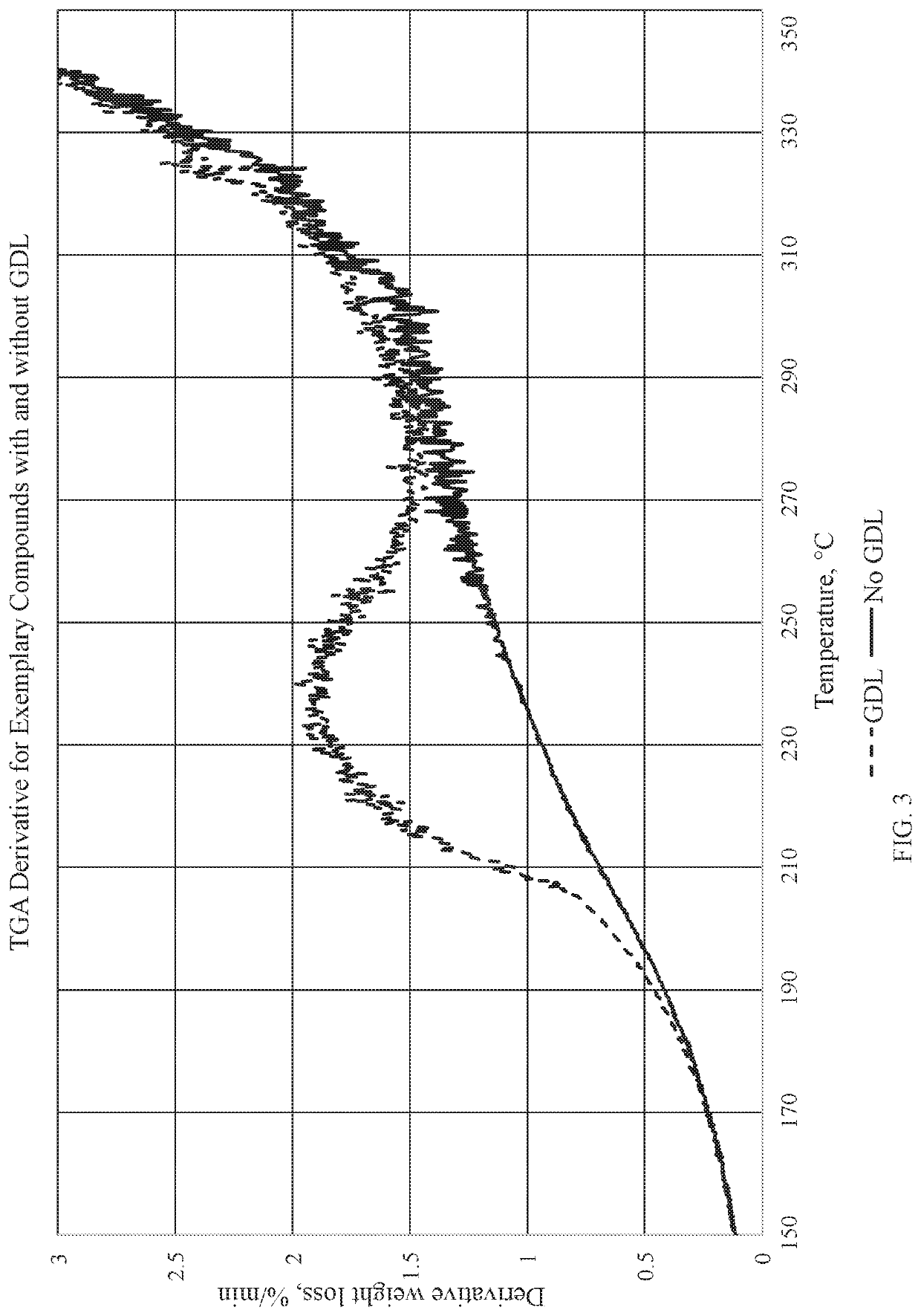

Molecular composites of functional silica and natural rubber

ActiveUS20210102046A1Reduce carbon dioxide emissionsReduce fuel consumptionSpecial tyresRolling resistance optimizationElastomerPolymer science

Briefly described, and according to one embodiment, aspects of the present disclosure generally relate to natural rubber and functional silica compositions for tire manufacturing and methods for forming the same. In at least one embodiment, the disclosed composition is a renewable elastomeric polymeric composition for rubber compounding applications, such as low rolling resistance tire tread and winter tire tread applications. The disclosed composition may also reduce fuel consumption and, thus, carbon dioxide emissions in gas-powered vehicles, and increase driving range in electric vehicles, because the disclosed composition is more energy efficient than current tire material compositions. In various embodiments, the disclosed composition may be formed by blending water-soluble silsesquioxane oligomers into a natural rubber latex system, followed by in-situ formation of a continuous, molecular silica network within the resulting polymer.

Owner:SILPARA TECH LLC

Production method of tire tread with low rolling resistance

The invention discloses a production method of a tire tread with low rolling resistance. The production method comprises the following steps: firstly, putting diene elastomers into a mesh type internal mixer, and uniformly mixing under a first predetermined condition; secondly, putting reinforcing stuffing and other auxiliaries into the mesh type internal mixer, processing under a second predetermined condition, and discharging glue into a twin-screw extrusion tablet press, thus forming first master batch after cooling; thirdly, adding the first master batch and part of white carbon black and carbon black into the mesh type internal mixer, and processing under a third predetermined condition, thus obtaining second master batch; fourthly, adding the second master batch, accelerant and sulphur into the mesh type internal mixer, processing under a fourth predetermined condition, discharging the glue, and batching out and cooling to room temperature, thus finishing the production of tread rubber.

Owner:雄鹰轮胎(青州)有限公司

Low-rolling-resistance tire tread rubber composition

ActiveCN103073754BHysteresis loss is smallReduce rolling resistanceSpecial tyresRolling resistance optimizationWaxPolymer science

Owner:TRIANGLE TIRE

Low-rolling-resistance wet-skid-resistant abrasion-resistant tire tread formula and preparation method thereof

The invention discloses a low-rolling-resistance wet-skid-resistant abrasion-resistant tire tread formula. The low-rolling-resistance wet-skid-resistant abrasion-resistant tire tread formula comprises the following components: 10-20% of natural rubber, 0-20% of polybutadiene rubber, 20-60% of solution polymerized styrene butadiene rubber, 20-40% of high-dispersion white carbon black and 4-8% of a coupling agent SI69. The formula has the beneficial effects that: the hardness of a product is reduced, the wet-skid resistant performance is improved, so that a tire does not easily skid, and thus safety of the tire is improved; the abrasion resistant performance of the tire is excellent, and thus the service life of the tire is greatly increased; the rolling resistance of the tire is low and can reach an A level or a B level, various physical and mechanical properties of the tire are basically consistent to those of a tire having no low rolling resistance, and the advantages of the tire in road holding on a wet land and on a dry land are retained.

Owner:KENDA RUBBER CHINA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com