Tread rubber for whole steel load bearing low-rolling-resistant tire

A low rolling resistance, tire tread technology, applied in the direction of rolling resistance optimization, special tires, tire parts, etc., can solve the problems of relatively little research, reduce tire tread rolling resistance, etc., and achieve good comprehensive physical and mechanical properties, The effect of low rolling resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0013] A kind of tread rubber for all-steel heavy-duty tires with low rolling resistance, the specific formula is as follows (in parts by weight):

[0014] 70 parts of natural rubber, 30 parts of neodymium-based butadiene rubber, 30 parts of carbon black N234, 20 parts of highly dispersed white carbon black, 752 parts of liquid Si, 3.5 parts of zinc oxide, 2 parts of stearic acid, 2 parts of anti-aging agent 6PPD, anti-aging agent 1 part of RD, 1 part of microcrystalline wax, 1.2 parts of oil-extended sulfur, 1.4 parts of accelerator NS, 0.7 parts of accelerator DTDM, and 0.2 parts of anti-scorch agent CTP.

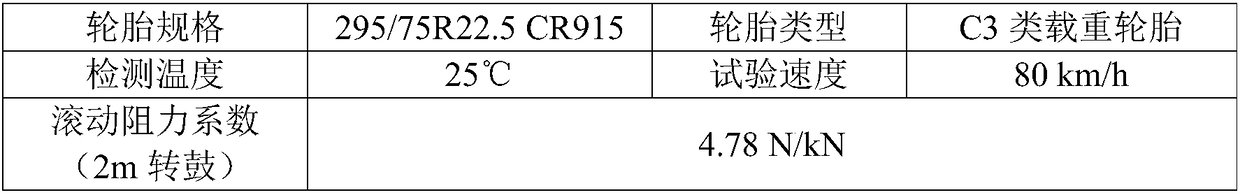

[0015] Use embodiment 1 to make the main technical index of tread compound as follows:

[0016] project

unit

Example 1

100% tensile strength

MPa

2.5

300% tensile strength

MPa

14.1

tear strength

MPa

28.8

Elongation at break

%

523

tear strength

MPa

164

rebound

%

34

hard...

Embodiment 2

[0021] A kind of tread rubber for all-steel heavy-duty tires with low rolling resistance, the specific formula is as follows (in parts by weight):

[0022] 62 parts of natural rubber, 38 parts of neodymium-based butadiene rubber, 34 parts of carbon black N234, 18 parts of highly dispersed white carbon black, 1.8 parts of liquid Si747, 3 parts of zinc oxide, 1.5 parts of stearic acid, 1.5 parts of anti-aging agent 6PPD, anti-aging 0.7 parts of agent RD, 1 part of microcrystalline wax, 1.4 parts of oil-extended sulfur, 1 part of accelerator NS, 1.2 parts of accelerator DTDM, and 0.2 parts of anti-scorch agent CTP.

Embodiment 3

[0024] A kind of tread rubber for all-steel heavy-duty tires with low rolling resistance, the specific formula is as follows (in parts by weight):

[0025] 78 parts of natural rubber, 22 parts of neodymium-based butadiene rubber, 27 parts of carbon black N134, 28 parts of highly dispersed white carbon black, 1.5 parts of liquid Si747, 3.5 parts of zinc oxide, 2 parts of stearic acid, 1.5 parts of anti-aging agent 6PPD, anti-aging 0.8 parts of agent RD, 1 part of microcrystalline wax, 1.05 parts of oil-extended sulfur, 1.7 parts of accelerator NS, 0.9 parts of accelerator DTDM, and 0.2 parts of anti-scorch agent CTP.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength at break | aaaaa | aaaaa |

| tear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com