Tire tread mix with low rolling resistance

A low rolling resistance, tire tread technology, applied in the direction of rolling resistance optimization, special tires, tire parts, etc., can solve the problems of high heat generation, unable to meet the requirements of low rolling resistance tires, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

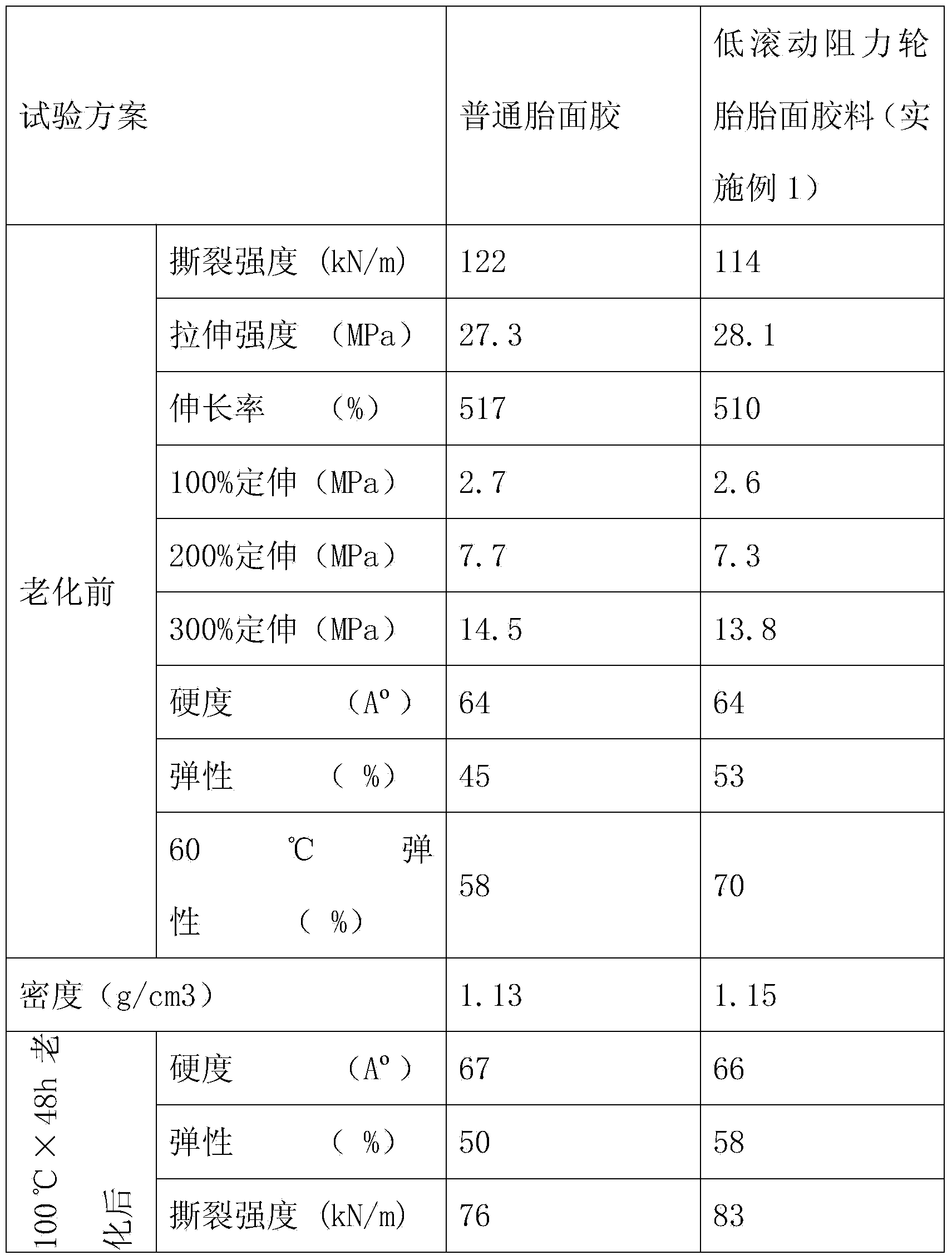

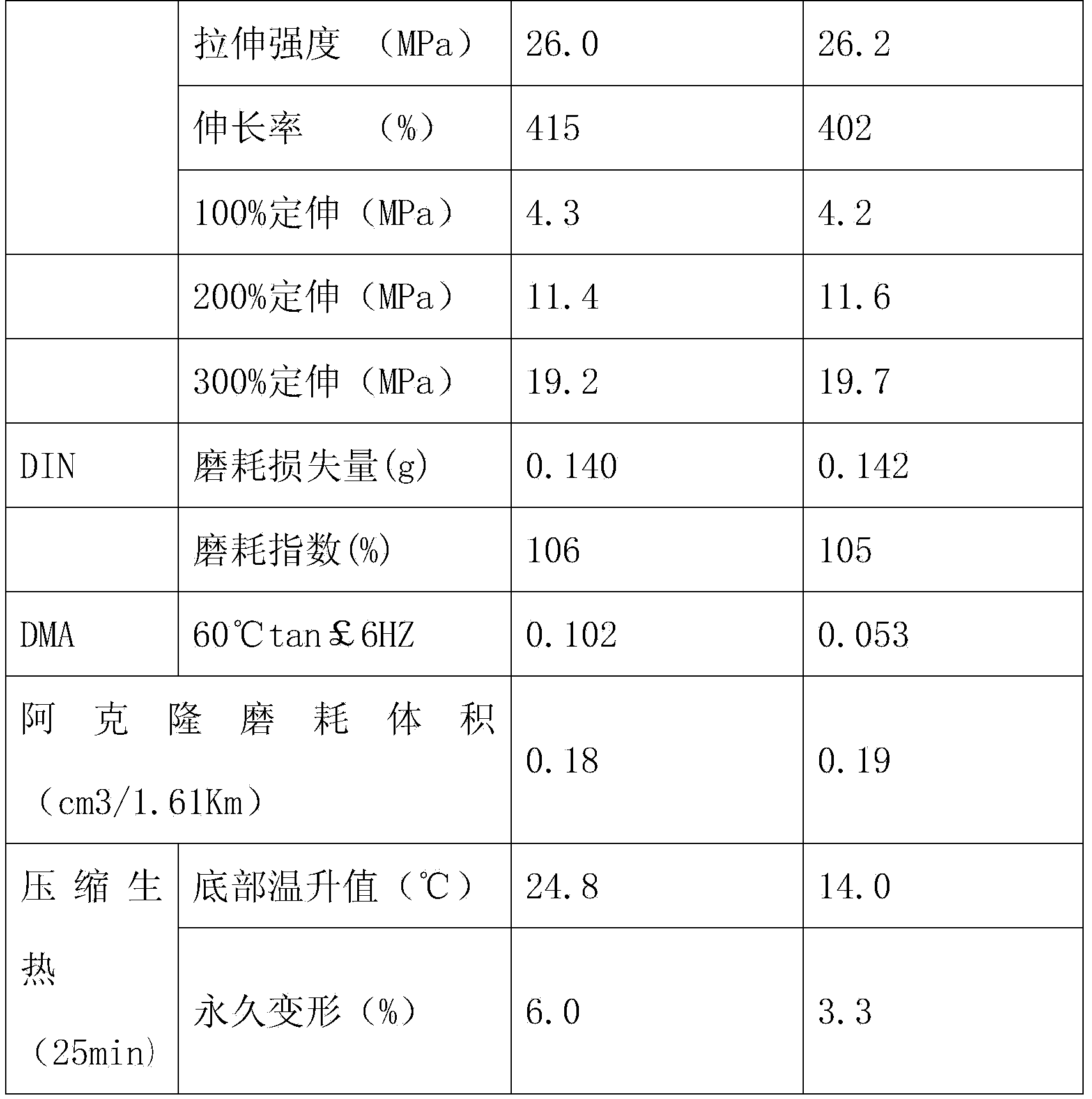

[0006] The present invention will be further described below in conjunction with embodiment:

[0007] The present invention can be realized by the embodiment listed in the following table

[0008] serial number

components

Example 1

Example 2

Example 3

1

90

85

80

2

butadiene rubber

10

15

20

3

N234 carbon black

10

20

25

4

Silica

45

35

30

5

Coupling agent si69

5

4.5

4

6

4.5

5

5

7

1

1

1

8

Antiaging agent 6PPD

2

2

2

9

Antiaging agent RD

2

2

2

10

1.6

1.5

1.45

11

Accelerator CZ

2

1.9

1.8

12

Anti-scorch agent CTP

0.1

0.1

0.1

13

protective wax

1

1

1

[0009] The specific preparation method is to use a rubber interna...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com