Improved brake bottom plate of drum brake

A drum brake and brake bottom plate technology, applied in the direction of brake parts, etc., can solve the problems of uneven friction surface, unsafe driving, uncomfortable ride, etc., and achieve the goal of improving driving safety, prolonging service life and uniform friction surface Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

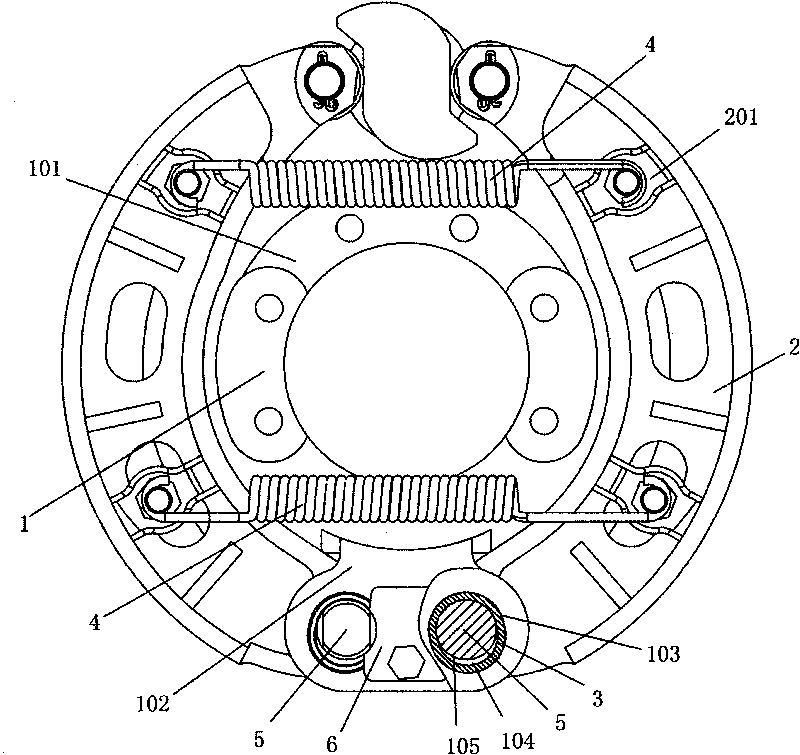

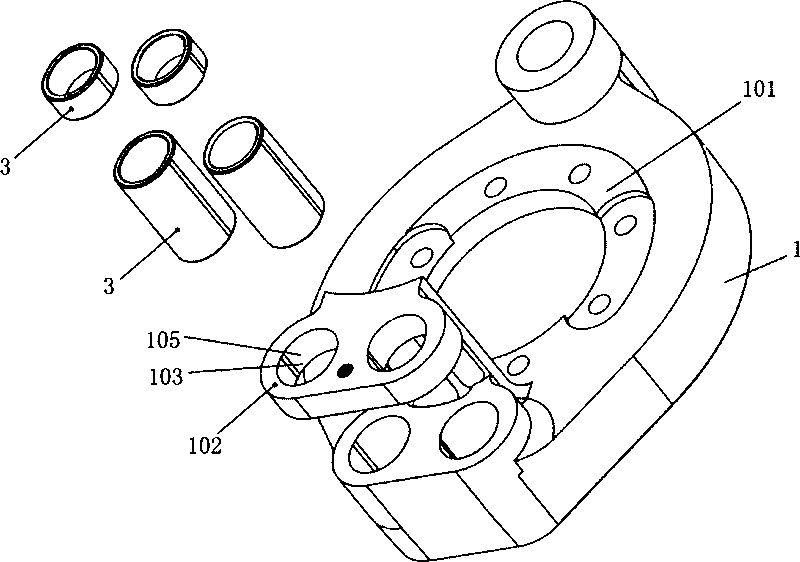

[0026] Such as Figures 1 to 7 Shown:

[0027] The improvement of the brake base plate of the drum brake includes a brake base plate 1, the brake base plate 1 is provided with a connection plate 101, and the connection plate 101 is provided with a plurality of mounting holes, and the brake base plate 1 protrudes a clamping part 102, clamping Connecting portion 102 is provided with connection through hole 103, and the ends of a pair of left and right brake shoes 2 are inserted into clamping portion 102 of brake base plate 1 to connect with it, and clamping portion 102 of brake base plate 1 It is the connection through hole 103 of the upper and lower layers, and there is a gap in the middle. The connection through hole 103 is cut with a certain gap 104 , and the gap 104 and the connection through hole 103 form an integral guide groove 105 .

[0028] The gap 104 is matched with the connecting through hole 103 and cut with a certain circular arc gap 104 to form a guide groove 105...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com