A test method for electrolyte used in electrolytic grinding of high-speed steel roll material

A technology of electrolytic grinding and test method, which achieves the effect of simple formula, easy purchase and acquisition, and low price

Active Publication Date: 2022-06-14

GUIZHOU UNIV

View PDF15 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0005] The present invention intends to provide a test method for the electrolyte used in the electrolytic grinding of high-speed steel roll materials, so as to solve the problem of mechanical grinding and repairing of high-speed steel roll processing in the prior art. Problems of low efficiency, high processing cost and poor surface quality

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

specific Embodiment approach

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

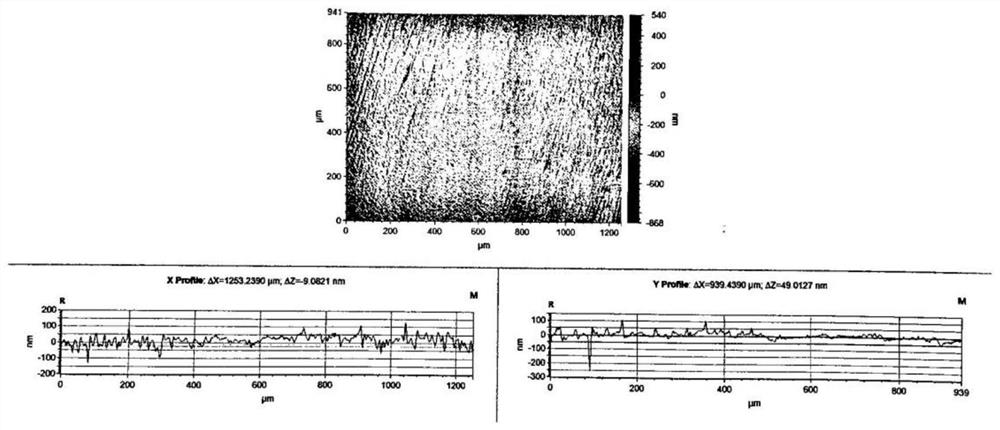

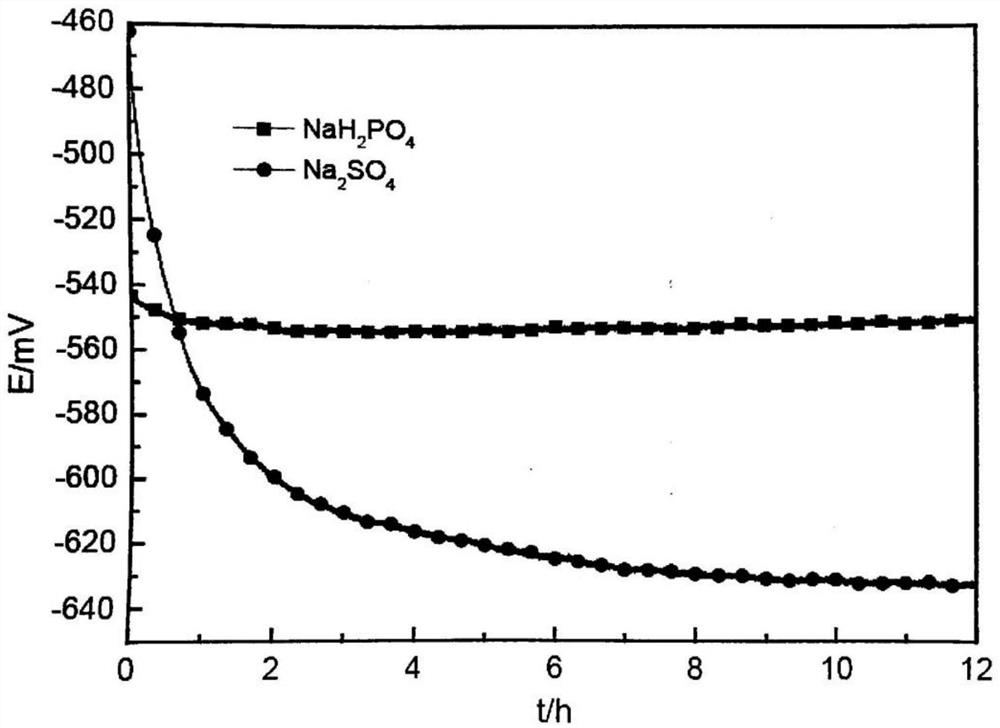

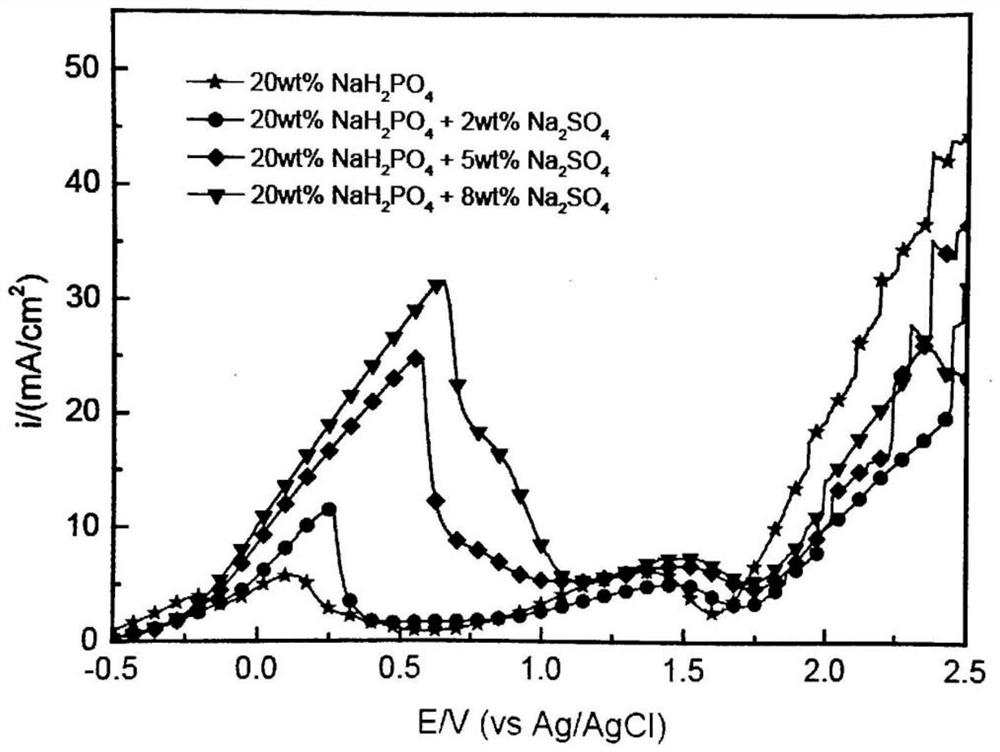

The invention belongs to the technical field of electrochemical processing of metal materials, and discloses a test method for the electrolyte used in the electrolytic grinding of high-speed steel roll materials. The electrolyte obtained by using the method is calculated by mass percentage: sodium sulfate 2%~8%, phosphoric acid Sodium dihydrogen is 20%, and the balance is deionized water; the method also uses an electrolyte liquid supply system for electrolytic grinding of high-speed steel roll materials, which includes processing power supply, grinding wheel, cathode tool, water tank, motor, Hydraulic pumps, electrolytic reaction tanks, filters, tee pipes, solenoid valves, safety valves, pressure reducing valves, pressure gauges, throttle valves, electromagnetic flowmeters, modification devices and chillers. The water tank is connected with liquid level switches, filter screen, PH detector, heater, temperature sensor, liquid level gauge, liquid unloading valve and water tank cover; the present invention solves the problem of low processing efficiency, high processing cost and surface quality of the prior art mechanical grinding processing and repairing high-speed steel rolls Poor problem, used for electrolytic grinding of high-speed steel roll material.

Description

technical field [0001] The invention relates to the technical field of electrochemical processing of metal materials, in particular to a test method for electrolyte used in electrolytic grinding of high-speed steel roll materials. Background technique [0002] The roll is the core component of the rolling mill, and its material and material properties directly affect the production quality of the steel plate. Due to the advantages of high-speed steel rolls such as good wear resistance, thermal shock resistance, hardenability and high friction coefficient, rolls made of high-speed steel rolls are mostly used as work rolls for hot rolling mills in the market. However, during the working process of the roll, if the cooling system fails to cool it in time, and the carbide itself is not uniformly dispersed, the roll is subjected to the rolling force and the matrix around it will be worn to varying degrees; in addition, the material of the high-speed steel roll The linear expansi...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): B23H5/08B23H5/14

CPCB23H5/08B23H5/14

Inventor 吴怀超曹刚袁奎聂龙

Owner GUIZHOU UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com