Anti-explosion permanent magnet direct-current brushless motor with controller

A permanent magnet DC, brushless motor technology, applied in the direction of connection with control/drive circuits, electromechanical devices, electrical components, etc., can solve the problems of large overload capacity, large volume, heavy quality, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with accompanying drawing:

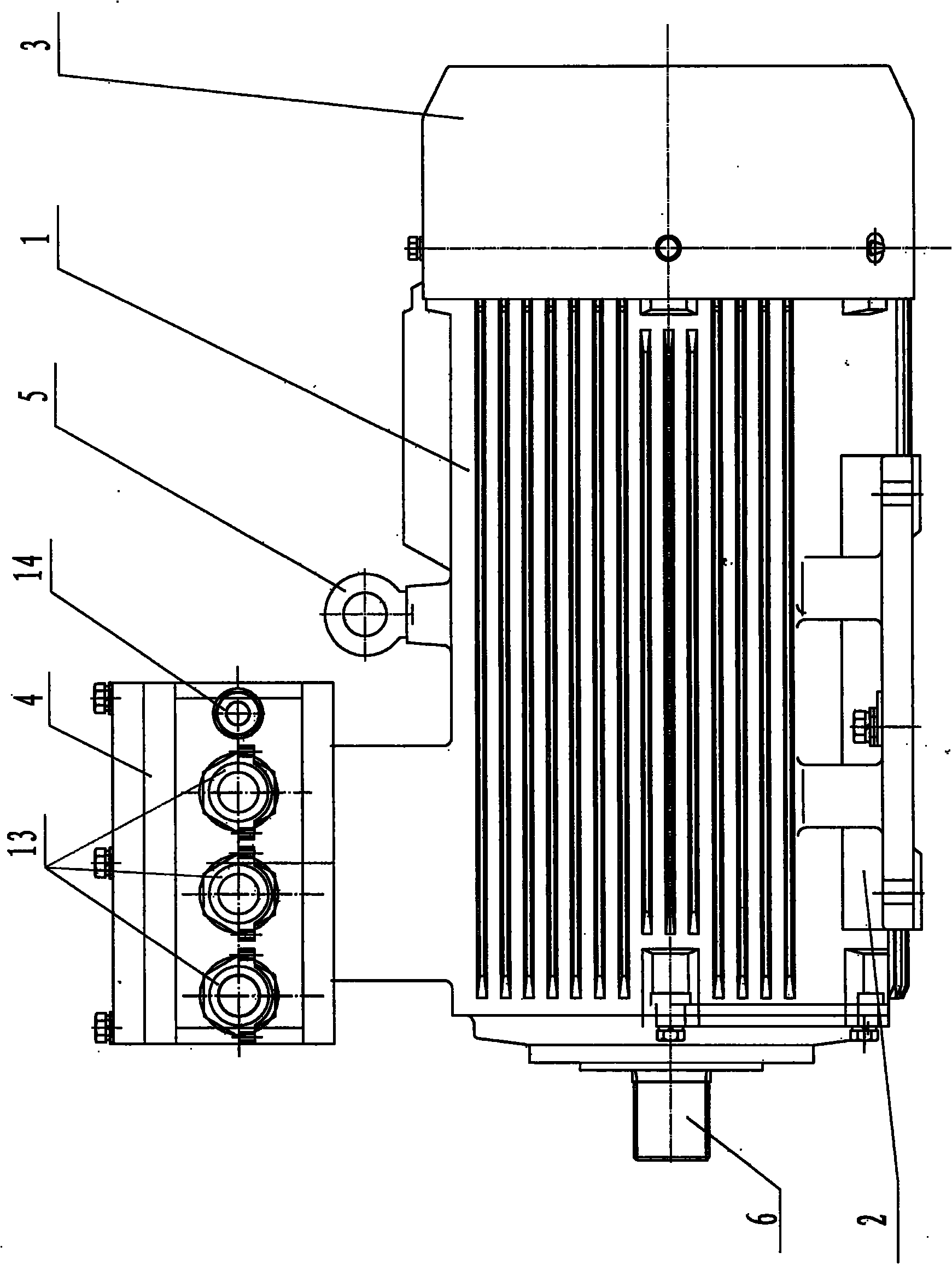

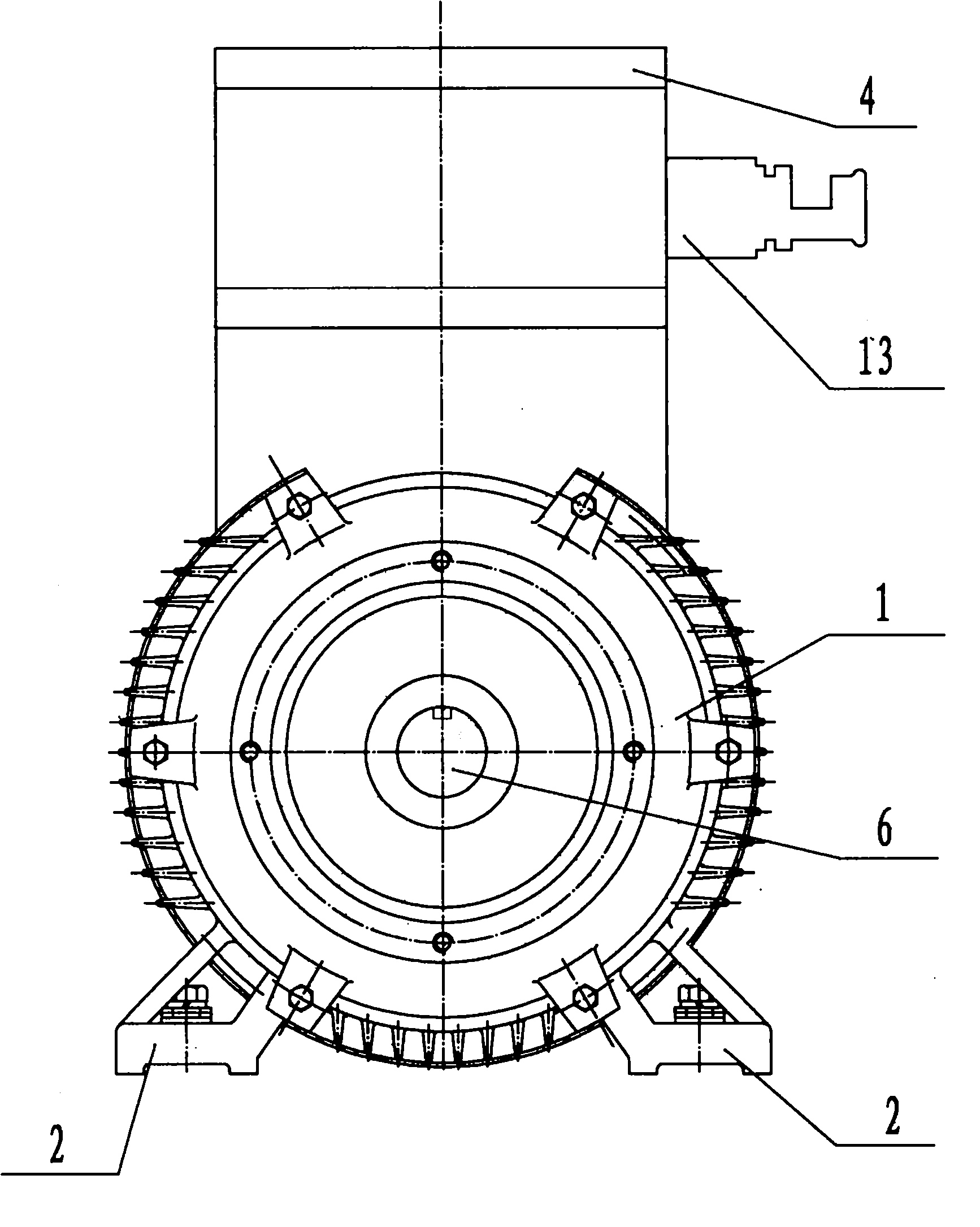

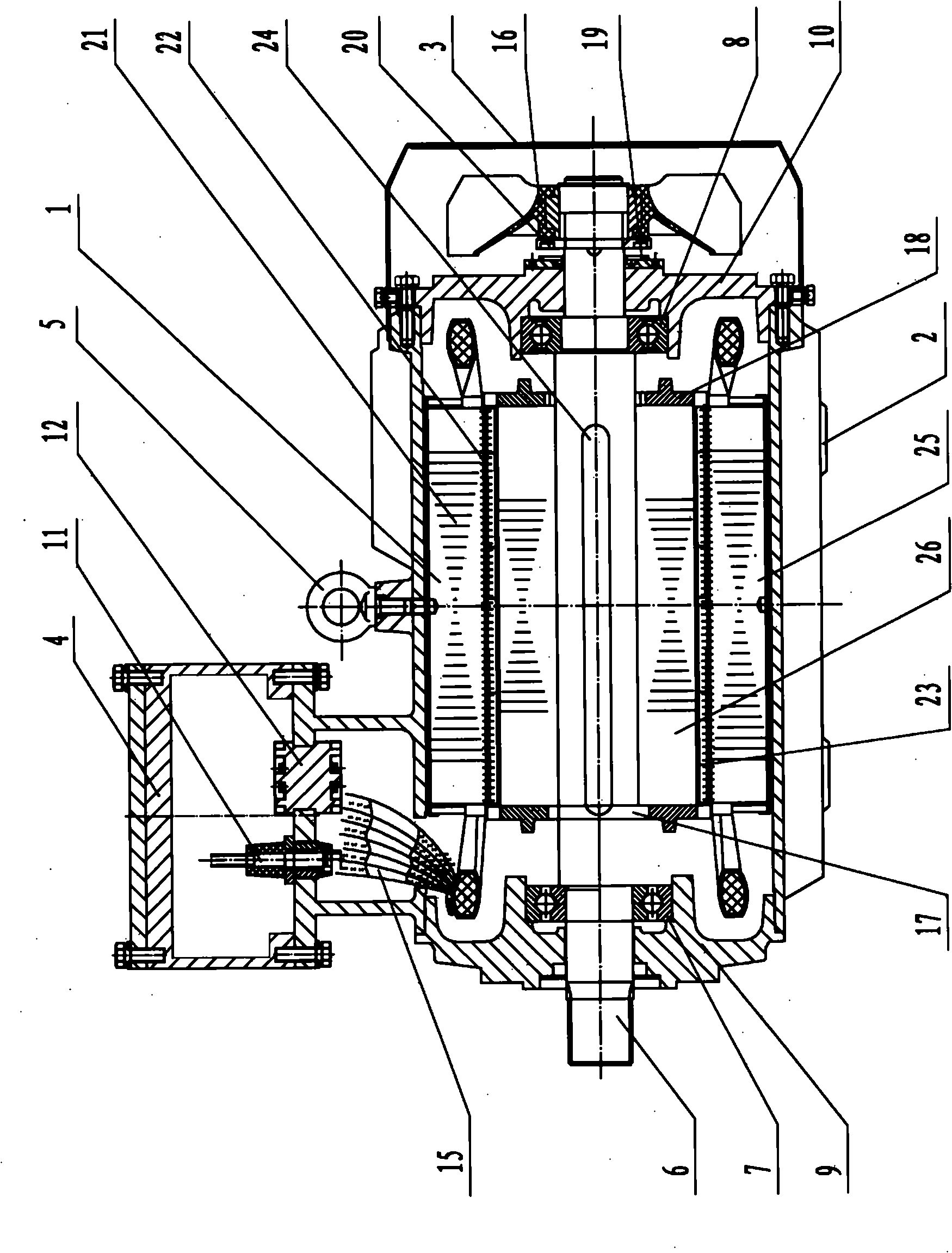

[0026] figure 1 , 2 . As shown in 3, it is the structural diagram of the motor. The position and connection relationship of each part must be correct and the installation should be firm.

[0027] The lower part of the motor 1 is the motor base 2, which is fixed by the bolt nut; the upper left part of the motor 1 is the junction box 4, and the front part is provided with a large junction tube 13 and a small junction pipe 14, which are fixed by the bolt nut. The strong current terminal 11 and the weak current terminal plate 12 are set as a set; the inside of the motor is a stator 25, and the inside of the stator 25 is a rotor 26, and the rotor 26 is installed on the motor shaft 6 and fixed by a flat key 24; the stator 25 is equipped with a stator silicon steel sheet 21. Wound by the stator coil 22; the rotor 26 is equipped with a rotor NdFeB magnet bar 23, and the two ends ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com