Anti-reverse automatic separation oil recovery screw pump direct drive system

An automatic separation, screw pump technology, used in rotary piston type/swing piston type pump components, pump combinations for elastic fluid rotary piston type/swing piston type, pumps, etc., can solve the control switch failure, reverse rotation Problems such as the flying car falling off the rod and the square clip flying off, to achieve the effect of stable operation, simple installation and convenient operation and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

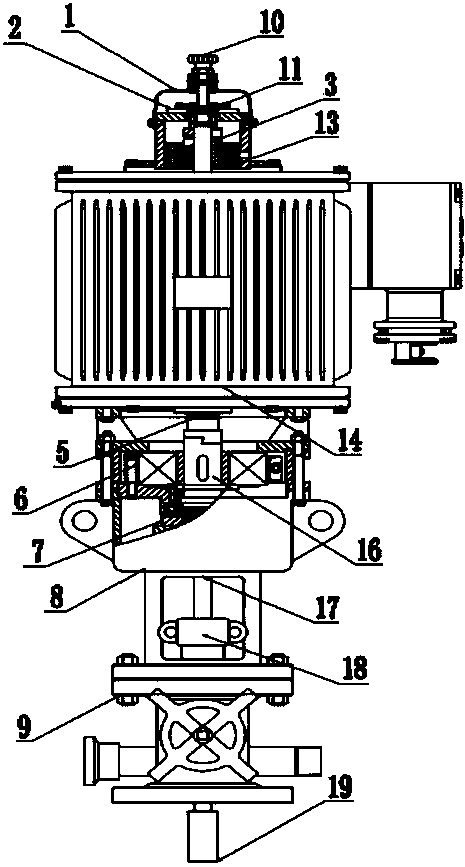

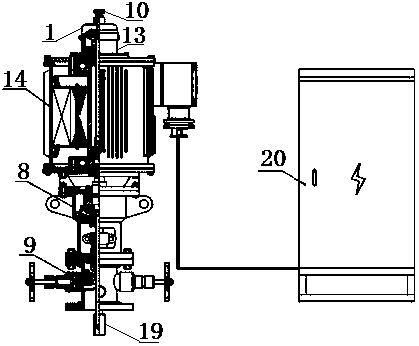

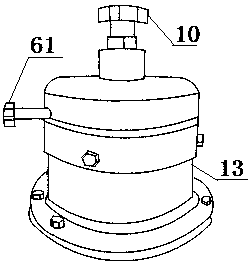

[0027] As shown in the figure, the anti-reverse automatic separation oil recovery screw pump direct drive system of the present invention includes a direct drive motor 14, the hollow shaft of the direct drive motor 14 is connected to drive the spline shaft 5 of its inner sleeve, and the lower end of the spline shaft 5 passes through the axial The separation and slip-off coupling is connected downward to drive the lower short shaft 16 of the bearing seat 7, and the bearing seat 7 is connected to the optical shaft 17 driving the sealing box 18, and the lower end of the optical shaft 17 has a joint 19 for connecting the sucker rod downward ; The upper end of the spline shaft 5 is equipped with a reverse-rotation lifting clutch separation device. When the spline shaft 5 is reversely driven to rotate, it will be lifted by the reaction force and separated from the lower short shaft 16, and it will rotate to ≥ 1 / 3- Locked by manual or automatic release locking mechanism at <1 week. I...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com