Cap mechanism

A technology of cap screwing and capping, which is applied in the direction of threaded bottle caps, etc., and can solve problems such as the machine cannot run stably

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Embodiments of the present invention are described in detail below:

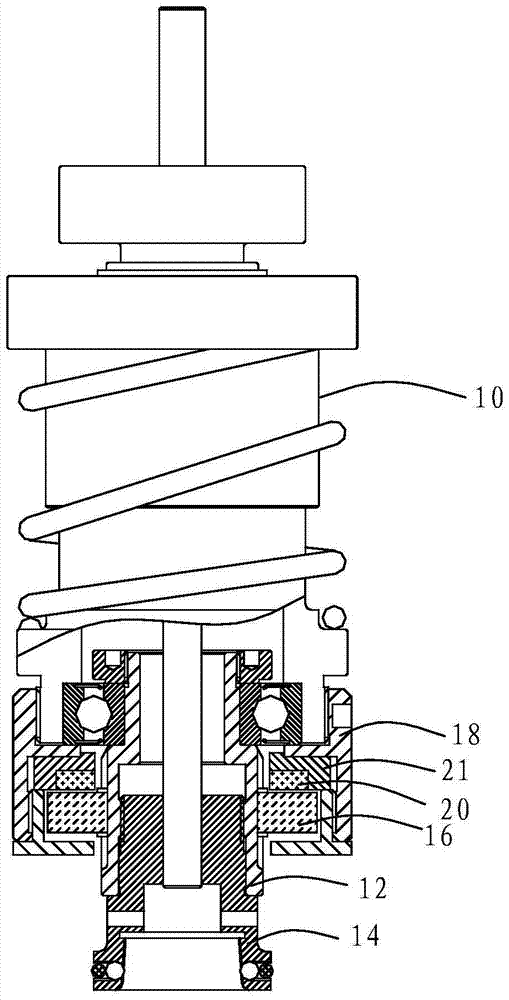

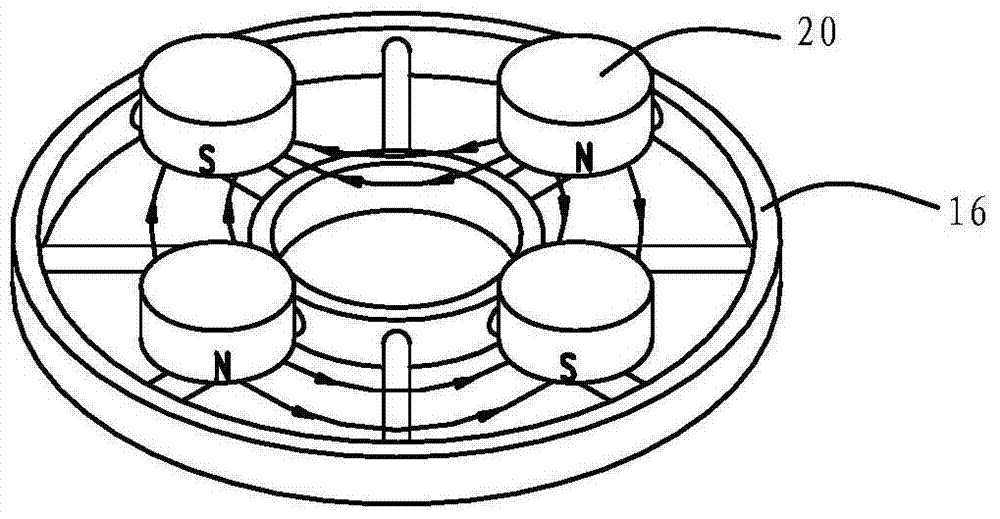

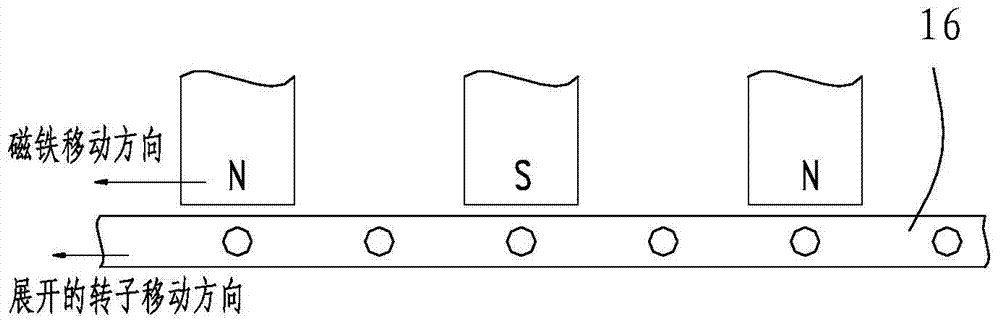

[0030] Such as Figure 1 to Figure 3 Shown, a kind of screw cap mechanism, it comprises screw cap main body 10, rotating shaft 12, catch cap head 14, disc rotor 16 and magnet fixing base 18; The bottom of described screw cap main body 10 and the top of described rotating shaft 12 Fixedly connected, the bottom of the rotating shaft 12 is fixedly connected with the cap gripping head 14, and the rotating shaft 12 is driven by the rotation of the cap main body 10 to rotate the capping head 14. The disc rotor 16 and the rotating shaft 12 The outer circumference of the magnet fixing base 18 is fixed with an upper magnet 20 or a lower magnet, the upper magnet 20 is located above the disc rotor 16, or the lower magnet is located below the disc rotor 16, and the upper Both the magnet 20 and the lower magnet include N magnetic regions and S magnetic regions, and the N magnetic regions and the S magnetic region...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com