Semi-automatic short distance cutting machine and its cutting method

A semi-automatic and cutting machine technology, applied in welding equipment, gas flame welding equipment, metal processing equipment, etc., can solve the problems of high operation level, high processing requirements, high technical requirements, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The technical contents and implementation methods of the present invention will be further described in detail below in conjunction with the accompanying drawings.

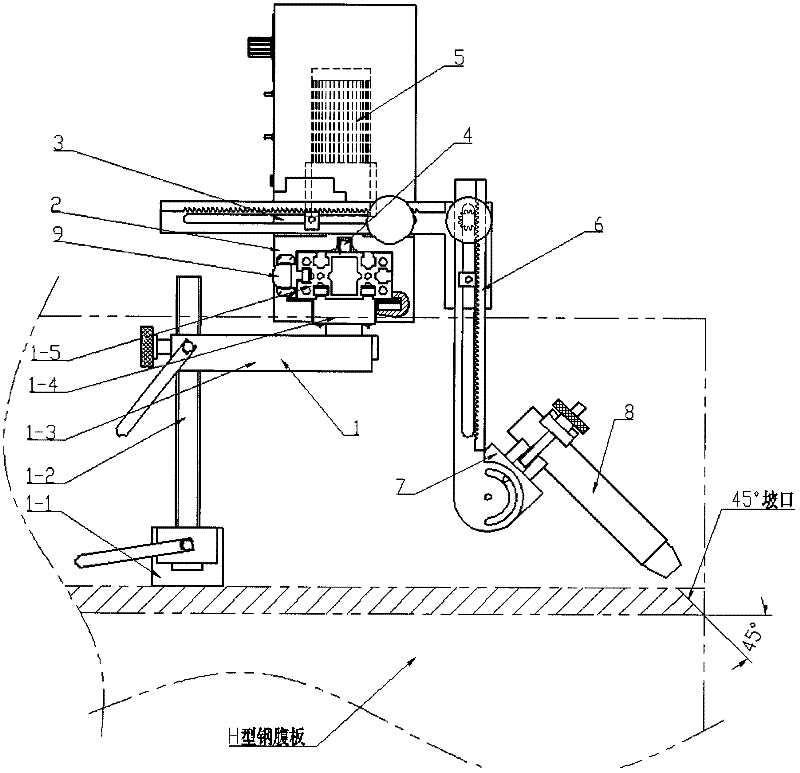

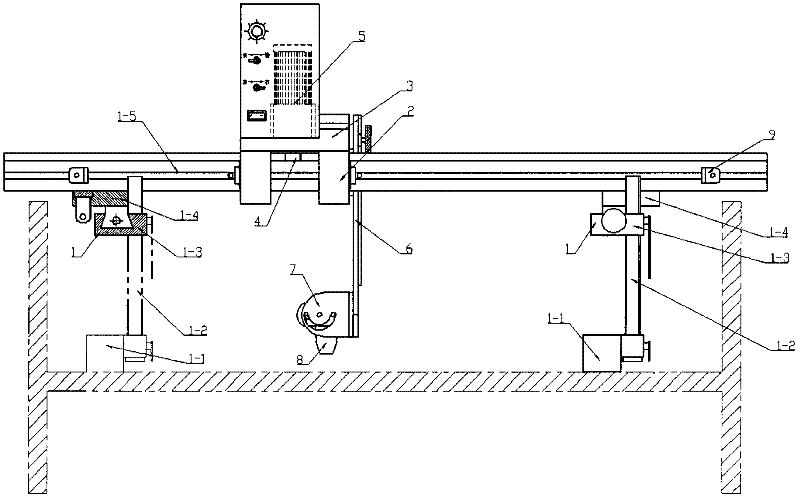

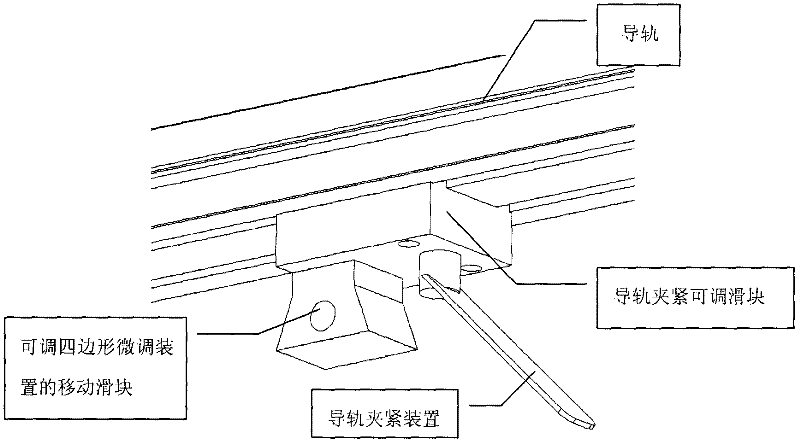

[0025] attached figure 1 , 2 For a preferred embodiment of the present invention, by attaching figure 1 , 2 The structure of the present invention can be clearly described, and the present invention simply utilizes the principle of magnetism—magnetism occurs between the strong magnetic base 1-1 and the processed iron workpiece to fix the cutting machine on the processed iron workpiece , can be used more flexibly in on-site operation, which is incomparable with the existing technology. The torch 8 is installed and arranged on the machine base 3 through a manual fine-tuning device, and the machine base 3 moves linearly along the guide rails 1-5 to complete the cutting task.

[0026] Cutting operation instructions of the semi-automatic short-distance cutting machine: According to the influence of the exter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com