Flexible rope driving device having automatic rope arranging and force measuring functions as well as method

A cable-driven and automatic rowing technology, which is applied in hoisting devices and clockwork mechanisms, can solve the problems of chaotic winding of cables, easy damage of cables, low tension measurement accuracy and real-time requirements, and facilitate installation Effects of transport, sensor noise reduction, and axial dimension reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings. It should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

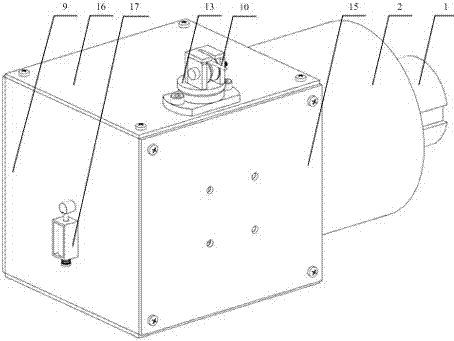

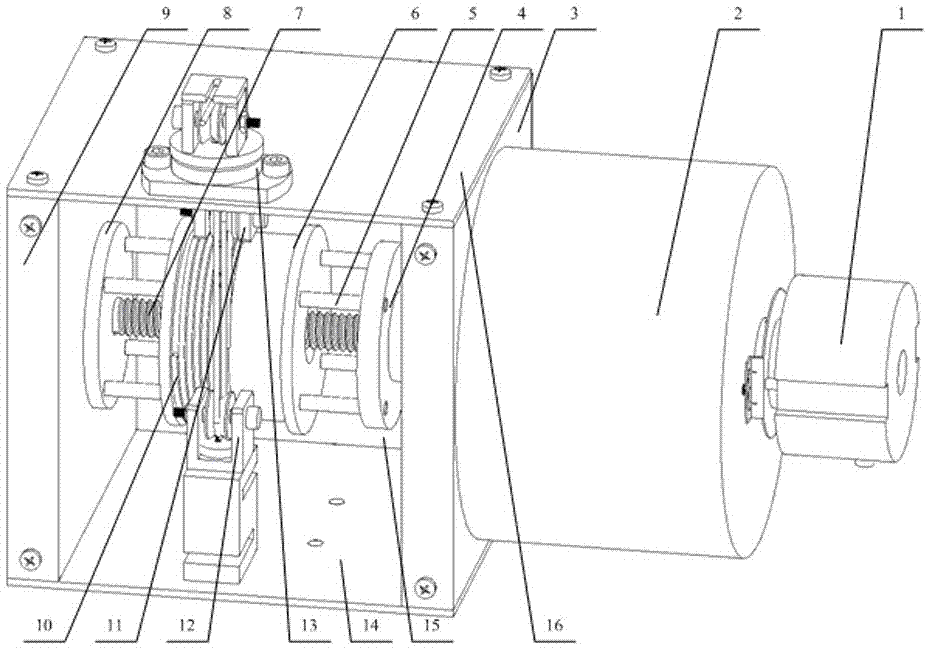

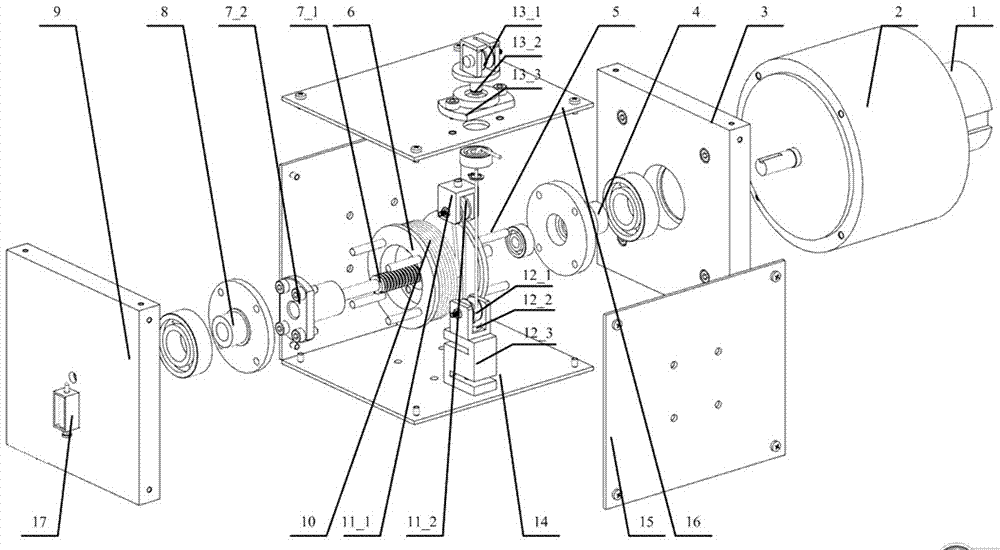

[0037] Refer to attached figure 1 , 2 and 3, the present invention provides a kind of flexible cable driving device with automatic rowing and force measuring function, its technical scheme is to include photoelectric encoder 1, permanent magnet DC torque motor 2, front bracket 3, driving flange 4, Cylindrical guide rail 5, roller 6, ball screw 7, support flange 8, rear bracket 9, flexible cable 10, U groove guide mechanism 11, force measuring guide mechanism 12, turnover guide mechanism 13, bottom plate 14, side plate 15, top plate 16 and locker 17;

[0038] The permanent magnet DC torque motor 2 is fixedly installed on the front bracket 3, the output shaft of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com