Patents

Literature

63results about How to "To achieve the purpose of optimization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Intelligent automobile path tracking hybrid control method

ActiveCN109318905AIssues with Harmonizing Lateral Control Performance RequirementsImprove ease of implementationControl devicesLow speedDynamic models

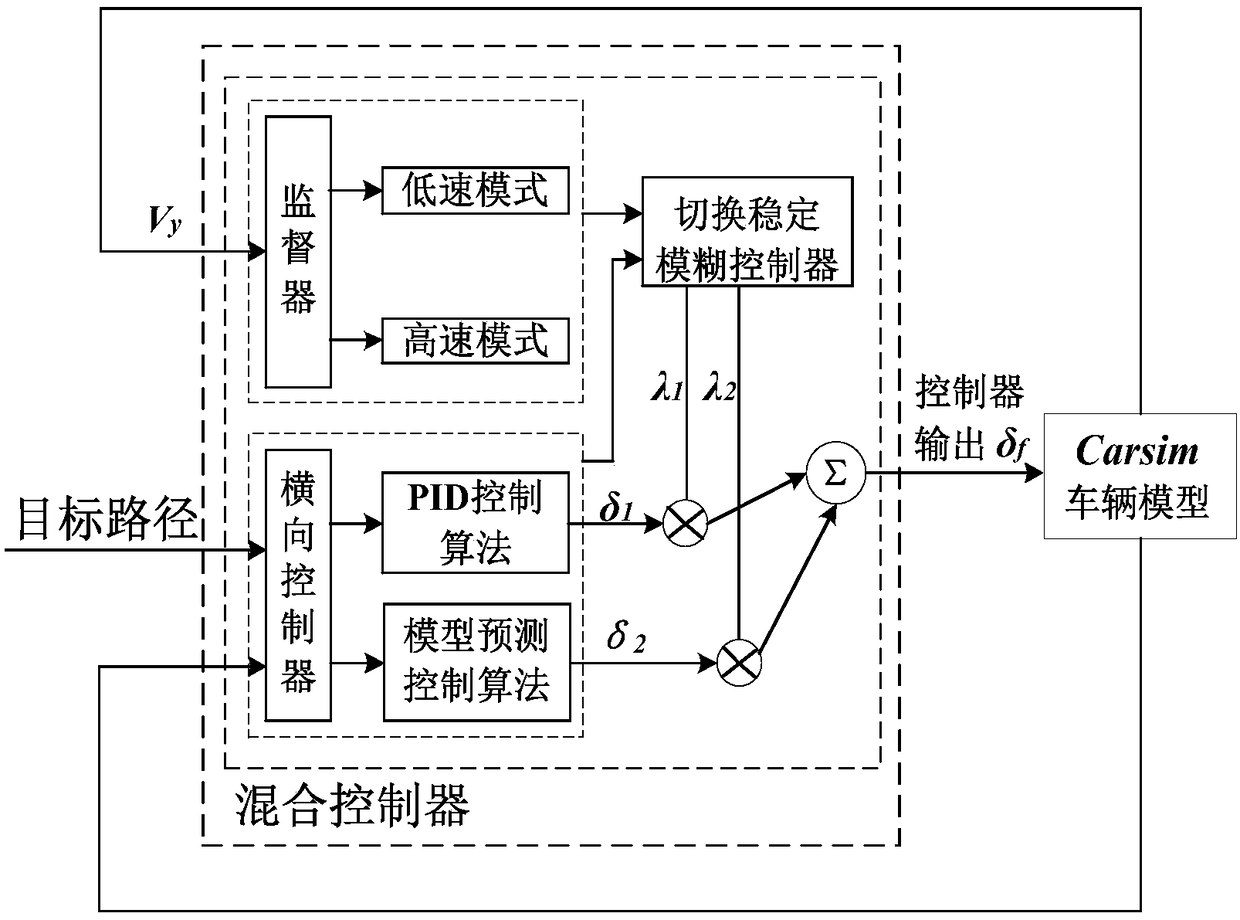

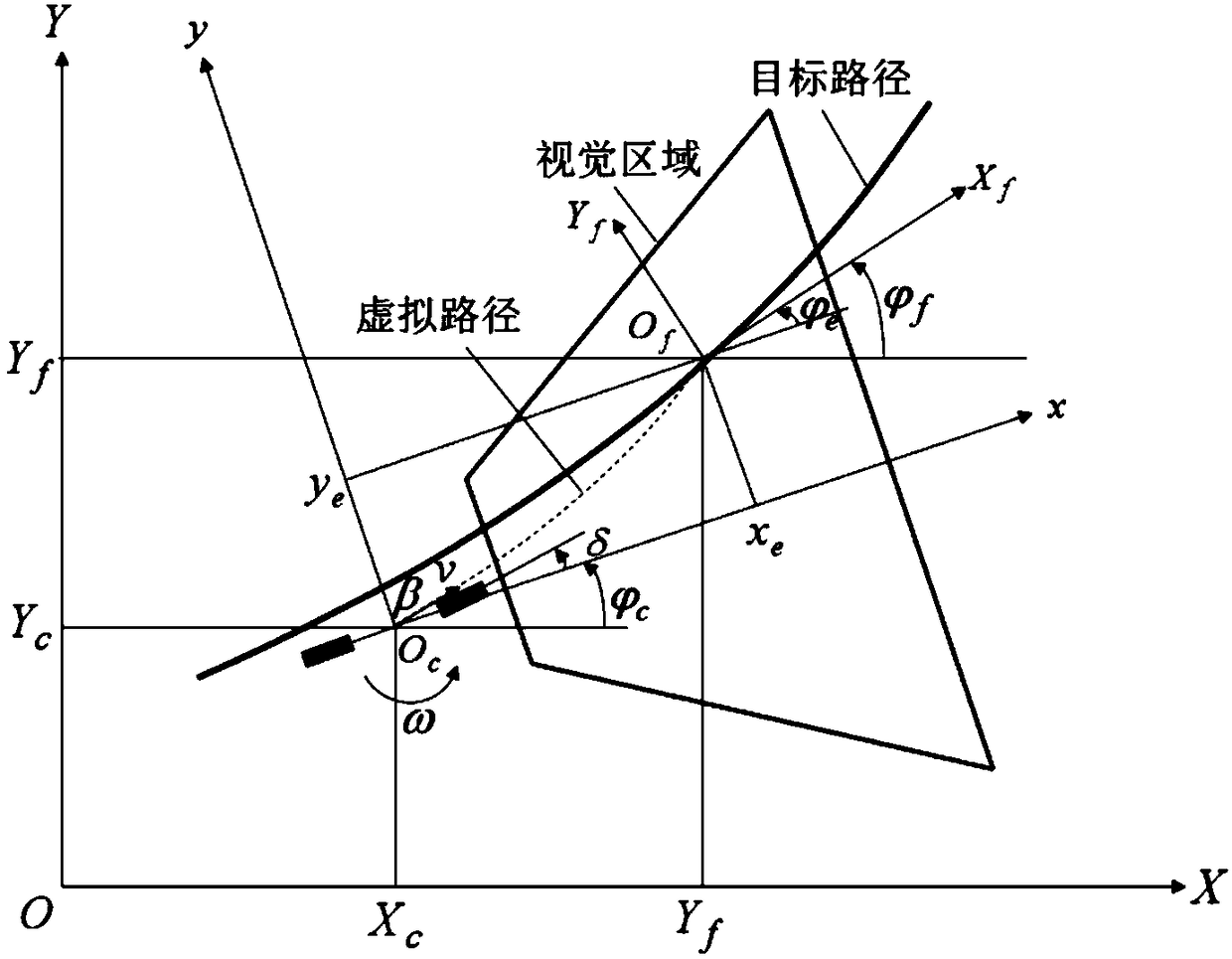

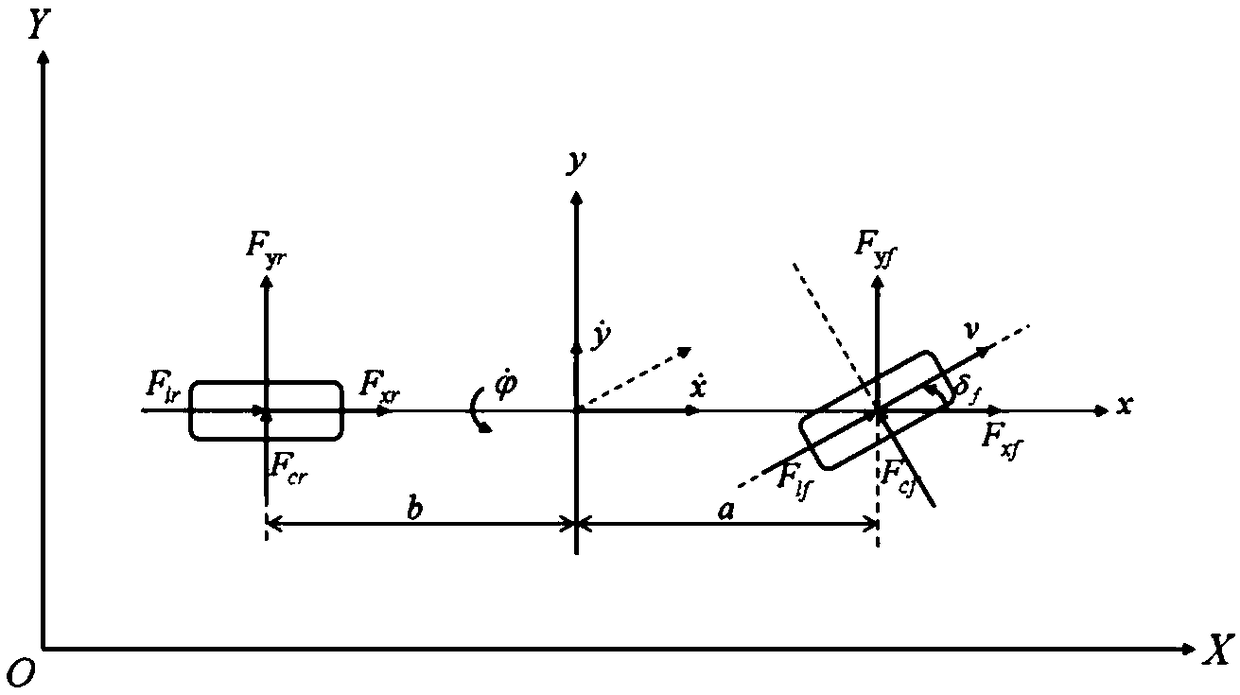

The invention discloses an intelligent automobile path tracking hybrid control method, and belongs to the technical field of intelligent automobile lateral control. The intelligent automobile path tracking hybrid control method comprises the following steps that step 1, an automobile lateral control preview kinematics model at a low speed is established; step 2, an automobile lateral control dynamic model at a high speed is established; and step 3, a path tracking hybrid controller is designed, the path tracking hybrid controller comprises a lateral controller, a supervisor and a switching stability fuzzy controller, wherein the lateral controller is designed based on PID control and model predictive control, the supervisor determines a tracking mode based on longitudinal vehicle speed, and the switching stability fuzzy controller is designed based on a fuzzy control theory. The intelligent automobile path tracking hybrid control method effectively solves the problem of lateral controlperformance requirements under high-speed and low-speed working conditions of an intelligent automobile, and the easy realization, accuracy and stability of path tracking of the intelligent automobile are improved.

Owner:JIANGSU UNIV

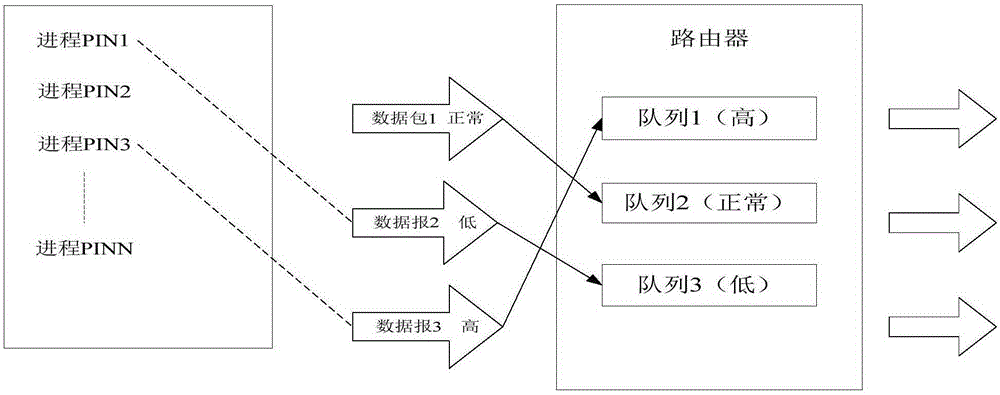

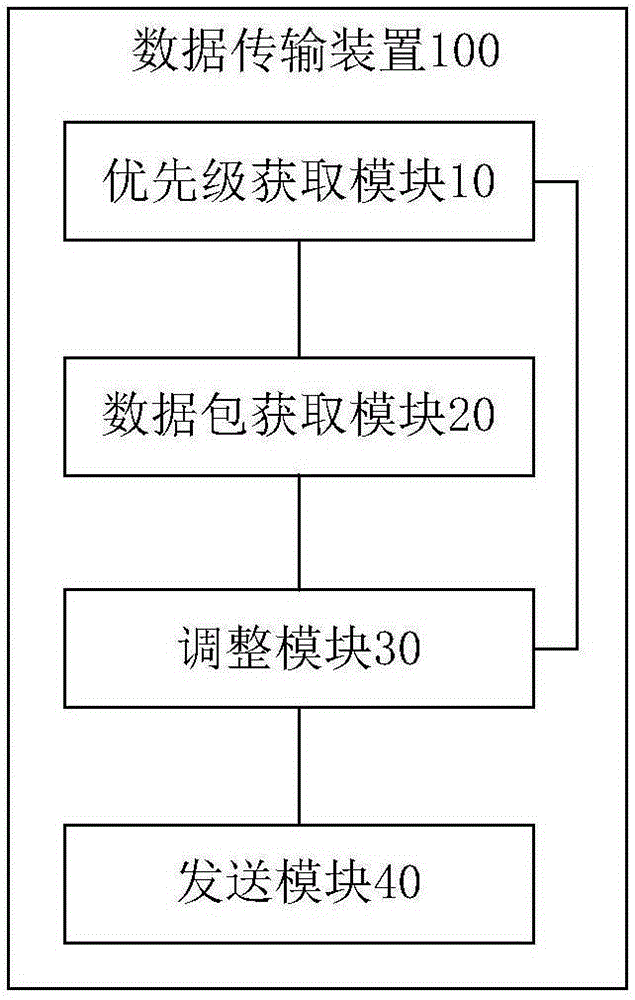

Data transmission method, device and system

ActiveCN105245469AImprove stabilityImprove optimization effectData switching networksPacket lossBroadband

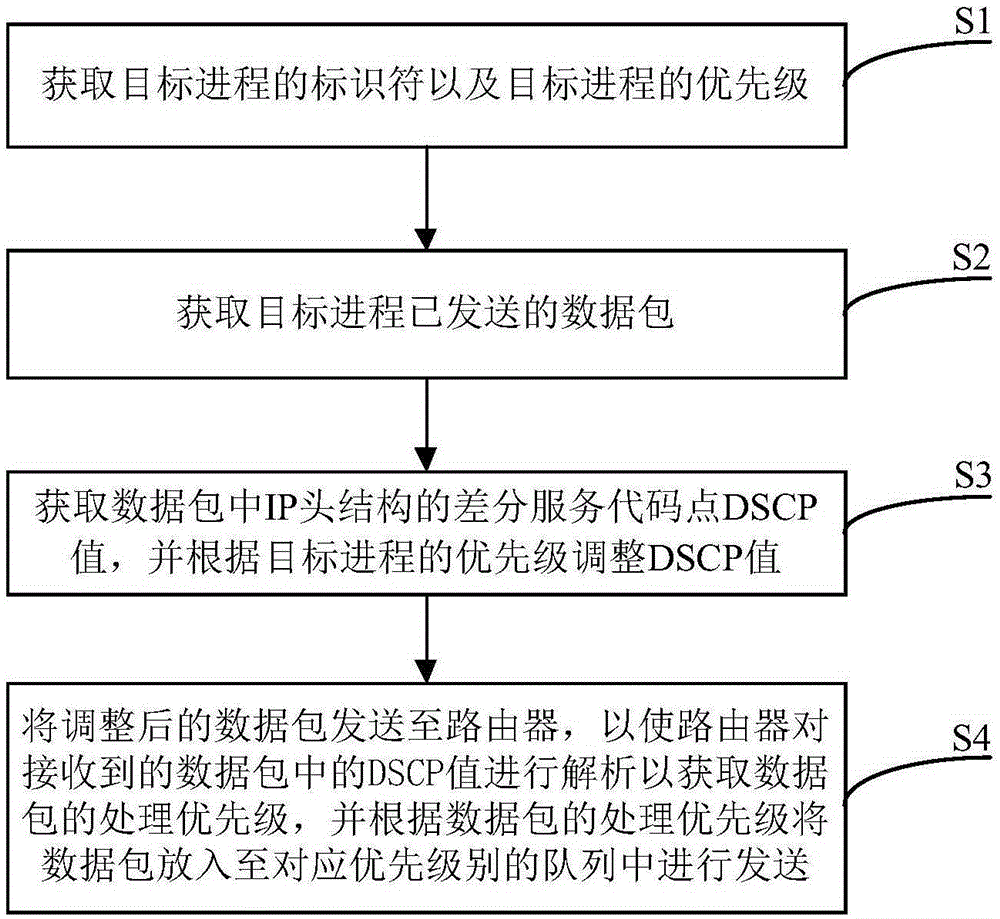

The invention discloses a data transmission method, device and system. The method comprises that an identifier and the priority of a target process are obtained; a data packet which is transmitted in the target process is obtained; the DSCP value of an IP header structure in the data packet is obtained and adjusted according to the priority of the target process; and the adjusted data packet is sent to a router so that the router optimizes the data packet according to the processing priority of the received data packet. According to the method, the processing priority of the data packet is adjusted by modifying the DSCP value of the IP header structure of the data packet, the router implements optimization according to the adjusted processing priority of the data packet, network data is optimized, packet loss processing is not needed in data packet upload and download in unit time, the data packets are prevented from loss, the present network stability and broadband utilization rate are improved, and the data optimization effect is improved.

Owner:珠海豹好玩科技有限公司

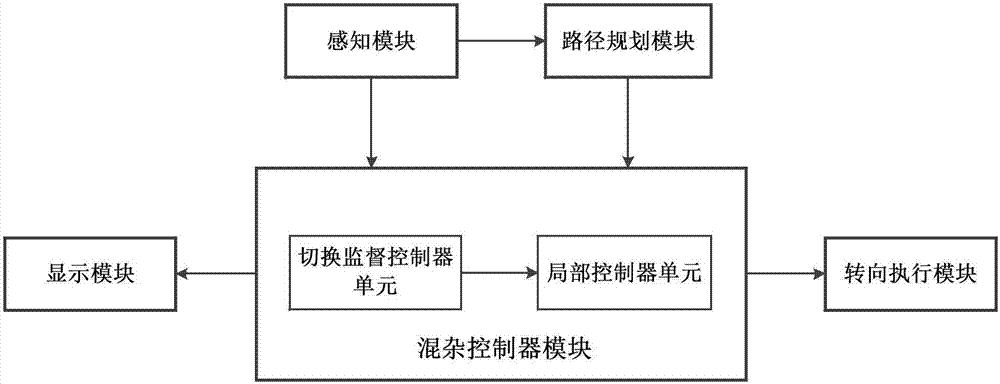

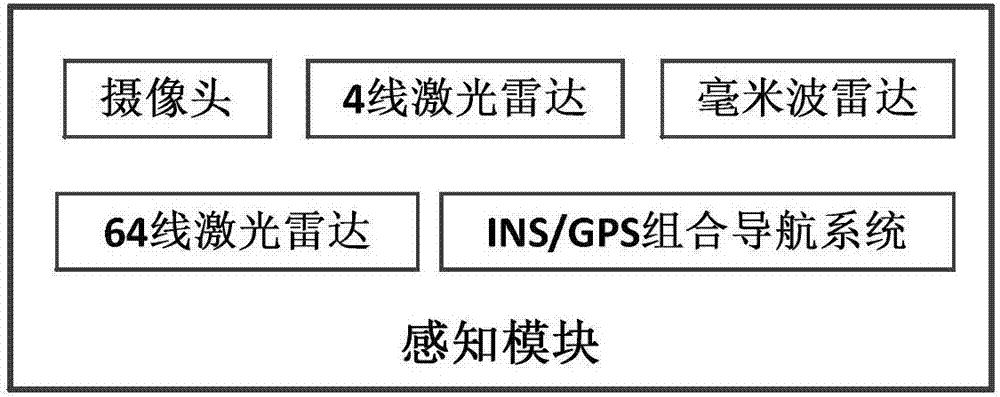

Traversal control system and method of driverless automobile based on hybrid theory

ActiveCN107139917AGuaranteed stabilityImplementation complexityExternal condition input parametersAutomatic steeringControl system

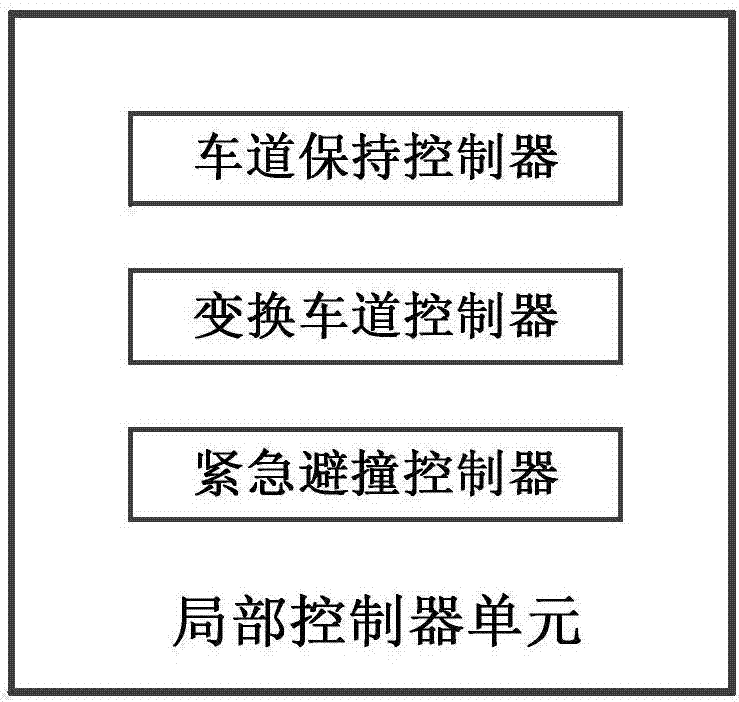

The invention discloses a traversal control system and method of a driverless automobile based on a hybrid theory. The system comprises a sensing module, a path planning module, a hybrid controller module, a steering executing module and a display module. The sensing module is used for acquiring the vehicle travelling environment and the vehicle operating state; the path planning module is used for planning a path based on the absolute position of a vehicle in a map and the position of the vehicle relative to peripheral obstacles and a lane line; the hybrid controller module comprises a local controller unit and a switching monitoring controller unit; the local controller unit designs a controller meeting a target for working conditions of lane-keeping, lane conversion and emergent collision avoidance; the switching monitoring controller unit driven by different discrete events drives effective mode switching, so that the switching stability is guaranteed; the steering executing module drives a steering motor according to a signal of the hybrid controller so as to realize automatic steering of the driverless automobile; and the display module is used for displaying sensing information, path planning information and control mode information.

Owner:JIANGSU UNIV

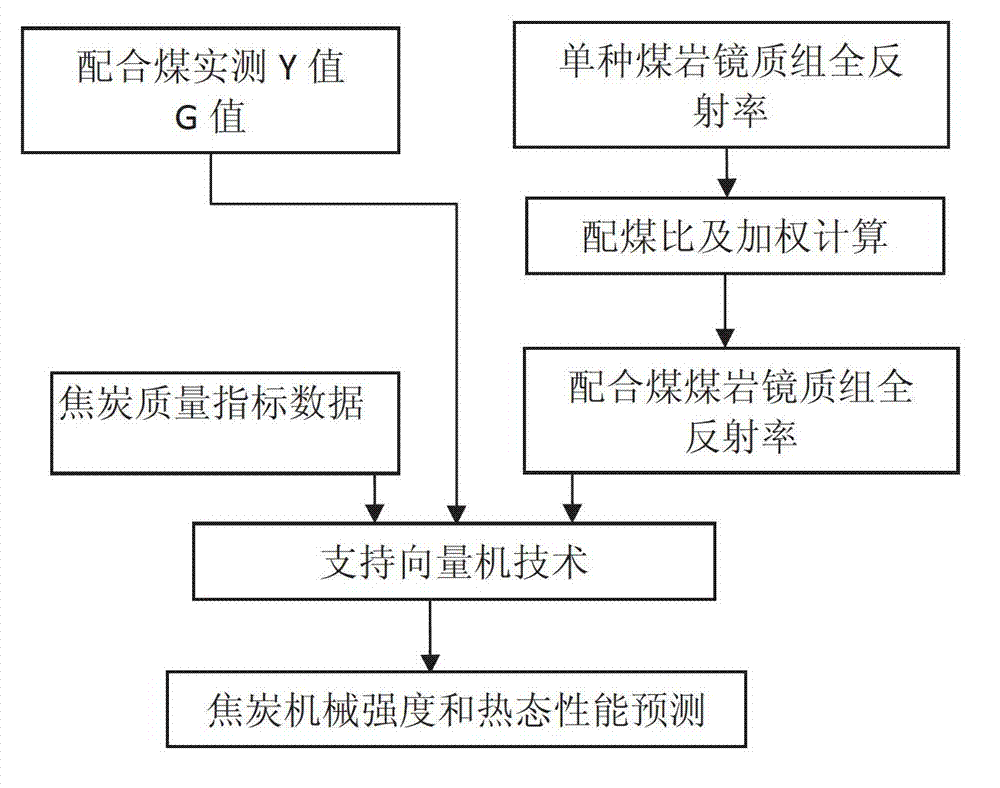

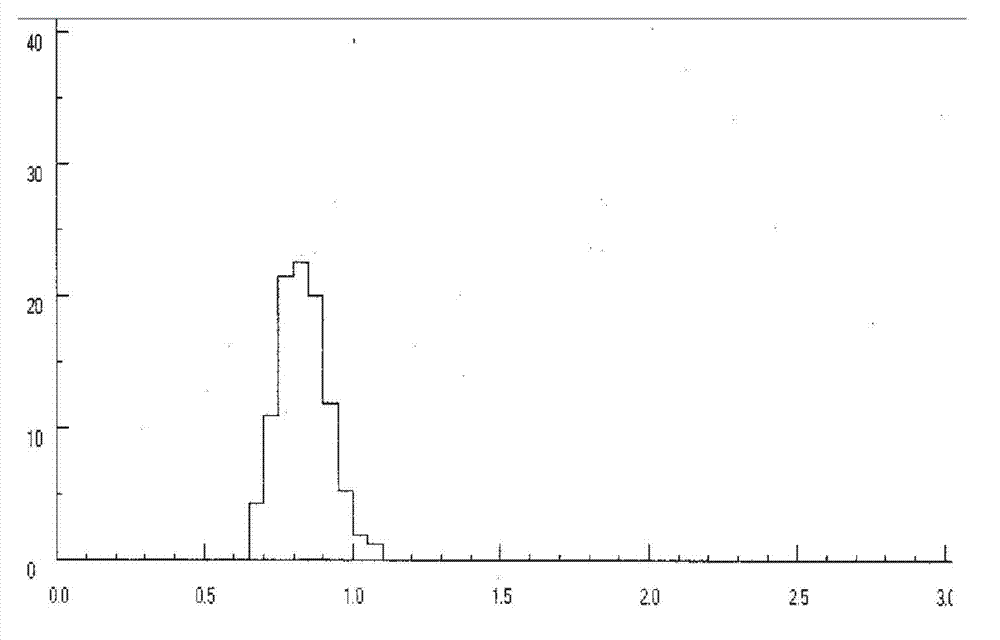

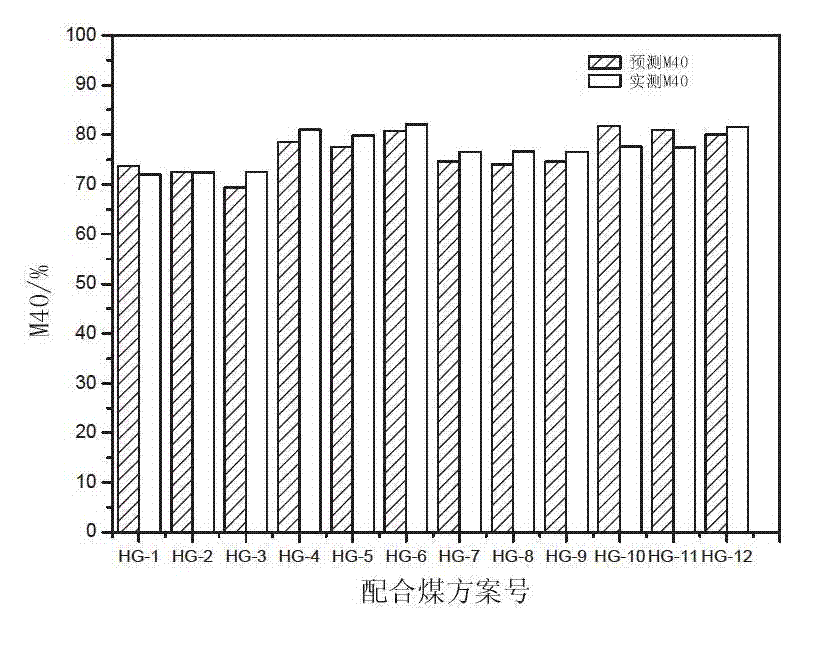

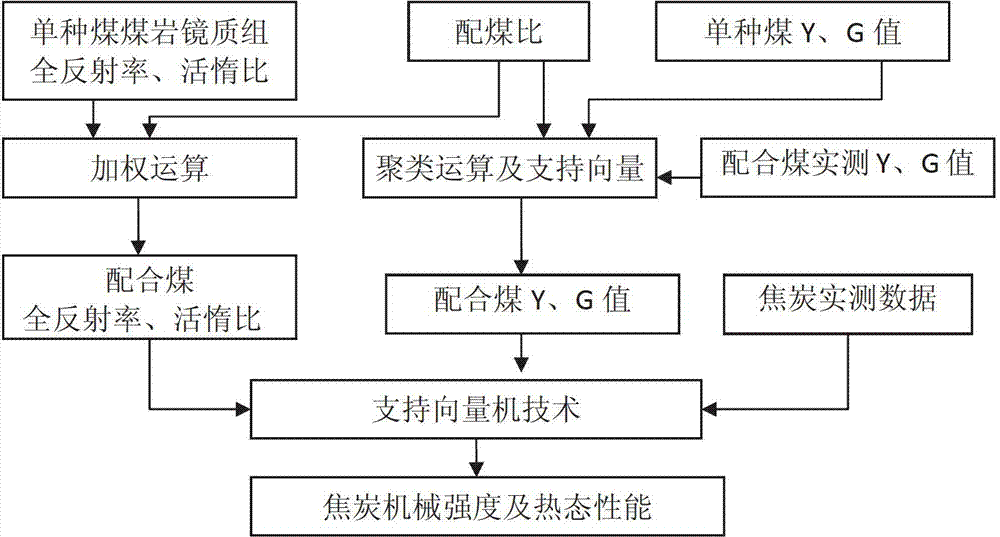

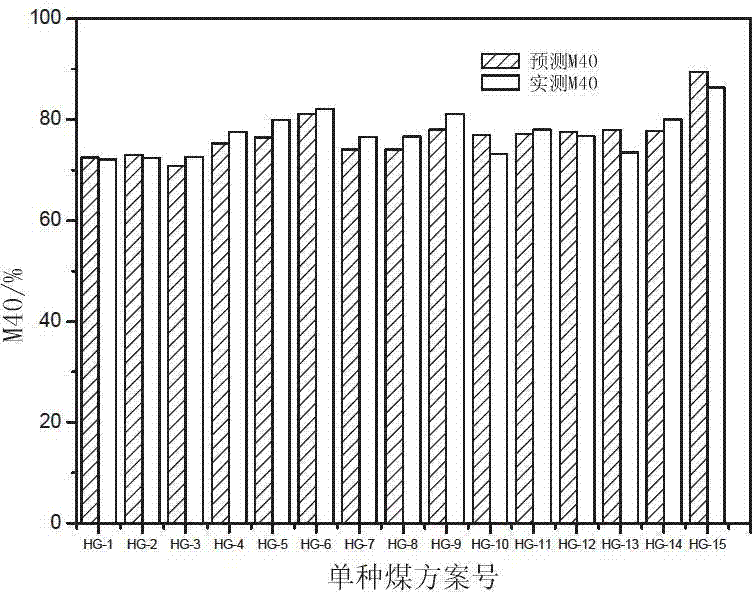

Method for predicting coke quality through nonlinear optimization coal blending based on coal rock vitrinite total reflectance

ActiveCN102890144AMultiple Intrinsic Indicator ParametersThe prediction method is practicalFuel testingSupport vector machineThermal state

The invention discloses a method for predicting coke quality through nonlinear optimization coal blending based on coal rock vitrinite total reflectance, thereby providing important technical assurance for the improvement of the stability and quality of coke produced by a coke making enterprise. The method provided by the invention comprises the following steps of: establishing a coking coal resource information database, and inputting the caking property index of coking blended coal and the coal rock index of single coking coal into the coking coal resource information database; and establishing a coke quality prediction model through a support vector machine, and then predicting the quality index of the coke according to the coal-quality caking property index level of the coking blended coal, wherein the coal-quality caking property index level comprises two factors, namely the maximum thickness value Y of a gelatinous layer and a caking index value G, and comprises coal rock vitrinite total-component reflectance and the liver-inert ratio of macerals. The method provided by the invention is capable of characterizing the maximum thickness value Y of the gelatinous layer indicating the quantity of metaplast in the softening process of the coking coal and indicating the caking property quality of the metaplast, thereby realizing the prediction process with the goal of predicting the mechanical strength and thermal state performance of the coke.

Owner:UNIV OF SCI & TECH LIAONING

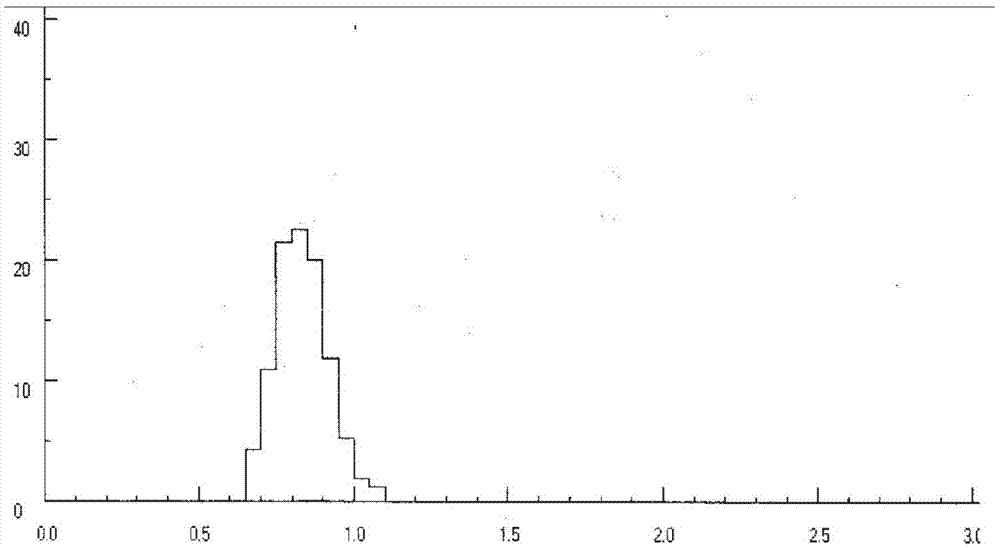

Method for performing nonlinear prediction on coke quality on basis of cohesiveness and coal-rock indexes of single coal

ActiveCN102890145AMultiple Intrinsic Indicator ParametersThe prediction method is practicalFuel testingSupport vector machineAir quality index

The invention discloses a method for performing nonlinear prediction on coke quality on the basis of cohesiveness and coal-rock indexes of single coal, which provides important technical guarantee for improving the stability and quality of coke produced by coke making enterprises. The method comprises the following steps of: establishing an information database storing qualities and coke quality indexes of the single coal for coking, and inputting the cohesiveness indexes and the coal-rock indexes of the single coal for coking into the coal information database; establishing a coal quality prediction model, and predicting quality indexes of matched coal by virtue of a clustering and support vector machine; defining the quality indexes of the matched coal, and predicting quality indexes of the coke according to the quality indexes of the single coal; and establishing a model for predicting the crushing strength and abrasive resistance of the coke. The invention further provides a coke quality prediction system with optimized coal blending of coal-rock, which aims to stabilize and improve the coke quality and reduce the coal blending cost, can form a prediction model with multiple parameters and high accuracy for the coal quality indexes and the coke quality indexes, and simultaneously, has a real-time updating function or a manual intervention function.

Owner:UNIV OF SCI & TECH LIAONING

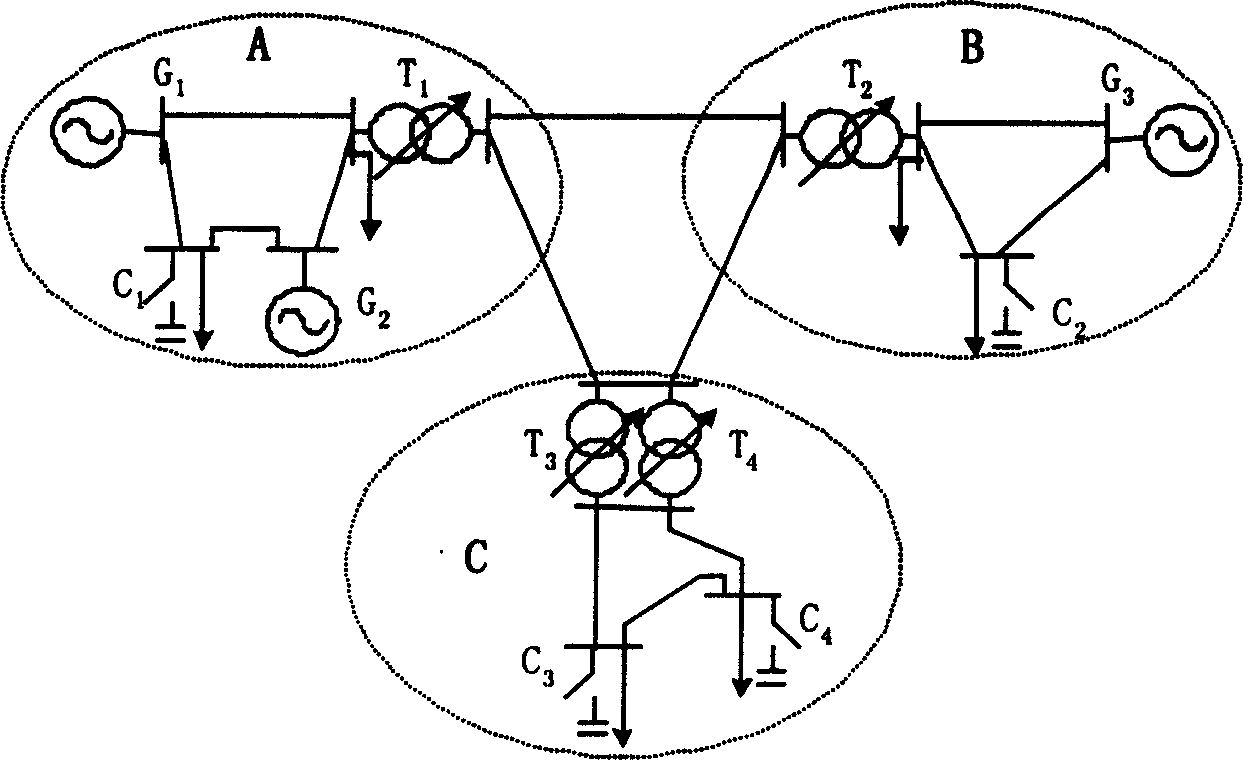

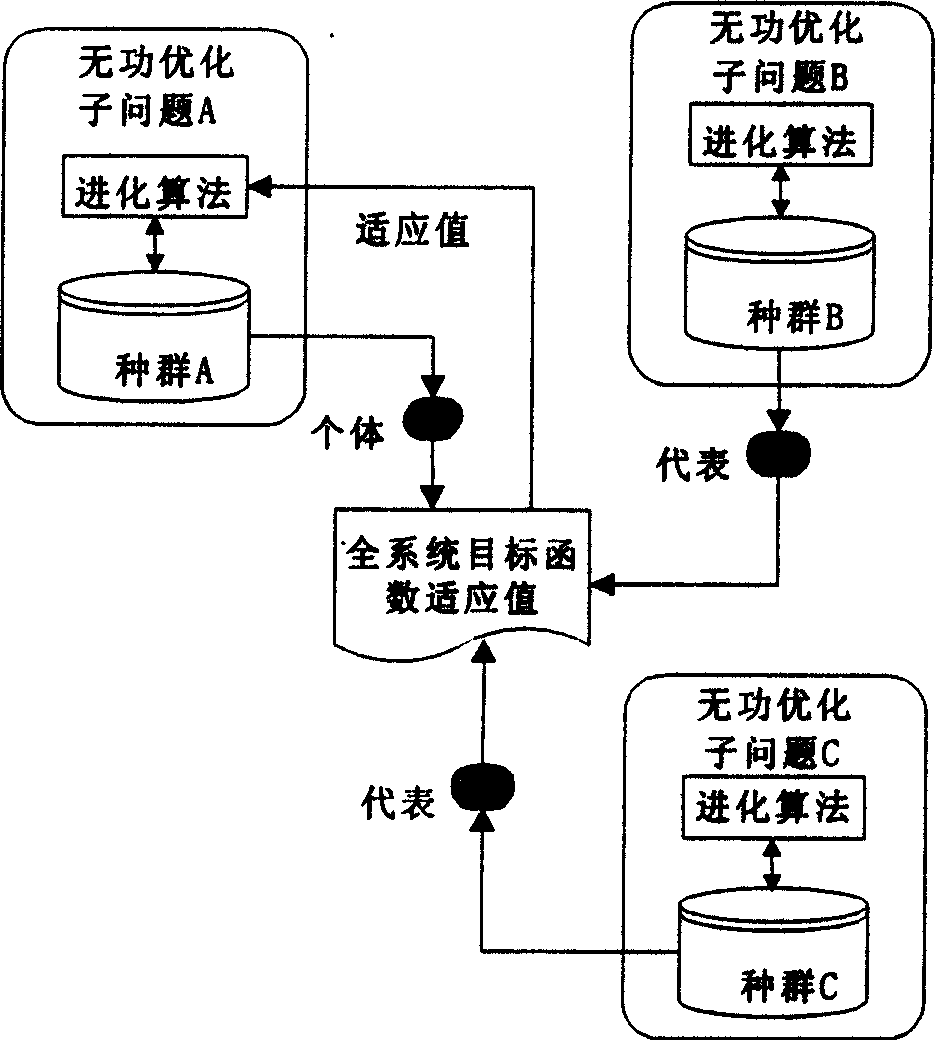

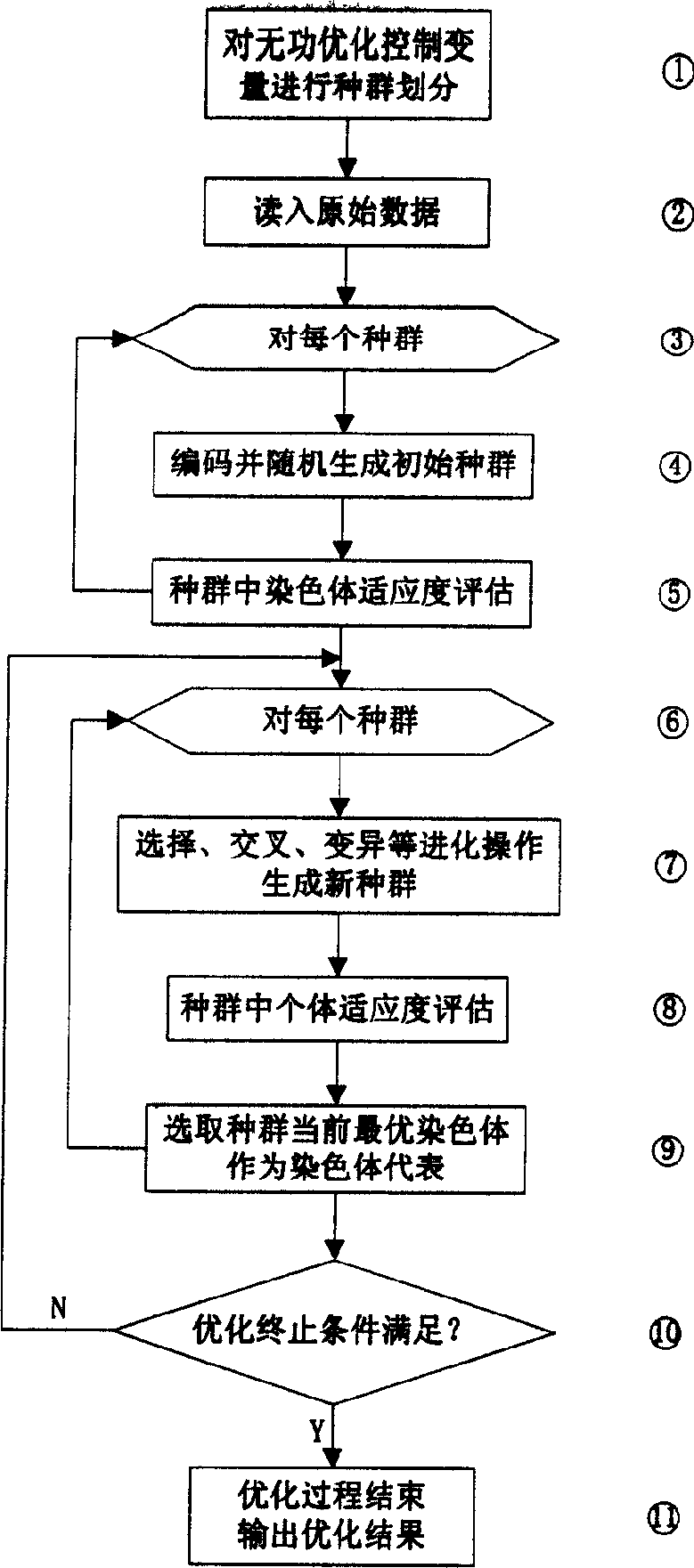

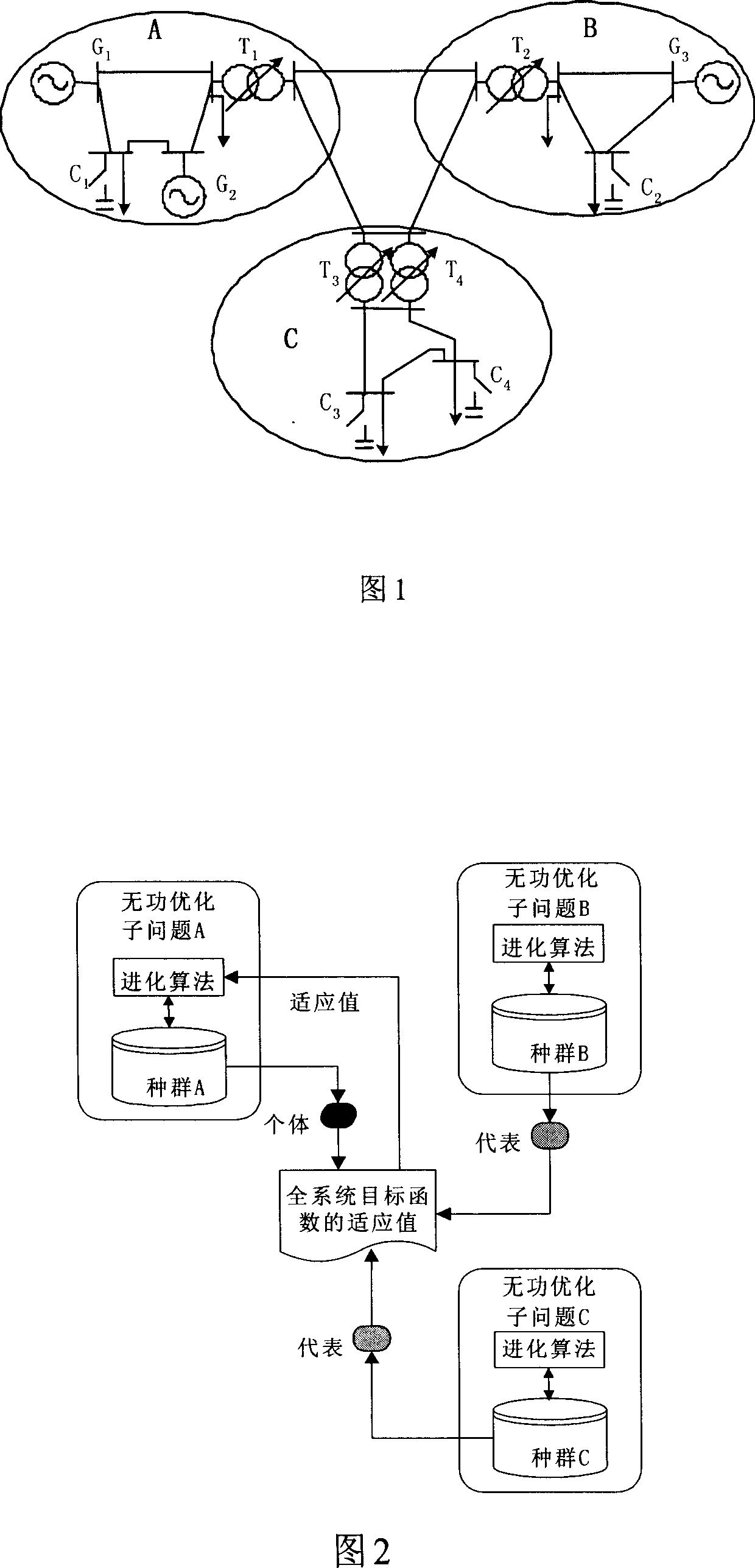

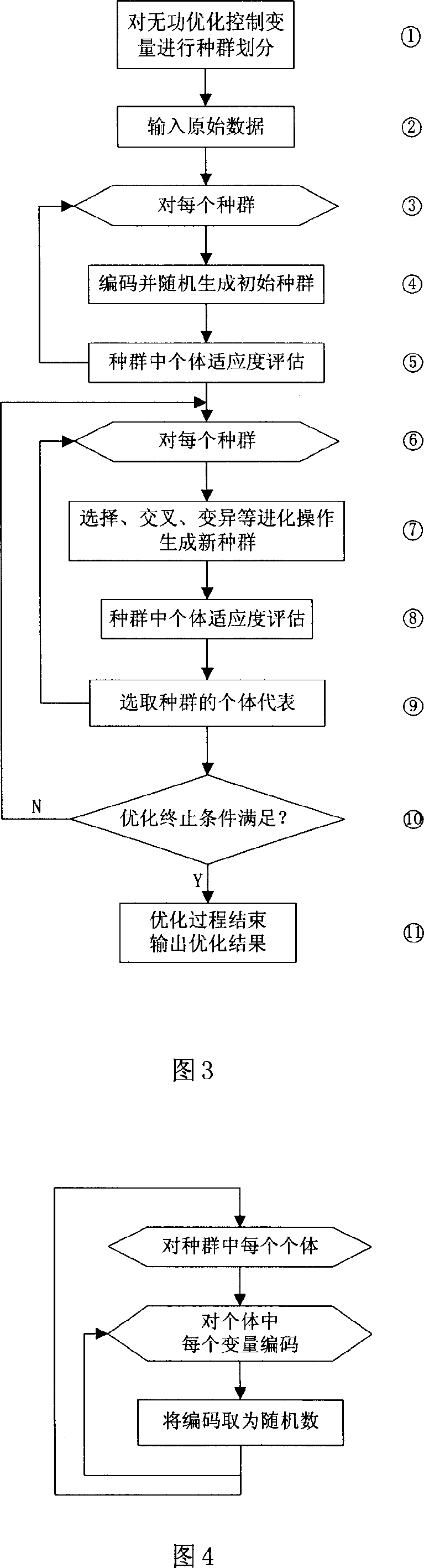

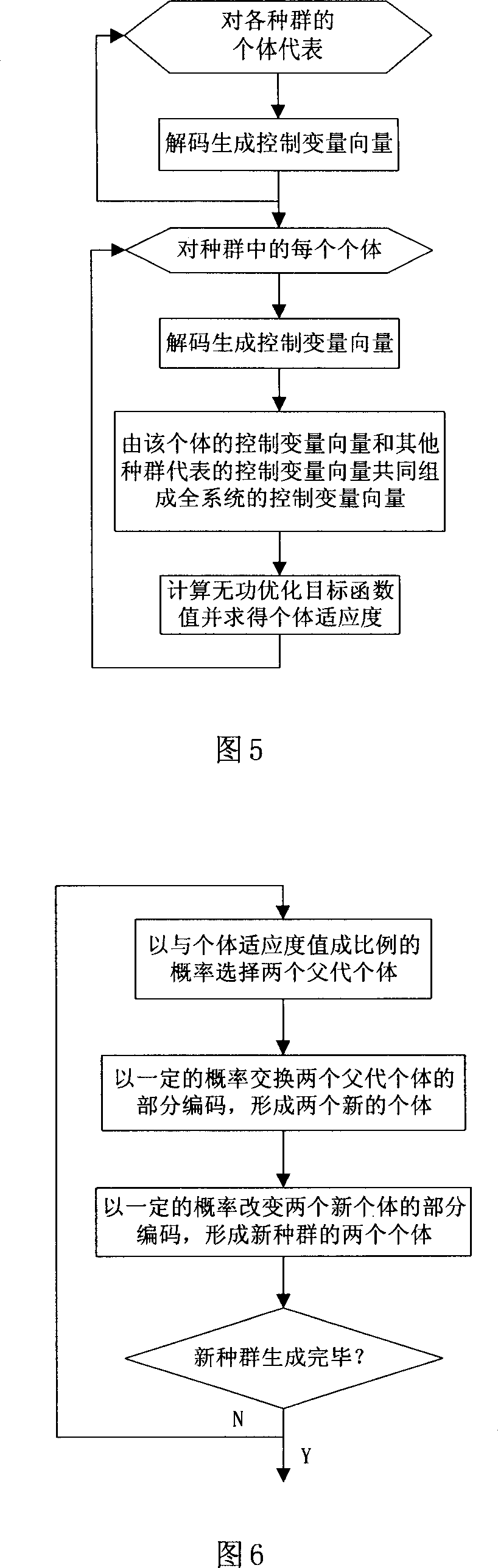

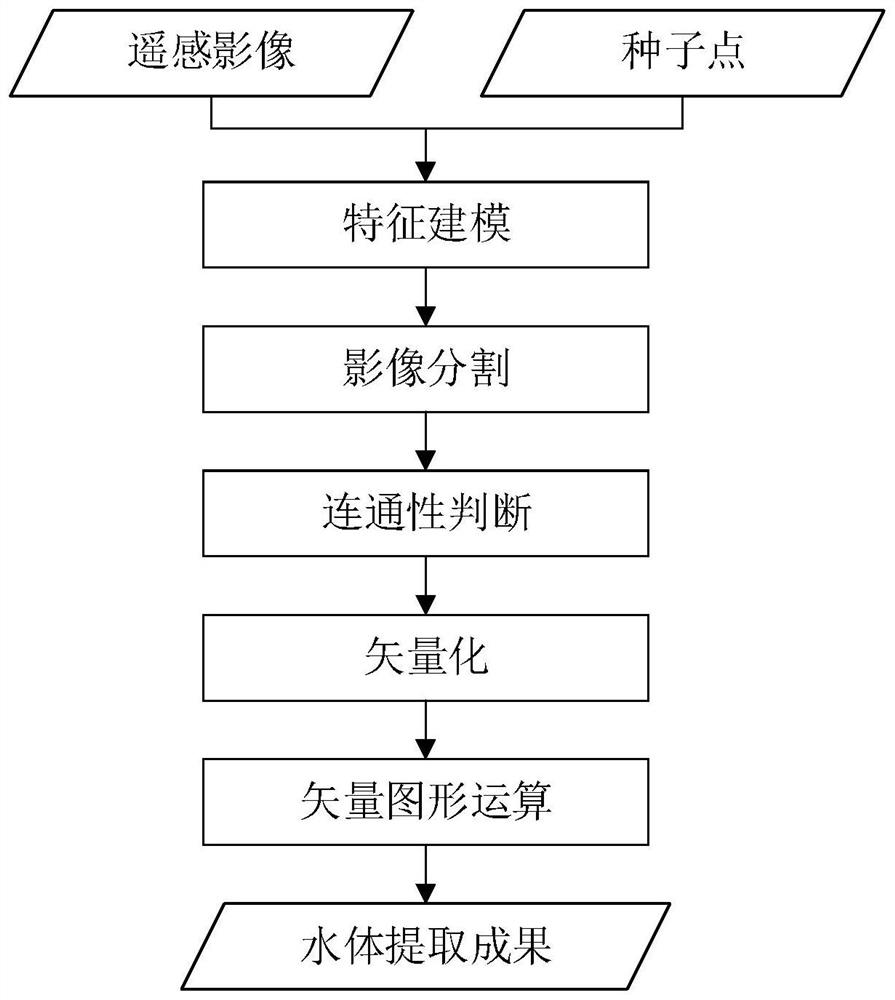

Reactive optimizing method of power system based on coordinate evolution

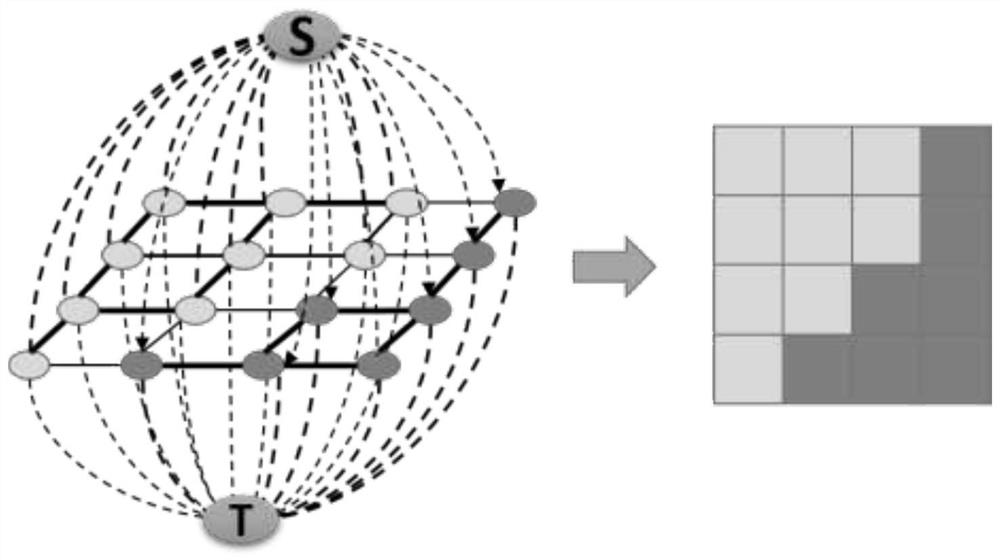

InactiveCN1564416ATo achieve the purpose of optimizationReactive power adjustment/elimination/compensationReactive power compensationElectric power systemOriginal data

The method includes following steps: dividing control variables (as plant or animal communities) for system reactive optimization into several groups, and each variable is corresponding to a flock in coevolution method; inputting original data, initializing each flock, calculating adaptation function value of each chromosome in initial flocks; based on previous generation, generating new generation through genetics operations of selection, chiasma, variation; calculating adaptation function value fro new generation; selecting optimum chromosome; evolutionary optimization of ecosystem is completed after optimizing each flock; determining whether condition of convergence of genetic algorithm is met, and outputting optimized result. In the invention, problem to be solved is mapped to ecosystem including multiple flocks. Coevolution of interactive flocks makes optimization of system.

Owner:XI AN JIAOTONG UNIV

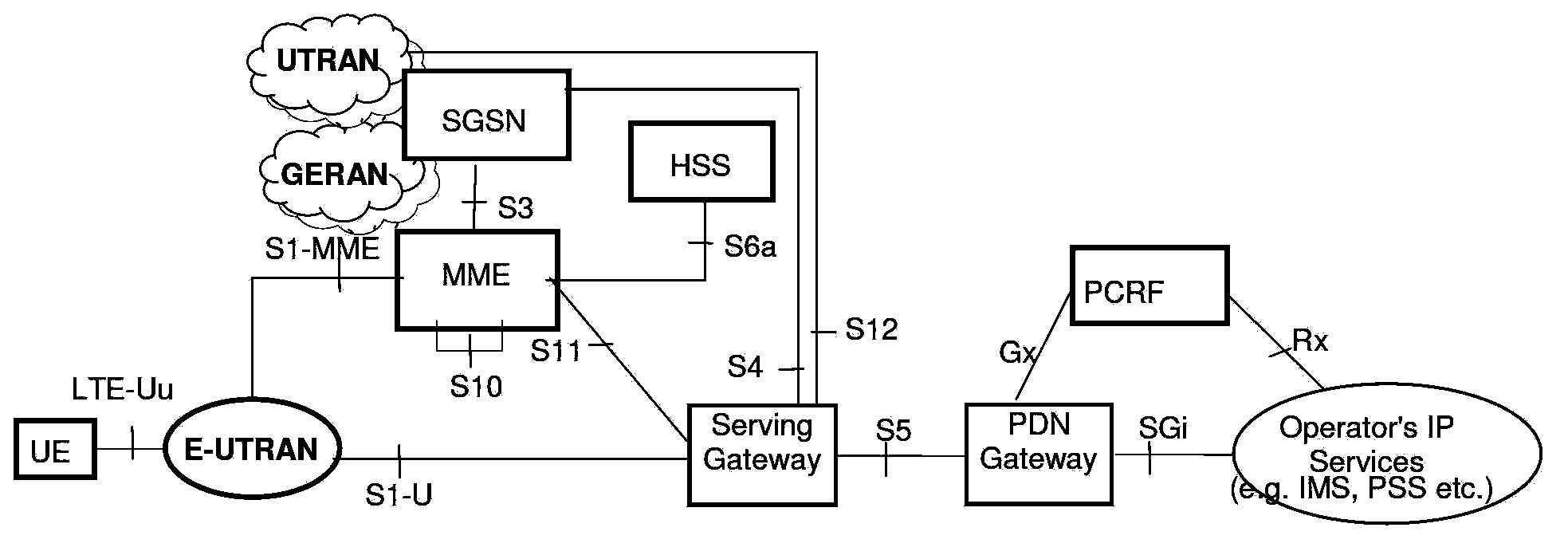

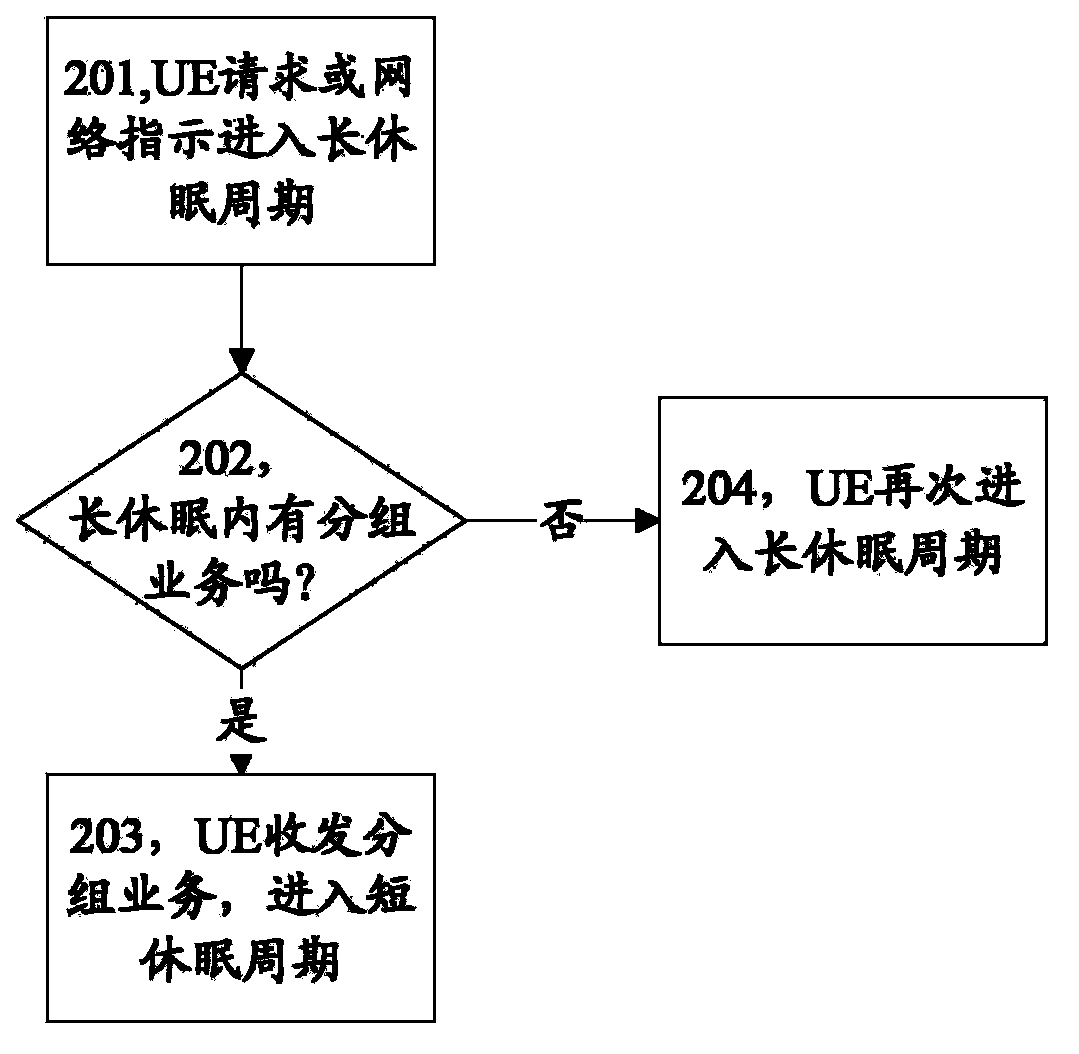

Electric energy optimization method and system

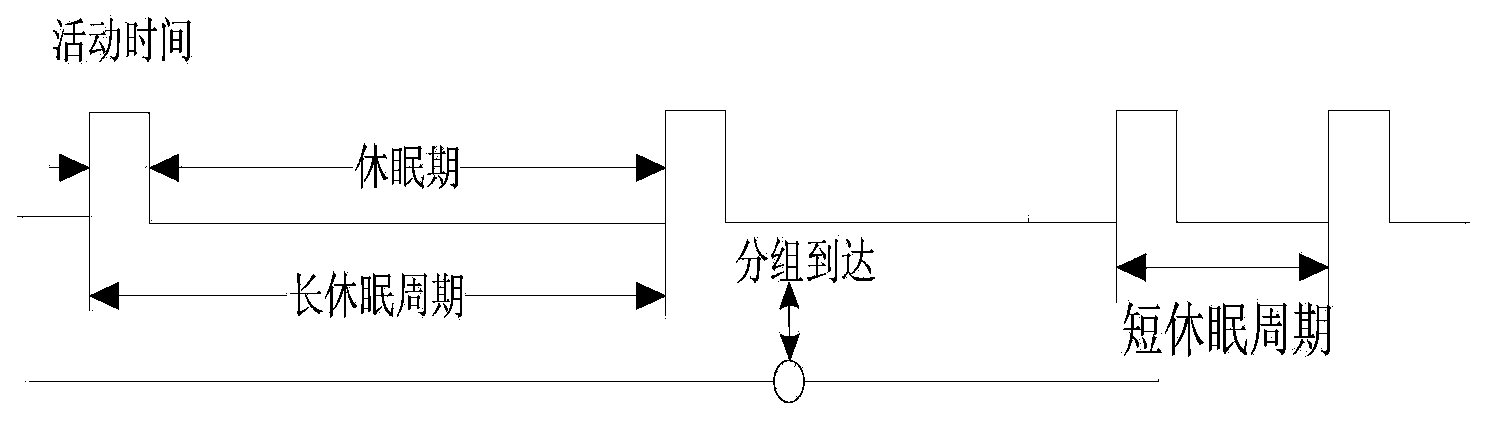

ActiveCN103686955AReduce power consumptionReduce signaling interactionEnergy efficient ICTPower managementTelecommunicationsTime delays

Owner:ZTE CORP

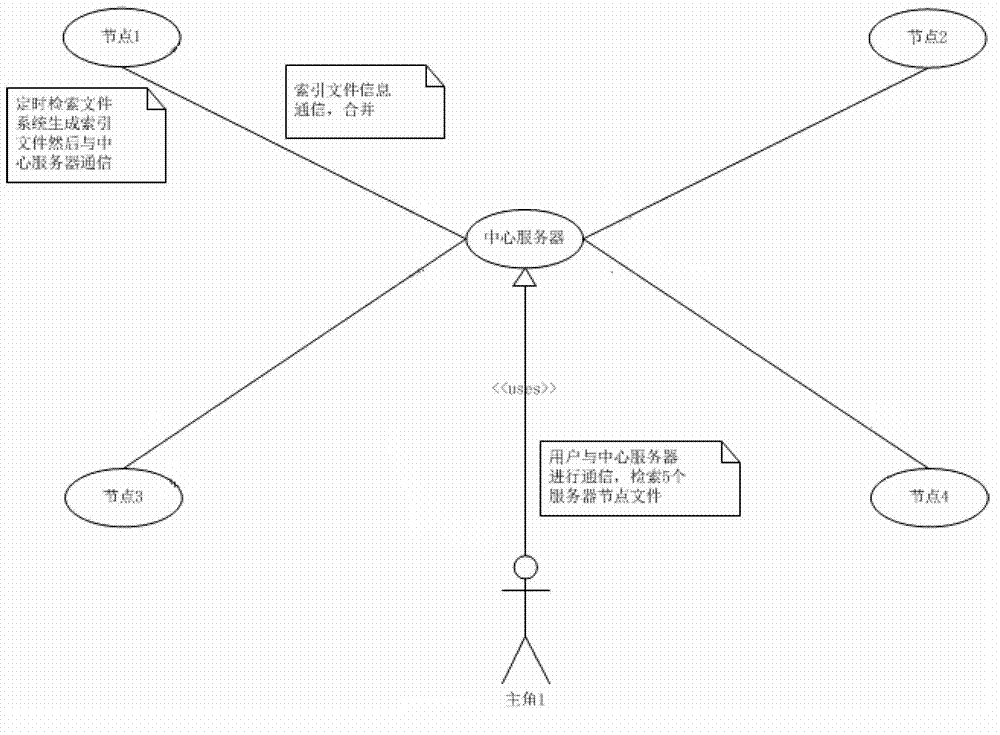

Distributed full-text retrieval system

InactiveCN102831253AImprove retrieval speedImprove stabilitySpecial data processing applicationsText retrievalLexicon

The invention belongs to the field of data processing and in particular relates to a distributed full-text retrieval system. The system consists of full-text retrieval servers comprising a distributed node server and a system center server which are arranged on each network node, wherein the distributed node server comprises a file information retrieval module and a server communication module; the file information retrieval module retrieves the full-text information of the file on the node server, segments words according to a defined lexicon, extracts the keyword information and establishes an index file; the server communication module realizes the information exchange between the distributed node server and the system center server; and the system center server merges the index files transmitted by each node server, provides a query interface for a user and shows the appropriate file which serves as a query result to the user.

Owner:BEIJING KEDONG ELECTRIC POWER CONTROL SYST +1

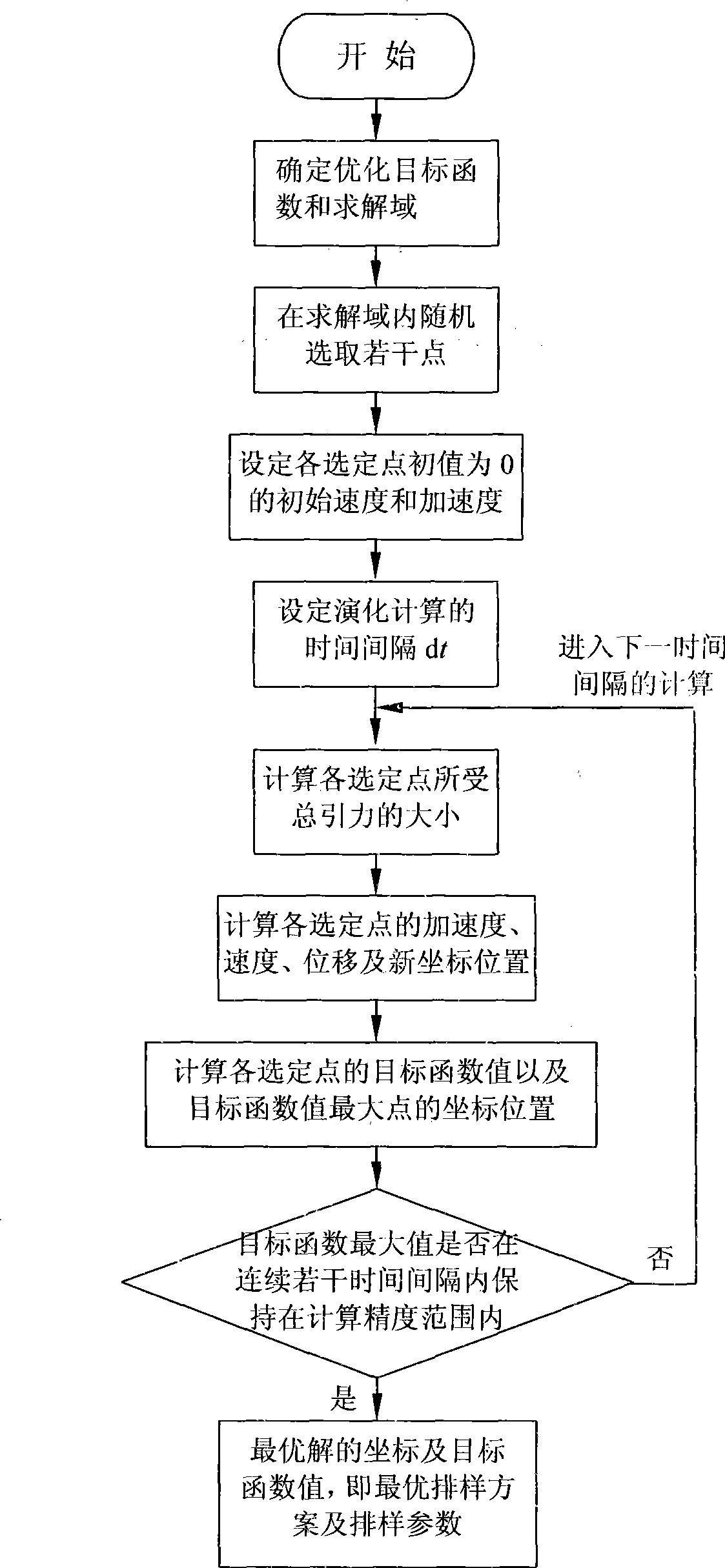

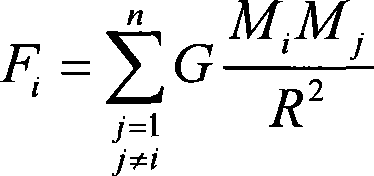

Blanking sample layout optimizing method

InactiveCN101441678ATo achieve the purpose of optimizationIngenious designSpecial data processing applicationsMassive gravityAlgorithm

The invention discloses a blanking layout optimization method for a blanking process in punch forming, which comprises the following steps: 1) a mathematical model is established according to a blanking part and a layout form, a layout optimization target function and an optimization parameter solution domain are determined, and a target function value is taken as the mass distribution in the solution domain to establish a corresponding gravity field; 2) a plurality of points are randomly selected in the solution domain, and coordinates of the points are layout parameters; 3) the initial speed and the acceleration of the selected points are preset as 0; 4) the time interval dt of the evolutionary computation is set according to the solution domain and the target function; 5) the total gravitation of the selected points is computed; 6) according to the received gravitation, the acceleration, the speed, the displacement and the position of a new coordinate of each selected point are computed; 7) a target function value of each selected point and the coordinate position of a maximum point of the target function value after the coordinate position is updated; 8) whether a maximum value of the target function and a coordinate of the point are maintained within the computational accuracy range in continuous time intervals is judged, and an optimum layout scheme and an optimum layout parameter are obtained if the maximum value of the target function and the coordinate of the point are maintained within the computational accuracy range in continuous time intervals; and 9) if not, the operation returns to the step 5 to continue the next evolutionary computation process until the optimum solution is obtained. The method adopts an evolutionary algorithm of simulating the gravitational contraction to realize the optimization of a blanking layout scheme according to four different layout forms, namely ordinary single layout, ordinary double layout, single opposite layout.

Owner:GUANGDONG UNIV OF TECH

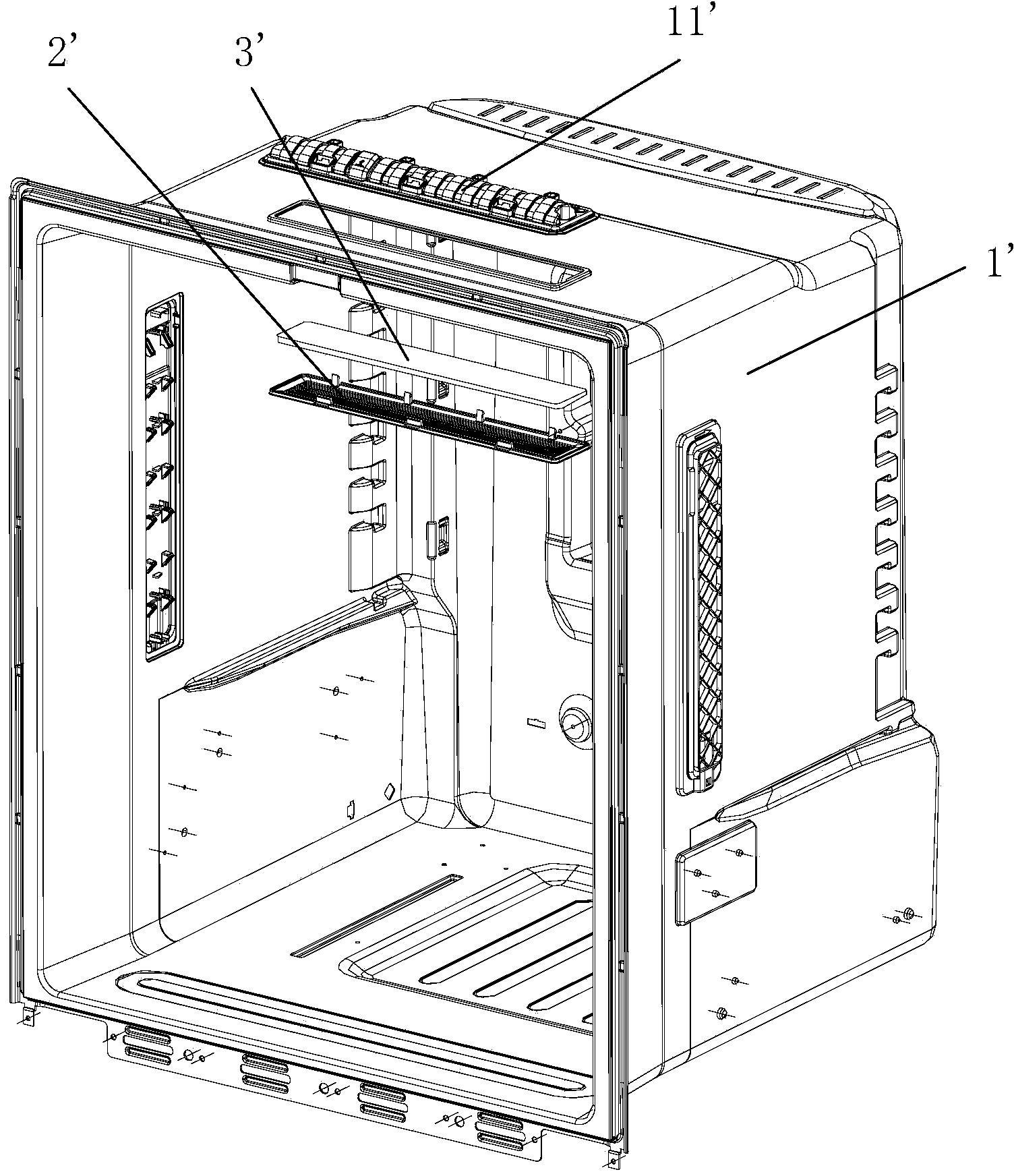

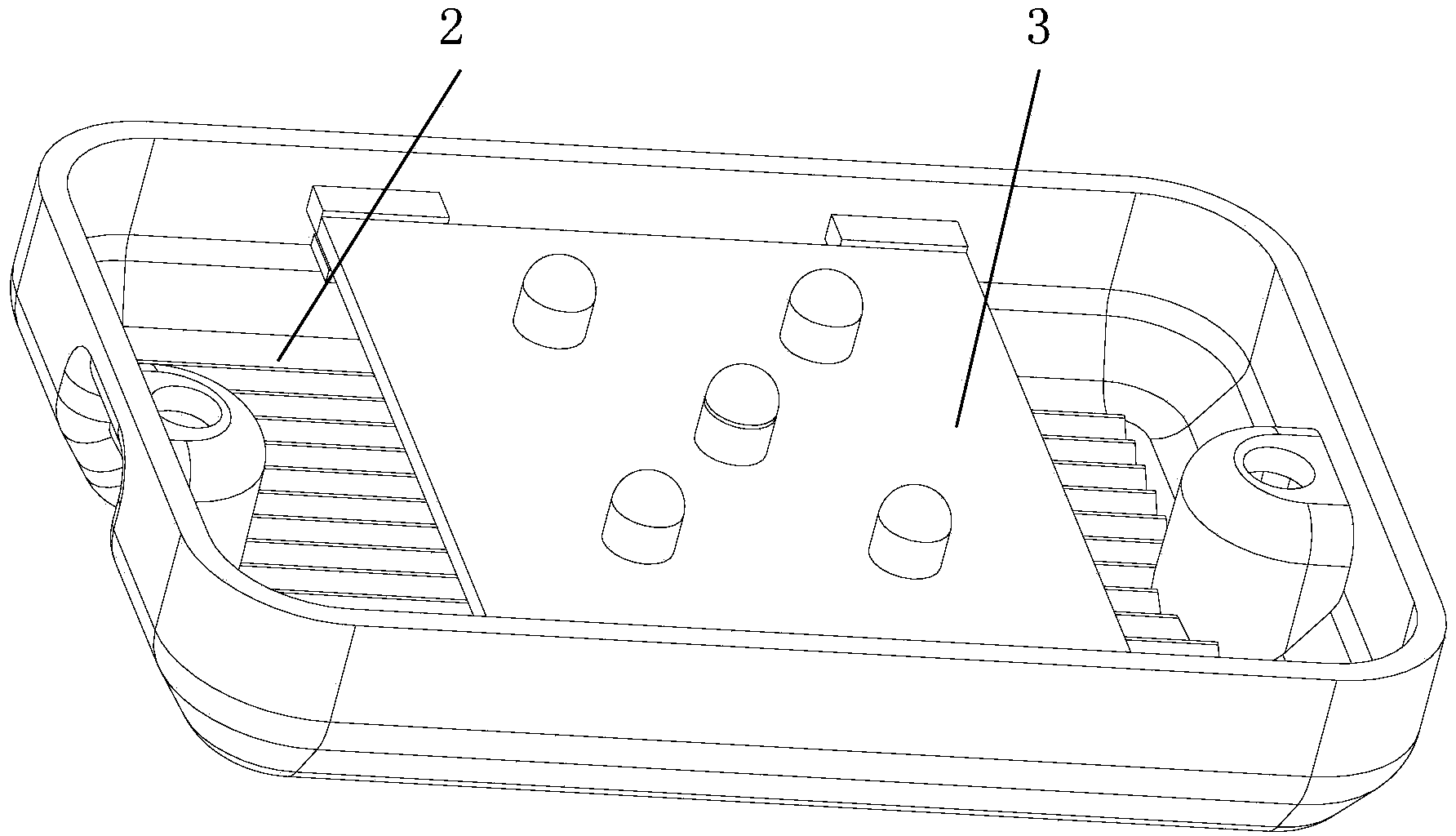

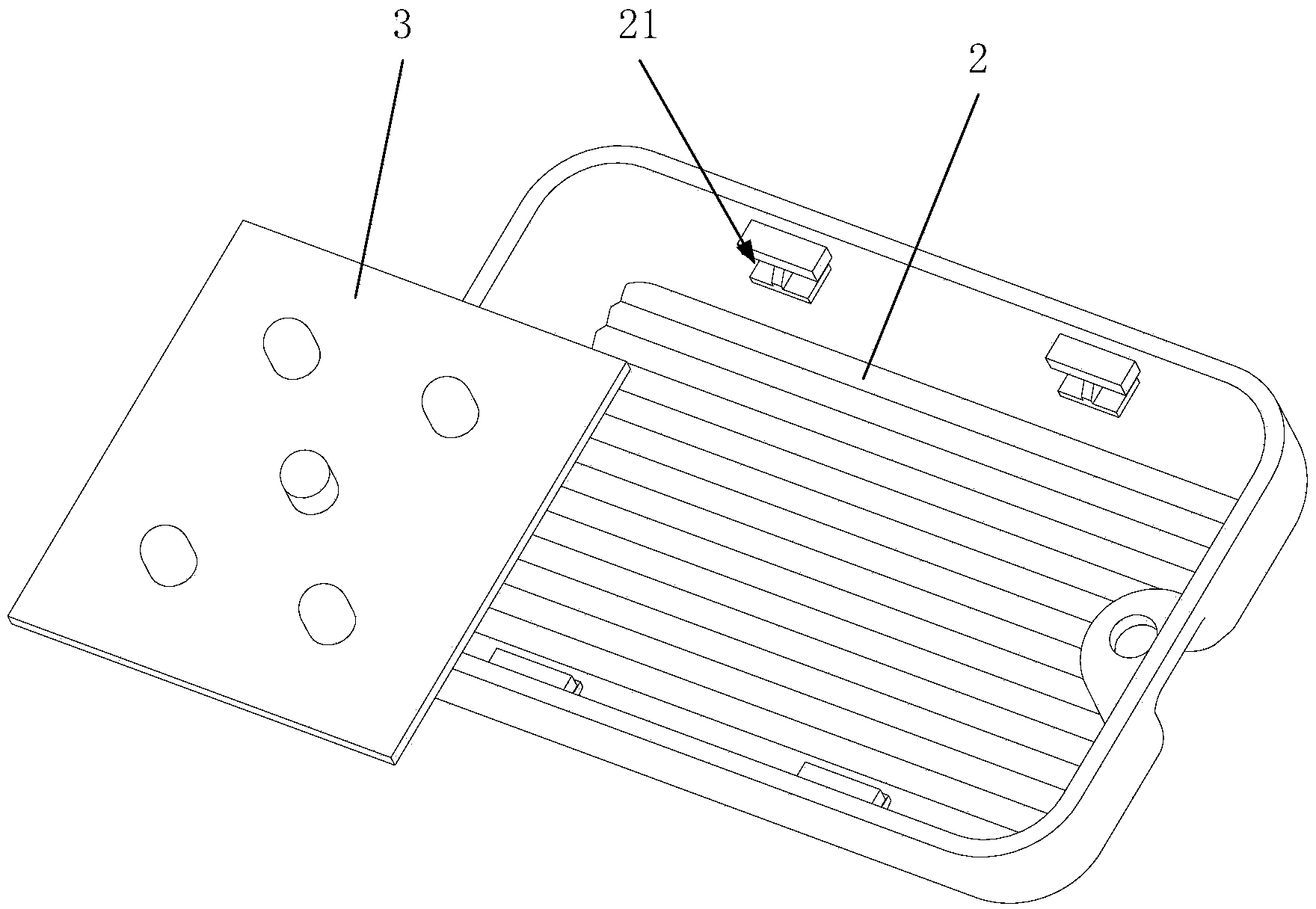

Refrigerator body and refrigerator

InactiveCN104019607ASimple structureEasy to assembleLighting and heating apparatusLighting arrangementRefrigerator carProduct optimization

The invention provides a refrigerator body and a refrigerator. The refrigerator body comprises a hollow refrigerator container with one end open, a lampshade fixed to the wall of the refrigerator container, and a light emitting piece fixed in the lampshade and used for lighting the interior of the refrigerator container. The refrigerator body is simple in structure and convenient to assemble, the lampshade and the light emitting body are directly fixed to the wall of the refrigerator container in a combined mode, a pre-buried box structure in the related technology is removed, the installing technology of the refrigerator body is effectively simplified, manufacturing cost of the refrigerator body is reduced, and the purpose of enterprise product optimization is achieved.

Owner:HEFEI MIDEA REFRIGERATOR CO LTD

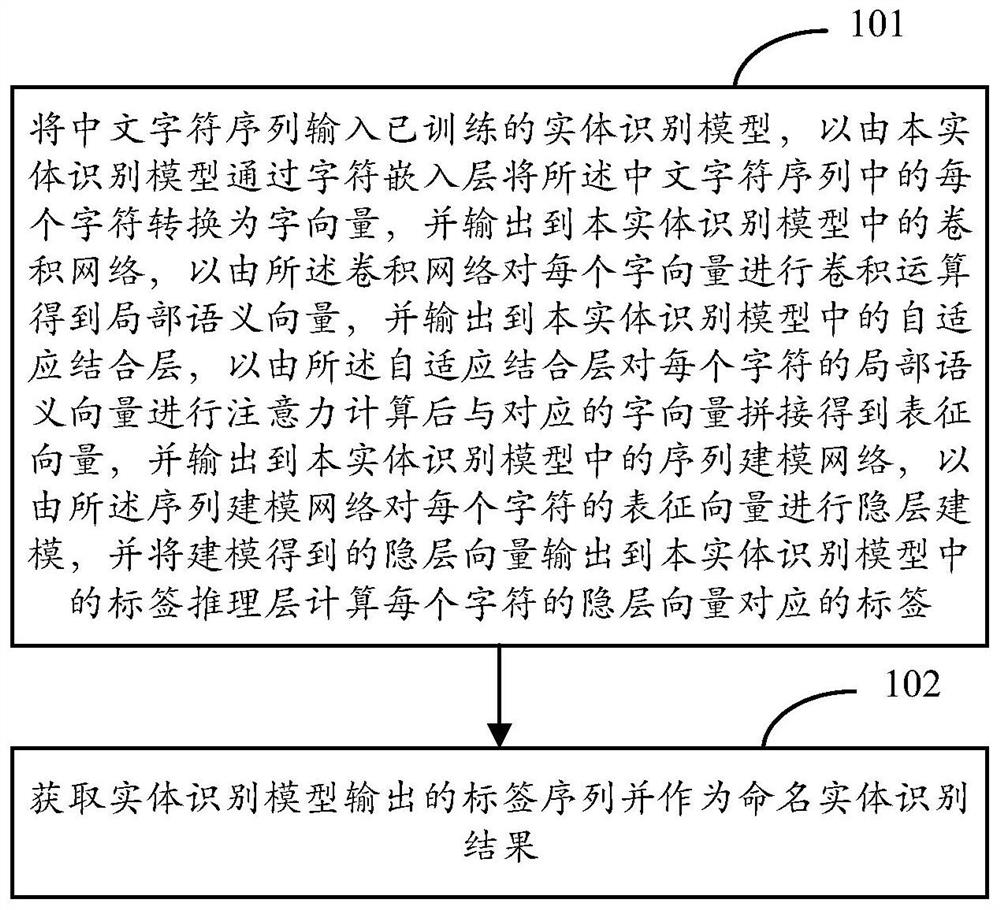

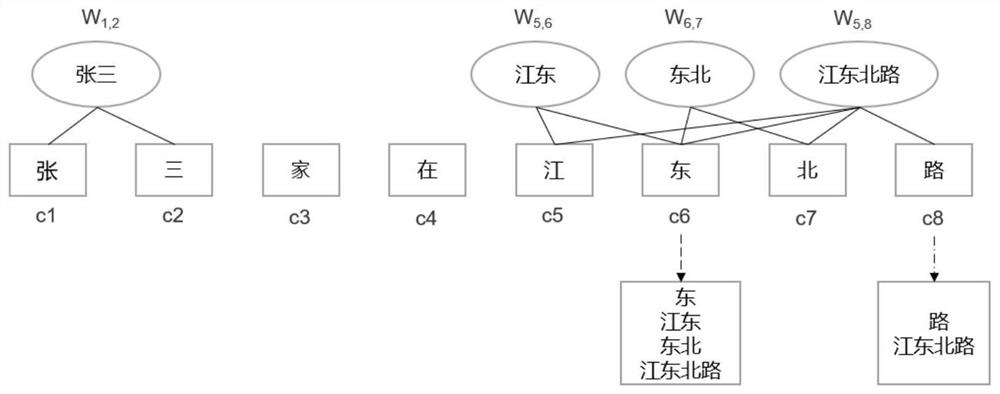

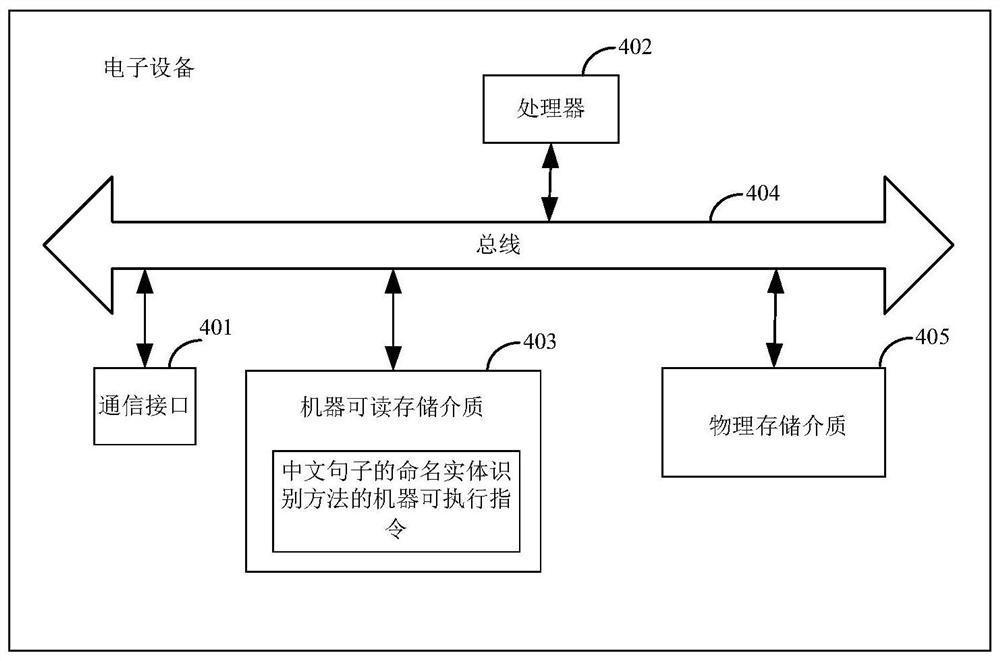

Named entity recognition method and device for Chinese sentences

ActiveCN112711948AAvoid the problem of border mispassingTo achieve the purpose of optimizationSemantic analysisNeural architecturesSemantic vectorHidden layer

The invention discloses a named entity recognition method for Chinese sentences, which comprises the following steps: inputting a Chinese character sequence into a recognition model, converting the Chinese character sequence into a character vector by the recognition model through a character embedding layer, and outputting the character vector to a convolutional network in the recognition model; the method also includes that the convolutional network performs convolution operation on each word vector to obtain a local semantic vector and outputs the local semantic vector to a self-adaptive combination layer in the recognition model; the self-adaptive combination layer performs attention calculation on the local semantic vector of the character and then splices the local semantic vector with the corresponding word vector to obtain a representation vector and outputs the representation vector to a sequence modeling network in the recognition model; and the sequence modeling network performs hidden layer modeling on the representation vector of the character and outputs the hidden layer vector obtained by modeling to a label reasoning layer in the recognition model to calculate a label corresponding to the hidden layer vector of the character. The local semantic information of the characters is extracted through the convolutional network and then is fused with the potential words based on the attention among the words, so that the utilization of the potential word information is realized, and the problem of wrong transmission of word boundaries is avoided.

Owner:BEIJING UNIV OF POSTS & TELECOMM

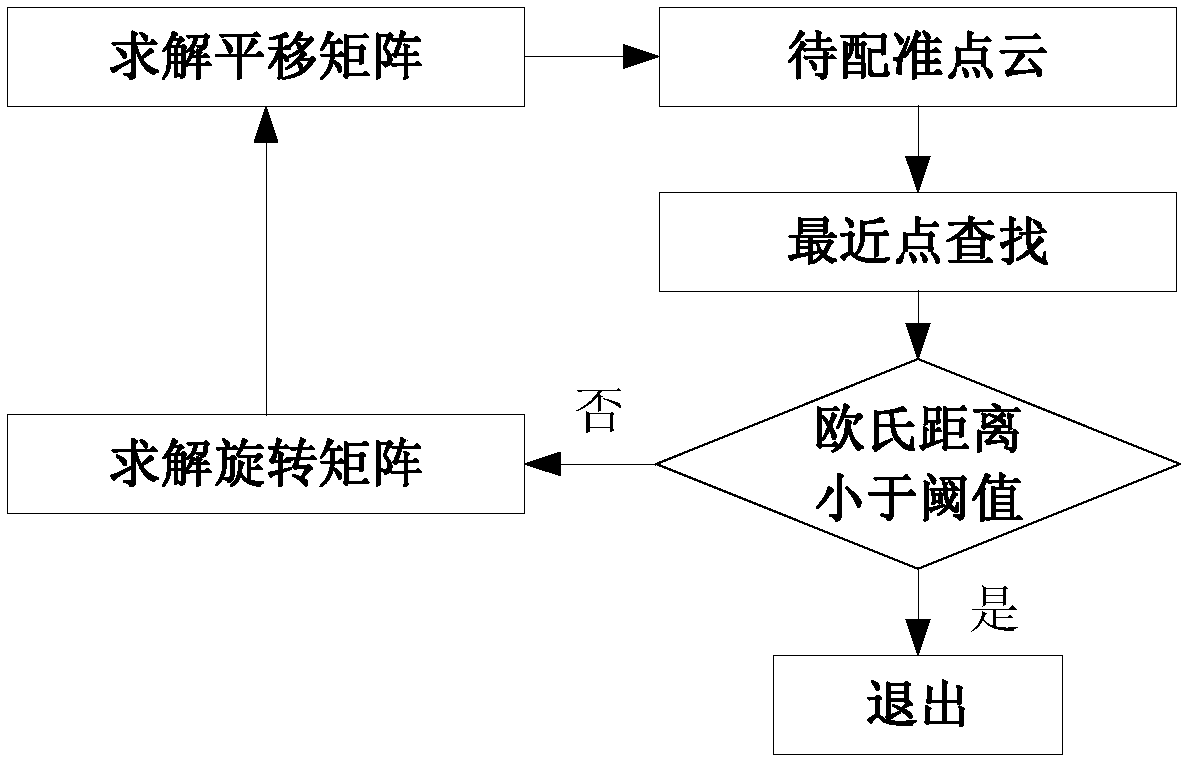

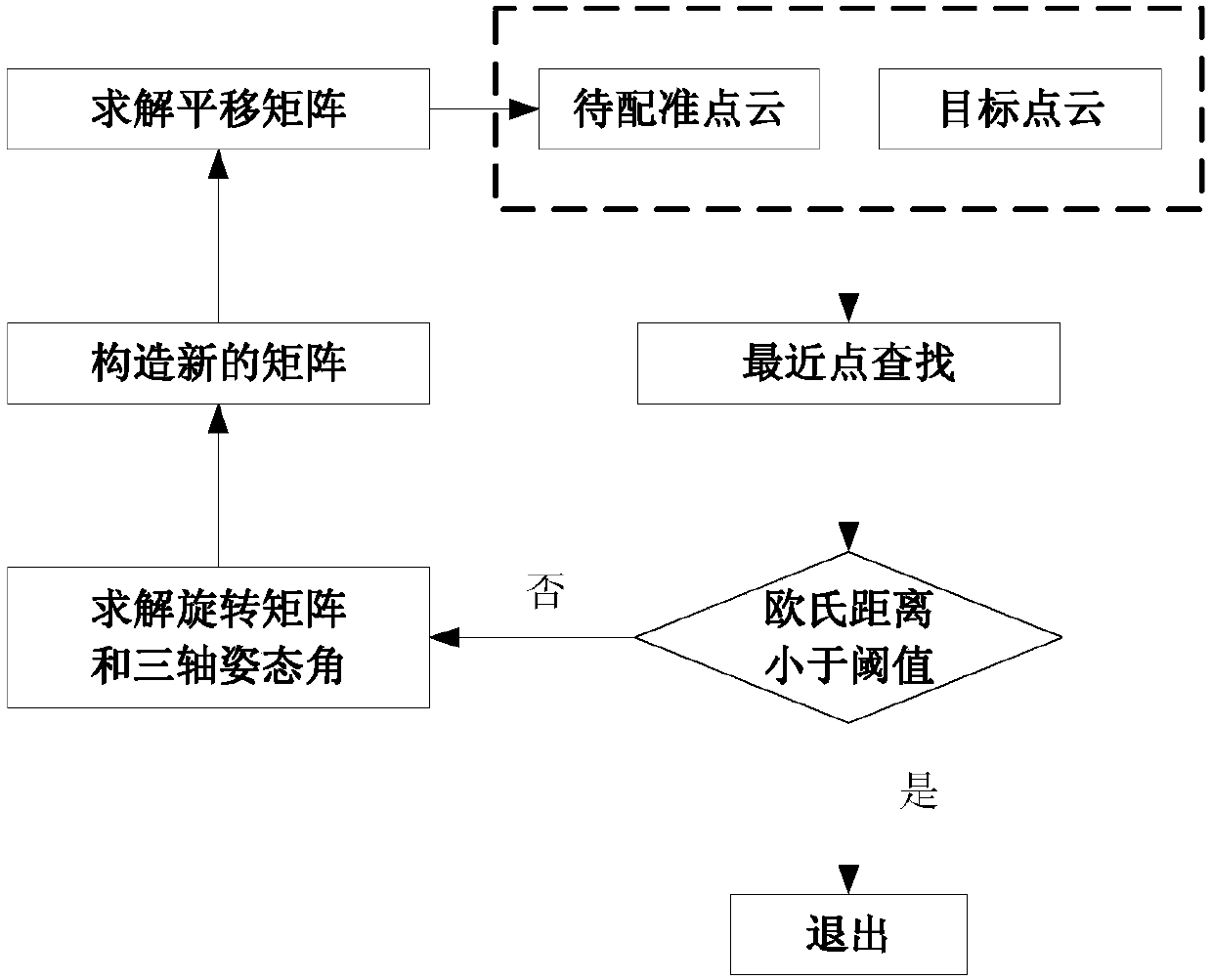

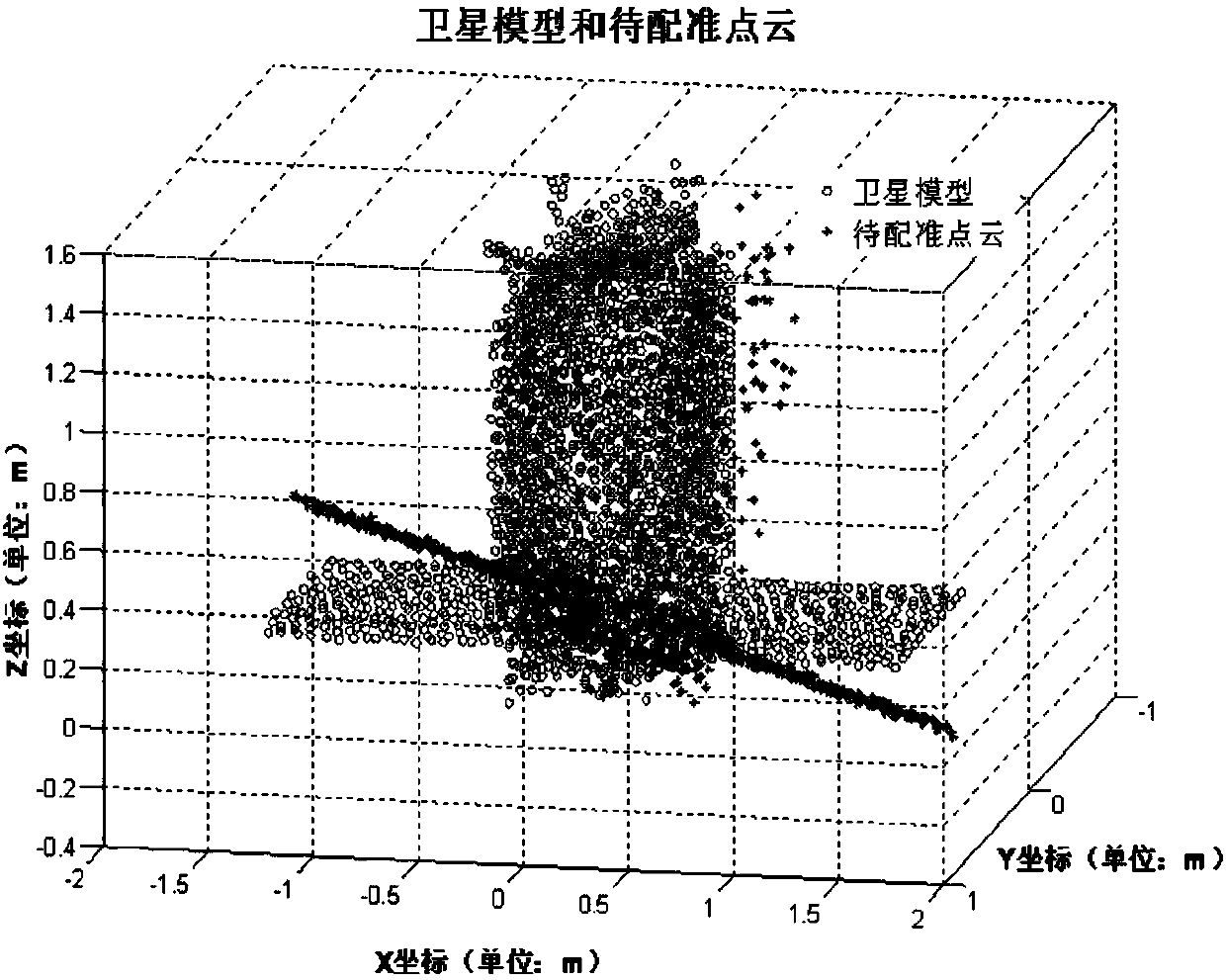

Improved nearest point iteration point cloud registration methods

ActiveCN107644433AFast convergenceTo achieve the purpose of optimizationImage analysisAlgorithmRotation matrix

The invention provides two improved nearest point iteration point cloud registration methods, and belongs to the field of image processing and three-dimensional point cloud registration. The method for improving the convergence speed of a nearest point iterative algorithm is based on a traditional nearest point iterative algorithm, and a step of constructing a rotation matrix is added, and the constructed rotating matrix is used for generating new to-be-registered point clouds in an iteration process. Two methods for constructing a matrix are provided. In one way, the matrix is constructed based on the matrix Ri obtained by current iteration, and in the other way, the matrix is constructed according to the difference of the three-axis attitude angle obtained through two adjacent iterations, and through the Eulerian angle formula. Through simulation verification, both methods can effectively improve the convergence speed of a traditional nearest point iterative algorithm, and the overall efficiency of the algorithm is improved. Especially under the condition that the great amount of data points are processed, the advantage of the efficiency improvement is more obvious.

Owner:BEIJING INST OF CONTROL ENG

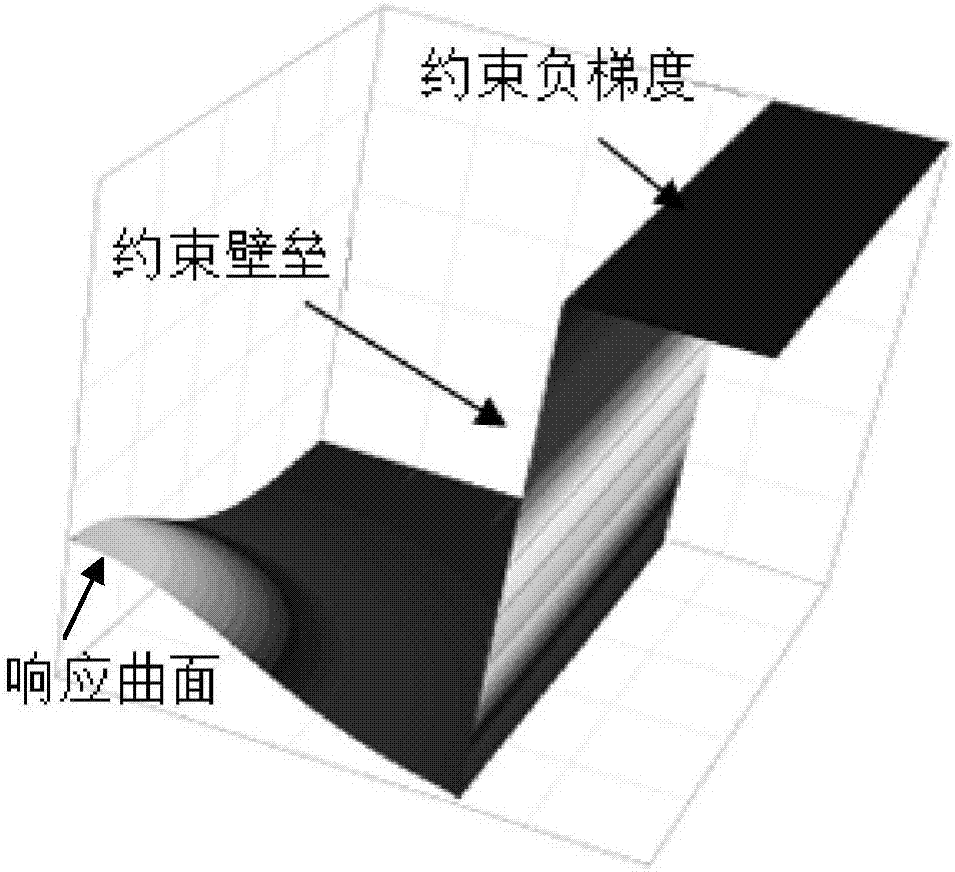

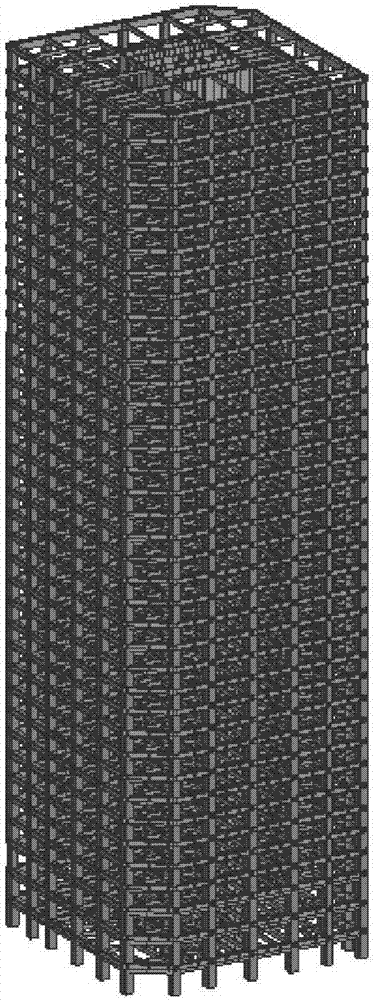

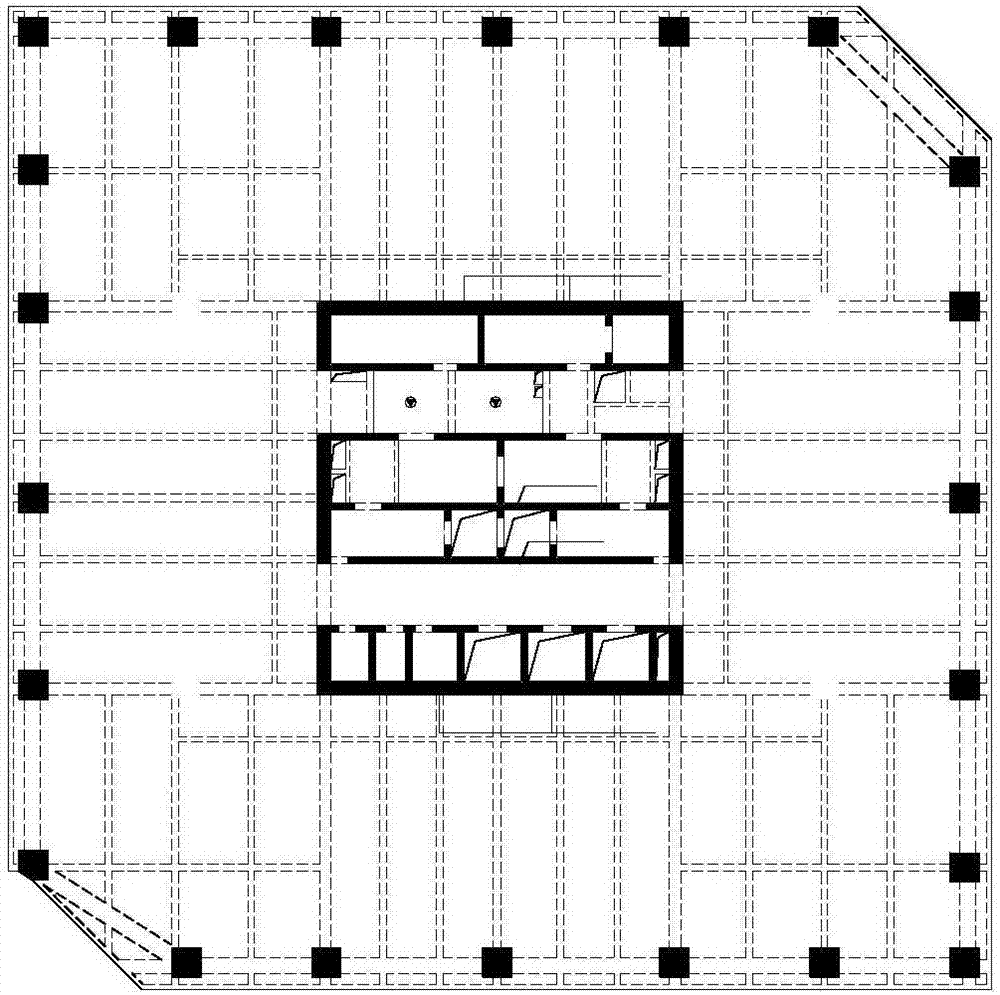

High-rise building structure anti-seismic property optimization method based on sensitivity coefficient method

InactiveCN107403032ATo achieve the purpose of optimizationSave building materialsGeometric CADDesign optimisation/simulationEngineeringHigh rise

The invention discloses a high-rise building structure anti-seismic property optimization method based on a sensitivity coefficient method. The optimization method includes (1), creating a high-rise building structure model; (2), selecting one anti-seismic property index in a displacement angle or displacement ratio as an optimization target, and grouping structural members; (3), setting constraint conditions and a target function for structural member optimization; (4), making optimization variables into a variable combination matrix; (5), modifying values of the variables in the combination, and performing structural anti-seismic calculation analysis to acquire a design experiment data result; (6), subjecting the acquired design experiment data result to response surface fitting to acquire a sensitivity coefficient; (7), calculating the target function on the basis of the sensitivity coefficient. The high-rise building structure anti-seismic property optimization method has the advantages that the contribution degrees of the structural members in a high-rise building structure to the displacement angle or displacement ratio under the earthquake action can be analyzed quantitatively, and accordingly, the anti-seismic property optimization direction of the high-rise building structure is determined.

Owner:ARCHITECTURAL DESIGN RES INST OF GUANGDONG PROVINCE

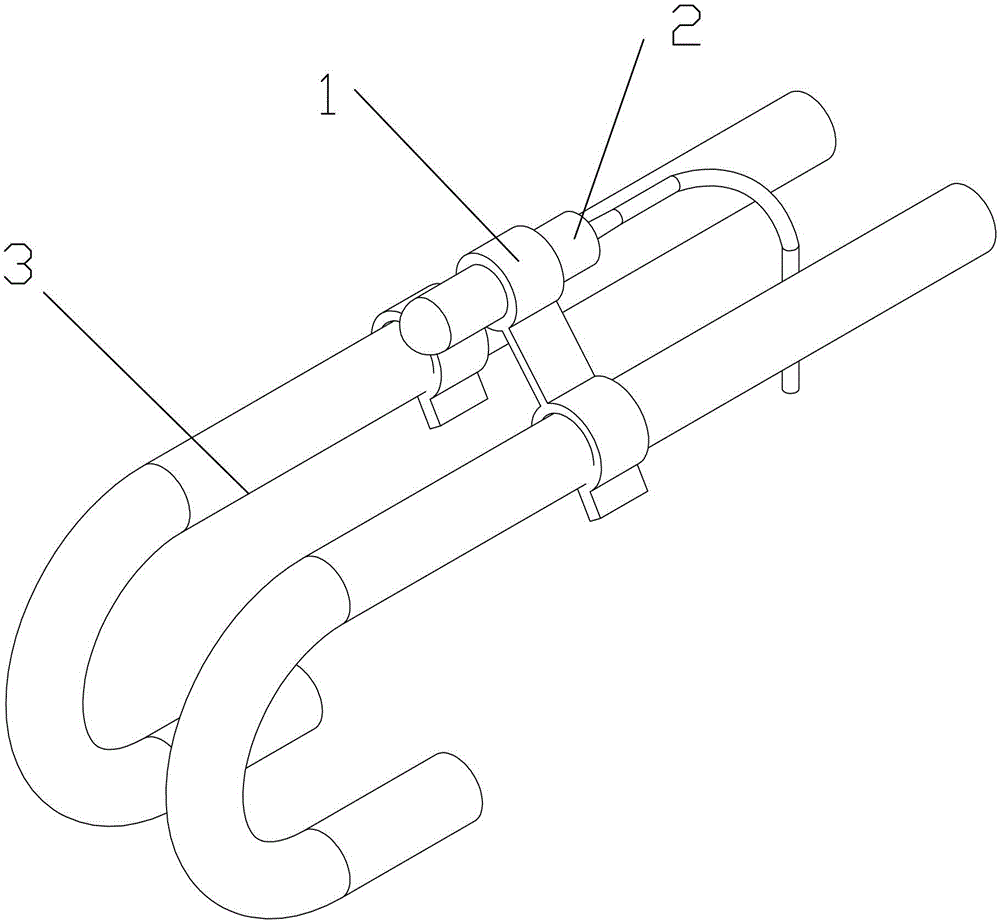

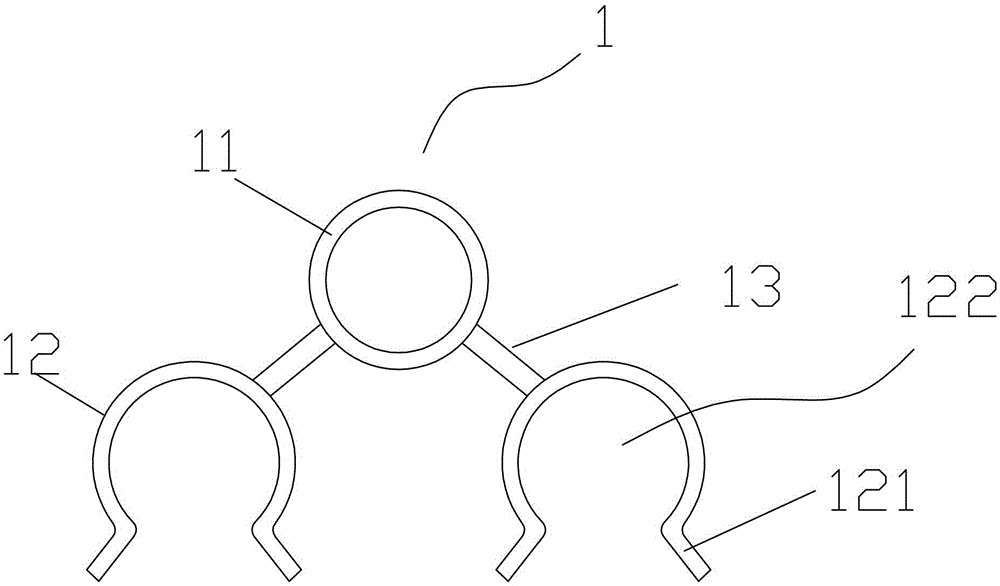

Positioning device for defrosting temperature sensing head of heat exchanger

InactiveCN105300009AGuaranteed reliabilityEasy to findLighting and heating apparatusDefrostingFrostEngineering

The invention discloses a positioning device for a defrosting temperature sensing head of a heat exchanger. The positioning device comprises a temperature sensing head chuck for containing the temperature sensing head, a heat exchanger pipe clamp for clamping a heat exchanger pipeline, and a connecting strip. The temperature sensing head chuck and the heat exchanger pipe clamp are connected through the connecting strip. The heat exchanger pipe clamp is provided with an elastic containing cavity, and the elastic containing cavity is provided with an opening with a guide arm. According to the positioning device for the temperature sensing head, the temperature sensing head is isolated from an aluminum pipe of an evaporator, the temperature sensing head can truly reflect the temperature of a frost layer around the evaporator, a refrigerator can be made to quit a defrosting mode more accurately, and high-efficiency operation of the refrigerator is ensured.

Owner:SHUNDE POLYTECHNIC

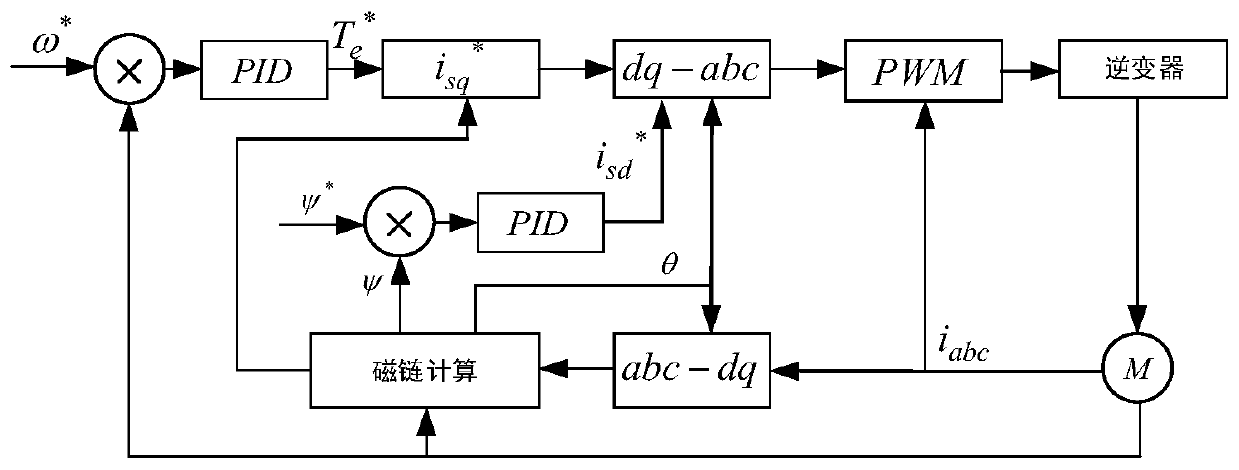

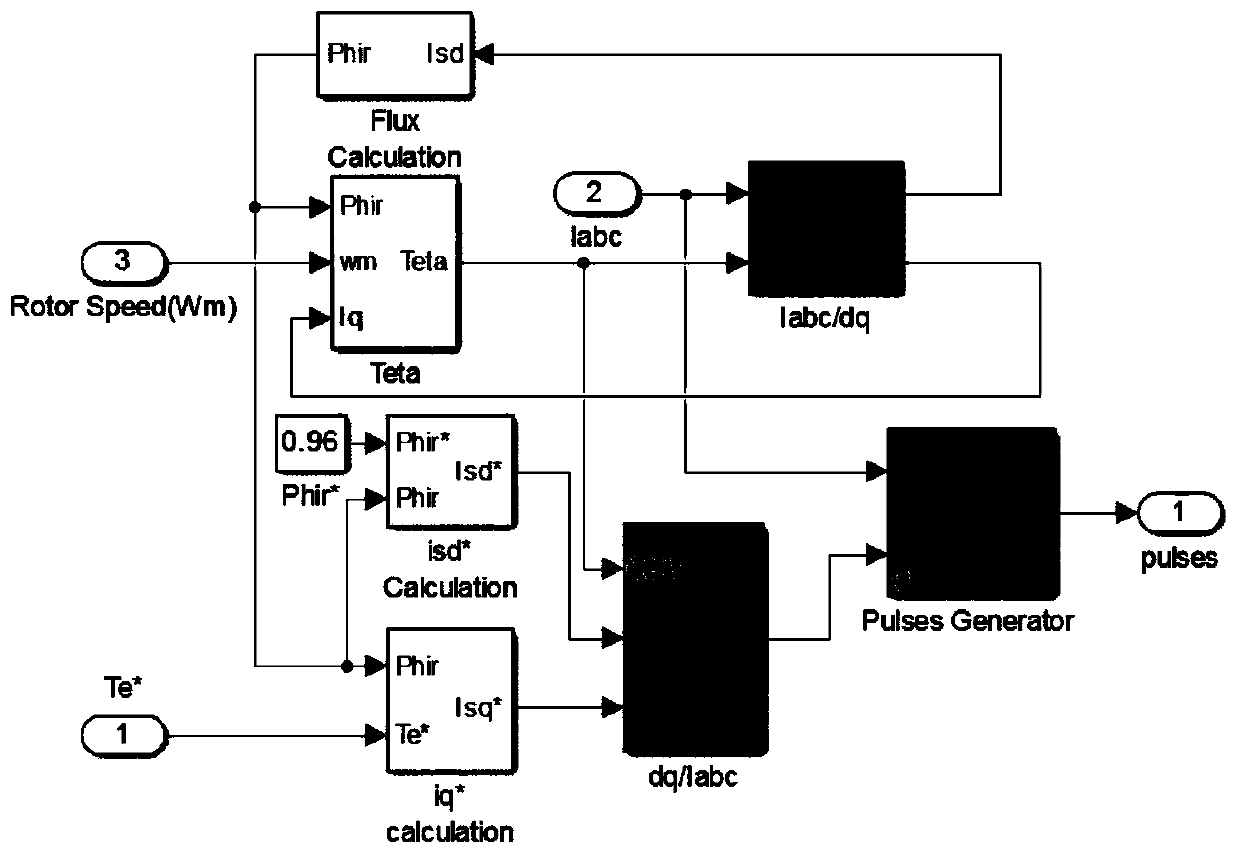

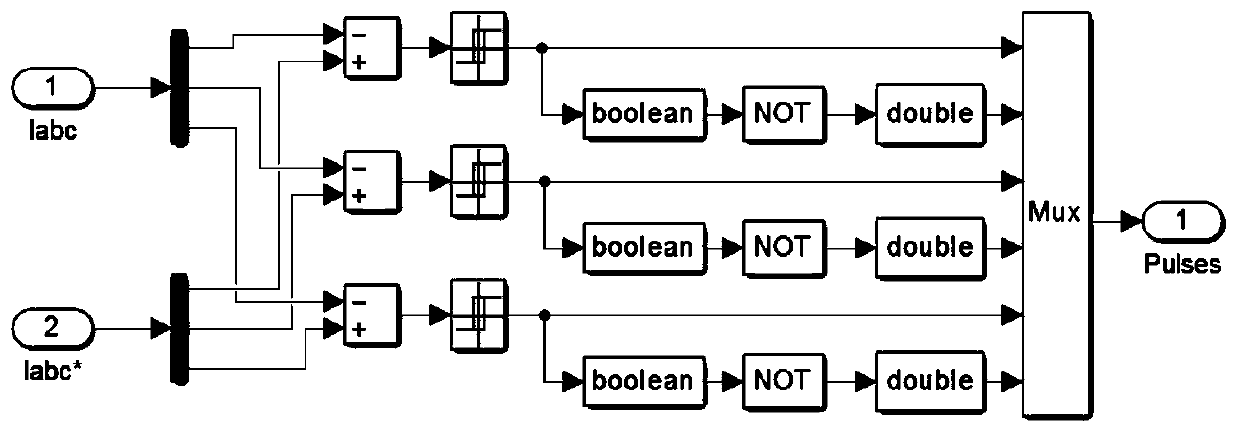

PID self-tuning method based on deep learning and LOGFA

InactiveCN110083055ATo achieve the purpose of optimizationLittle prior knowledgeControllers with particular characteristicsSelf-tuningInduction motor

The invention provides a PID self-tuning method based on deep learning and LOGFA. The method comprises the following steps that firstly, the principle of a LOGDA algorithm is simply introduced, the DBN is combined with the LOGFA, a LOGFA-DBN tuning algorithm is provided, the LOGFA-DBN tuning algorithm can achieve parameter tuning offline operation, the algorithm is not limited by a controlled object, and parameter tuning speed is accelerated. The asynchronous motor is used as a simulation model to carry out a simulation experiment, and experimental results show that compared with a genetic algorithm and an FA algorithm, the tuning speed of the algorithm is faster and more stable. According to the invention, the problem that the PID is difficult to tune is solved.

Owner:XIANGTAN UNIV

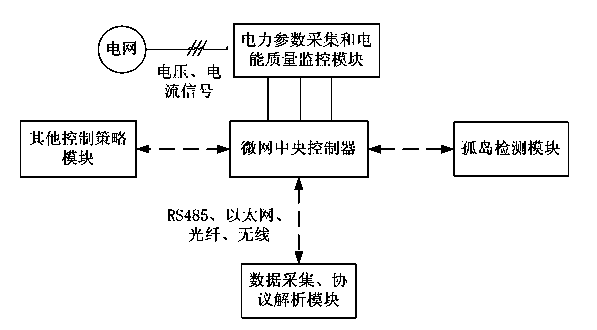

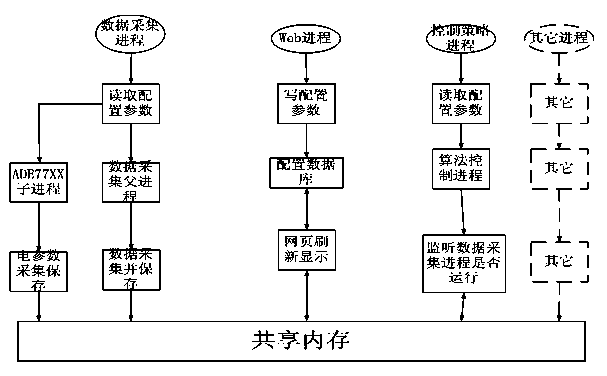

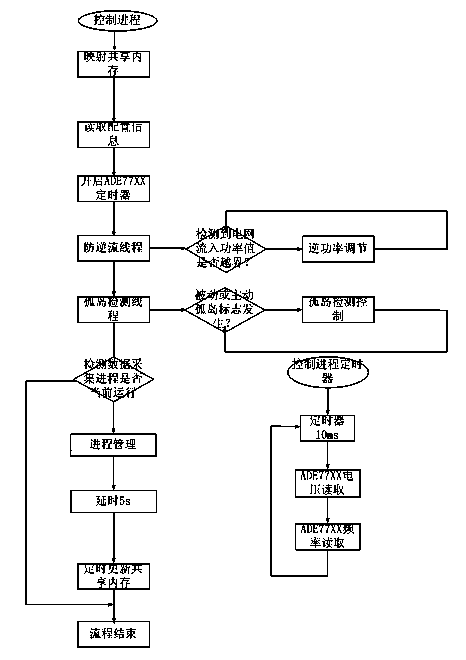

Micro-power-grid central control unit

ActiveCN104218606AReach powerTo achieve the purpose of optimizationSingle network parallel feeding arrangementsSystems intergating technologiesPower qualityData acquisition

The invention discloses a micro-power-grid central control unit. The micro-power-grid central control unit is characterized by comprising a CPU (central processing unit) module, an electric parameter acquisition module, a power quality monitoring module, a data acquisition and protocol parsing module, an inverse power control module, an island detection module and other special functional modules. Through certain strategic coordinated optimization control, all distributed-type power supplies in a micro power grid are coordinated to be operated orderly, an inverter and equipment in a micro-power-grid system are subjected to continuous and smooth power regulation, the distributed-type generation power supplies and loads are controlled within a certain proportional and reasonable range, the distributed-type power generation equipment is reasonably utilized, and efficiency of the distributed-type power generation equipment is improved; meanwhile, the micro-power-grid central control unit has multiple software upgrading modes and debugging modes of network remoteness, local and the like, and maintainability and flexibility and easiness in use of the micro-power-grid control system are improved.

Owner:ELECTRIC POWER RESEARCH INSTITUTE, CHINA SOUTHERN POWER GRID CO LTD

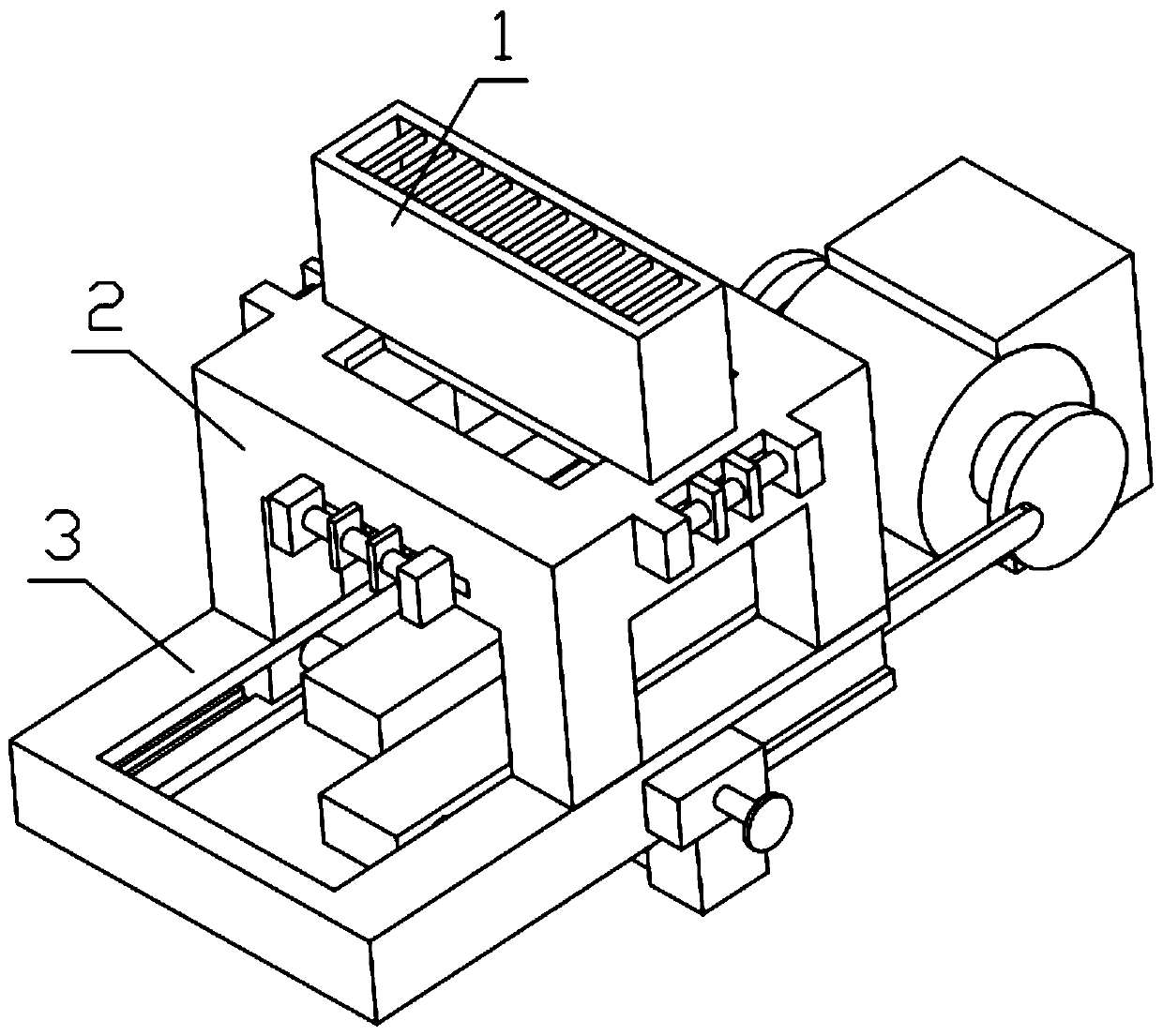

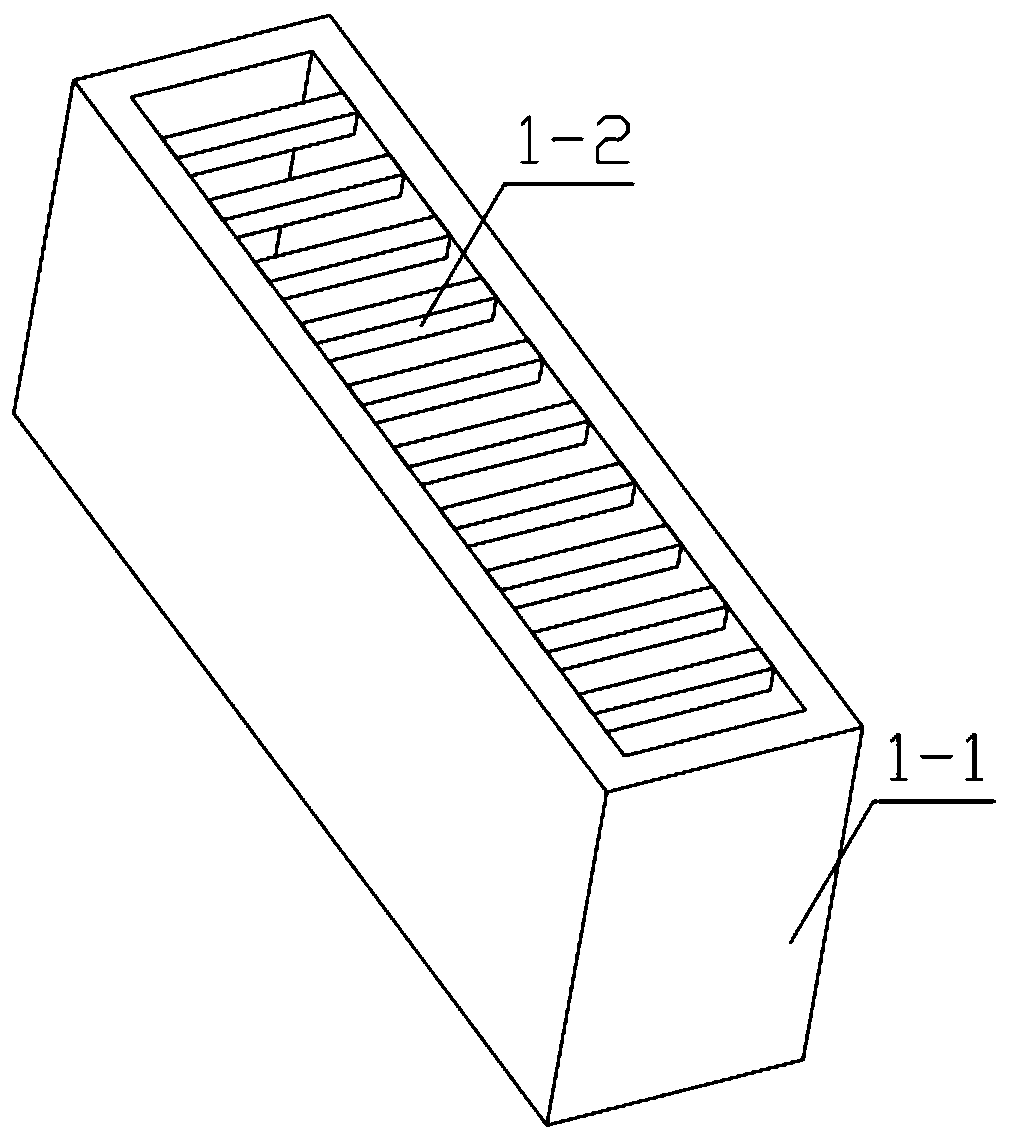

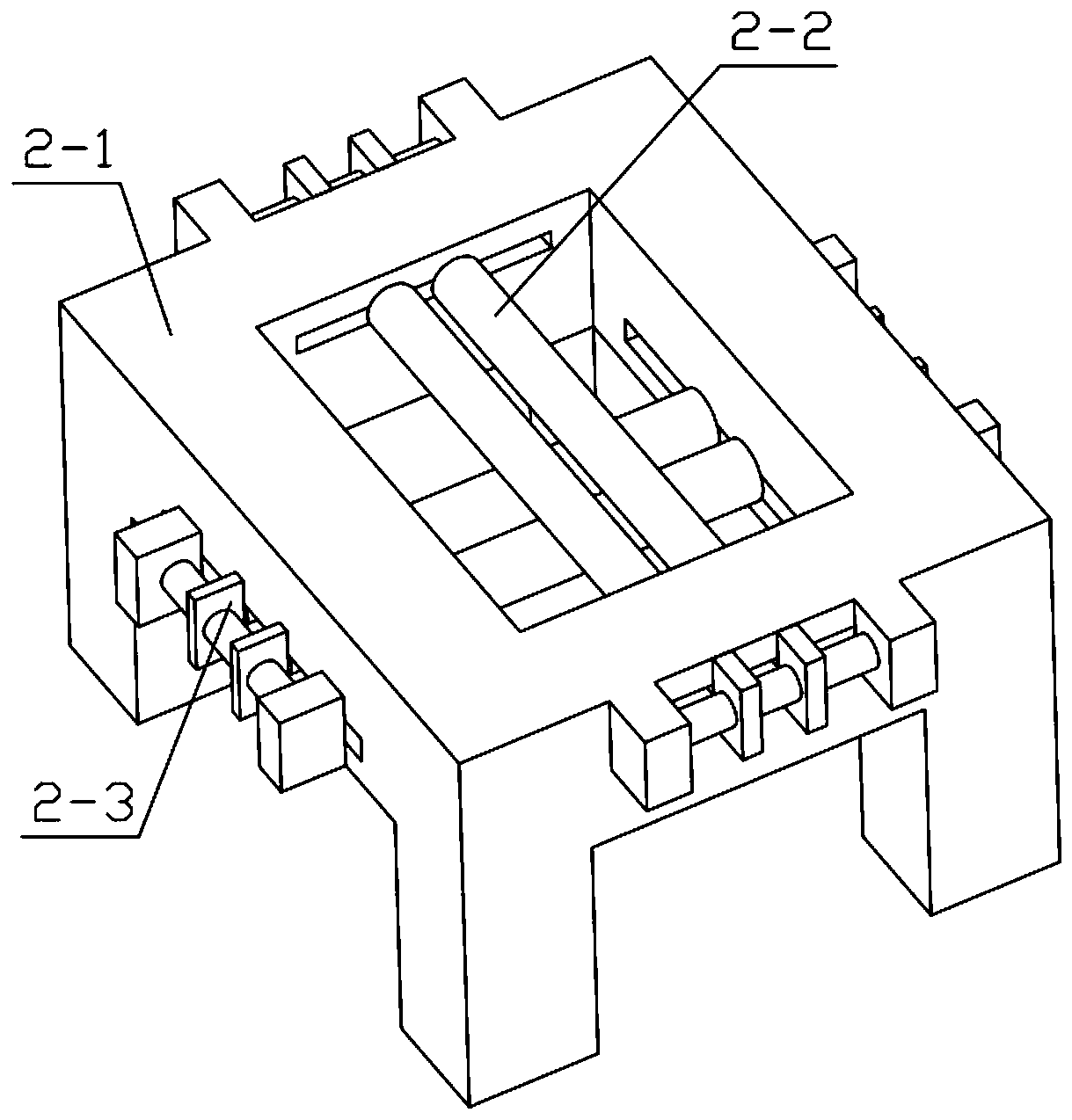

Drawing optimization device for textile use

ActiveCN110791842AThe adjustment method is simple and convenientEasy to operateDrafting machinesSpinningIndustrial engineering

The invention relates to a spinning drawing device, in particular to a drawing optimization device for textile use, which comprises a distributing box, an adjustable drawing mechanism and a drawing optimization mechanism. Adhesion of cotton slivers combined is promoted by the drawing optimization device for textile use, the cotton slivers rarely separate, and optimizing the drawing step is achieved. The distributing box is fixedly mounted on the adjustable drawing mechanism, and the adjustable drawing mechanism is fixedly mounted on the drawing optimization mechanism.

Owner:聊城市蓓朵智能科技有限公司

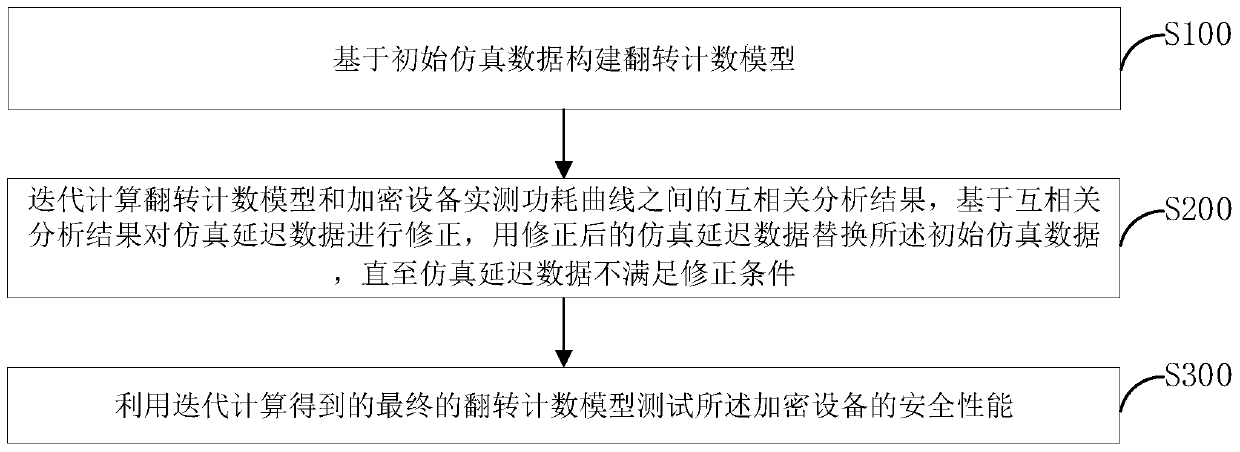

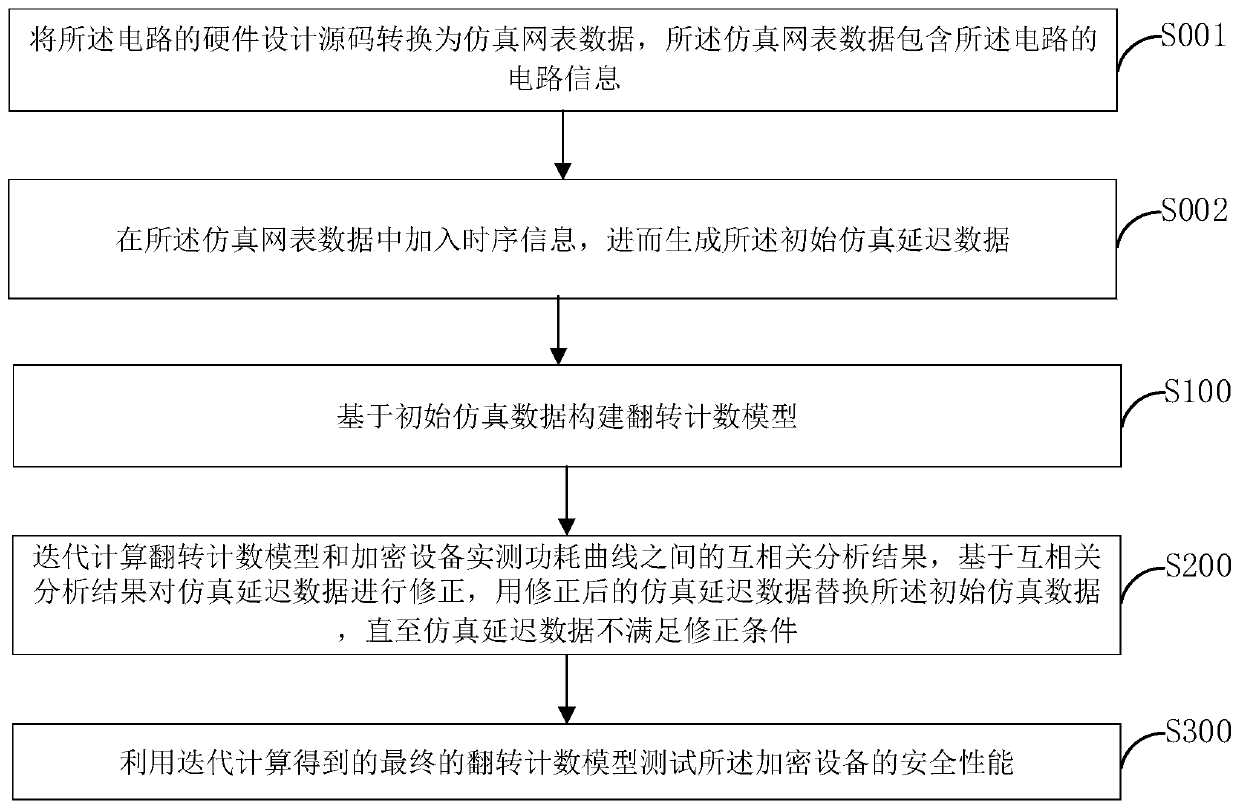

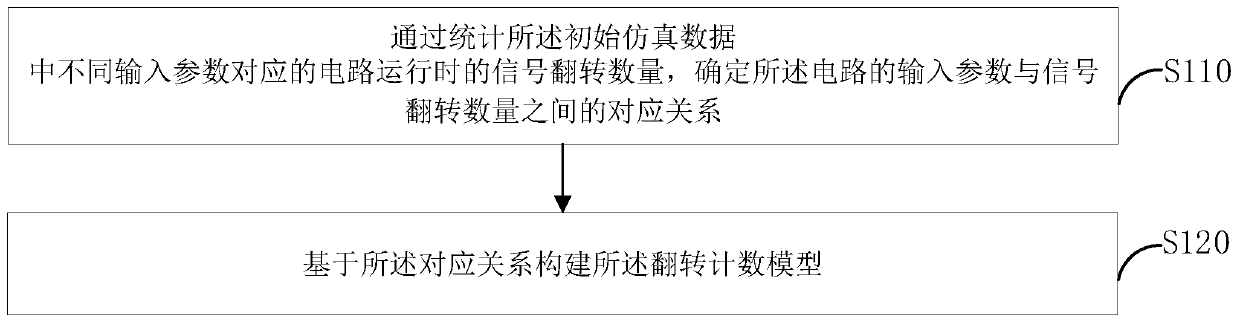

Security analysis method and system for encryption equipment with mask combination circuit

ActiveCN110020534AImprove effectivenessHigh precisionDigital data protectionInternal/peripheral component protectionCross correlation analysisSecurity analysis

The invention provides a security analysis method and system for encryption equipment with a mask combination circuit. A cross-correlation analysis result between an overturning counting model and anactual measurement power consumption curve of encryption equipment is calculated; an optimized flip count model is determined, and finally, the safety performance of the encryption equipment is testedby utilizing the optimized flip counting model, so that the influence caused by the difference between the reverse annotation information obtained by simulation and the real delay in the actual circuit is eliminated, the simulation precision is improved, and the effectiveness of the flip counting model applied to the safety analysis of the encryption equipment is further improved. Meanwhile, theoptimization scheme only needs to combine with an actual measurement power consumption curve to correct the delay information in the standard delay format file so as to achieve the purpose of model optimization, and the method is simple and efficient.

Owner:CHINA ACADEMY OF INFORMATION & COMM

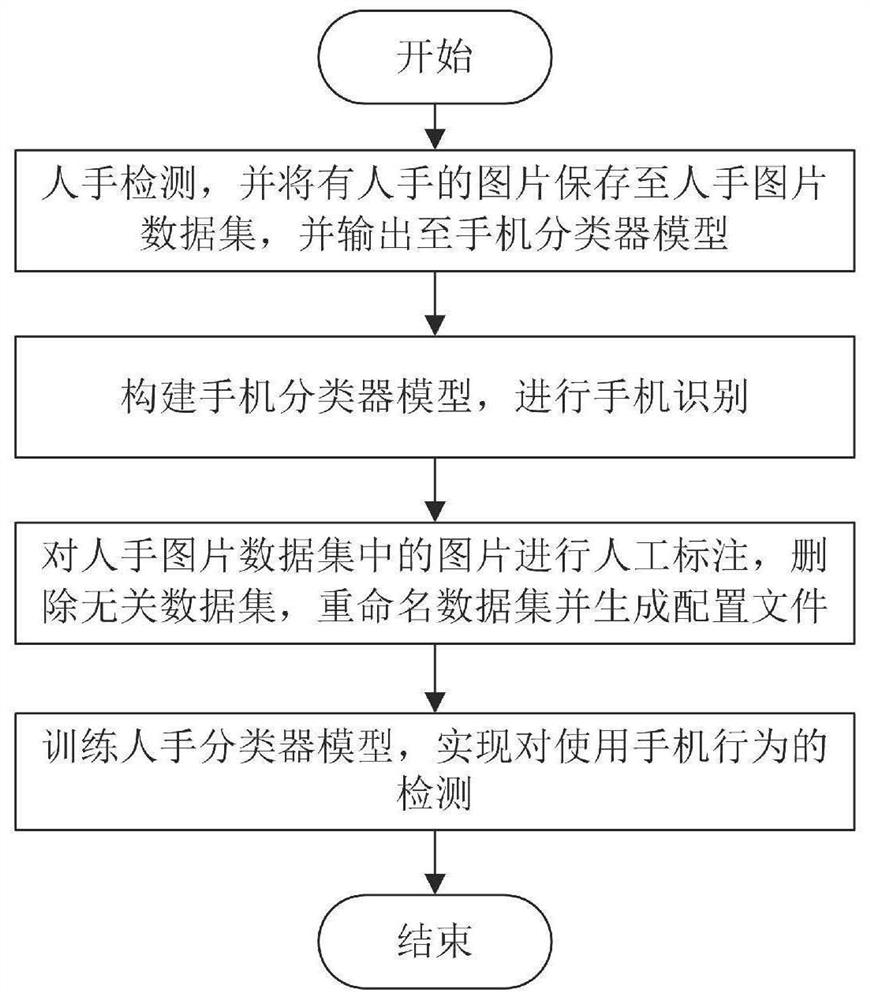

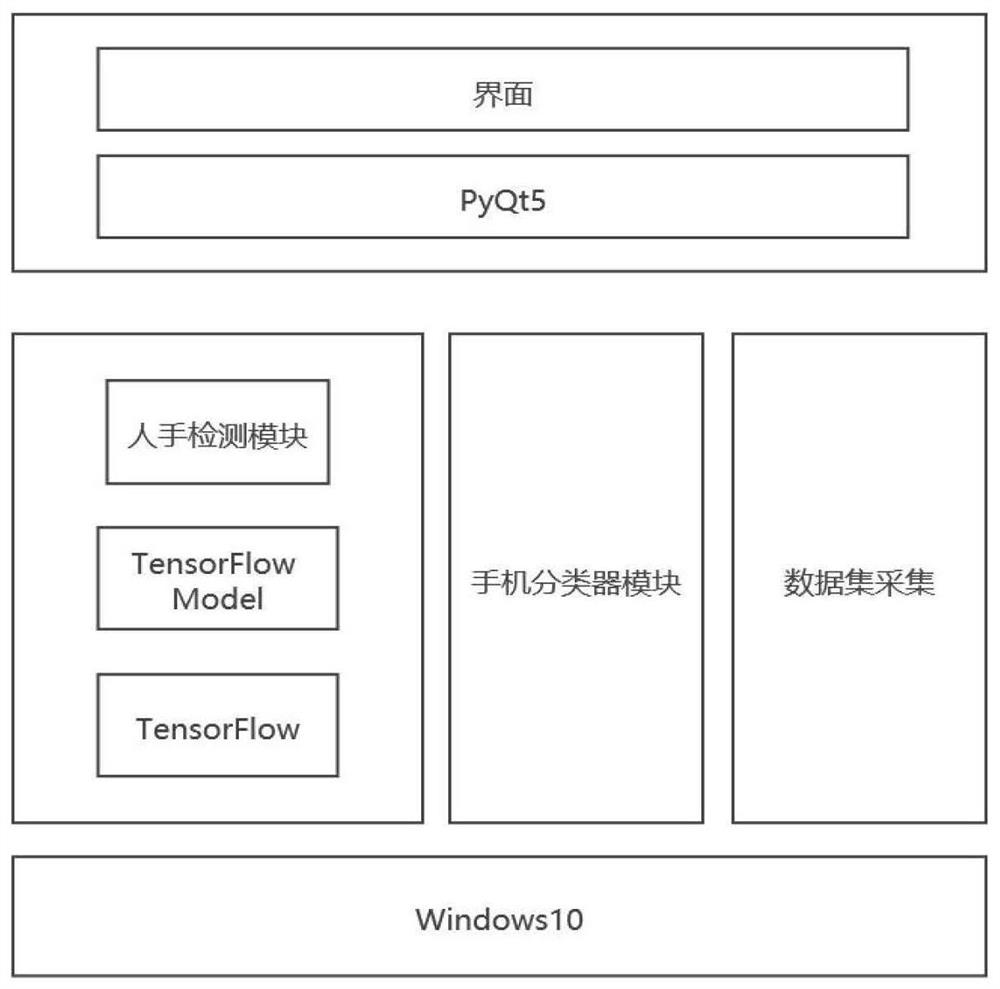

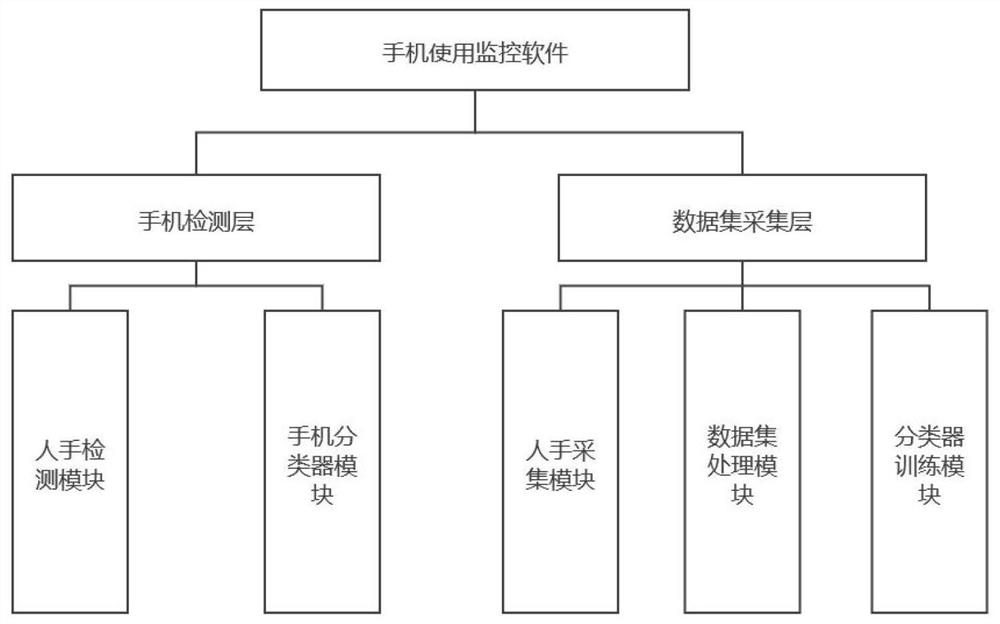

Mobile phone use behavior detection method based on target detection

PendingCN113139452ATo achieve the purpose of optimizationTaking into account the detection accuracyCharacter and pattern recognitionPattern recognitionData set

The invention provides a mobile phone use behavior detection method based on target detection, and relates to the technical field of target detection. The method comprises the following steps: firstly, inputting a video or an image of a to-be-detected mobile phone use behavior into a human hand target detection model, then detecting whether a human hand exists in the video or the image, storing a picture with the human hand into a human hand picture data set, and outputting the picture to a mobile phone classifier model; using the trained HOG + SVM model as a mobile phone classifier model to carry out binary classification on the human hand picture, judging whether the human hand picture is a human hand picture with a mobile phone or not, and outputting the human hand picture in three output modes; manually marking pictures in the human hand picture data set, deleting an irrelevant data set, renaming the data set and generating a configuration file; and finally, training and testing an HOG + SVM classifier model through the processed human hand data set and the configuration file to realize detection of mobile phone using behaviors. The method combines a candidate region-based target detection technology and an end-to-end-based target detection technology, and gives consideration to the detection accuracy and efficiency.

Owner:中国人民解放军91054部队

Process for treating low turbidity water

InactiveCN1884113AIncrease the difficultyTo achieve the purpose of optimizationWater/sewage treatment by flocculation/precipitationRefluxTurbidity

The invention discloses a low-turbidity water disposing method, which comprises the following steps: (1) refluxing mud water in the sedimenting pool and inversing-washing water in the filtering pool to form reflux water; (2) adjusting solid content rate of reflux water in the adjusting pool at 0.5-1 percent; (3) blending low-turbidity original water and reflux water with 60-400 NTU turbidity according to reflux rate between 0 and 5 percent; (4) obtaining water through condensing, sedimenting and filtering the blended disposed water.

Owner:HARBIN INST OF TECH

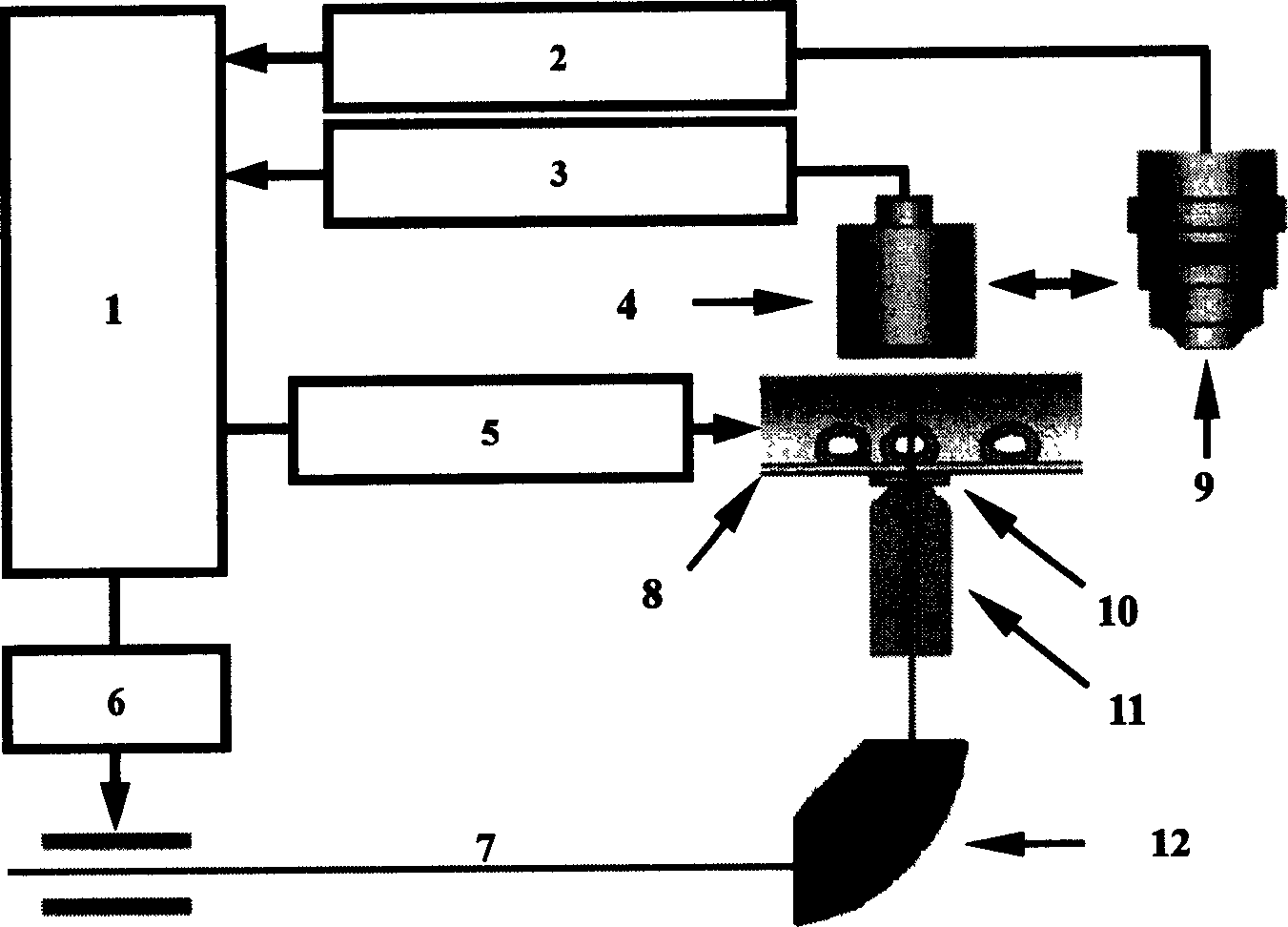

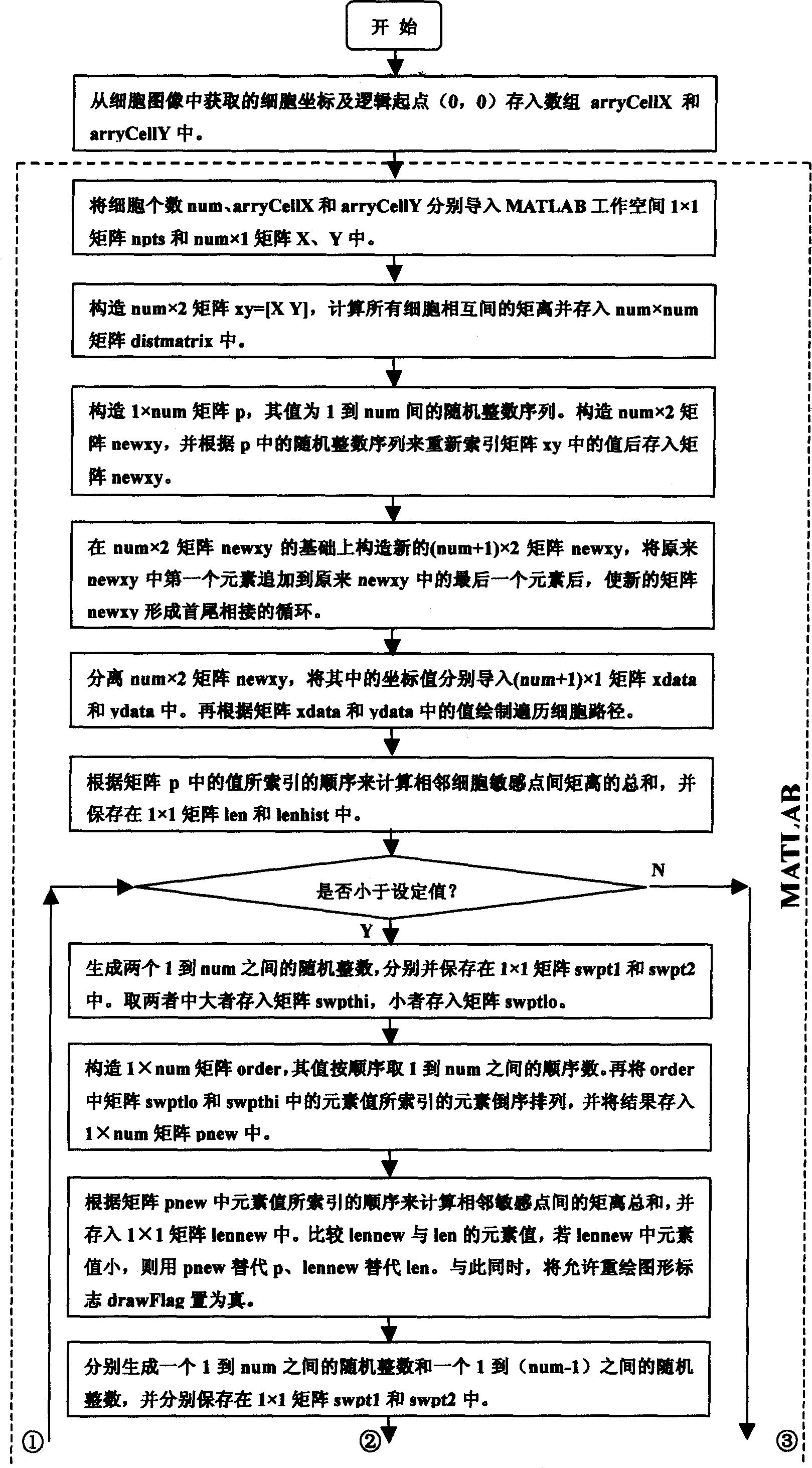

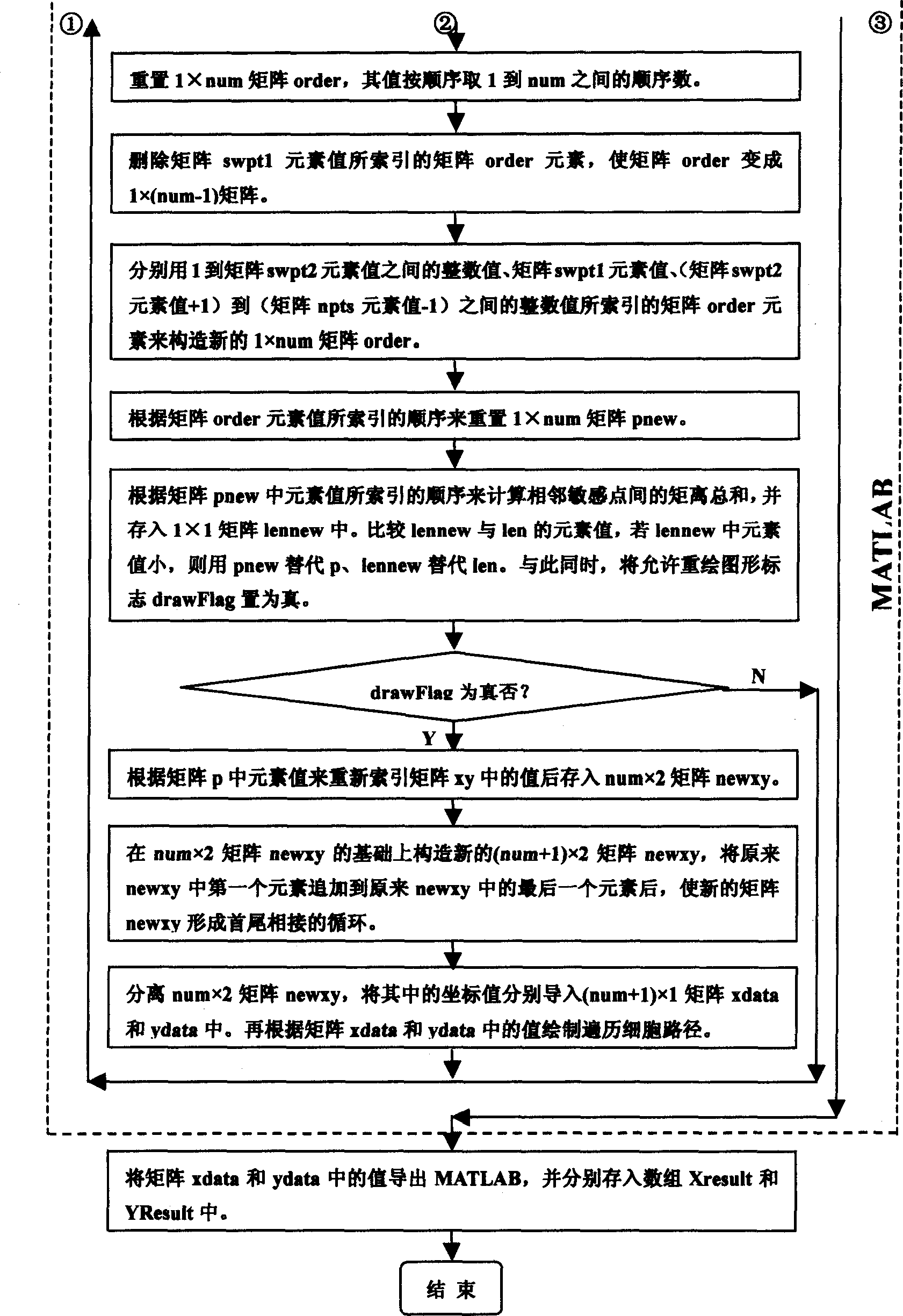

Path optimization technology of traversing cell sensitive spots for microbeam device

InactiveCN1567191AVersatileReduce chance of mutationRandom number generatorsMicrobiological testing/measurementCell sensitivityComputer science

This invention discloses a kind of microbeam apparatus traversal cell sensitivity spot path optimizing technique. By utilizing the existing microbeam apparatus, it can realize general problem solving the hypo-optimizing Hamilton loop algorithm under MatrixVB environment. When searching the traversal cell sensitivity spot path, its advantage is: if it circulates 500 times, the average increased optimizing efficiency is 41.78 percent; if it circulates 1000 times, the average increased optimizing efficiency is 50.54 percent; if it circulates 2000 times, the average increased optimizing efficiency is 56.33 percent. It uses about 1-2 second when circulates 500 to 1000 times, there is no new bottleneck.

Owner:INST OF PLASMA PHYSICS CHINESE ACAD OF SCI

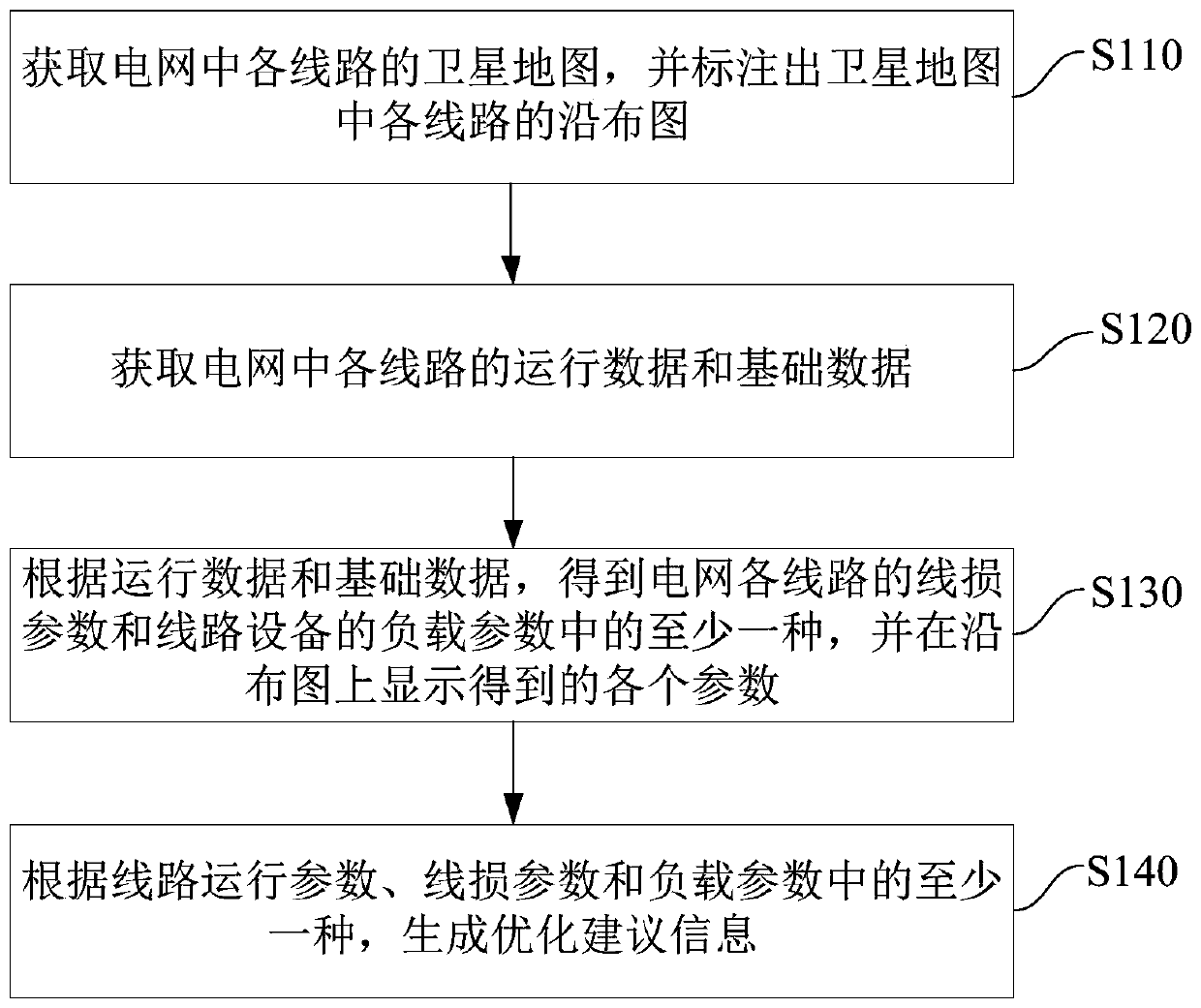

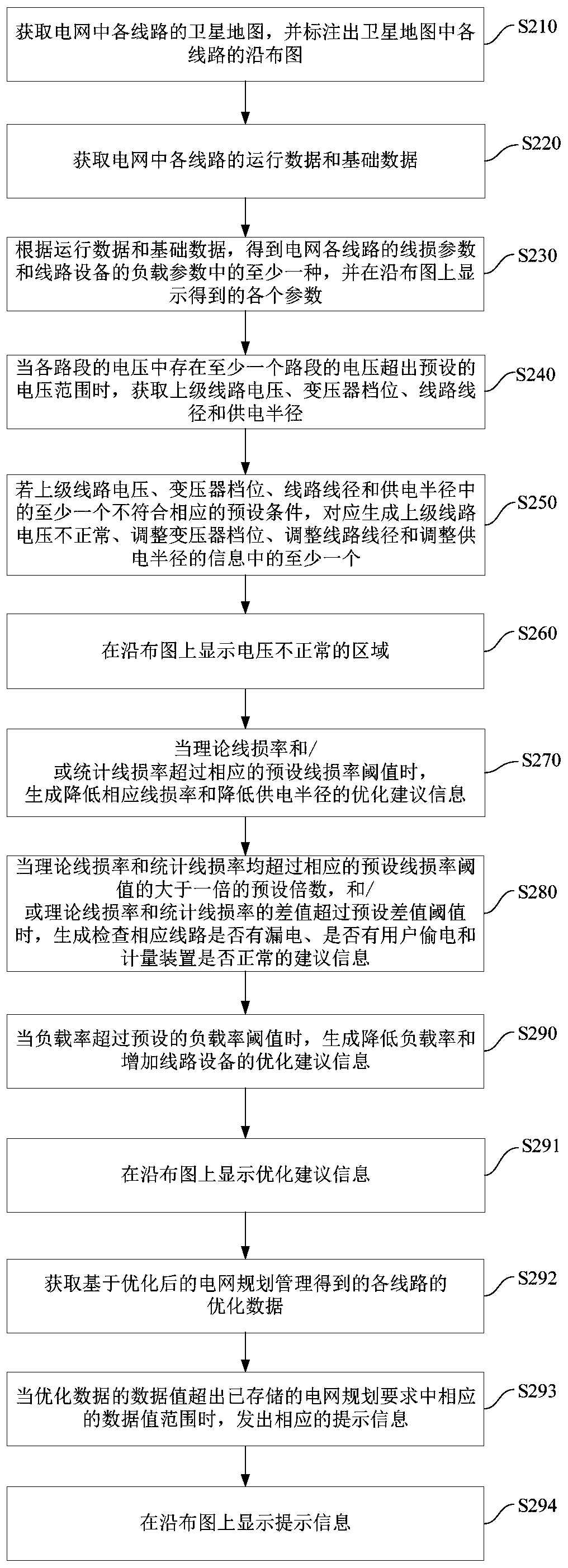

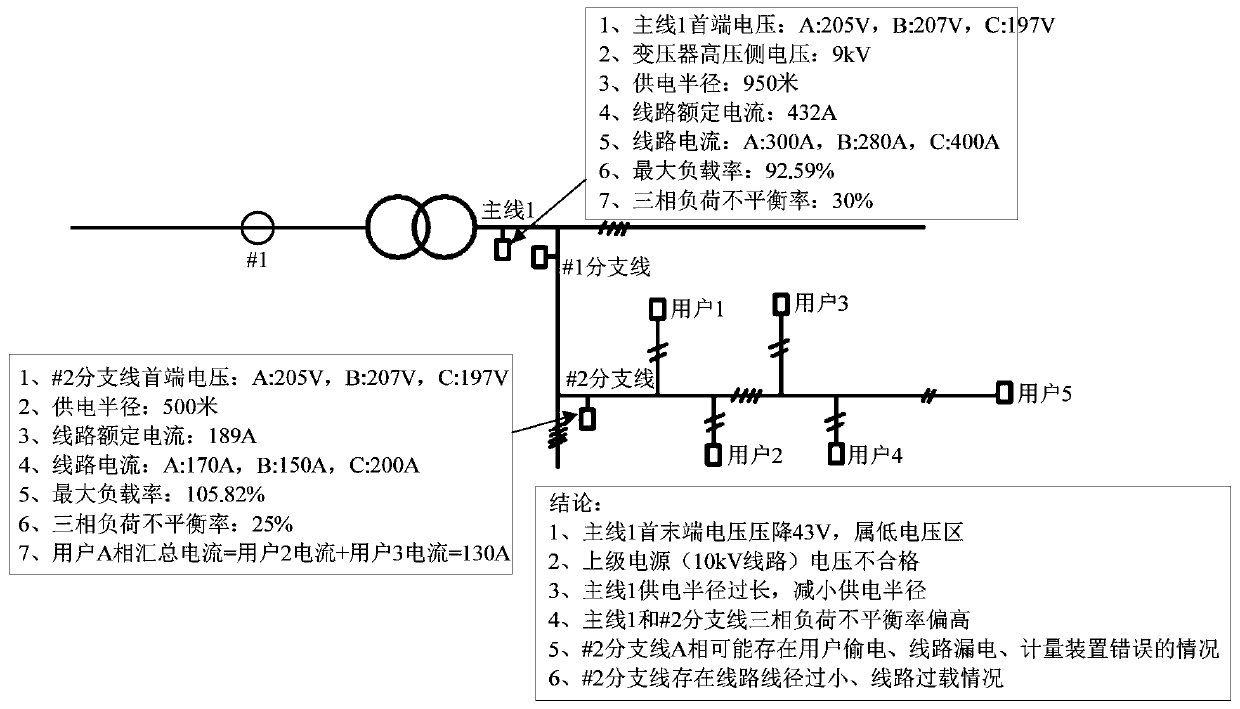

Optimization method, device and equipment for power grid planning management

PendingCN111428947ATo achieve the purpose of optimizationObservation is intuitiveForecastingGeographical information databasesData packControl engineering

The embodiment of the invention discloses an optimization method, device and equipment for power grid planning management, and the method comprises the steps: obtaining a satellite map of each line ina power grid, and marking an edge layout of each line in the satellite map; obtaining operation data and basic data of each line in the power grid; according to the operation data and the basic data,obtaining at least one of a line loss parameter of each line of the power grid and a load parameter of line equipment, and displaying the obtained parameters on an edge layout, the operation data including line operation parameters; and generating optimization suggestion information according to at least one of the line operation parameters, the line loss parameters and the load parameters so asto optimize power grid planning management. According to the optimization method, device and equipment for power grid planning management provided by the embodiment of the invention, the purpose of optimizing power grid planning management can be achieved, and related workers can observe parameters in a power grid more intuitively.

Owner:QINGYUAN POWER SUPPLY BUREAU OF GUANGDONG POWER GRID CO LTD

Reactive optimizing method of power system based on coordinate evolution

InactiveCN1323478CTo achieve the purpose of optimizationReactive power adjustment/elimination/compensationElectric variable regulationElectric power systemOriginal data

The method includes following steps: dividing control variables (as plant or animal communities) for system reactive optimization into several groups, and each variable is corresponding to a flock in coevolution method; inputting original data, initializing each flock, calculating adaptation function value of each chromosome in initial flocks; based on previous generation, generating new generation through genetics operations of selection, chiasma, variation; calculating adaptation function value fro new generation; selecting optimum chromosome; evolutionary optimization of ecosystem is completed after optimizing each flock; determining whether condition of convergence of genetic algorithm is met, and outputting optimized result. In the invention, problem to be solved is mapped to ecosystem including multiple flocks. Coevolution of interactive flocks makes optimization of system.

Owner:XI AN JIAOTONG UNIV

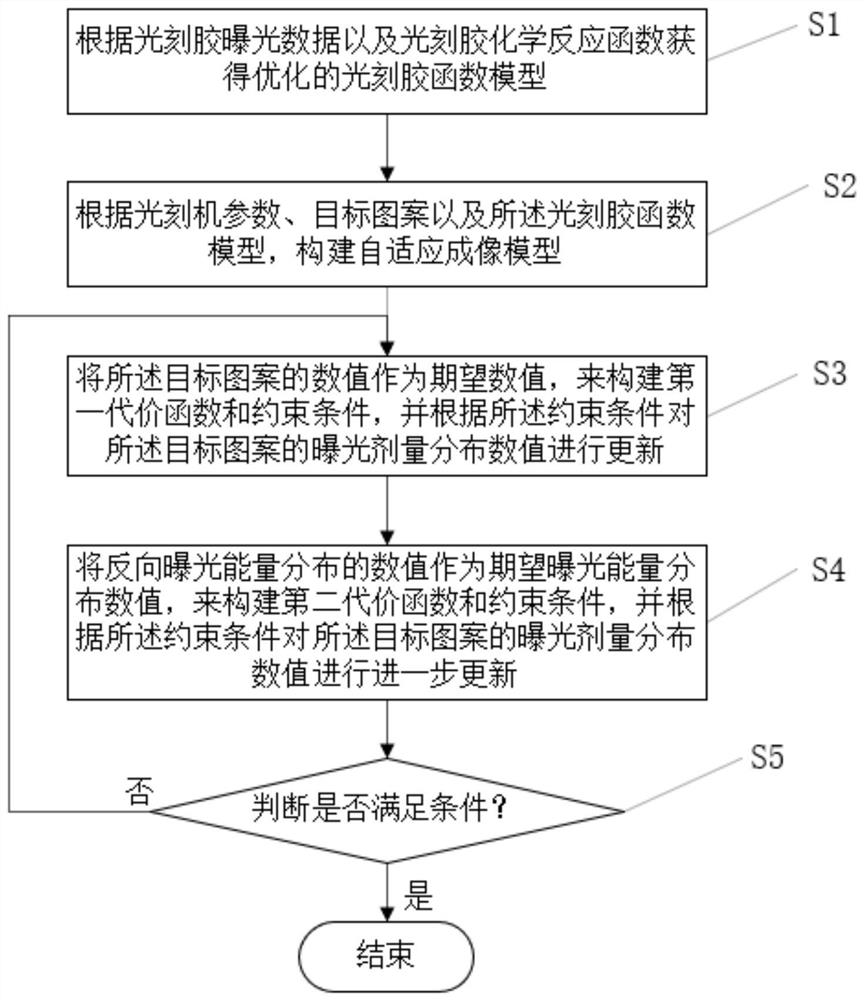

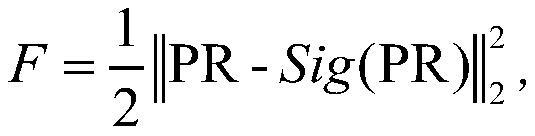

Maskless photoetching optimization method based on OPC model

PendingCN113359385AReduce operating costsReduce computational costPhotomechanical exposure apparatusMicrolithography exposure apparatusAdaptive imagingChemical reaction

The invention provides a maskless photoetching optimization method based on an OPC model. The maskless photoetching optimization method comprises the following steps of: S1, obtaining an optimized photoresist function model according to photoresist exposure data and a photoresist chemical reaction function; S2, constructing a self-adaptive imaging model according to the parameters of a photoetching machine, a target pattern and the photoresist function model; S3, constructing a first cost function and a constraint condition by taking the numerical value of the target pattern as a pixelated numerical value of a wafer circuit board diagram, and updating the numerical value of the exposure dose distribution of the target pattern according to the constraint condition; and S4, constructing a second cost function and a constraint condition by taking the numerical value of the reverse exposure energy distribution as the numerical value of the exposure energy distribution, and further updating the numerical value of the exposure dose distribution of the target pattern according to the constraint condition. The optimization method disclosed by the invention is small in calculation amount, simple in setting and capable of carrying out parallel optimization on global exposure points according to requirements.

Owner:矽万(上海)半导体科技有限公司 +1

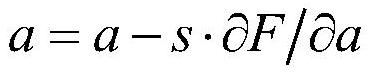

Remote-sensing image semi-automatic water body extraction method

PendingCN111862138AReduce and simplify extraction operationsImprove extraction efficiencyImage enhancementImage analysisEngineeringImage segmentation

The invention discloses a remote sensing image semi-automatic water body extraction method. The method comprises the following steps: modeling features of data; carrying out image segmentation by adopting a graph segmentation technology; judging the connectivity; carrying out vectorization; performing vector graphic operation; and carrying out semi-automatic water body extraction to achieve the effect of instant operation and instant preview. Through the method, the extraction operation of an operator is greatly reduced and simplified; the extraction result is ensured to be more accurate and fit the edge of the ground object; the purpose of optimizing the extraction result is achieved; positive and negative extraction in the water body region extraction process is achieved; the extractionefficiency of an operator is improved, the interaction is simple, the operation is easy, and the extraction is preview.

Owner:BEIJING GEOWAY SOFTWARE

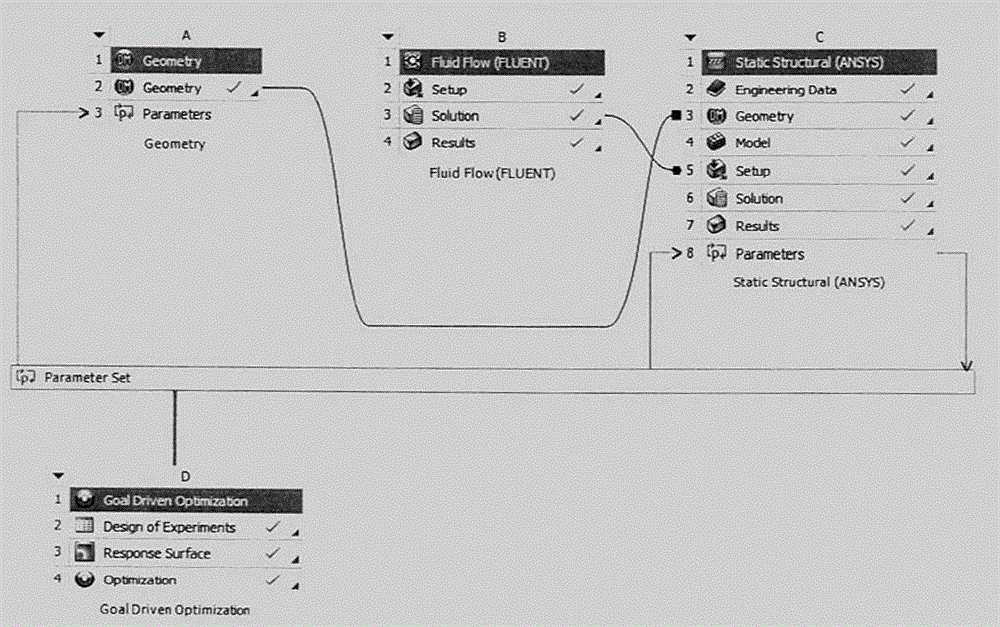

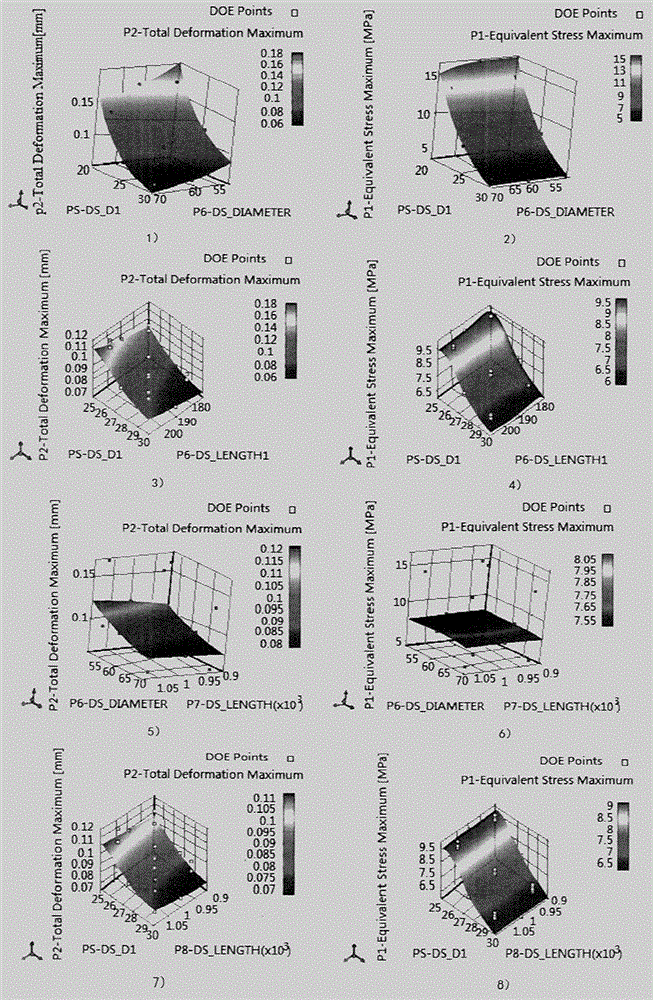

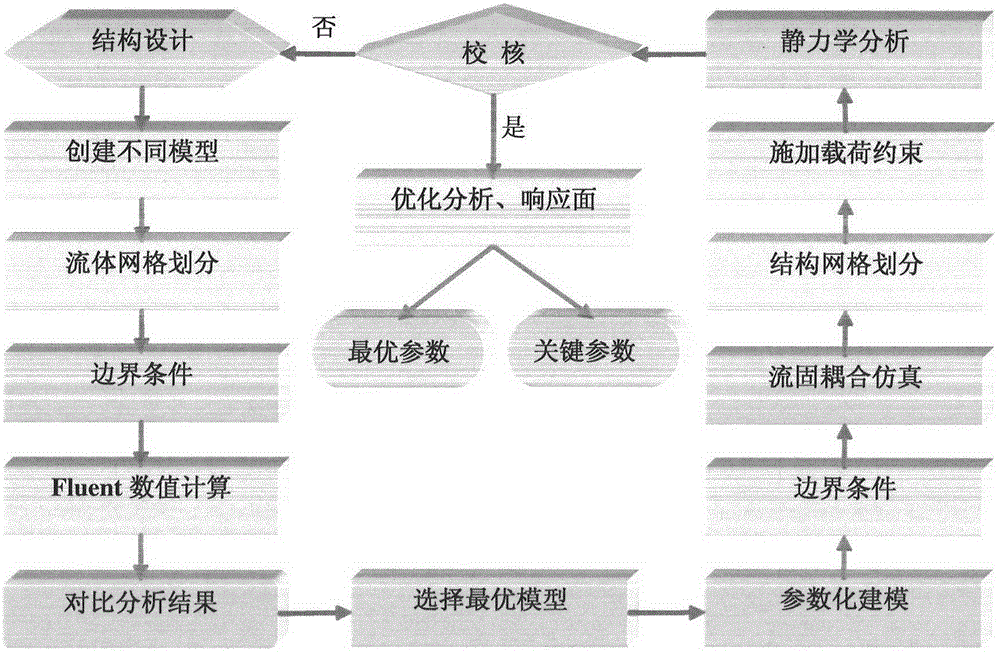

Foam asphalt mixture stirring device structure design and optimization analysis method

ActiveCN105893647AImprove reliabilityEffective and rapid analysis methodSpecial data processing applicationsEngineeringAnalysis method

The present invention discloses a foam asphalt mixture stirring device structure design and optimization analysis method, and is applicable to the technical field of foam asphalt. A counteraction of a foam asphalt mixture pseudo-fluid in numerical simulation of CFD software on a structure is loaded into a stirring structure without a data loss by means of an interface between an ANSYS Workbench platform and the CFD software, and optimization analysis is performed on the structure by means of an ANSYS Workbench optimization tool, so that a seamless connection is performed on driving of a stirring blade, stirring of a mixture pseudo-flow-field and a counteraction of the pseudo-flow-field on the stirring blade, so as to optimize and analyze a structure of a foam asphalt mixture stirring device, and therefore, an effective and rapid design method for the stirring device is provided, and reliability of a stirring device analysis result is improved.

Owner:程海鹰

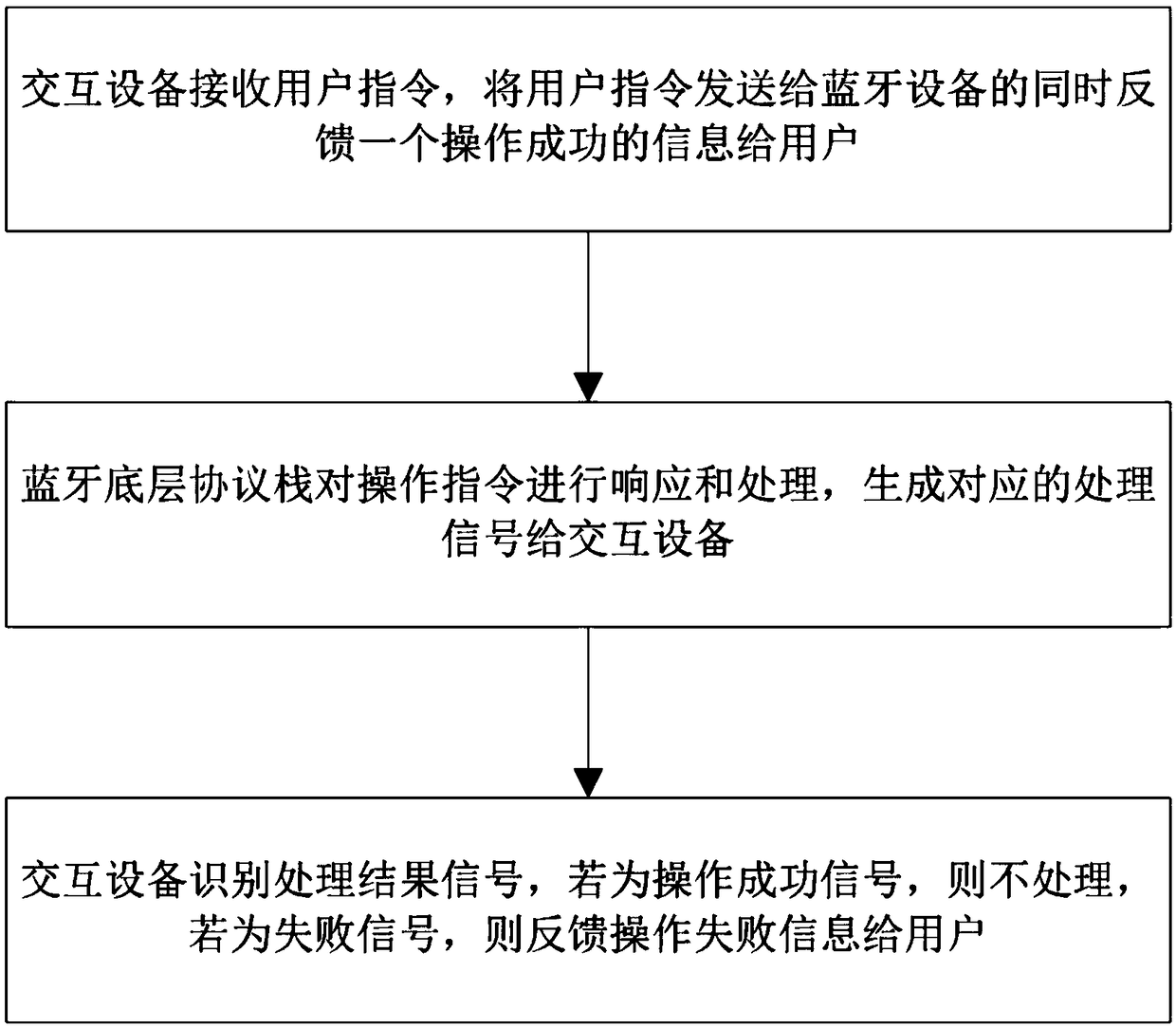

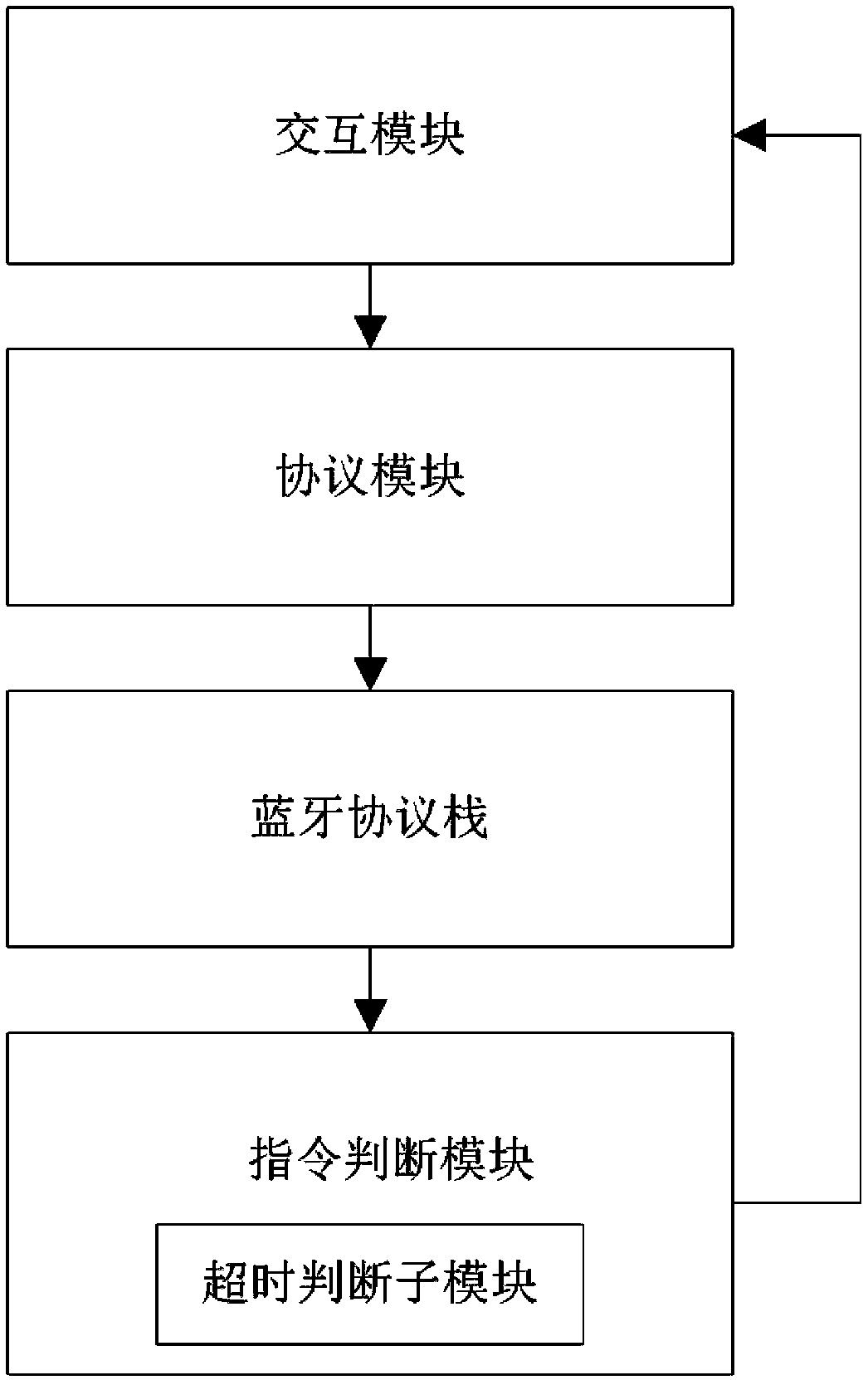

Bluetooth connection optimization method and Bluetooth connection optimization system for embedded system

ActiveCN109413632AAvoid duplicationRelieve stressConnection managementShort range communication serviceInteraction deviceBluetooth

The invention provides a Bluetooth connection optimization method and a Bluetooth connection optimization system for an embedded system. The method comprises the following steps: a user sends an operation instruction to the Bluetooth through an interaction device, the interaction device first feeds back the operation success information to the user after receiving the operation instruction, the interaction device sends the operation instruction to an underlying protocol stack of the Bluetooth at the same time, the underlying protocol stack responds and processes the operation instruction and generates a processing result signal, the processing result signal is sent to the interaction device, the interaction device identifies the processing result signal, if the processing result signal isan operation success signal, the interaction device does not process, and if the processing result signal is an operation failure signal, the interaction device feeds back operation failure information to the user. The Bluetooth connection optimization method and Bluetooth connection optimization system use the protocol to filter user instructions to prevent repeated user instructions from exerting pressure on the protocol stack of the Bluetooth, and at the same time, use a method of feeding back information in advance to achieve the purpose of prompting the user, so as to prevent the user from blindly repeating operations multiple times without receiving feedback information.

Owner:蜂巢(武汉)微系统技术有限公司

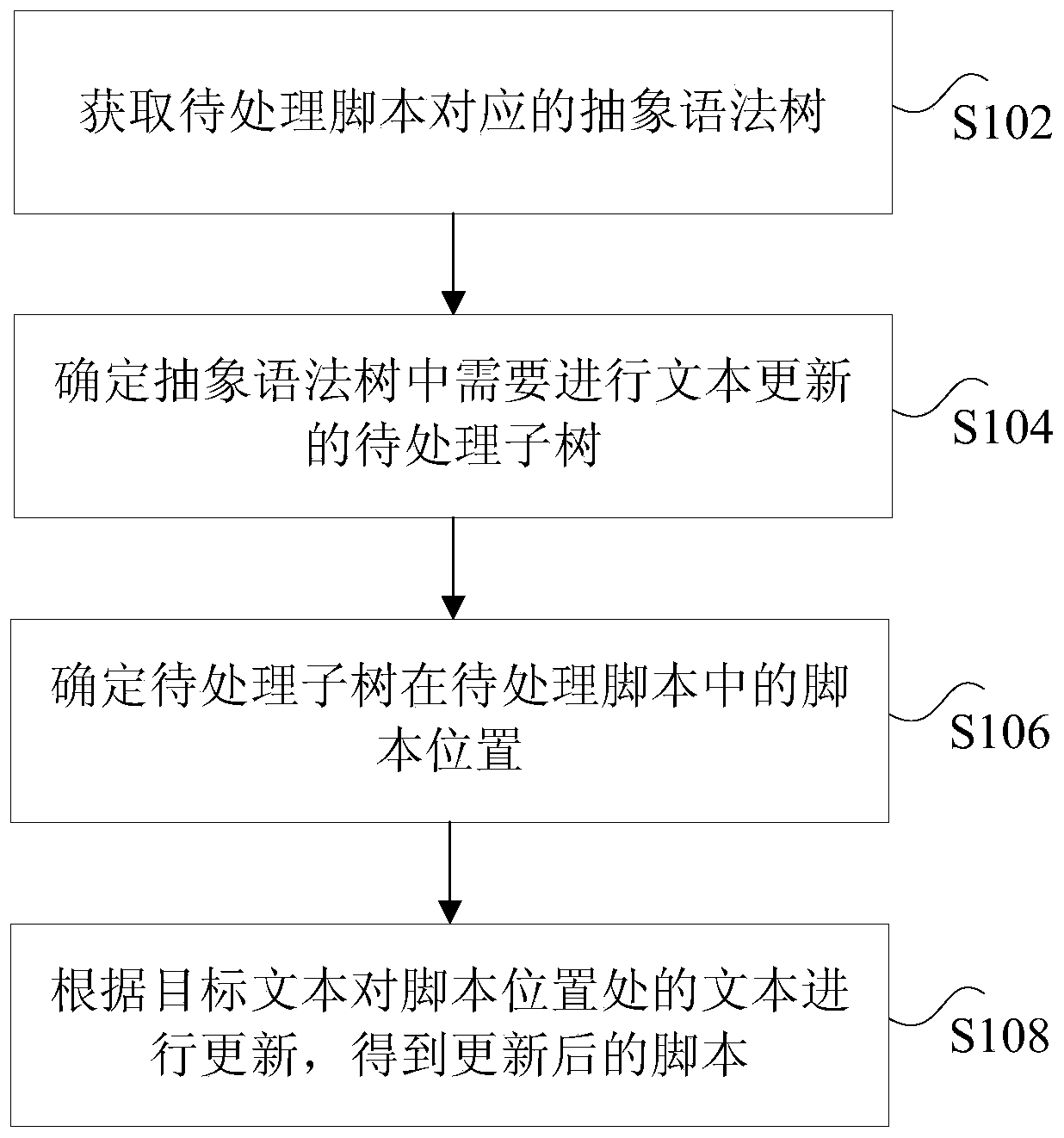

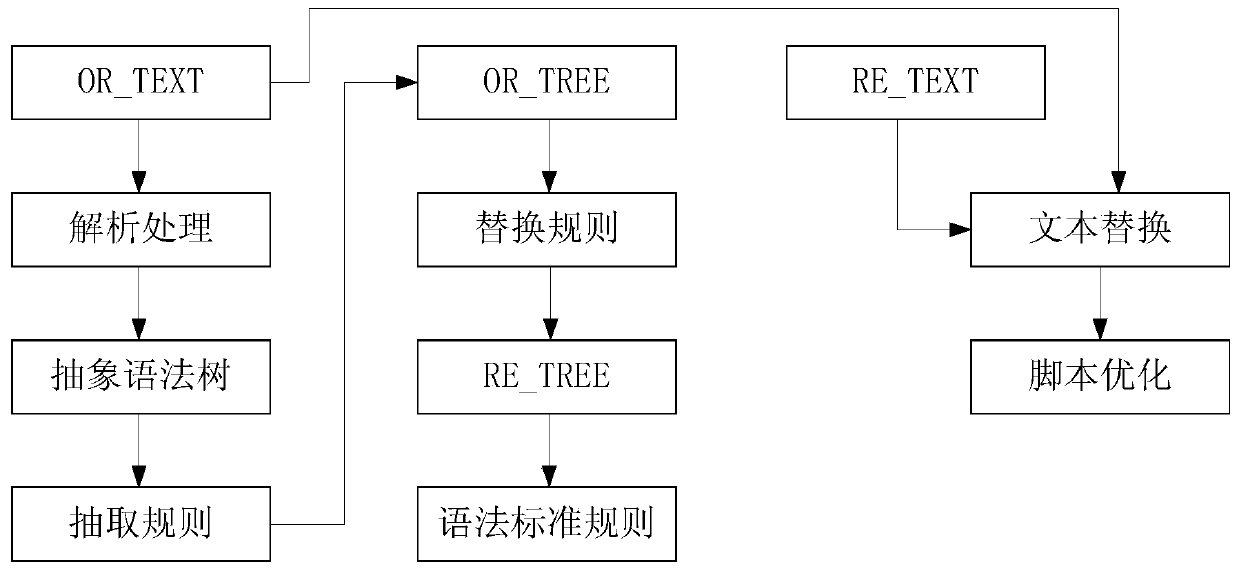

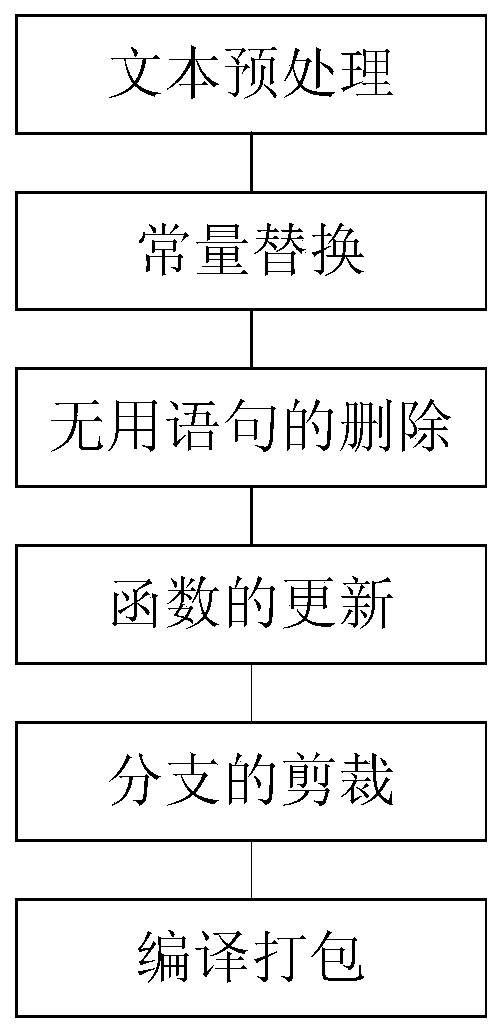

Script updating method and device

PendingCN110347416ATo achieve the purpose of optimizationImprove optimization efficiencySoftware deploymentProgramming languageTheoretical computer science

The invention discloses a script updating method and device. The method comprises: obtaining an abstract syntax tree corresponding to a script to be processed, wherein the abstract syntax tree is a tree-shaped expression form of an abstract syntax structure of the script to be processed; determining a to-be-processed sub-tree needing text updating in the abstract syntax tree; determining a scriptposition of the to-be-processed sub-tree in a to-be-processed script; and updating the text at the script position according to the target text to obtain an updated script. The technical problem of low script optimization efficiency in the prior art is solved.

Owner:NETEASE (HANGZHOU) NETWORK CO LTD

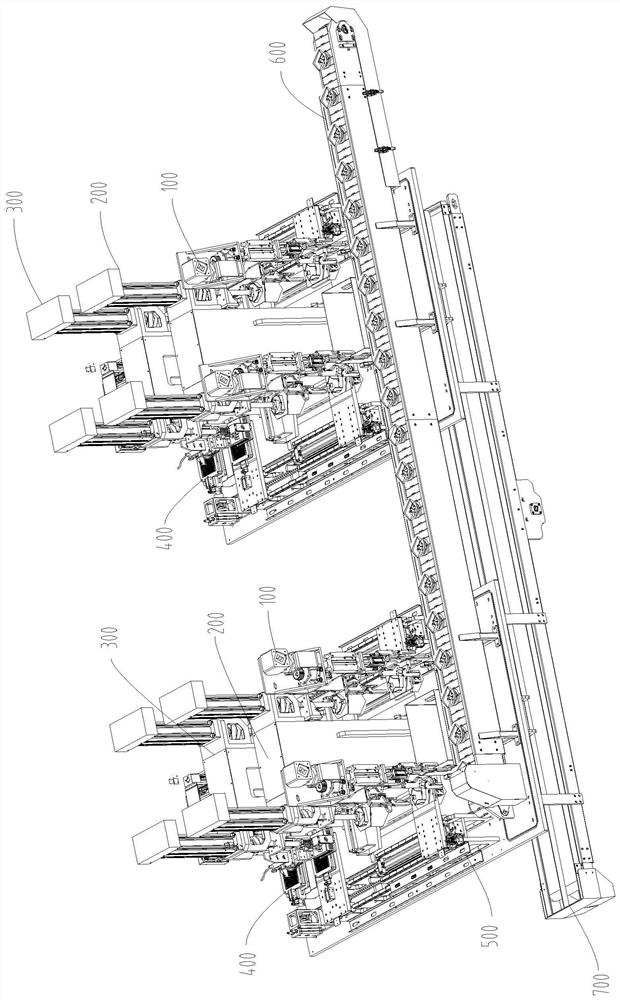

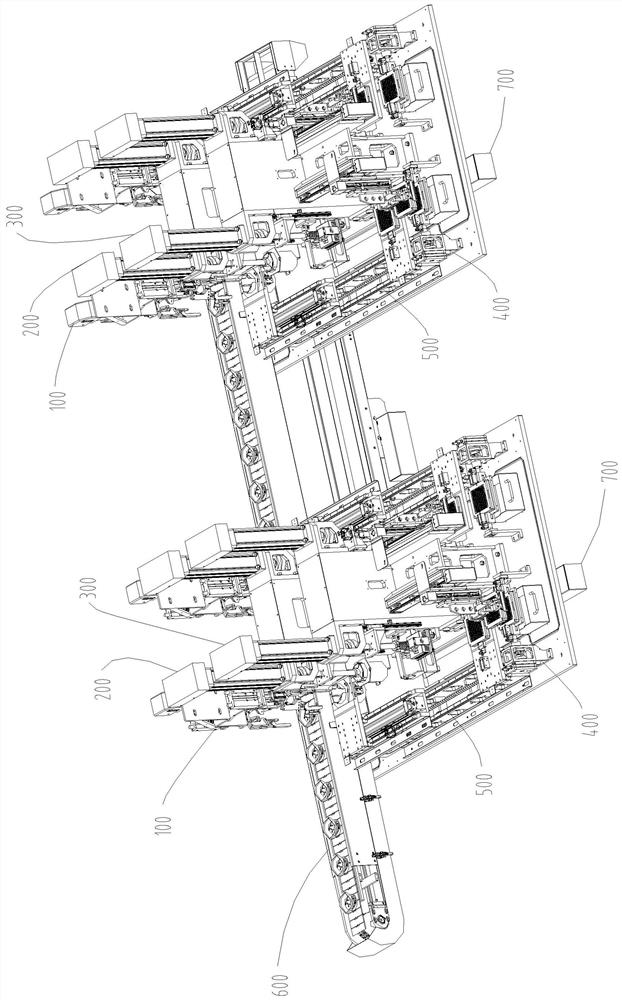

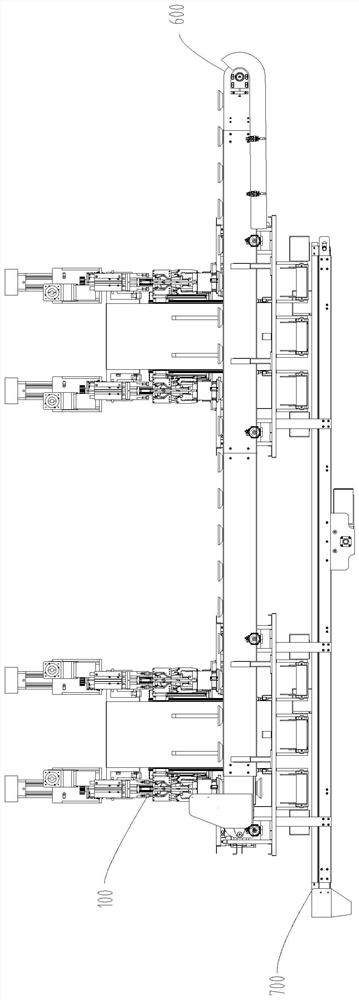

Automatic pickled mustard tuber processing device and operation method thereof

PendingCN114083615AGood quality extruded wireReduce labor intensityMetal working apparatusProcess engineeringCleaning station

The invention relates to an automatic pickled mustard tuber processing device which comprises a feeding mechanism and a material receiving belt, wherein one side of the feeding mechanism is provided with a processing unit, the processing unit comprises a track, a first conveying module and a second conveying module, the first conveying module conveys a grid cutter head, and the second conveying module conveys a guide cylinder; one side of the track is provided with a material taking station, a shred pressing station, a shred extruding and discharging station and a cutting board overturning and cleaning station; the material taking station comprises a material taking mechanism and is used for clamping and carrying the pickled mustard tuber into the guide cylinder; the shred pressing station comprises a pre-pressing mechanism and is used for extruding the pickled mustard tuber in the guide cylinder, and the shredded pickled mustard tuber is placed on the grid cutter head; the extruding and shredding station comprises an extruding and shredding mechanism and is used for slicing the pickled mustard tuber on the grid cutter head, pushing skins and extruding and shredding the pickled mustard tuber; the cutting board overturning and cleaning station comprises a cutting board conveying mechanism and a cutting board overturning mechanism and is used for cleaning residual pickled mustard tuber on the grid cutter head; and the material receiving belt is used for receiving and conveying the shredded pickled mustard tuber and residual pickled mustard tuber. The automatic pickled mustard tuber processing device can efficiently conduct shred extruding and discharging on the pickled mustard tuber.

Owner:无锡市宝御达机械设备制造有限公司

Graph editing distance solving method for letter recognition

ActiveCN107609592APracticalAvoid restrictionsCharacter and pattern recognitionEdit distanceLetter recognition

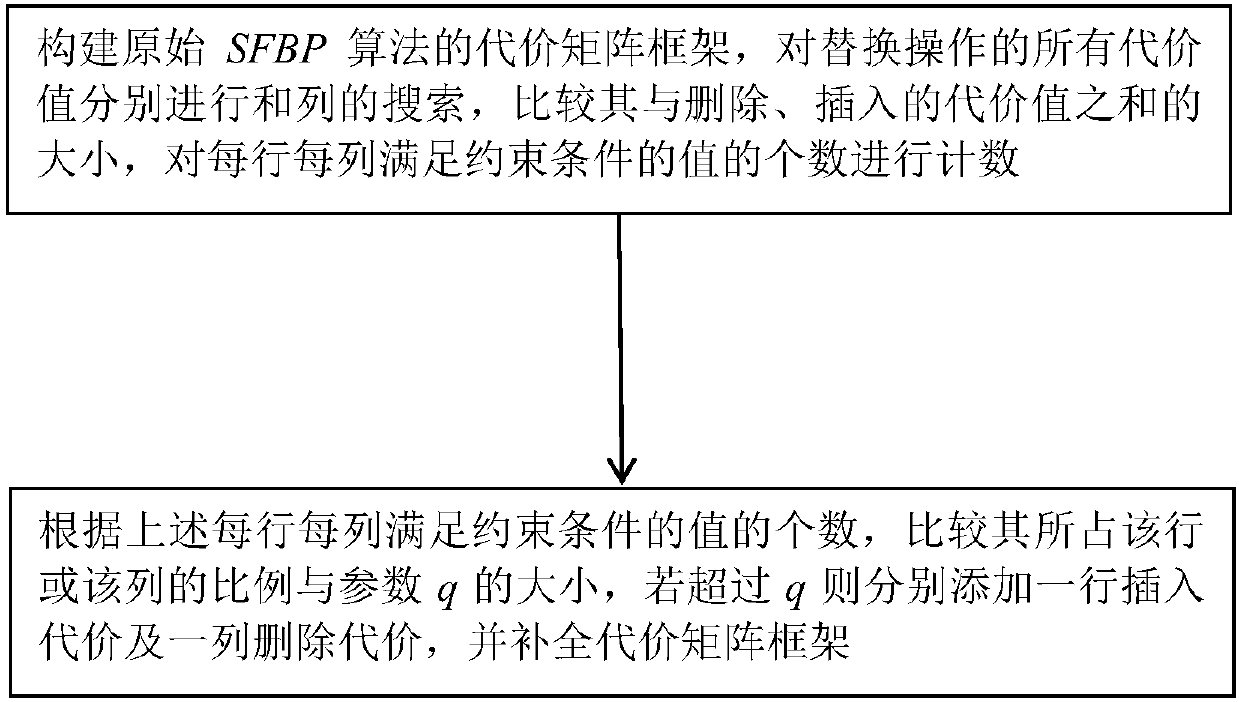

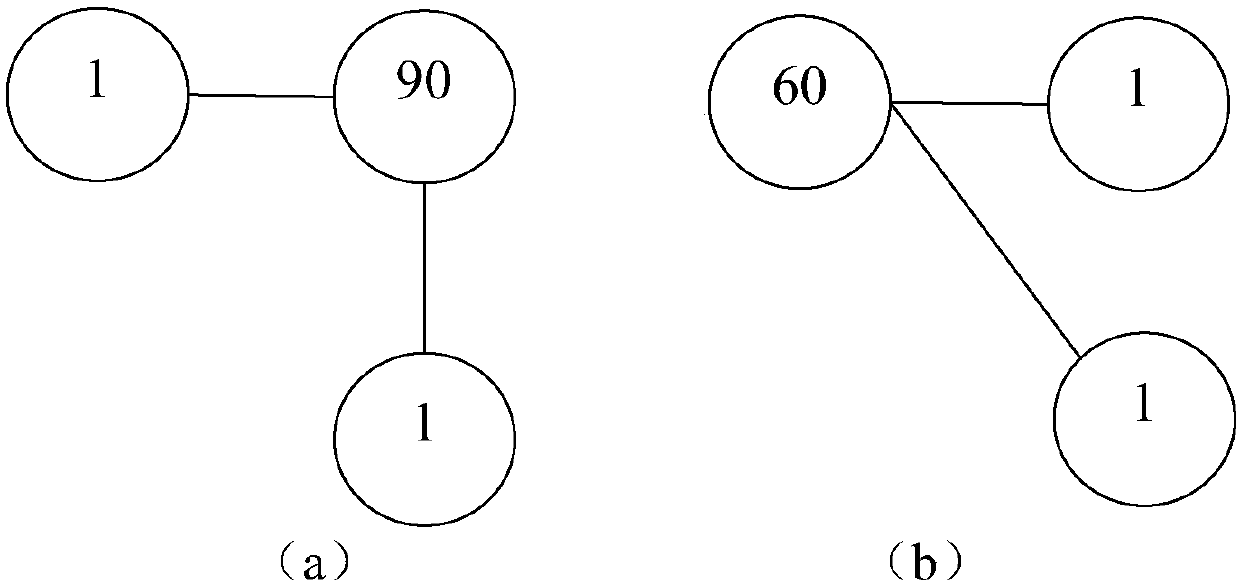

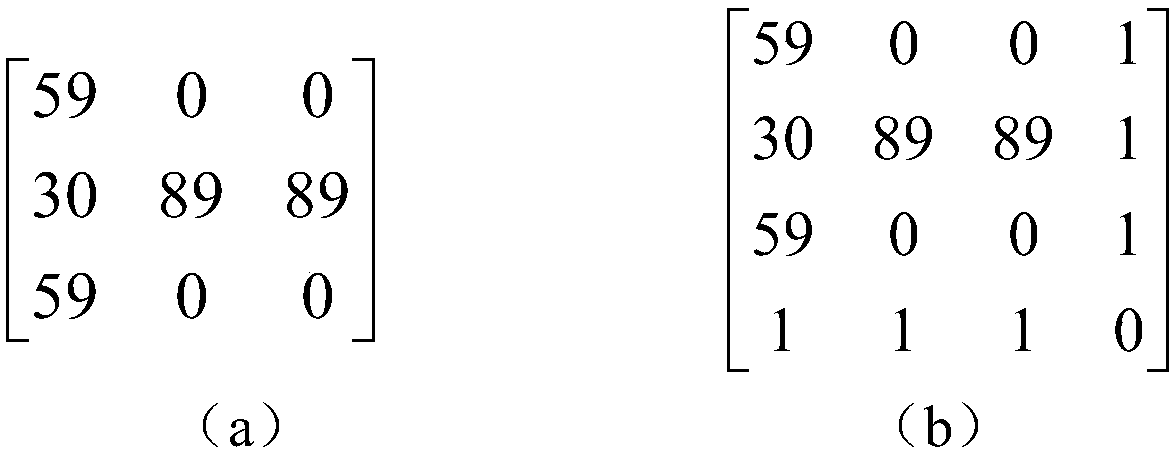

The invention discloses a graph editing distance solving method for letter recognition. According to the method, based on an existing SFBP algorithm framework, the number of elements meeting a constraint condition in each row and each column is counted through item-by-item search comparison of the elements of a cost matrix framework; and by comparing the ratio of the number of the elements meetingthe constraint condition in each row and each column to the elements in each row and each column, a corresponding number of rows and columns of cost values is added to the SFBP cost matrix frameworkto change the cost matrix framework, and therefore the purpose of optimization is achieved. When the optimization objective is achieved, a solving algorithm can be used to perform solving calculationon a cost matrix, therefore, the limitation of the constraint condition on algorithm usage is avoided, and the algorithm is better applied to the letter recognition field.

Owner:GUILIN UNIV OF ELECTRONIC TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com