Drawing optimization device for textile use

An optimized device and drawing frame technology, which is applied in the direction of textiles and papermaking, spinning machines, drafting equipment, etc., can solve the problem of weak adhesion of sliver, and achieve the effect of simple and convenient adjustment method and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

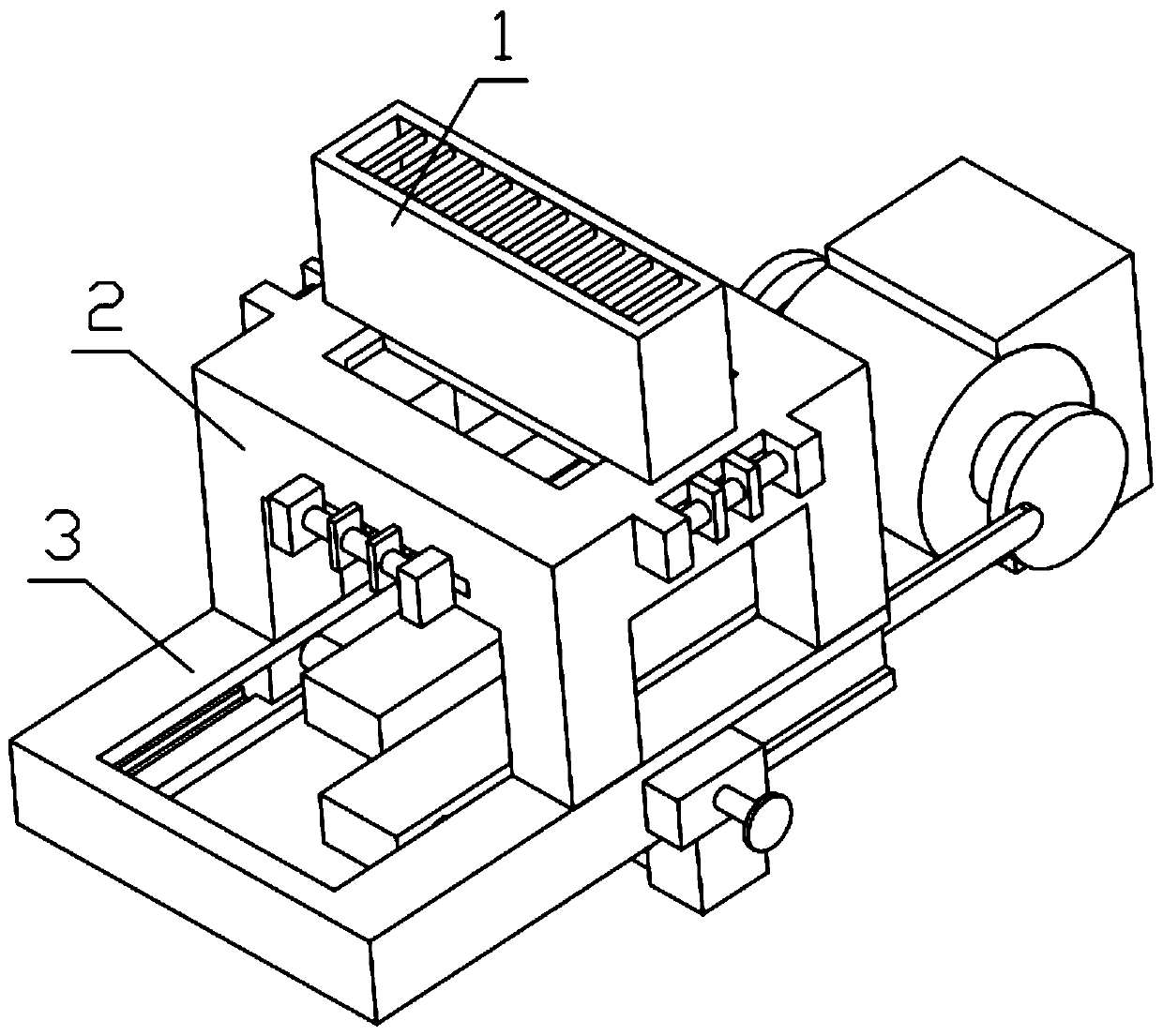

[0026] Combine below Figure 1-10 Describe this embodiment, a drawing frame optimization device for textiles, including a branch box 1, an adjustable draw frame mechanism 2 and a draw frame optimization mechanism 3, and the thread branch box 1 is fixedly installed on the adjustable draw frame mechanism 2 , the adjustable draw frame 2 is fixedly installed on the draw frame optimization mechanism 3 .

specific Embodiment approach 2

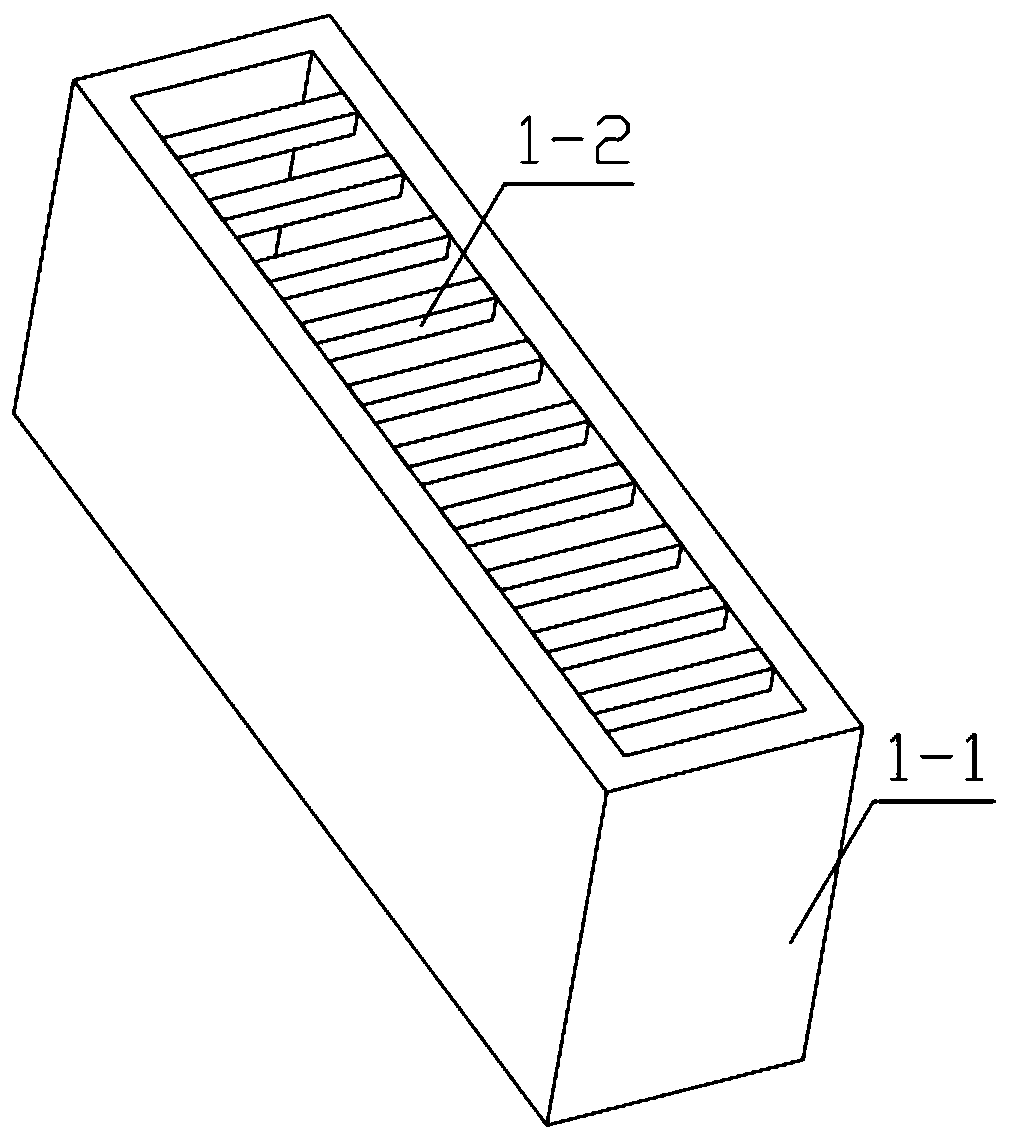

[0028] Combine below Figure 1-10 Describe this embodiment, this embodiment will further explain Embodiment 1, the described junction box 1 includes a rectangular shell 1-1, a partition 1-2, and there are multiple partitions 1-2, which are evenly fixed Installed on the rectangular shell 1-1.

specific Embodiment approach 3

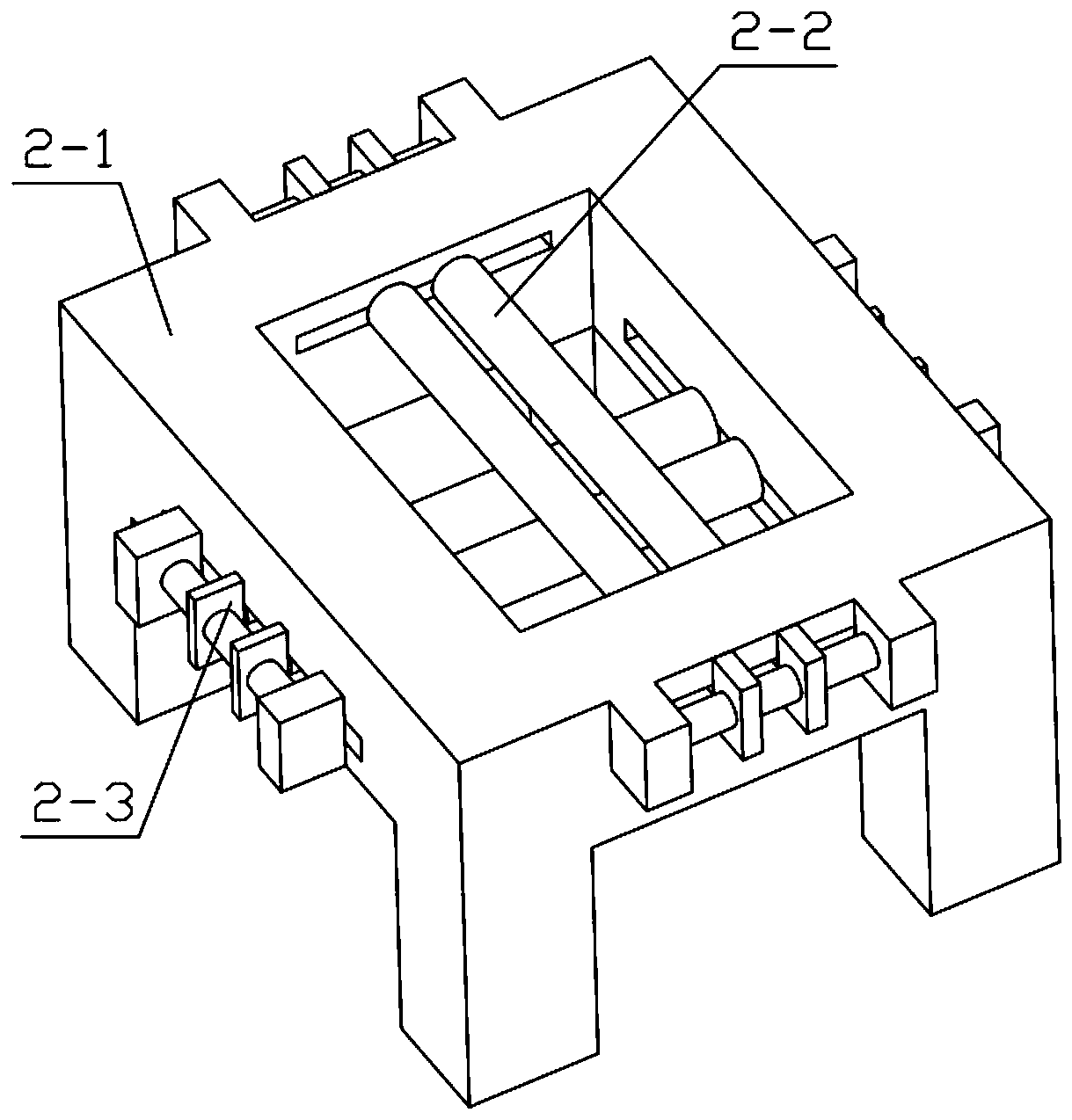

[0030] Combine below Figure 1-10 Describe this embodiment, this embodiment will further explain the first embodiment, the adjustable drawing frame 2 includes a fixed frame 2-1, a longitudinal limit cotton roller assembly 2-2, and a transverse limit cotton roller assembly 2-3 , the longitudinal limit cotton roller assembly 2-2 is movably installed on the through hole provided on the fixed frame 2-1, and the transverse limit cotton roller assembly 2-3 is movably installed on the through hole provided on the fixed frame 2-1; The limit cotton roller assembly 2-2 includes cotton roller 2-2-1, central shaft 2-2-2, moving plate 2-2-3, limit circular piece 2-2-4, two-way threaded rod 2- 2-5, the central axis 2-2-2 passes through the cotton roller 2-2-1, the cotton roller 2-2-1 is movably installed on the central axis 2-2-2, and the moving plate 2-2-3 is fixedly installed On the central axis 2-2-2, the moving plate 2-2-3 is threadedly connected with the two-way threaded rod 2-2-5, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com