Printer roller platen rotation angle adjusting method and apparatus

A technology of embossing rollers and printing machines, applied in printing machines, rotary printing machines, printing, etc., can solve the problems of low alignment accuracy of printing plate rollers, affect the printing quality of printed products, and long adjustment strokes, and achieve direct adjustment methods Simple, short stroke, and the effect of improving printing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

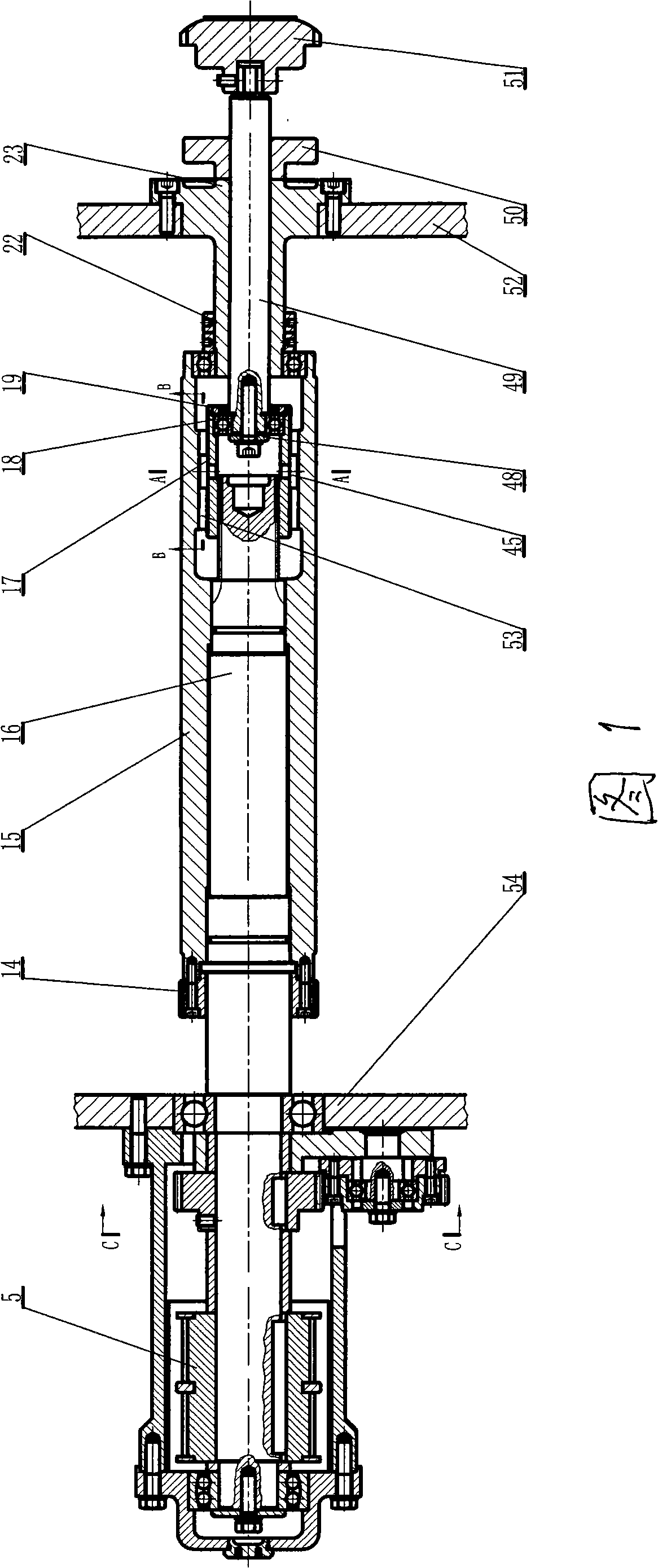

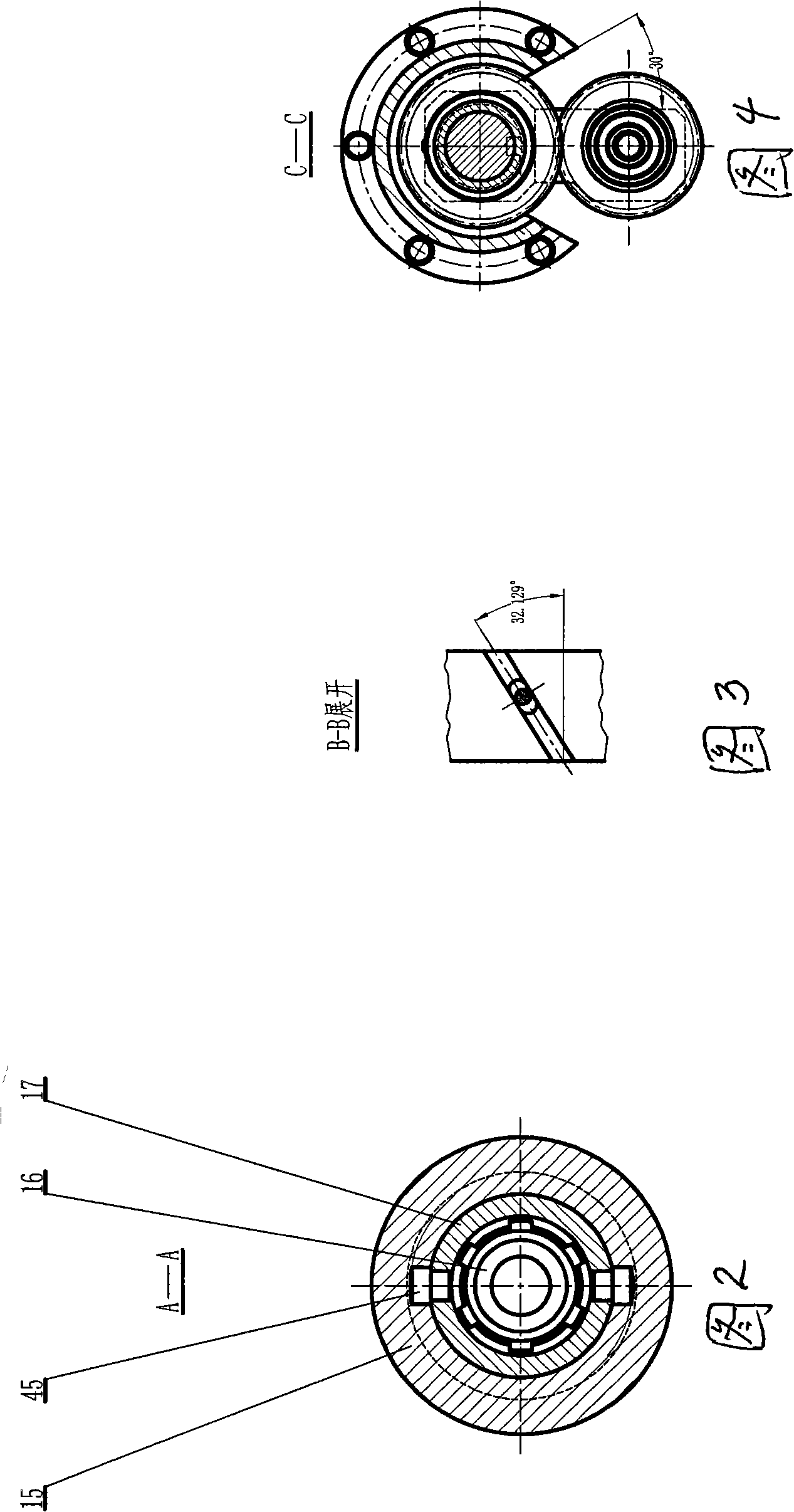

[0012] With reference to the accompanying drawings, the embossing roller corner setting method of the printing press of the present invention is: first, unclamp the nut 50 that is mounted on the screw rod 49 and the outer end of the threaded seat 23 that is sleeved on the screw rod 49; The knob 51 rotates the screw rod 49, and then the inner spline sleeve 17 which is installed on the periphery of the bearing 18 at the inner end of the screw rod 49 and connected with the inner end of the embossing roller shaft 16 moves horizontally; The shifting block 45 on the inner spline sleeve 17 and embedded in the rectangular threaded groove 53 on the inner wall of the embossing roller 15 moves, due to the dual restriction of the shifting block 45 and the rectangular threaded groove on the embossing roller 15, Force the embossing roller 15 and the embossing roller shaft 16 to produce relative rotational movement (about ± 30 degrees, as shown in Figure 4), due to the effect of the gear 14 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com