Self-locking hydraulic variable-diameter threshing cylinder and combine harvester

A threshing drum, hydraulic technology, applied in the direction of harvesters, threshing equipment, cutters, etc., can solve the problems of complex structure, heavy weight, and poor automatic control of variable diameter drums, so as to ensure operation stability, reduce weight, Effects that are easy to automate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention is not limited thereto.

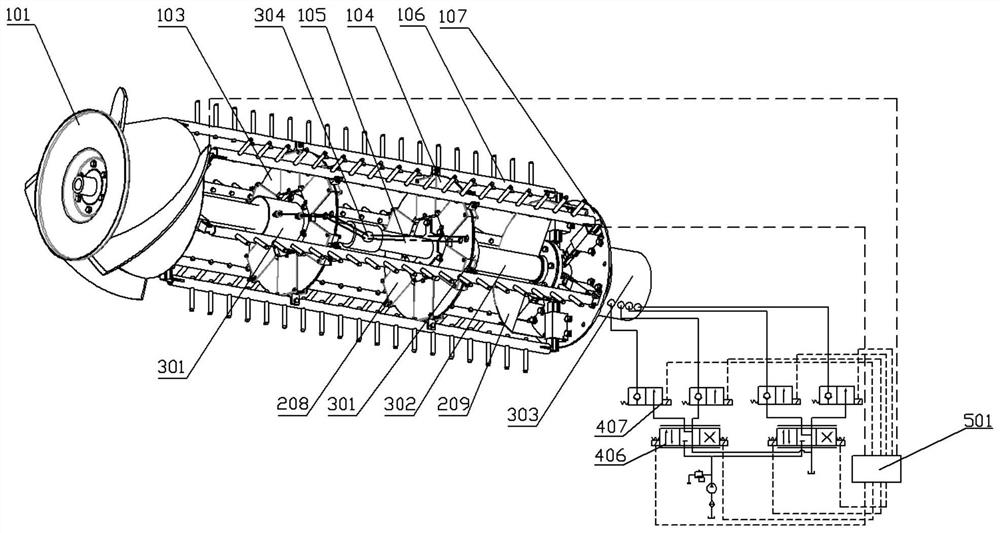

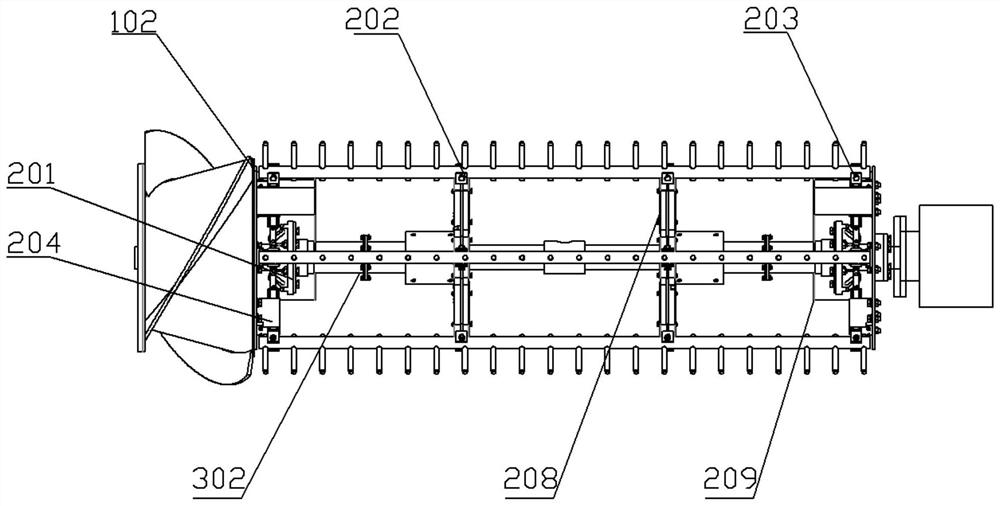

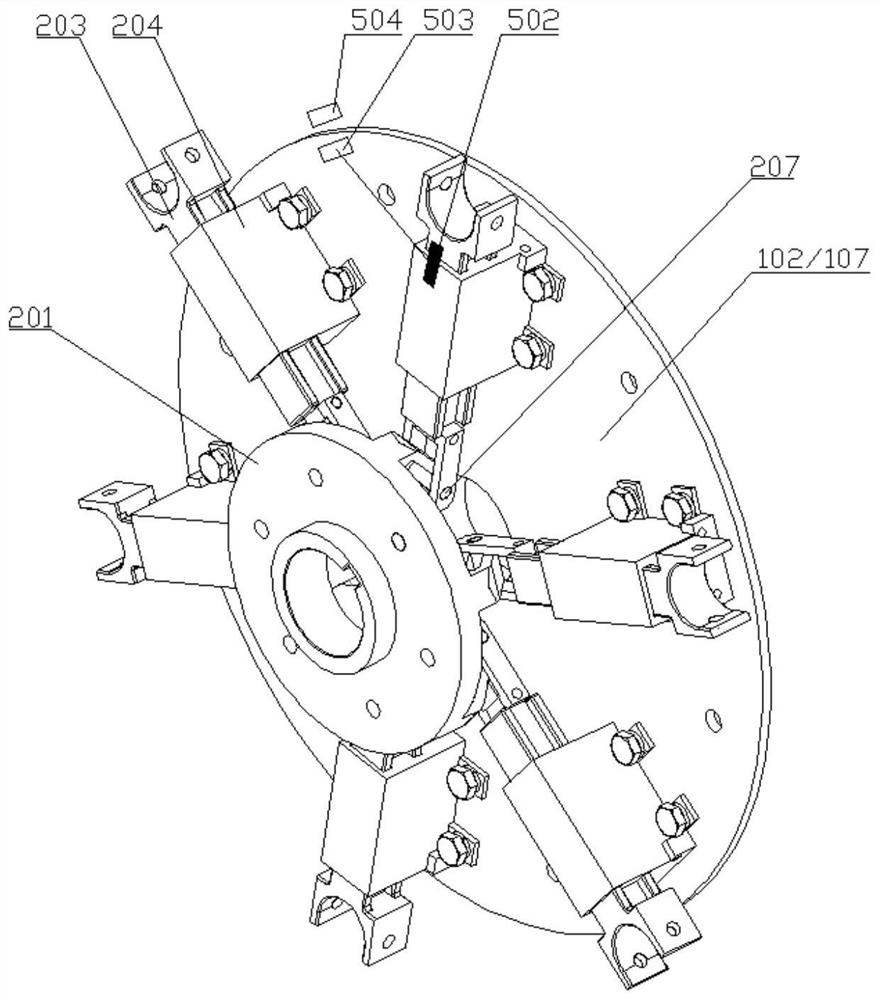

[0039] Such as figure 1 , figure 2 As shown, the self-locking hydraulic variable-diameter threshing drum of the present invention includes a threshing drum, a diameter adjustment device, a hydraulic transmission device, a hydraulic pump station, and a signal acquisition control system. The diameter adjustment device is located inside the threshing drum and is respectively installed on the The inner sides of the support discs at both ends of the drum and the installation grooves of the middle support discs are symmetrical to each other, and the first dustproof cover 208 and the second dustproof cover 209 are installed to prevent dust.

[0040] Described threshing drum comprises drum main shaft 105, along the feed direction from front to back is installed on the feeding w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com