Sand making machine transmission twin-roller machine assembly

A technology of double roller machine and sand making machine, which is applied in the direction of grain processing, etc., which can solve the problems of inconvenient adjustment and heavy roller, and achieve the effect of simple and convenient adjustment method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

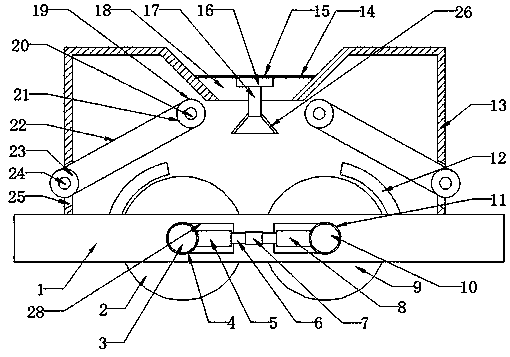

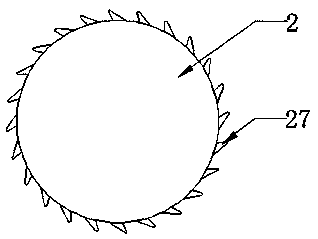

[0025] see Figure 1-3 , this embodiment provides a sand making machine transmission roller assembly, including a side support plate 1, a first roller 2 and a third roller 9; the side support plate 1 is provided with two opposite pieces, and The middle parts of the two side support plates 1 are provided with adjustment slots 28, the first roller 2 and the second roller 9 are located between the two side support plates 1, and the two ends of the first roller 2 pass through the first rotating shaft 3 respectively Through the corresponding adjustment slots 28 on the two side support plates 1, the two ends of the second roller 9 respectively pass through the corresponding adjustment slots 28 on the two side support plates 1 through the second rotating shaft 10; The first sleeve 4 is sleeved on the first rotating shaft 3, and the second sleeve 11 is sleeved on the second rotating shaft 10; the right side of the first sleeve 4 is fixedly connected to the first threaded cylinder 5, a...

Embodiment 2

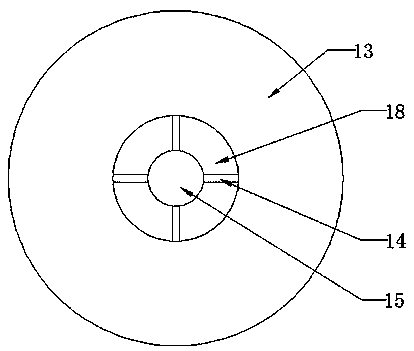

[0028] see figure 1 with Figure 4 , a sand making machine transmission roller machine assembly, also includes iron removal devices 19 located on the left and right sides of the dispersing rotating rod 26 in the box body 1; the iron removal device 19 includes a first pulley 21 and a second belt pulley Wheel 23; the second pulley 23 is located at the taphole 25 on the lower left side of the box body 1; the second pulley 23 is covered with a conveyor belt 22; Extend and sleeve to the first pulley 21, the outer surface of the conveyor belt 22 is provided with a number of magnet pieces 29 distributed at equal intervals; 29 for adsorption and delivery to the outside of the box body 1 through the iron tap 25, so as to achieve the purpose of removing iron from the stone.

[0029] The working principle of the present invention is: the threaded rod 6 is driven to rotate by rotating the adjusting fixed block 7, so that the first threaded cylinder 5 on the left side and the second thre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com