Foam asphalt mixture stirring device structure design and optimization analysis method

A technology for mixing equipment and foamed asphalt, applied in the field of foamed asphalt, can solve the problem that the asphalt mixing equipment cannot meet the construction and production requirements, etc., and achieve the effect of an effective and rapid analysis method, improving reliability and improving reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

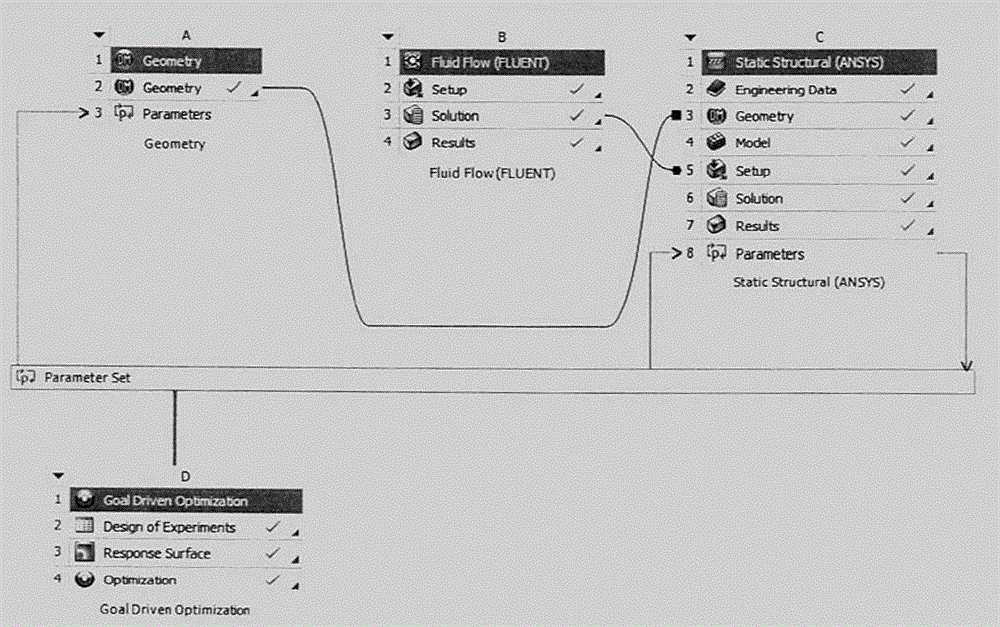

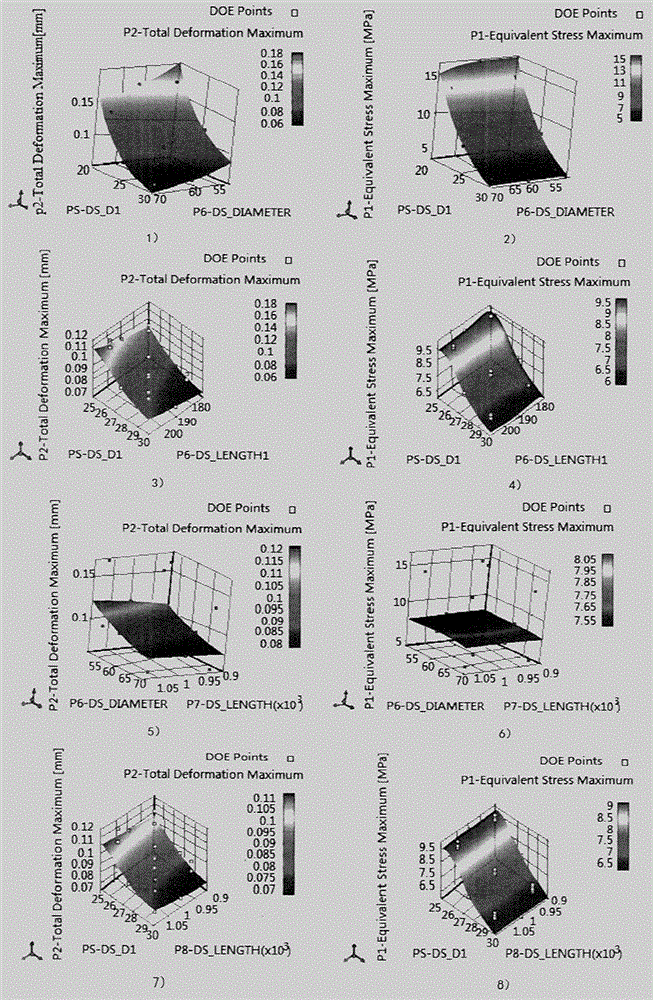

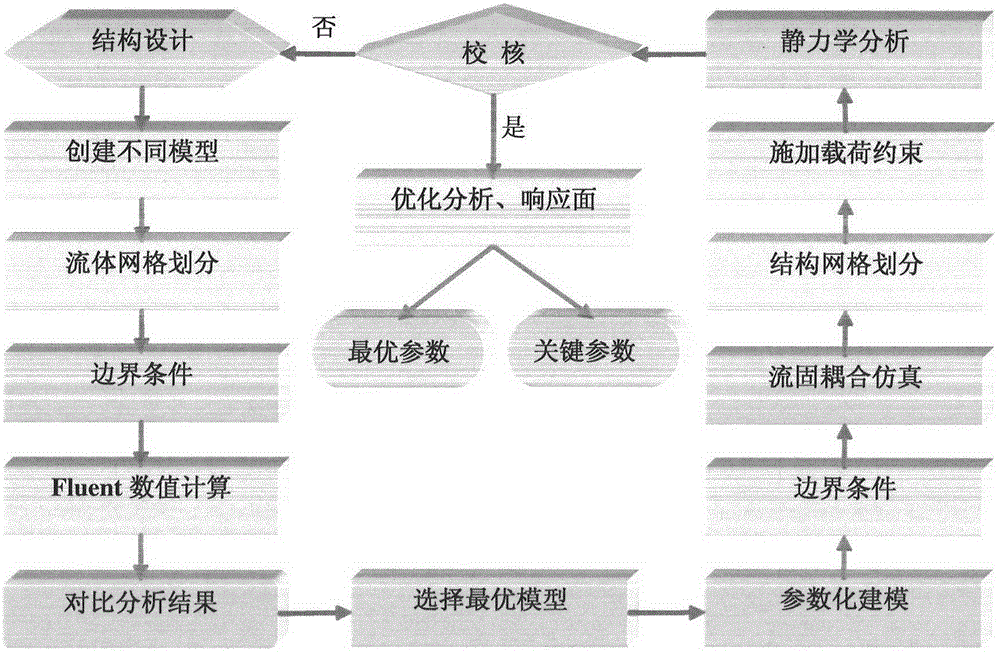

[0025] An analysis method for structural design and optimization of foamed asphalt mixture mixing equipment, the steps include (see attached figure 1 Shown): The structural design of the foamed asphalt mixture mixing equipment, the creation of different solid models of blades with reverse, positive and negative, and positive and negative, the mesh division and boundary condition definition of the model, the mixing of foamed asphalt mixture in the mixing equipment Numerical simulation of combined effects, comparison and analysis of simulation results to obtain the optimal model, parametric modeling of the optimal model and static analysis of the stirring shaft and blades through fluid-solid coupling analysis, if the check conditions are not met, the structure will be re-engineered Design, otherwise, analyze and optimize the main structural parameters of the equipment. The specific implementation is as follows:

[0026] For a twin-shaft forced intermittent foam asphalt mixing e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com