Manufacturing method of invisible correcting device and based on numerical control machining

A technology of invisible aligners and manufacturing methods, which is applied in the field of orthodontics, can solve the problems of low precision and high cost of invisible aligners, and achieve the effects of saving costs, protecting from scratches, and preventing falling off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

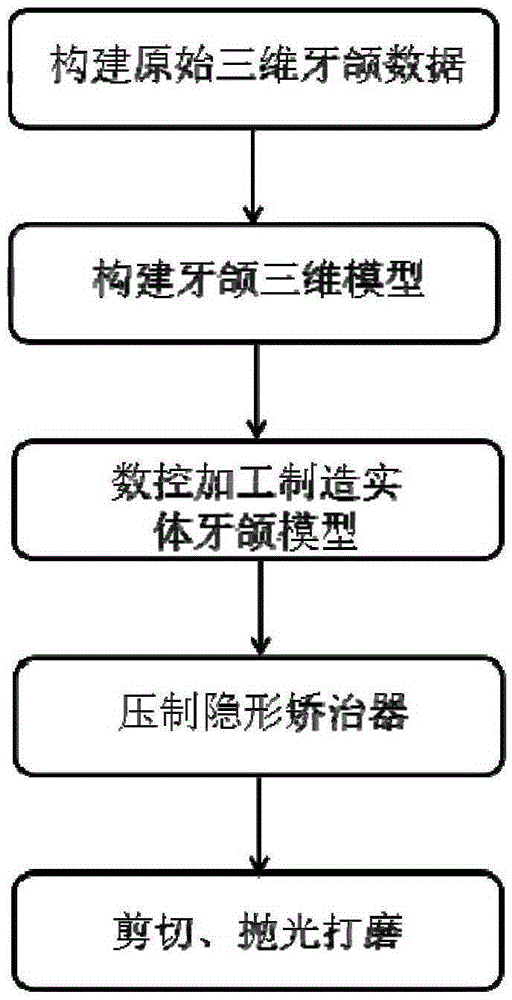

Method used

Image

Examples

Embodiment 1

[0042] Example 1 Manufacture of bracketless invisible appliance

[0043] 1. Obtain the patient's silicone dental mold.

[0044] 2. Make the patient's plaster dental jaw prototype according to the dental jaw female mold.

[0045] 3. Scan the patient's gypsum dental jaw prototype with a laser three-dimensional scanner to obtain the patient's oral data, and establish a three-dimensional model of the patient's oral cavity based on the oral data. The three-dimensional model includes teeth and gum data.

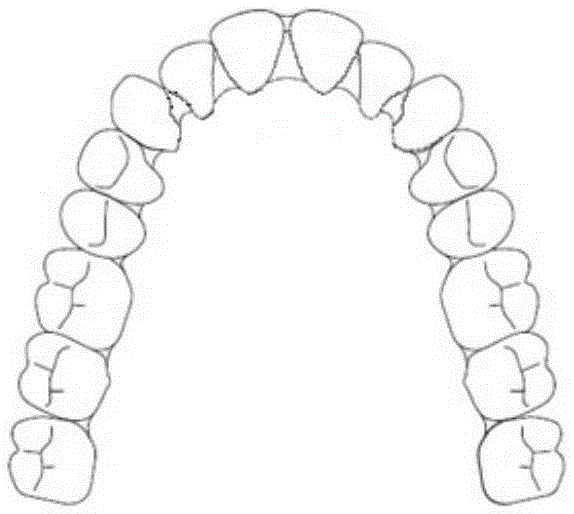

[0046] 4. The dentist designs a treatment plan based on the three-dimensional dental model, adjusts the teeth to be corrected to the target correction position, and obtains the final mobile dental model.

[0047] 5. According to the movement path of the tooth to be corrected on the final mobile jaw model, use CAD simulation software to generate a series of orthodontic jaw models at various stages, in which the maximum displacement of each tooth to be corrected in each step is 0.25mm.

[0048]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com