Method of preventing via hole from oil dropping in lead-free HASL process of circuit board

A technology of circuit boards and vias, which is applied in the field of circuit board manufacturing and can solve the problem of oil loss in vias

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The core idea of the present invention is: in the present invention, the circuit board is subjected to micro-etching and browning treatment to form a rough surface on the wall of the via hole, and then green oil is plugged in the via hole formed with the rough surface, and then baked. Board treatment, so that the green oil in the via hole can form adhesion with the rough surface of the hole wall, and in the subsequent lead-free tin spraying process, ensure that the temperature is too high to cause the green oil to expand and separate from the hole wall, resulting in dropout oil phenomenon.

[0030] In order to illustrate the idea and purpose of the present invention, the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

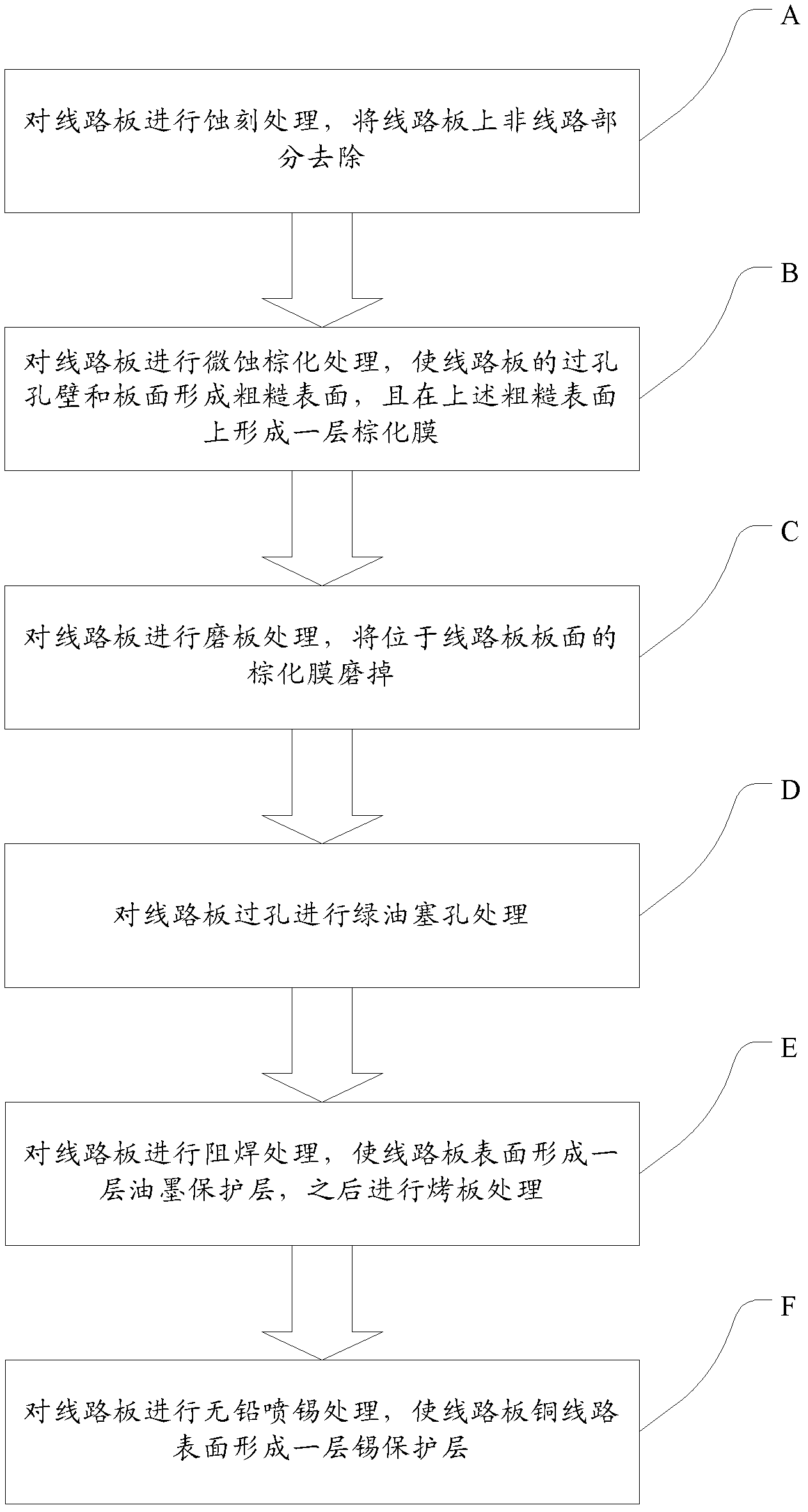

[0031] See figure 1 as shown, figure 1 It is a process flow diagram of the present invention. The present invention provides a method for preventing oil loss through holes dur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com