Rosin modified composite resin and preparation method

A composite resin and rosin modification technology, applied in the field of rosin resin, can solve the problems of high risk, difficult price competition, high cost, etc., and achieve the effect of less process, lower production cost and sales price, and lower cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

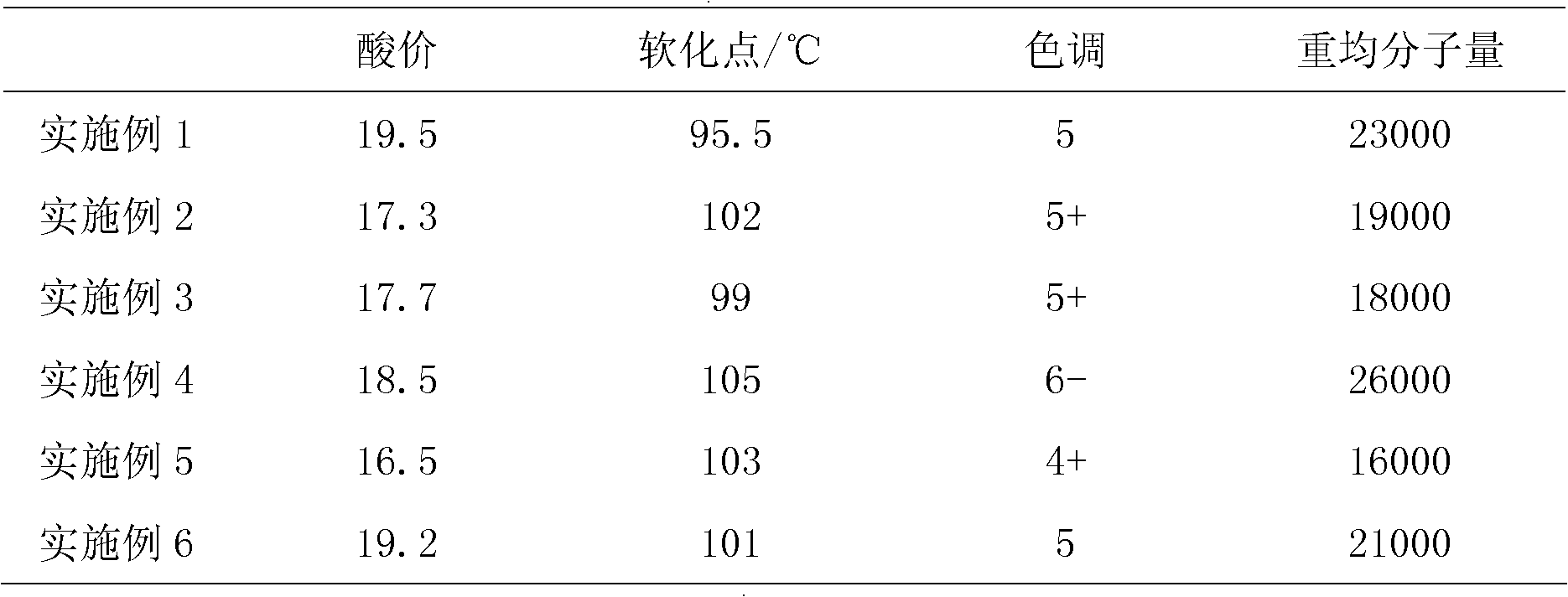

Embodiment 1

[0036] Rosin modified composite resin formula: rosin 64g, fumaric acid 6g, pentaerythritol 12g, anti-3000.5g, DTBHQ0.5g, soybean oil 17g.

[0037] By the raw material of above-mentioned formula, prepare according to the following steps (full process is protected by nitrogen) rosin modified composite resin:

[0038] put the molten rosin into the reactor and raise the temperature to 160°C;

[0039] Add soybean oil, fumaric acid, anti-300;

[0040] After keeping warm for 30 minutes, add pentaerythritol, heat up to 270°C and keep warm;

[0041] After the sampling test is qualified, the pressure is reduced for 1 hour and then the temperature is lowered. When the temperature is lowered, 0.5g of DTBHQ is added.

Embodiment 2

[0043] Rosin modified composite resin formula: rosin 75g, maleic anhydride 4g, pentaerythritol 13g, anti-3000.5g, DTBHQ 0.5g, soybean oil fatty acid 7g.

[0044] By the raw material of above-mentioned formula, prepare according to the following steps (full process is protected by nitrogen) rosin modified composite resin:

[0045] put the molten rosin into the reactor and raise the temperature to 160°C;

[0046] Add soybean oil fatty acid, maleic anhydride, anti-300;

[0047] After keeping warm for 30 minutes, add pentaerythritol, heat up to 270°C and keep warm;

[0048] After the sampling test is qualified, the pressure is reduced for 1 hour and then the temperature is lowered. When the temperature is lowered, 0.5g of DTBHQ is added.

Embodiment 3

[0050] Rosin modified composite resin formula: rosin 70g, maleic anhydride 6g, pentaerythritol 13g, anti-300 0.5g, DTBHQ 0.5g, stearic acid 10g.

[0051] By the raw material of above-mentioned formula, prepare according to the following steps (full process is protected by nitrogen) rosin modified composite resin:

[0052] put the molten rosin into the reactor and raise the temperature to 160°C;

[0053] Add stearic acid, maleic anhydride, anti-300;

[0054] After keeping warm for 30 minutes, add pentaerythritol, heat up to 270°C and keep warm;

[0055] After the sampling test is qualified, the pressure is reduced for 1 hour and then the temperature is lowered. When the temperature is lowered, 0.5g of DTBHQ is added.

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com