Color jet printing machine and jet printing method

A jet printer and color technology, applied in dyeing, printing, typewriter and other directions, can solve the problems of high cost and low work efficiency, and achieve the effect of improving adhesion, improving work efficiency and ensuring no falling off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

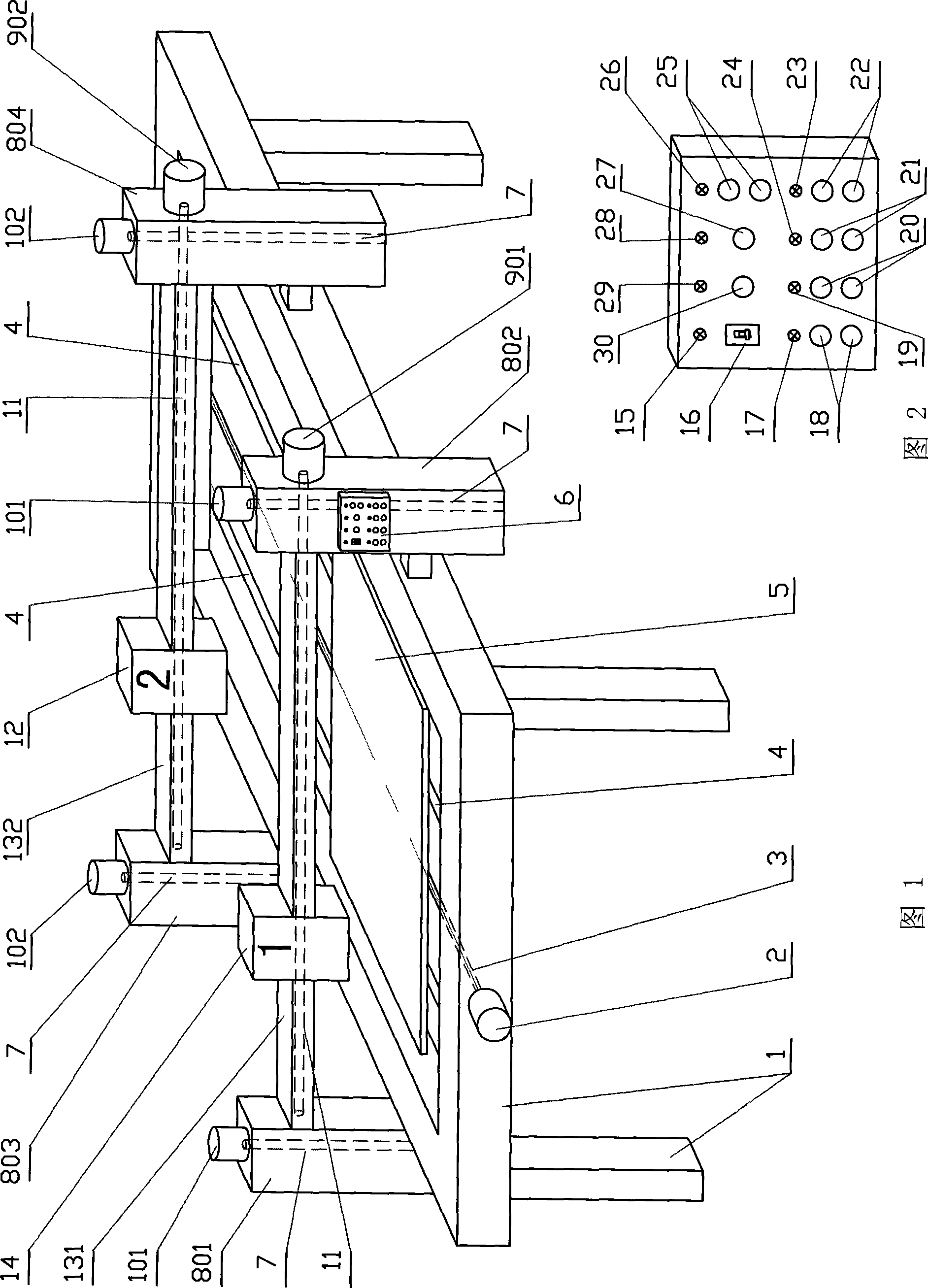

[0030] Embodiment 1 As shown in Figure 1-2: a color jet printing machine with a translational workbench, including a frame, columns, horizontal beams, a jet printing workbench and an electric control box.

[0031] Columns 801 and 802 are provided on both sides of the rectangular frame 1, and the two ends of the 1# horizontal beam 131 perpendicular to the long side of the rectangular frame 1 and the columns 801 and 802 are slidably installed on the vertical guide rails of the columns 801 and 802 respectively. Above: There are vertical transmission screw rods 7 inside the columns 801 and 802, the vertical motors 101 installed on the top of the columns 801 and 802 are connected to the vertical transmission screw rods 7, and the transmission nuts at both ends of the 1# horizontal beam 131 are respectively fastened Engage with the vertical transmission screw 7 located in the same column; 1# inkjet box 14 is slidably installed on the guide rail of 1# horizontal beam 131, and a horizo...

Embodiment 2

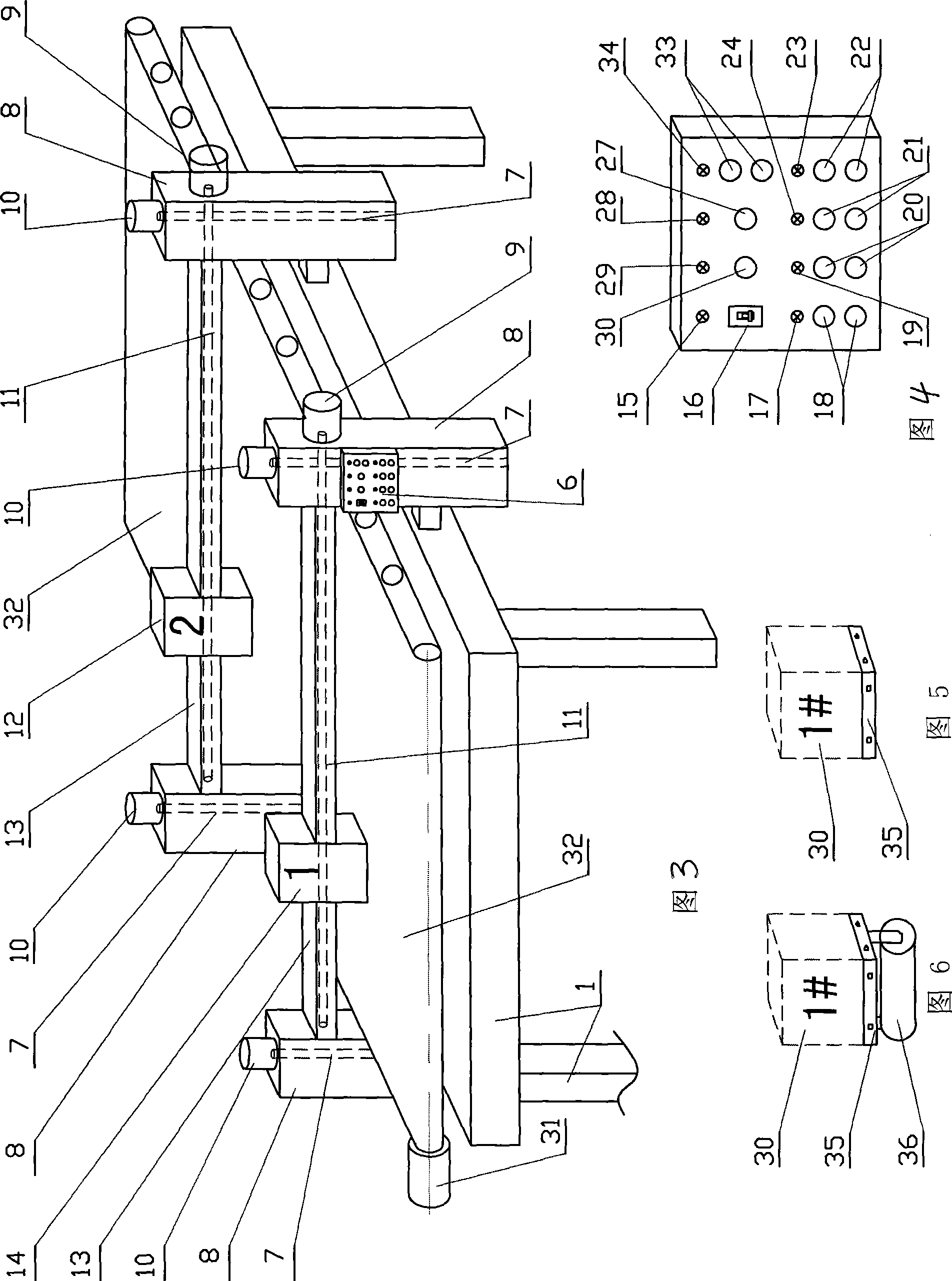

[0036] Embodiment 2: As shown in Figure 3-4: a color jet printing machine with a rotary conveyor belt, including a frame, a column, a horizontal beam, a jet printing workbench and an electric control box.

[0037]Columns 801 and 802 are provided on both sides of the rectangular frame 1, and the two ends of the 1# horizontal beam 131 perpendicular to the long side of the rectangular frame 1 and the columns 801 and 802 are slidably installed on the vertical guide rails of the columns 801 and 802 respectively. Above: There are vertical transmission screw rods 7 inside the columns 801 and 802, the vertical motors 101 installed on the top of the columns 801 and 802 are connected to the vertical transmission screw rods 7, and the transmission nuts at both ends of the 1# horizontal beam 131 are respectively fastened Engage with the vertical transmission screw 7 located in the same column; 1# inkjet box 14 is slidably installed on the guide rail of 1# horizontal beam 131, and a horizon...

Embodiment 3

[0041] Embodiment 3: as shown in Fig. 1-4: a kind of method of jet printing that adopts the color jet printing machine described in embodiment 1 or embodiment 2, comprises the following steps:

[0042] [1] Lay the fabric to be printed flat on the translational workbench 5 or the rotary conveyor belt 32, under the 1# horizontal beam 131, close the main switch 16 of the power supply; reasonably adjust 1 according to the size of the fabric and the area of the sprayed pattern #The height of the horizontal beam 131 and the lateral position of the 1# inkjet box 14 are aligned with the area to be sprayed on the fabric;

[0043] [2] Press the 1# inkjet cartridge printing instruction button 30, and the 1# inkjet cartridge controlled by the computer program will spray the white bottom layer to the fabric pattern area; The rear alignment of frame 1 inner frame stops under the 2# inkjet box 12 positioned at 2# horizontal beam 132;

[0044] [3] Press the 2# inkjet cartridge printing com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com