Dispensing adhesive agent for connection of mosaics and production process

An adhesive and mosaic technology, applied in the direction of adhesives, adhesive types, polyurea/polyurethane adhesives, etc., can solve the problems of poor moisture resistance, affect the bonding strength, mosaic peeling, etc., to improve construction efficiency and Quality, guaranteed aesthetics, good weather resistance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] Formula one (the total mass of the formula is 100g)

[0057] (1) Plasticizer: 5g of dibutyl phthalate, 12g of dioctyl phthalate, 10g of dioctyl adipate

[0058] (2) PVC paste resin: homopolyvinyl chloride paste resin (K value 70) 12g

[0059] Copolymerized polyvinyl chloride paste resin (K value 75) 13g

[0060] (3) Curing agent: Hexamethylene diisocyanate (HDI) trimer 1.5g

[0061] (4) Blocked polyurethane prepolymer: 5.0 g of toluene diisocyanate prepolymer blocked by methyl ethyl ketone oxime

[0062] (5) Nano calcium carbonate: 10g

[0063] (6) Heavy calcium carbonate: 8g

[0064] (7) Calcite powder: 18g

[0065] (8) Coupling agent: γ-(2,3-epoxypropoxy)propyltrimethoxysilane 0.5g

[0066] (9) Heat stabilizer: zinc oxide 0.6g, dibutyltin dilaurate 1.0g

[0067] (10) Water remover: bicyclic oxazolidine 0.2g, calcium oxide 1.0g

[0068] (11) Thixotropic agent: fumed silica 1.2g

[0069] (12) Thinner: solvent kerosene 1.0g

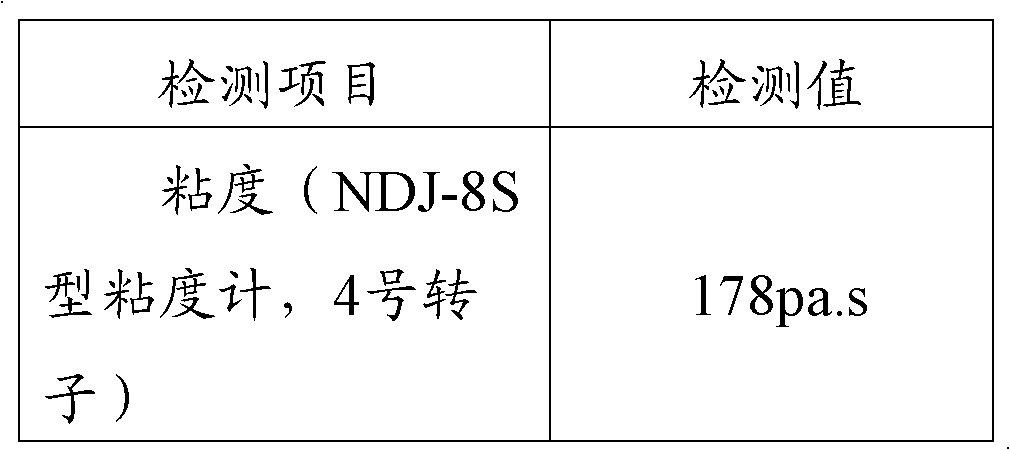

[0070] In this formula example, aft...

Embodiment 2

[0075] Formula two (the total mass of the formula is 100g)

[0076] (1) Plasticizer: butyl benzyl phthalate 10g, diisodecyl phthalate 5g,

[0077] Dioctyl adipate 7g;

[0078] (2) PVC paste resin: homopolyvinyl chloride paste resin (K value 75) 18g

[0079] (3) Curing agent: 1.2 g of TDI-TMP adduct prepared by reaction of toluene diisocyanate and trimethylolpropane

[0080] (4) Blocked polyurethane prepolymer: 3,5-dimethylpyrazole-blocked hexamethylene diisocyanate (HDI) trimer prepolymer 6g

[0081] (5) Nano calcium carbonate: 13g

[0082] (6) Heavy calcium carbonate: 12g

[0083] (7) Calcite powder: 23g

[0084] (8) Coupling agent: γ-aminopropyltriethoxysilane 0.3g

[0085] (9) Heat stabilizer: butyltin maleate 1.2g

[0086](10) Water remover: calcium oxide 2.0g

[0087] (11) Thixotropic agent: fumed silica 1.3g

[0088] (12) Thinner: 0g

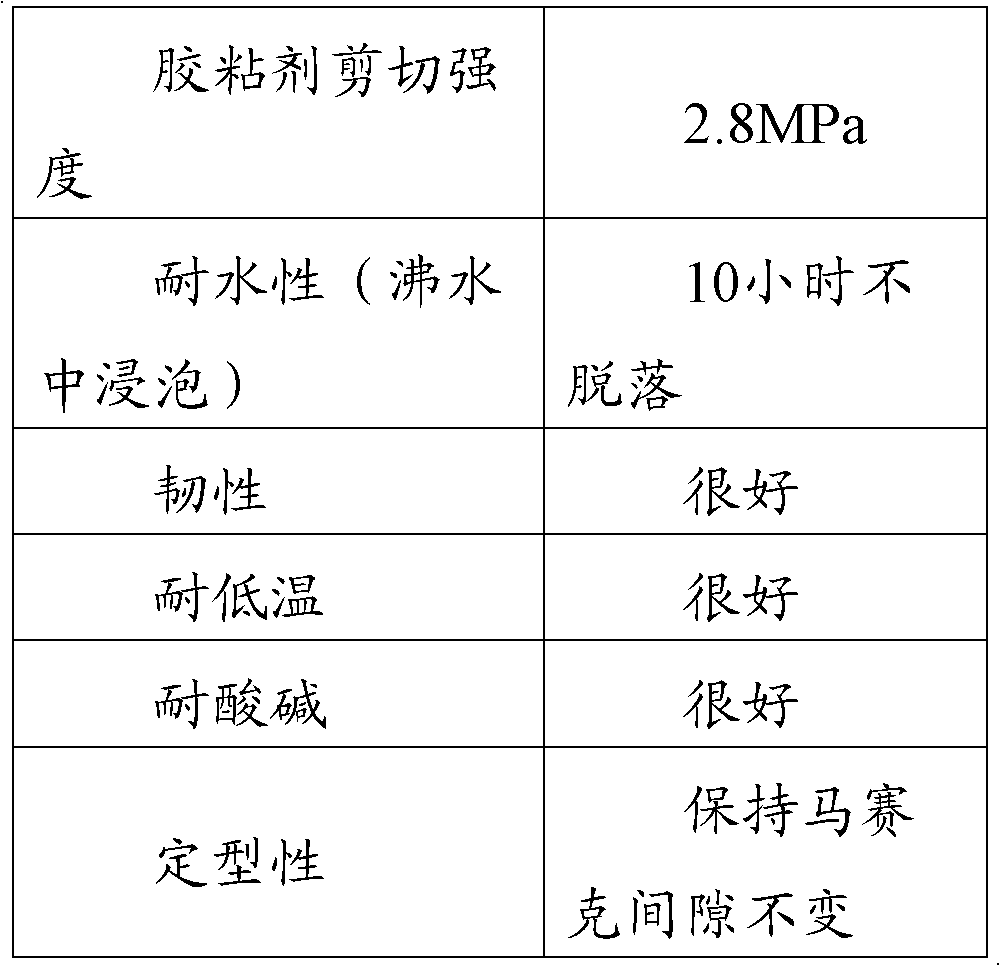

[0089] In this formula example, after dispersing and mixing evenly, after aging for 24 hours, the mosaic is bonded. The size of...

Embodiment 3

[0093] Formula three (the total mass of the formula is 100g)

[0094] (1) Plasticizer: epoxy soybean oil 8g, butyl benzyl phthalate 15g, dioctyl phthalate 8g

[0095] (2) Polyvinyl chloride paste resin: Copolymerized polyvinyl chloride paste resin 30g

[0096] (3) Curing agent: Hexamethylene diisocyanate (HDI) biuret 1.8g

[0097] (4) Blocked polyurethane prepolymer: 9g of hexamethylene diisocyanate (HDI) prepolymer blocked by 3,5-dimethylpyrazole

[0098] (5) Nano calcium carbonate: 10g

[0099] (6) Heavy calcium carbonate: 3g

[0100] (7) Calcite powder: 4g

[0101] (8) Coupling agent: γ-(2,3-epoxypropoxy)propyltrimethoxysilane 0.6g

[0102] (9) Heat stabilizer: zinc oxide 1.2g

[0103] Dibutyltin oxide (dibutyltin oxide) 2.0g

[0104] (10) Dehydrating agent: calcium oxide 5g, p-methylphenylsulfonyl isocyanate 1.0g

[0105] (11) Thixotropic agent: fumed silica 1.4g

[0106] (12) Thinner: 0g

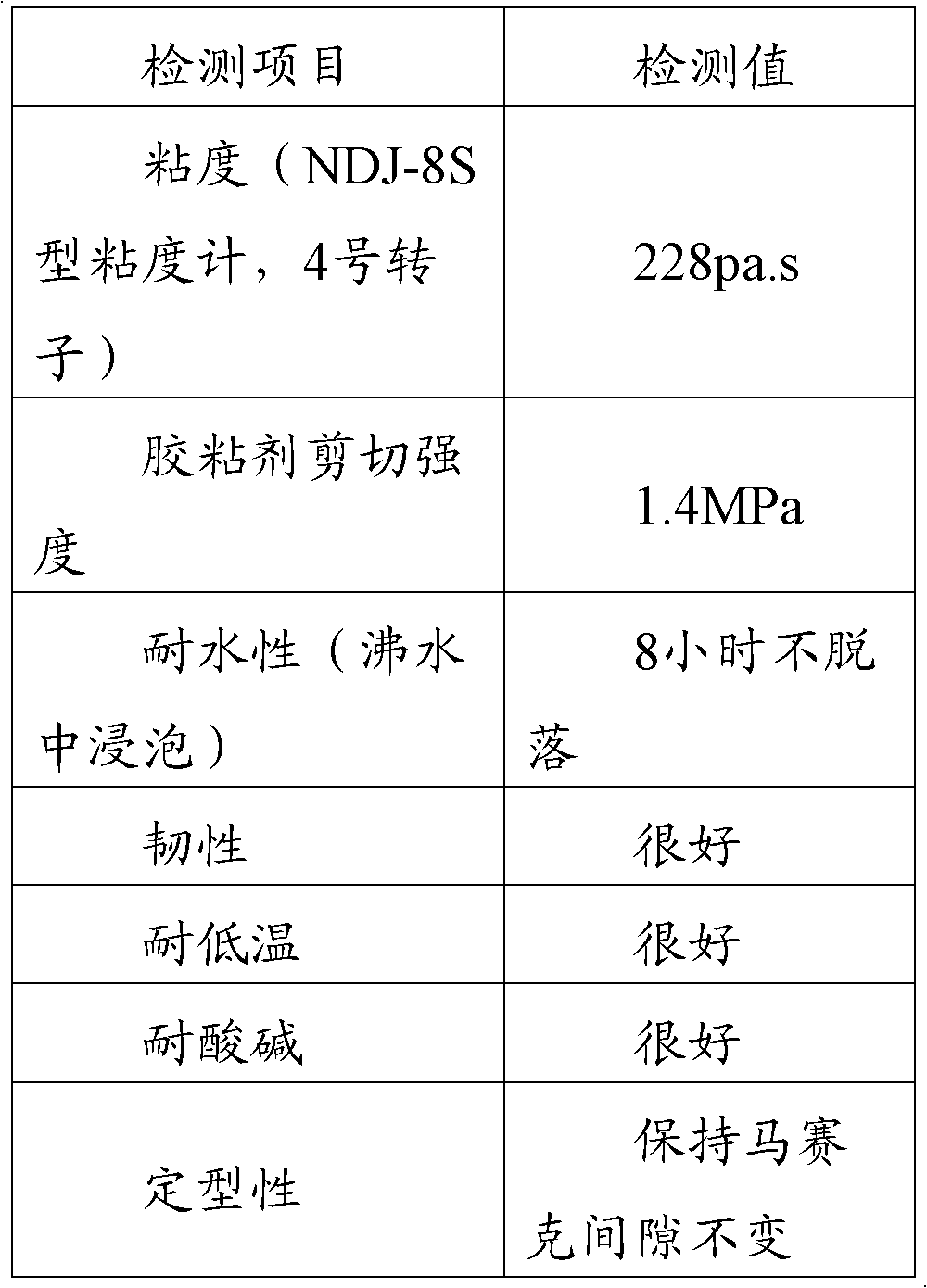

[0107] In this formula example, after dispersing and mixing evenly, after...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com