Processing method of large-sized sapphire ultrathin double-side-polished diaphragm

A technology of double-sided polishing and processing method, applied in stone processing equipment, surface-polished machine tools, metal processing equipment, etc., can solve the problems of easily broken pieces and low qualified rate of finished products, and achieve the effect of high qualified rate and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] A large-size sapphire ultra-thin double-sided polishing window processing method, the method is as follows:

[0026] (1) Cut the sapphire ingot into a sapphire window with a thickness of 0.42mm with a diamond wire multi-wire slicer;

[0027] (2) The cut sapphire window is rounded to protect the edge, and the size of the rounded corner is R=0.20mm;

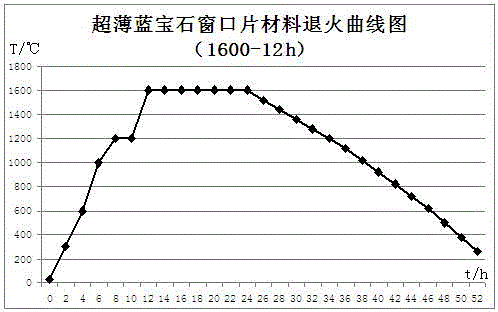

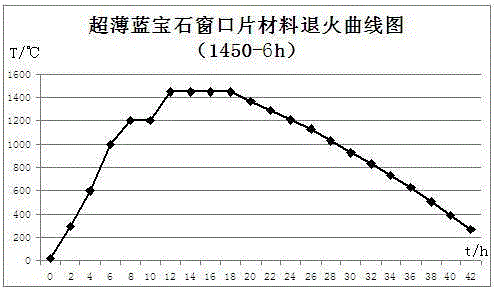

[0028] (3) Anneal the rounded sapphire window, press figure 1 The annealing curve is first heated to an annealing temperature of 1450°C and then kept for 6 hours. First, the temperature is lowered to 1130°C at a cooling rate of 80°C / h, then to 630°C at a cooling rate of 100°C / h, and then at a cooling rate of 120°C / h Cool down to 270°C, and finally cool down to room temperature naturally;

[0029] (4) The annealed sapphire window is subjected to double-sided rough grinding, the particle size of the ground boron carbide is W40, and the grinding removal amount is 0.12mm;

[0030] (5) Perform secondary annealing on the roughl...

Embodiment 2

[0036] A large-size sapphire ultra-thin double-sided polishing window processing method, the method is as follows:

[0037] (1) Cut the sapphire ingot into a sapphire window with a thickness of 0.45mm with a diamond wire multi-wire slicer;

[0038] (2) The cut sapphire window is rounded to protect the edge, and the size of the rounded corner is R=0.23mm;

[0039] (3) Anneal the rounded sapphire window, press figure 1 The annealing curve is first heated to an annealing temperature of 1450°C and then kept for 6 hours. First, the temperature is lowered to 1130°C at a cooling rate of 80°C / h, then to 630°C at a cooling rate of 100°C / h, and then at a cooling rate of 120°C / h Cool down to 270°C, and finally cool down to room temperature naturally;

[0040] (4) The annealed sapphire window is subjected to double-sided rough grinding, the particle size of the ground boron carbide is W40, and the grinding removal amount is 0.14mm;

[0041] (5) Perform secondary annealing on the roughl...

Embodiment 3

[0047] A large-size sapphire ultra-thin double-sided polishing window processing method, the method is as follows:

[0048] (1) Cut the sapphire ingot into a sapphire window with a thickness of 0.40mm with a diamond wire multi-wire slicer;

[0049] (2) The cut sapphire window is rounded to protect the edge, and the size of the rounded corner is R=0.18mm;

[0050] (3) Anneal the rounded sapphire window, press figure 1 The annealing curve is first heated to an annealing temperature of 1450°C and then kept for 6 hours. First, the temperature is lowered to 1130°C at a cooling rate of 80°C / h, then to 630°C at a cooling rate of 100°C / h, and then at a cooling rate of 120°C / h Cool down to 270°C, and finally cool down to room temperature naturally;

[0051](4) The annealed sapphire window is subjected to double-sided rough grinding, the particle size of the ground boron carbide is W40, and the grinding removal (thickness) is 0.13mm;

[0052] (5) Perform secondary annealing on the ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com