Sapphire and machining method thereof

A processing method and sapphire technology, applied in the direction of stone processing equipment, metal processing equipment, manufacturing tools, etc., can solve the problems of unable to obtain material utilization rate, increase material cost, and low product market acceptance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Place the grown sapphire crystal on a fixed tooling, use diamond wires for multi-wire cutting (generally 3 multi-wire cutting machines), and cut the crystal into cubes (cuboid-shaped cubes), the cross-section of which is 55X55mm square, the length is the length actually cut from the crystal.

[0019] The sapphire square is processed into a thin square piece of 55X55mm by intensive multi-wire cutting, and the thickness can be 0.6mm or 0.7mm according to the thickness of the final product.

[0020] Grinding the wafer to remove the cutting line marks; after cleaning, the square wafer is annealed at a temperature of 1400 degrees Celsius in the annealing furnace; the wafer is CMP polished to complete the processing of the sapphire double-sided polished square wafer , to complete the square piece of 55X55mm, the thickness can be 0.3mm, or 0.4mm

[0021] Cut double-sided polished squares into small pieces (windows), which can be cut with an ultra-fast laser. Ultrafast refers...

Embodiment 2

[0026] Adopt the method of embodiment 1 to cut, take the cross-section in the sapphire crystal and take the square square of different side lengths and make a square substrate, further intercept small window slices as needed, and compare with the intercepted quantity of standard 2-inch sapphire discs :

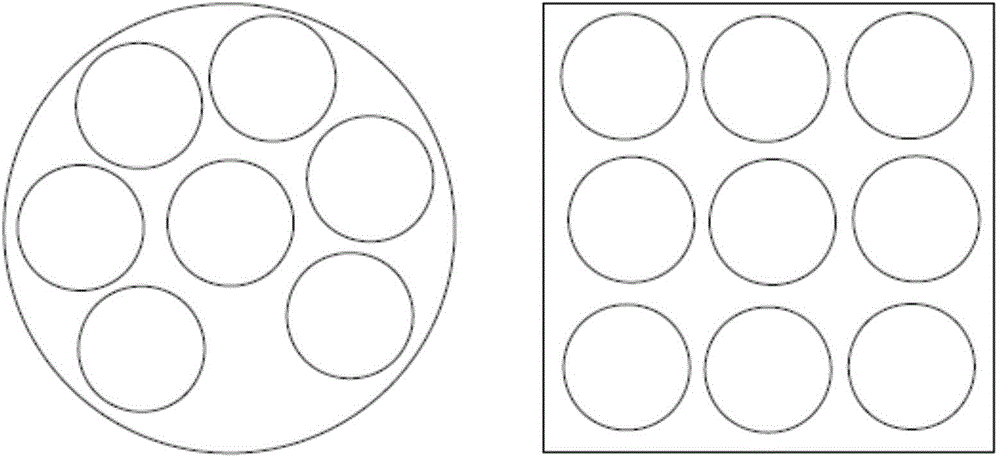

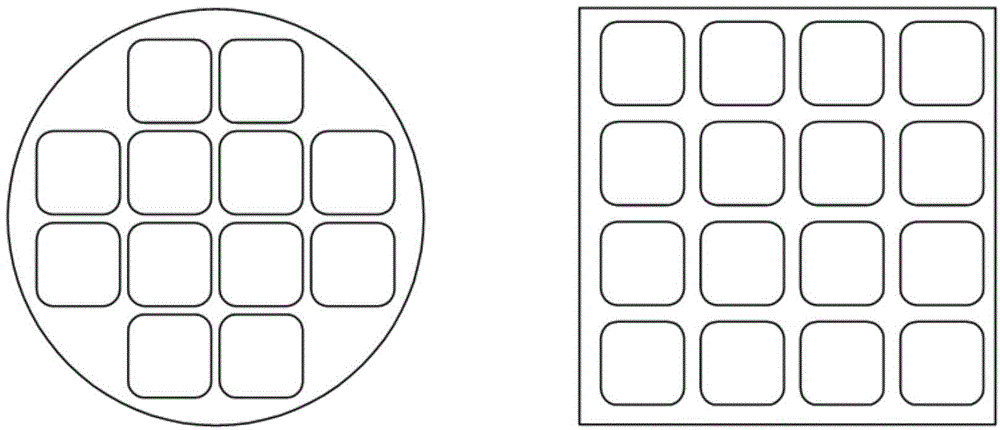

[0027] Take 12 and 14 square pieces with a side length of 10mm and a circle with a diameter of 10mm from a 2-inch circle, respectively;

[0028] From the square sheet of 55X55mm, 25 sheets and 25 sheets can be taken respectively by taking a square sheet with a side length of 10mm and a circular sheet with a diameter of 10mm.

[0029] Take 9 and 12 square pieces with a side length of 11mm and a circle with a diameter of 11mm from a 2-inch circle;

[0030] From the square sheet of 60X60mm, 25 sheets and 25 sheets can be taken respectively by taking a square sheet with a side length of 11 mm and a round sheet with a diameter of 11 mm.

[0031] Take 7 and 10 square pieces with a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com