Method for extracting high-purity flaxseed oil by aid of molecular distillation processes

A technology of molecular distillation and linseed oil, which is applied in the direction of fat oil/fat refining, fat production, fatty acid production, etc., can solve the problem that it is difficult to obtain pure α-linolenic acid products, so as to achieve stable and reliable product quality, maintain naturalness, reduce pollution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

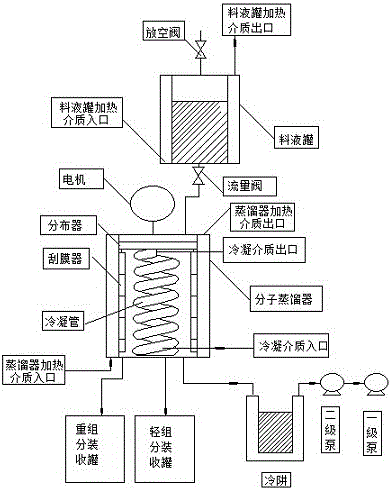

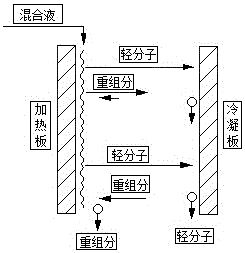

[0019] Such as figure 1 - figure 2 As shown, a method for extracting high-purity α-linolenic acid by molecular distillation in the present invention comprises the following steps: 1) The purpose of the first-order molecular distillation step is to remove light impurities in the raw material, and the distillation temperature is 110°C. The heating temperature is 80°C, the internal cooling temperature is 40°C, and the rotational speed is 290r / min. The test conditions are used to separate and obtain the product of the first-stage molecular distillation; 2) The second-stage molecular distillation step The second-stage molecular distillation uses the product of the first-stage molecular distillation receiving tank as raw material , the purpose is to remove the heavy impurities; in the two-stage molecular distillation, the preheating temperature is fixed, the distillation temperature is controlled at 200°C, the internal cooling temperature is 40°C, and the wiper speed is 40r / min to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com