Top suction type range hood of novel oil screens

A range hood and oil screen technology, applied in the field of top-suction range hoods, can solve problems such as not being fully filtered and drawn out, reducing the space of the upward convex smoke collection chamber, solidification, or falling to the stove, etc., to achieve improved The degree of separation, the increased area, and the effect of smooth air intake

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Below in conjunction with accompanying drawing and embodiment the present invention is further described:

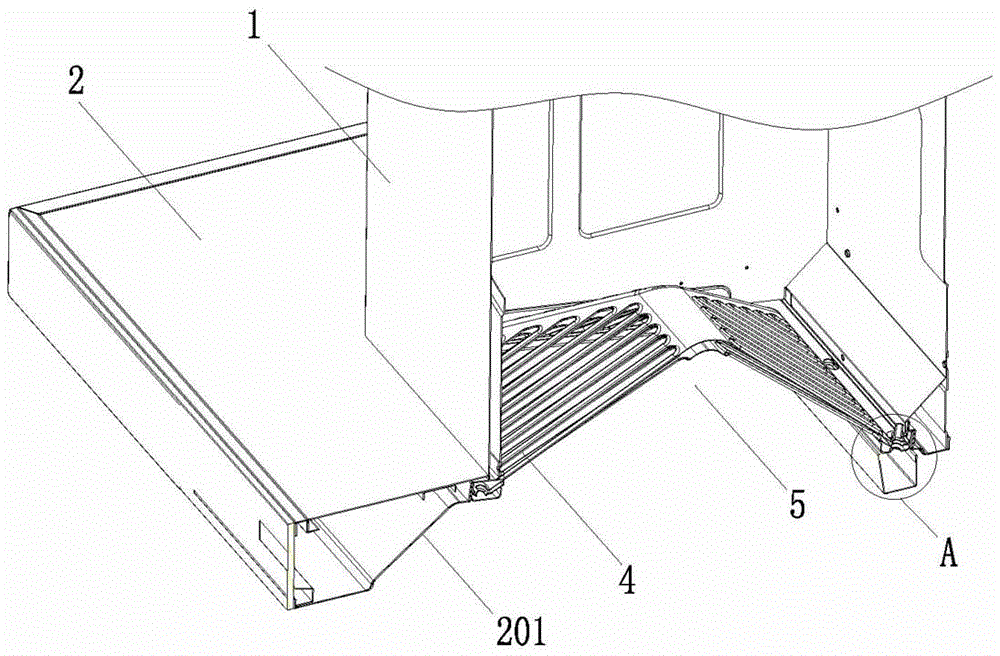

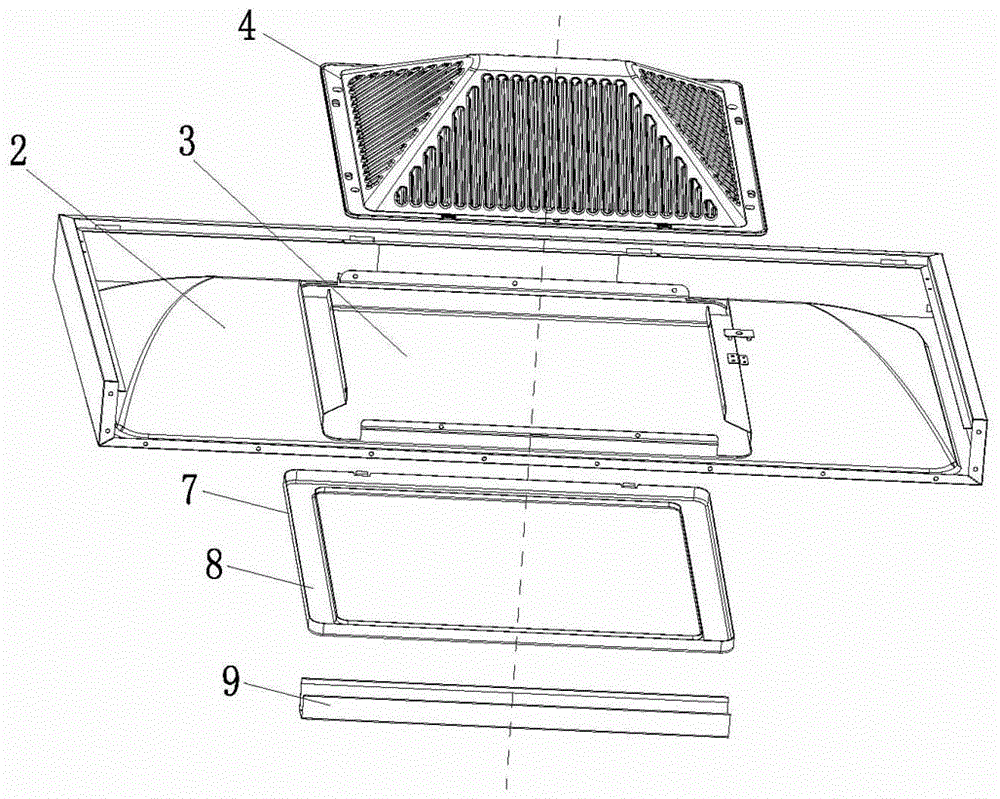

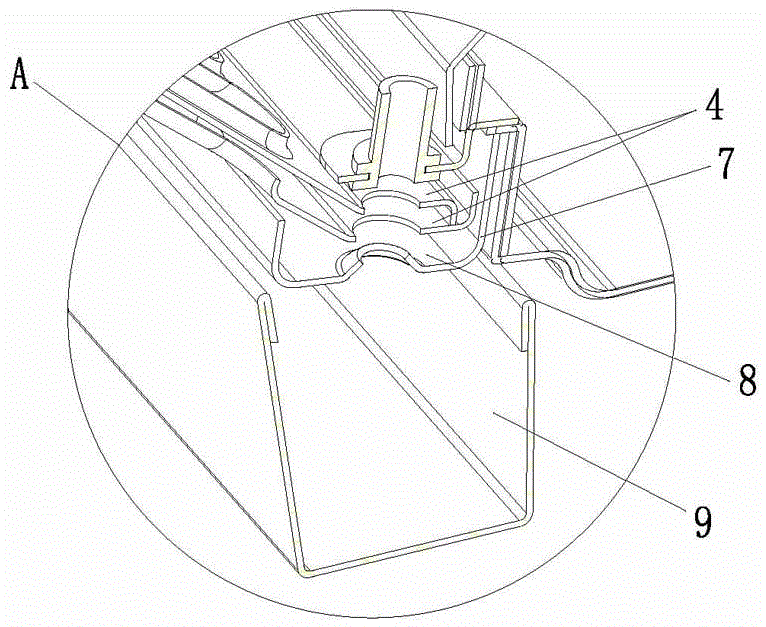

[0026] Such as Figure 1 to Figure 8 Shown: a new top-suction range hood with oil mesh, including a box body 1 and a smoke collection panel 2. The smoke collection panel 2 is provided with a smoke collection port 3, and the smoke collection port 3 is equipped with upper and lower layers of oil The net 4 is characterized in that each layer of oil net 4 is a convex cover formed by stretching the smoke collecting port 3 toward the box body 1, and the lower convex cover forms a smoke collecting cavity 5, and each layer of convex There are a plurality of smoking holes 6 on the cover body, the smoke collection panel 2 is inclined, and the corresponding smoke collection port 3 is inclined, so that the convex cover body is installed on the smoke collection port 3 obliquely, and the edge of the smoke collection port 3 A hollow oil guide frame 7 is installed, and the oil g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com