Recovery method of sapphire polishing waste liquid

A recycling method and sapphire technology, applied in grinding/polishing equipment, metal processing equipment, manufacturing tools, etc., can solve the problems of high price, lack of mature and efficient recycling methods for diamond polishing liquid, and high price of artificial diamond materials. Achieve the effect of saving materials, reducing impact and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

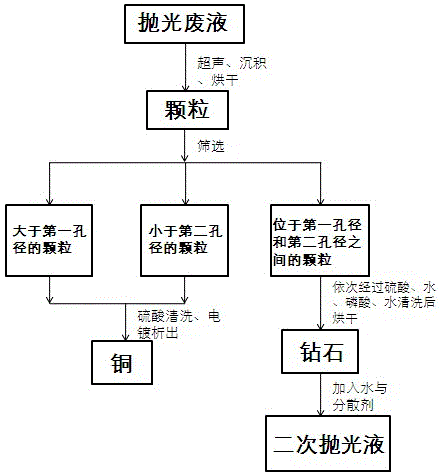

[0023] See attached figure 1 , the recovery method of a kind of sapphire polishing waste liquid that the present invention provides, polishing waste liquid comprises diamond particles, resin copper shavings, sapphire shavings, dispersant, because in the polishing process, copper plate wears out faster, causes the resin in polishing waste liquid Copper shavings and metal copper shavings account for a higher proportion than other components, and they also have a certain recovery value. Based on the differences in the characteristics of the components contained in the polishing waste liquid, the processes of vibrating screening, chemical separation, and electroplating separation are used respectively. For example, include the steps:

[0024] S1 collects the waste slurry, and adds water equivalent to more than 3 times of the waste slurry, and the multiple used in this embodiment is 4;

[0025] S2 Ultrasonic dispersion of waste slurry particles is carried out by ultrasonic waves w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com